Patents

Literature

48results about How to "Same technical effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

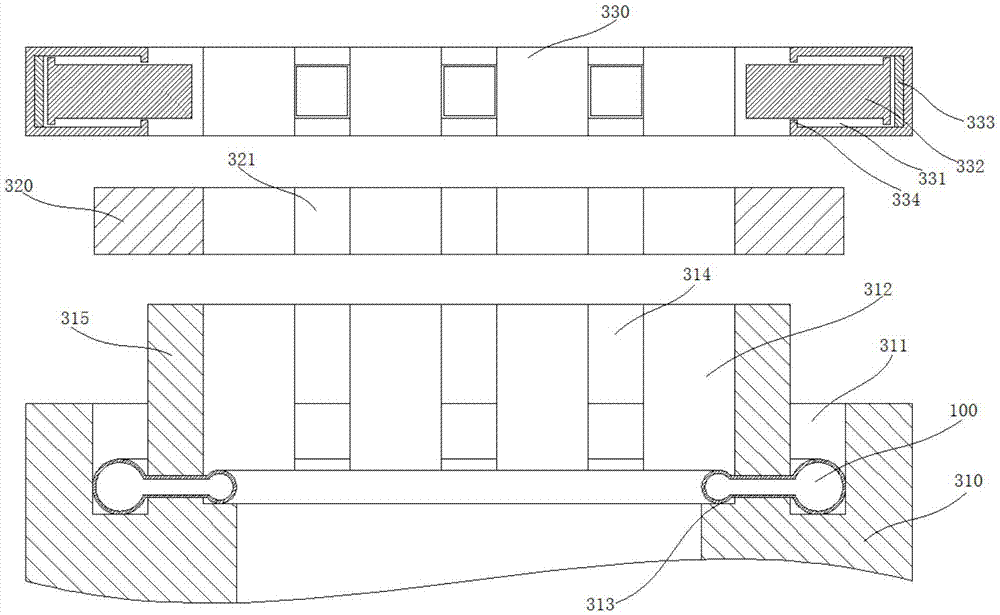

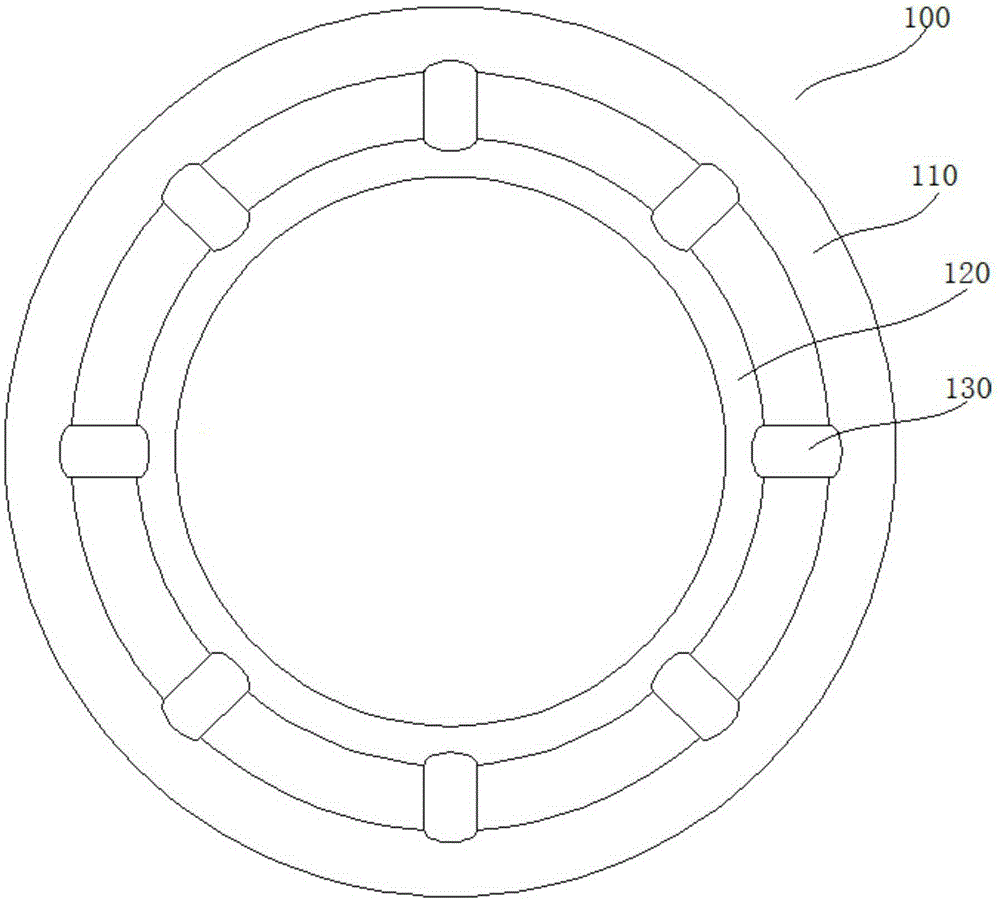

