Light and thin refractory material special-shaped curved surface grinding machining device and method

A technology for refractory materials and special-shaped curved surfaces, which is applied in the field of grinding and processing devices for light and thin refractory materials with special-shaped curved surfaces. It can solve problems such as difficult clamping of refractory materials, and achieve the effects of avoiding vibration, high reliability, and reducing block and drop angles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

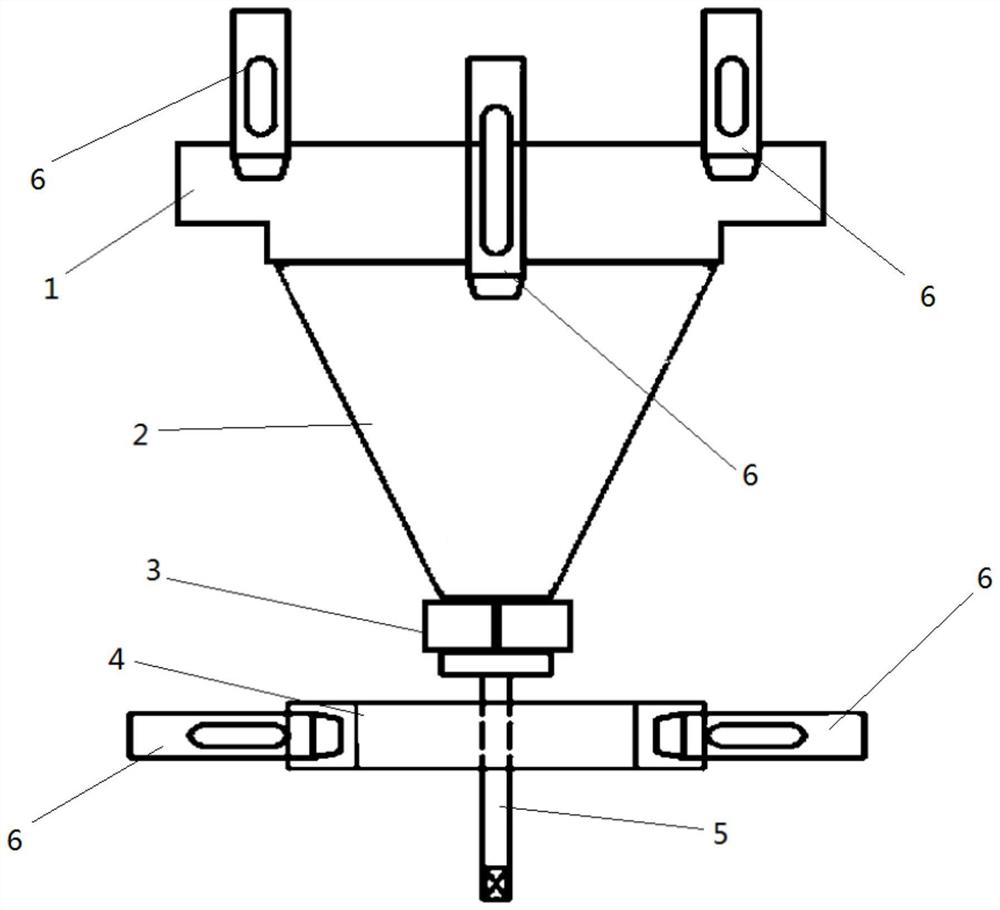

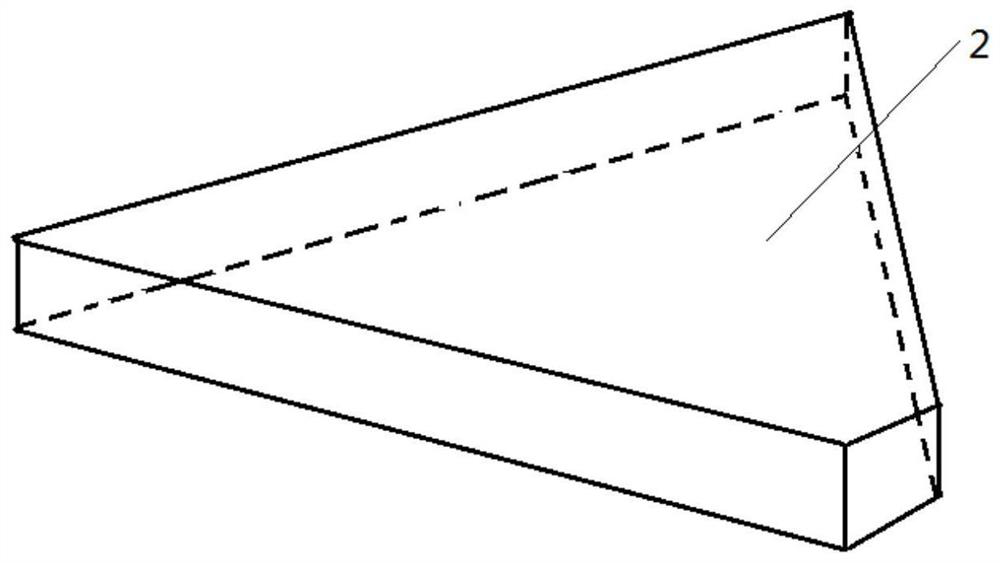

[0034] The present invention is a light and thin refractory special-shaped curved surface grinding device, such as figure 1 As shown, including block 1, spacer 2, top block 3 and fixing seat 4;

