Insert integration type processing process

A processing technology, an integrated technology, applied in the field of machining, can solve the problems of high difficulty in clamping special-shaped inserts, easy deformation of small inserts, low processing efficiency, etc., to solve the difficulty of clamping, reduce clamping time, The effect of preventing deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

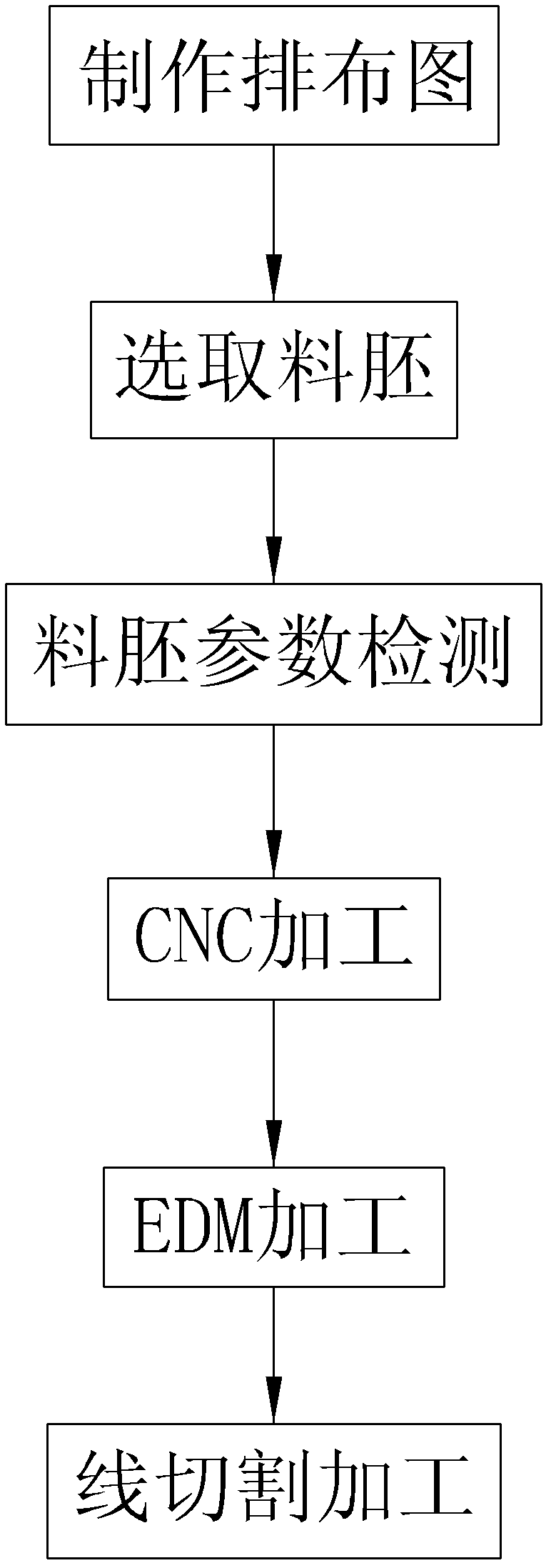

[0024] refer to Figure 1 to Figure 4 As shown, the present invention discloses an integrated processing technology for inserts, which has high processing efficiency and the processed small inserts are not easily deformed. It includes the following steps:

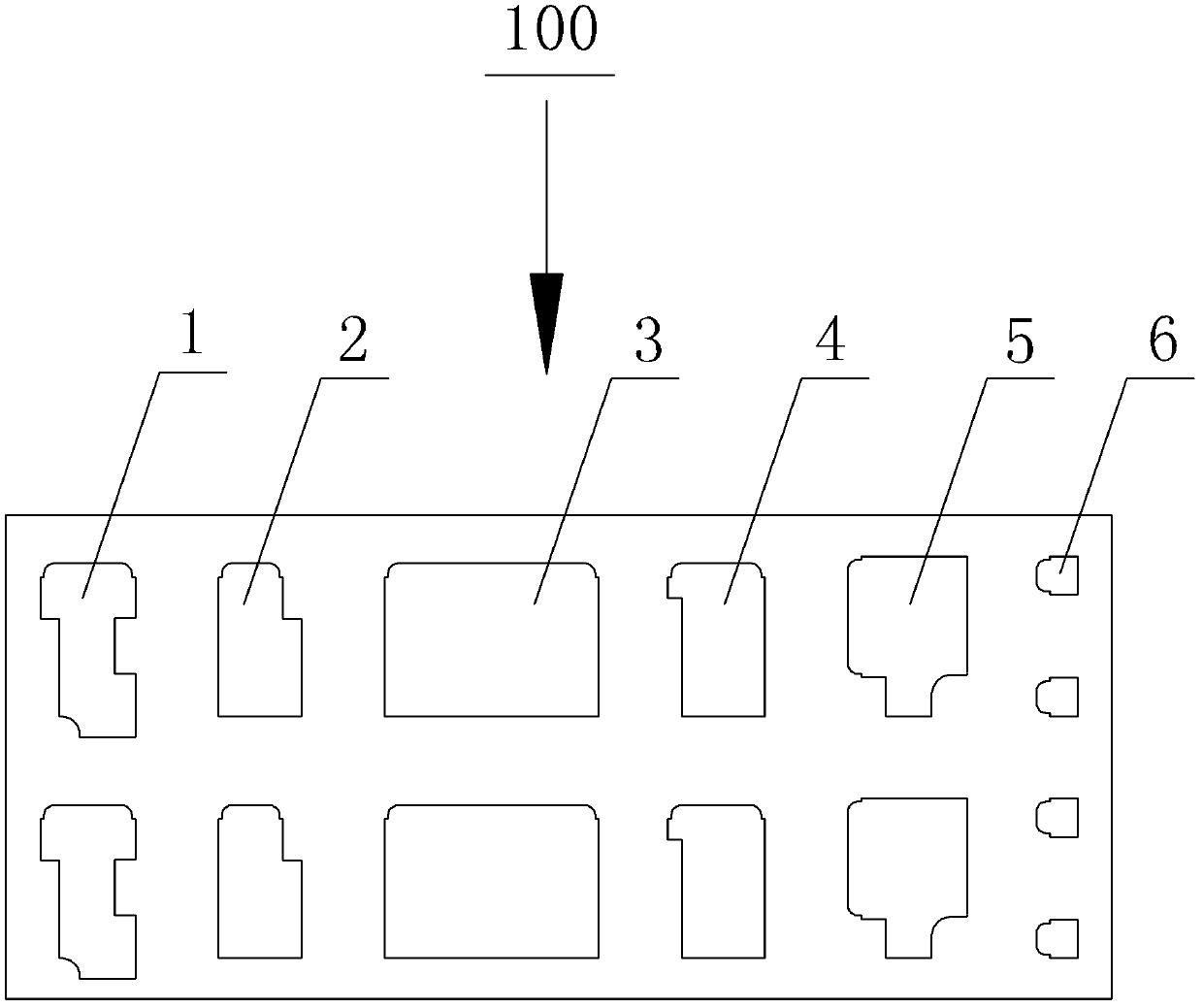

[0025] Step 1. Make the layout drawing drawing 100: according to the size and shape of each insert 7-11 to be processed, draw a drawing with multiple different or identical insert outlines 1-6, each insert outline 1-6 There is a space between them, and the size of the space is set according to specific needs. This drawing serves as a reference for selecting the blank 200 .

[0026] Step 2, select the material blank 200: according to the layout drawing drawing 100, determine the size of the required material blank 200, select the material blank 200 that meets the size requirements and material requ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com