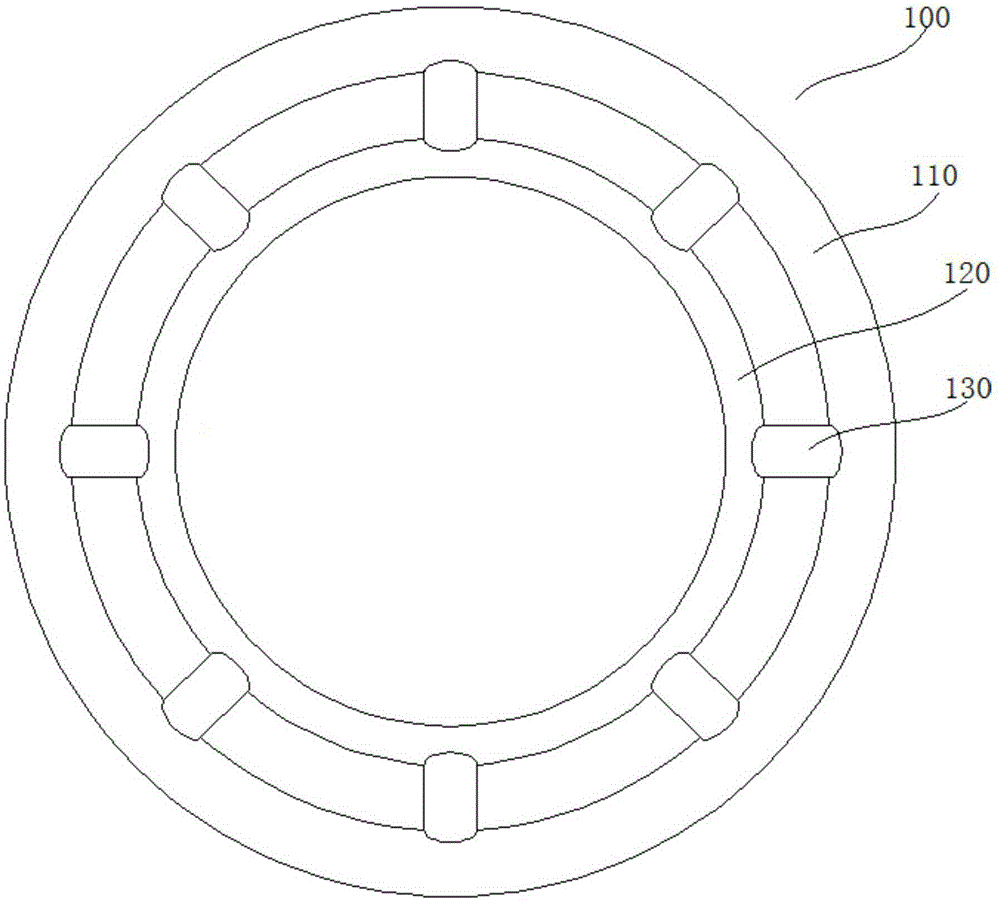

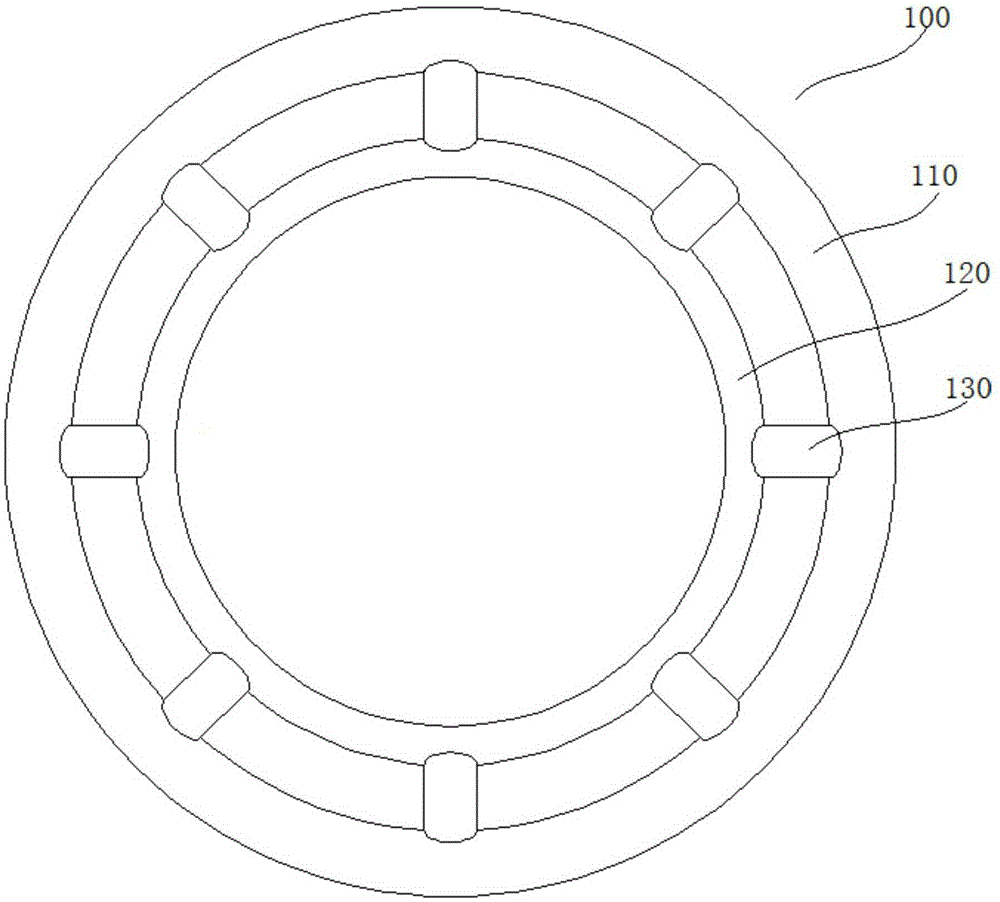

