Measuring device and method for weld strength

A technology of weld strength and measuring device, which is applied in the direction of measuring device, strength characteristics, and the use of stable tension/pressure test material strength, etc., can solve the problem of inability to measure the strength of welded joints, and achieve the convenience and convenience of measurement Fast fixation, the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

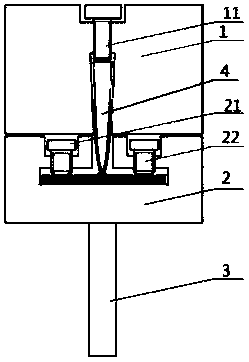

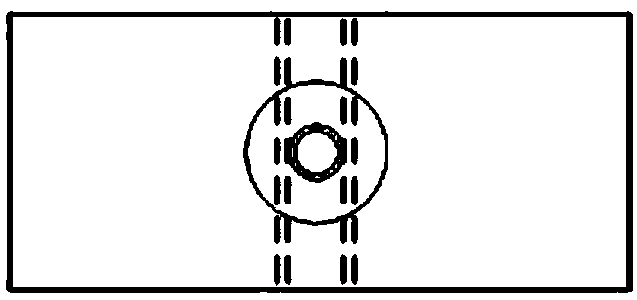

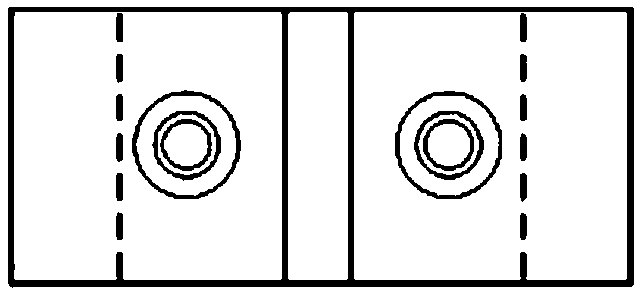

[0074] First, prepare the corresponding ratio of E-7 adhesive 42 according to the test requirements. A sample is cut from the brazed material containing the fins 43 and the base plate 45 by using the electric spark cutting method, and a compact 41 similar to the structure formed by the two fins 43 in the sample is made or selected for use. The size of the sample after the cutting is: the length of the substrate is 30mm, the width is 10mm (that is, the length of the weld is 10mm), the width of the weld is 1.2mm, and the area of the weld is 1.2*10=12mm 2 The fin 43 is located at the middle position of the base plate 45, and the length of the clampable part of the fin 43 is 30 mm. Grinding treatment is performed on each surface to be pasted of the sample and the pressing block 41. The surface to be adhered of the pressing block 41 is bonded between the two sides of the fin 43 of the sample through an adhesive 42.

[0075] Place the well-bonded sample in a furnace, and heat up to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com