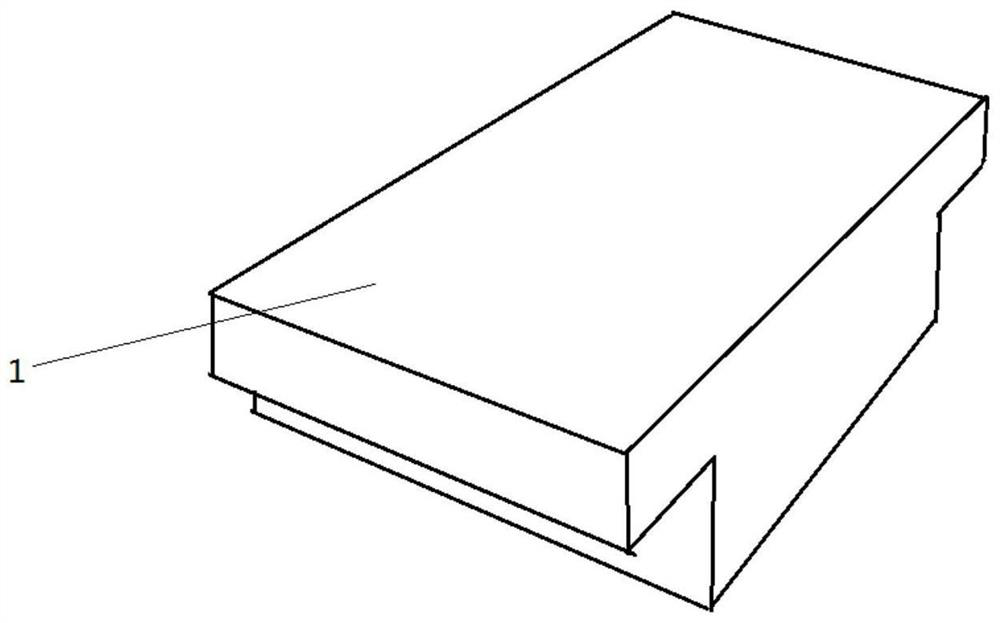

[0035] The stopper 1 is a cuboid structure, and the lower parts of both sides have strip gaps, such as figure 2 As shown, it is used to give way to the processing tool. Specifically, the purpose of this device is to cut the workpiece to be processed into a special-shaped curved surface structure. Therefore, in the process of cutting the tool, it needs to involve the adjustment of the cutting angle of the tool, and the curved surface In some cases where there is a special shape, it needs to be processed from below the horizontal line of the workpiece, and the strip gaps on the lower sides of the sto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com