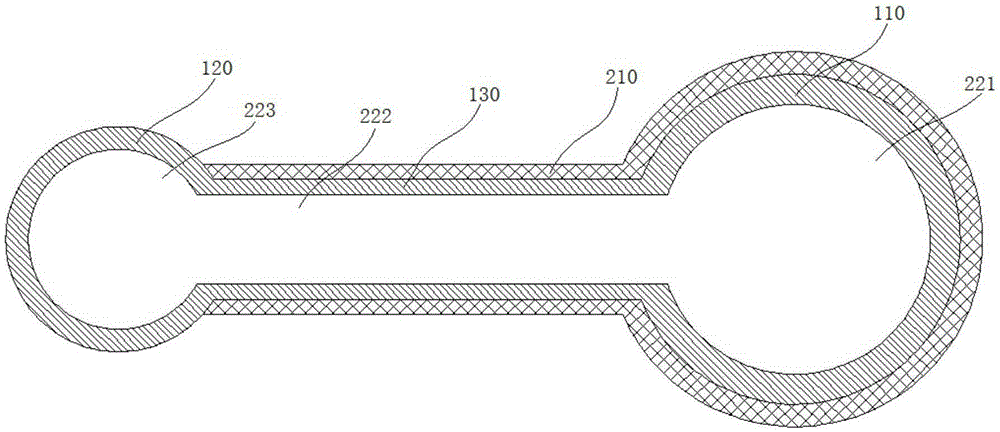

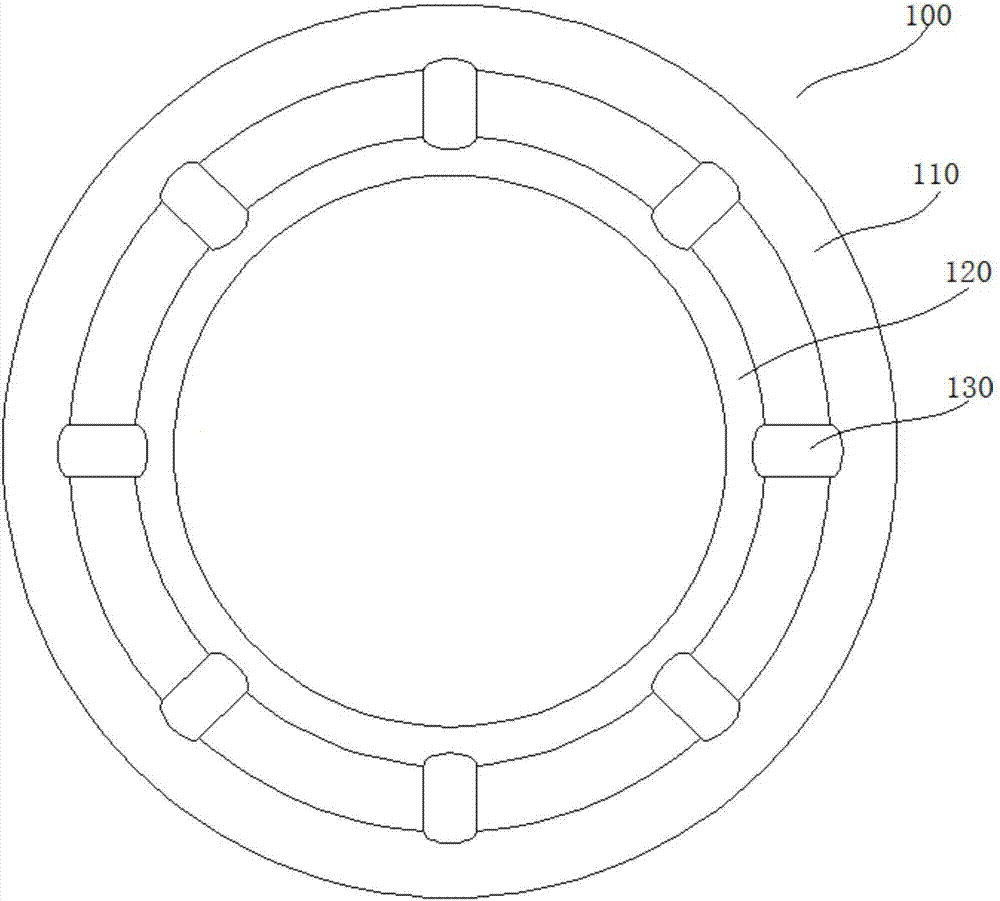

