A Processing Technology for Precise Forming of Hemispherical Body of Large Thin-wall Storage Tank

A technology of precision forming and processing technology, which is applied in the field of precision forming processing technology of large thin-walled storage tank hemispheres. It can solve problems such as difficult measurement and clamping, easy instability, wrinkling and cracking of flange parts, and achieve improvement. The effect of processing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

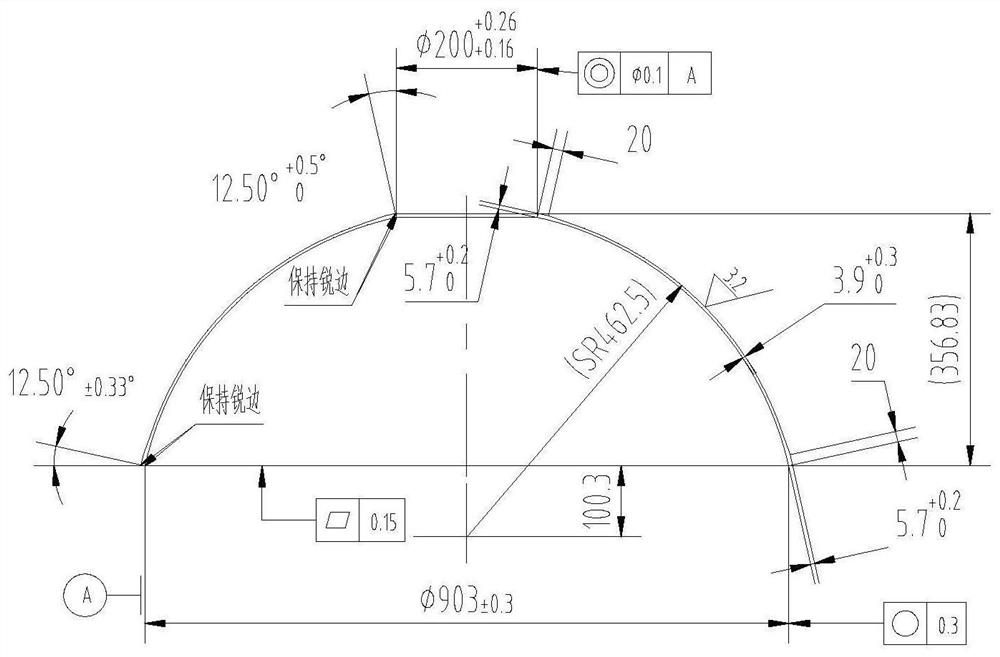

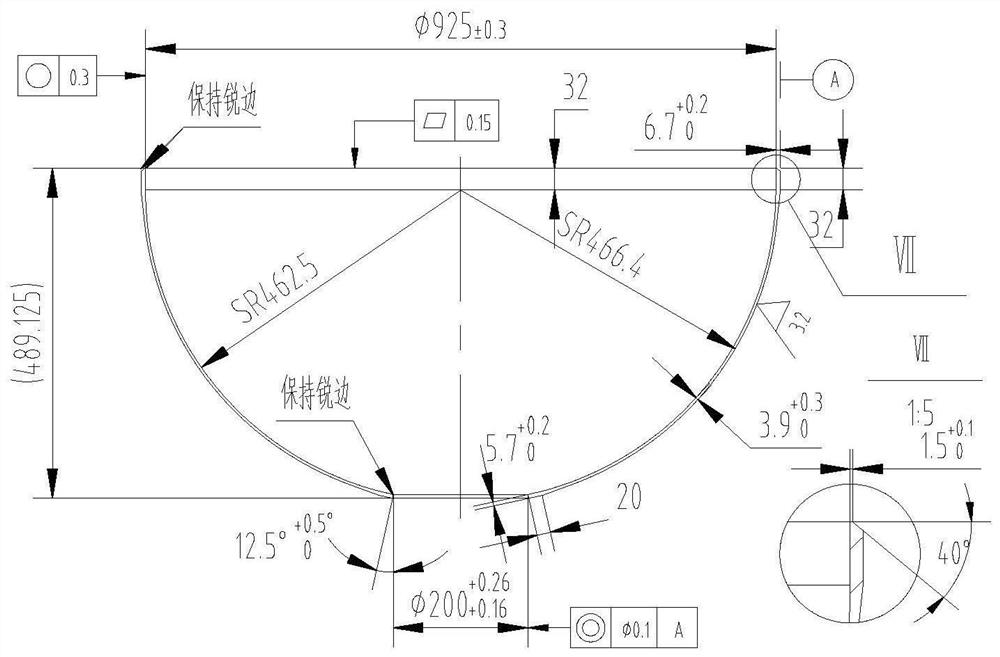

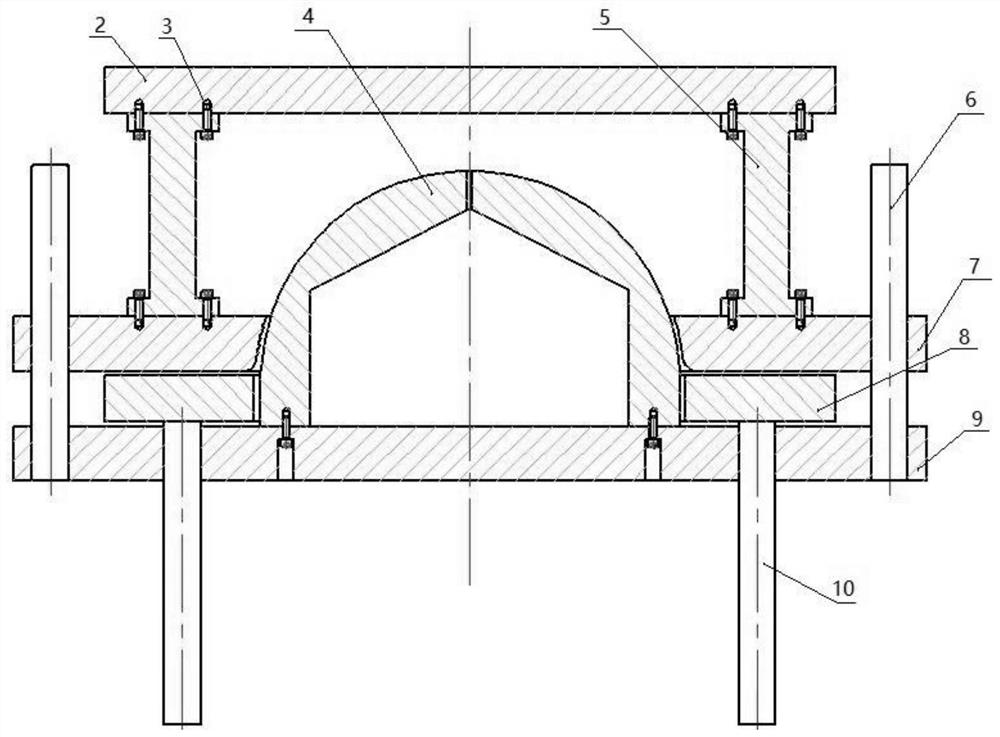

[0048] Such as figure 1 , figure 2 , image 3 As shown, a processing technology for precision forming of a large thin-walled storage tank hemisphere, including plasma gas cutting, stamping forming, cutting, shaping, finishing the inner spherical surface, finishing the outer spherical surface, and surface treatment steps, specifically includes the following steps:

[0049] (1) Plasma gas cutting: first calculate the size of the blank, then use plasma gas cutting equipment to cut the outer circle, and then punch the blank and cut it;

[0050] (2) Stamping forming: Grinding and cleaning with a pneumatic grinding wheel. Steps (1) The cutting slag on the edge of the billet cut by plasma gas, and then using a 2000T hydraulic drawing forming die and an aluminum alloy special annealing furnace to repeat drawing forming and annealing four times. Then carry out the fifth drawing forming to obtain the hemispherical semi-finished product;

[0051] Using 2000T hydraulic drawing forming...

Embodiment 2

[0060] Such as figure 1 , figure 2 , image 3 As shown, a processing technology for precision forming of a large thin-walled storage tank hemisphere, including plasma gas cutting, stamping forming, cutting, shaping, finishing the inner spherical surface, finishing the outer spherical surface, and surface treatment steps, specifically includes the following steps:

[0061] (1) Plasma gas cutting: first calculate the size of the blank, then use plasma gas cutting equipment to cut the outer circle, and then punch the blank and cut it;

[0062] (2) Stamping forming: Grinding and cleaning with a pneumatic grinding wheel. Steps (1) Cut slag on the edge of the billet cut by plasma gas, and then use a 2000T hydraulic drawing forming die and an aluminum alloy special annealing furnace to repeat drawing forming and annealing four times. Then carry out the fifth drawing forming to obtain the hemispherical semi-finished product;

[0063] Using 2000T hydraulic drawing forming die and a...

Embodiment 3

[0072] Such as figure 1 , figure 2 , image 3 As shown, a processing technology for precision forming of a large thin-walled storage tank hemisphere, including plasma gas cutting, stamping forming, cutting, shaping, finishing the inner spherical surface, finishing the outer spherical surface, and surface treatment steps, specifically includes the following steps:

[0073] (1) Plasma gas cutting: first calculate the size of the blank, then use plasma gas cutting equipment to cut the outer circle, and then punch the blank and cut it;

[0074] (2) Stamping forming: Grinding and cleaning with a pneumatic grinding wheel. Steps (1) The cutting slag on the edge of the billet cut by plasma gas, and then using a 2000T hydraulic drawing forming die and an aluminum alloy special annealing furnace to repeat drawing forming and annealing four times. Then carry out the fifth drawing forming to obtain the hemispherical semi-finished product;

[0075] Using 2000T hydraulic drawing forming...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com