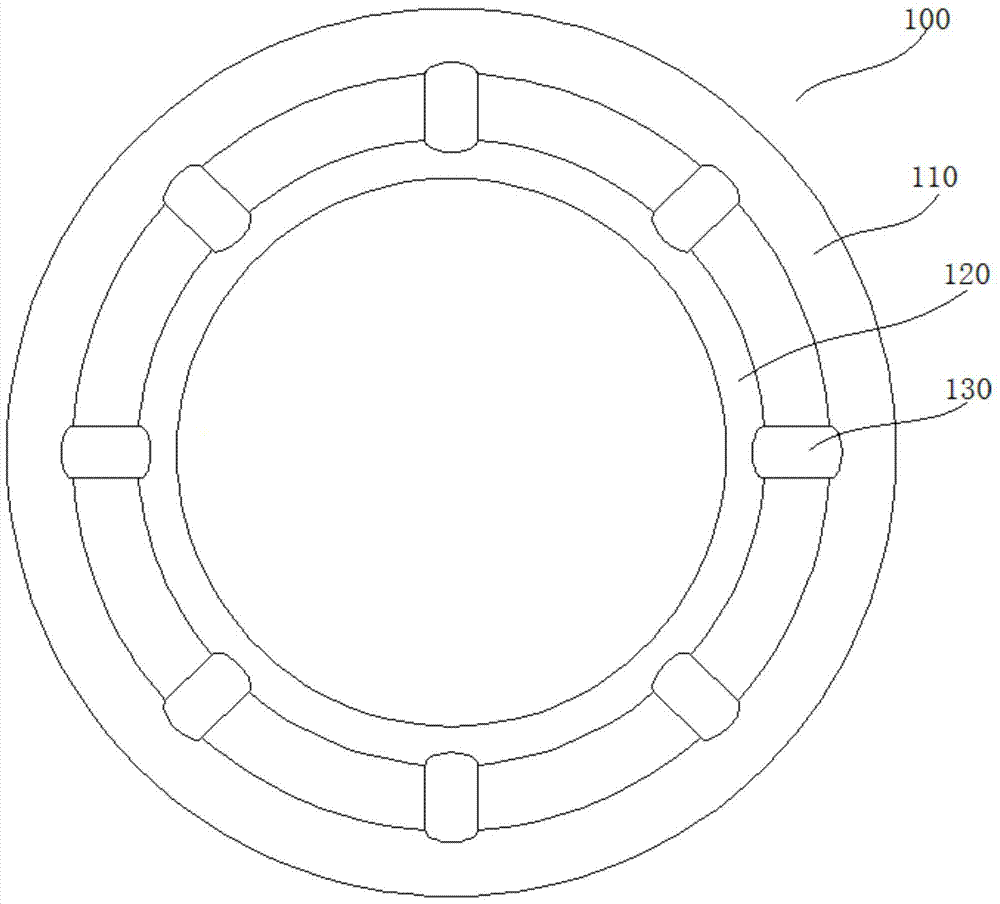

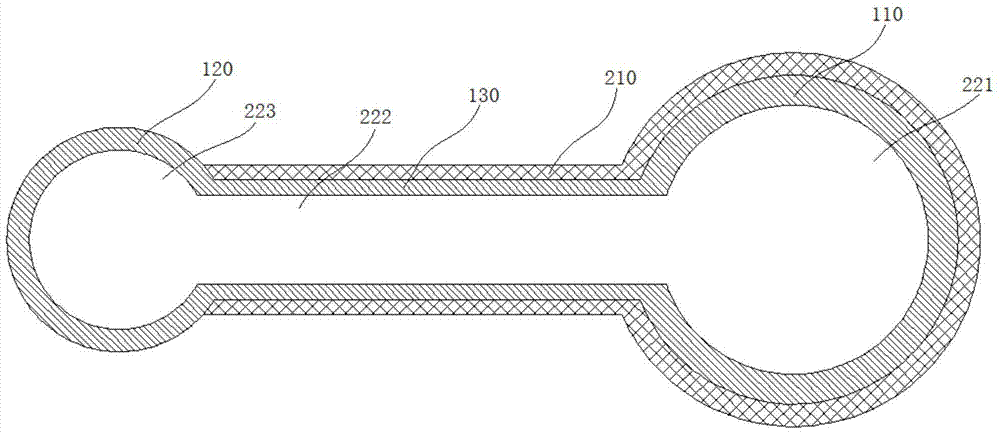

Sealing ring used for pipe gastight connection

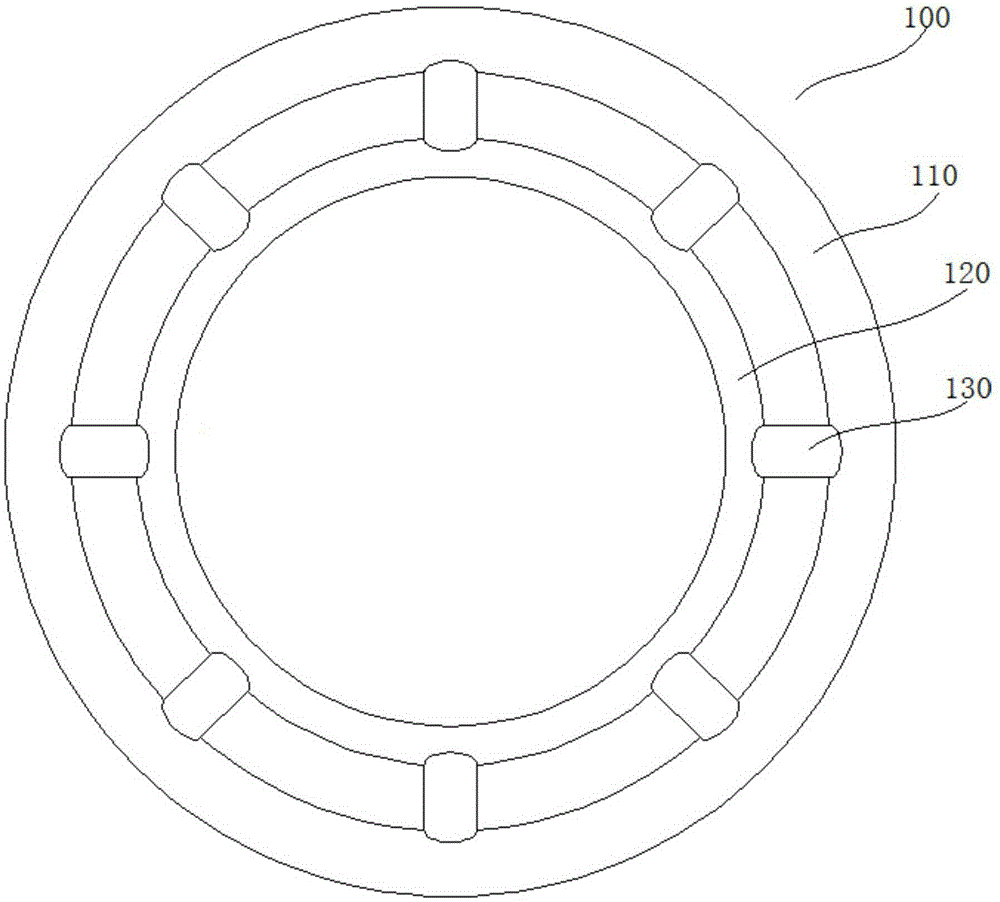

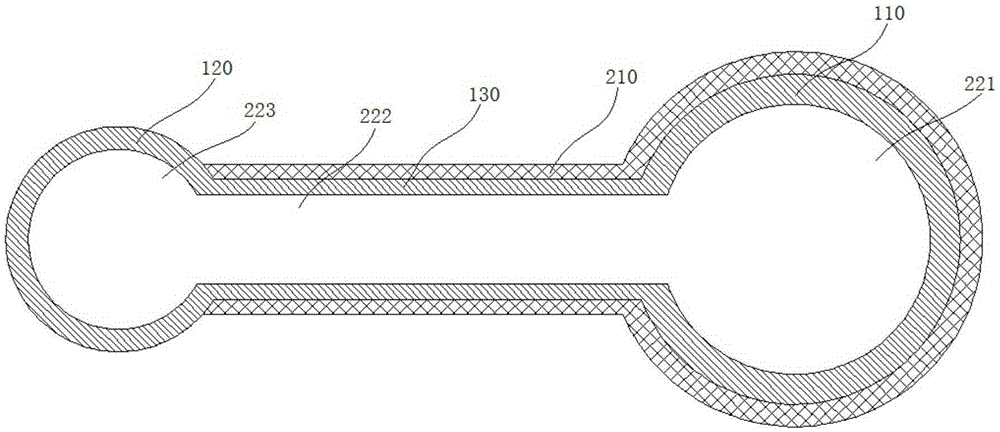

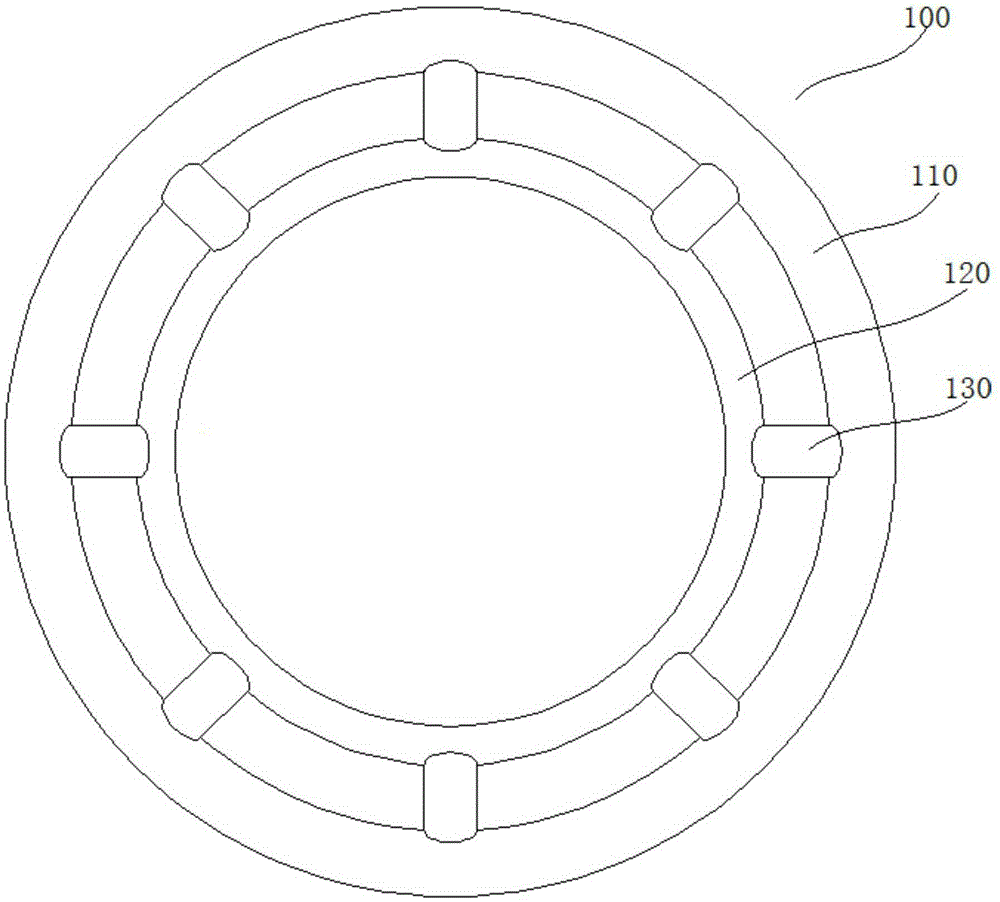

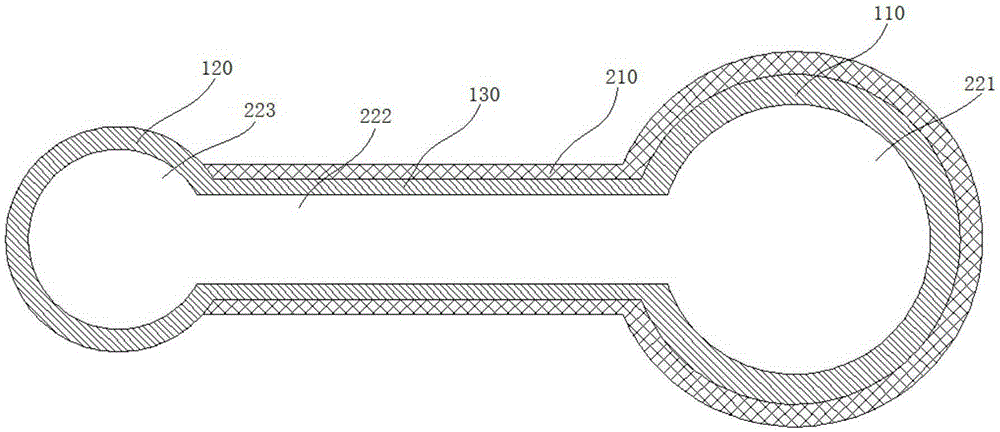

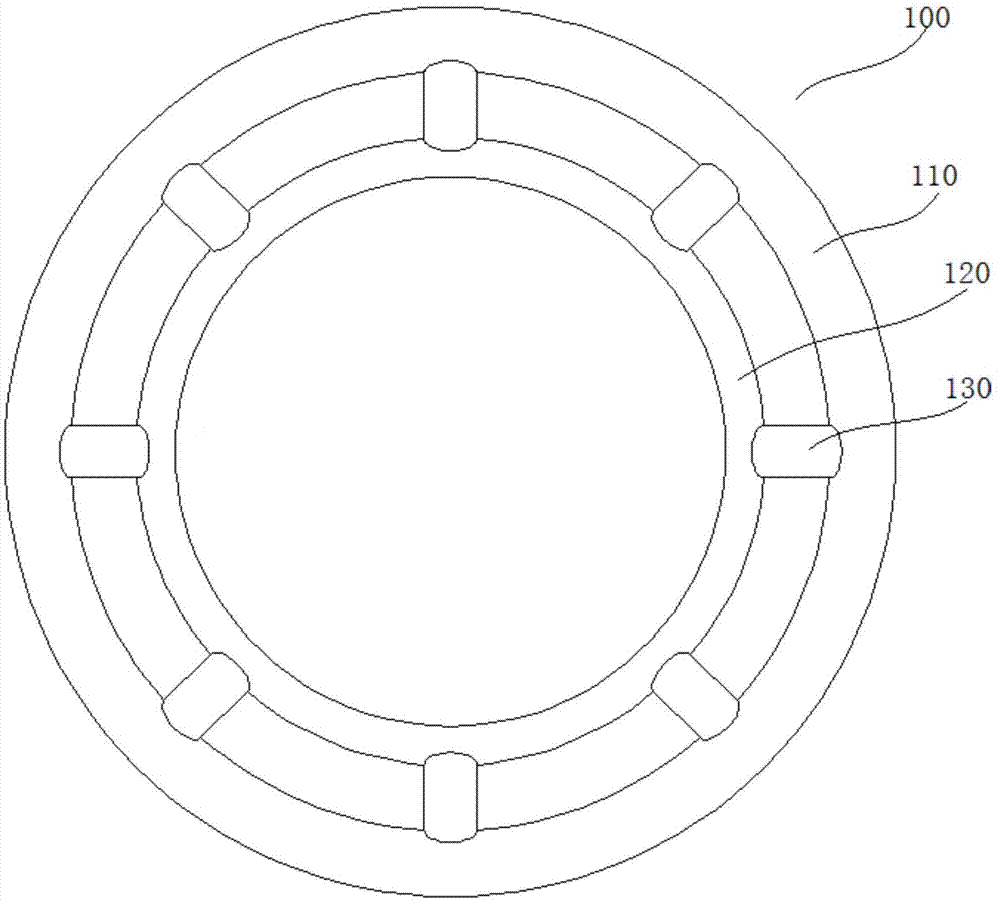

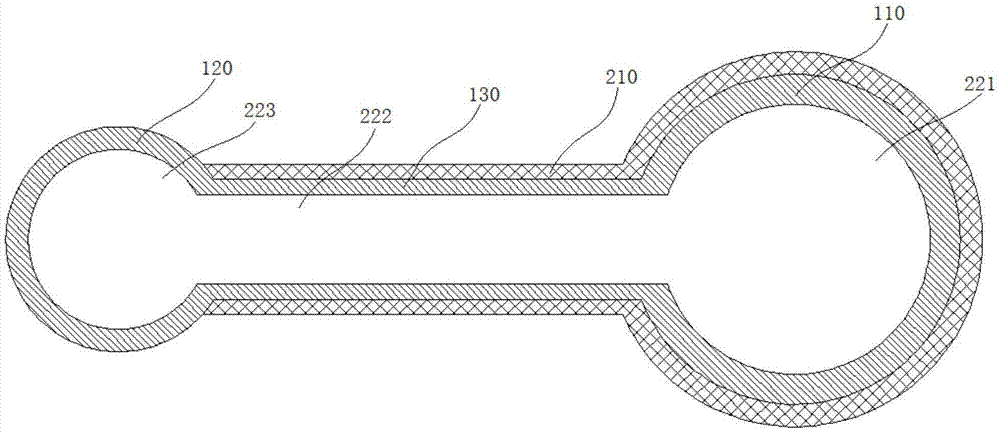

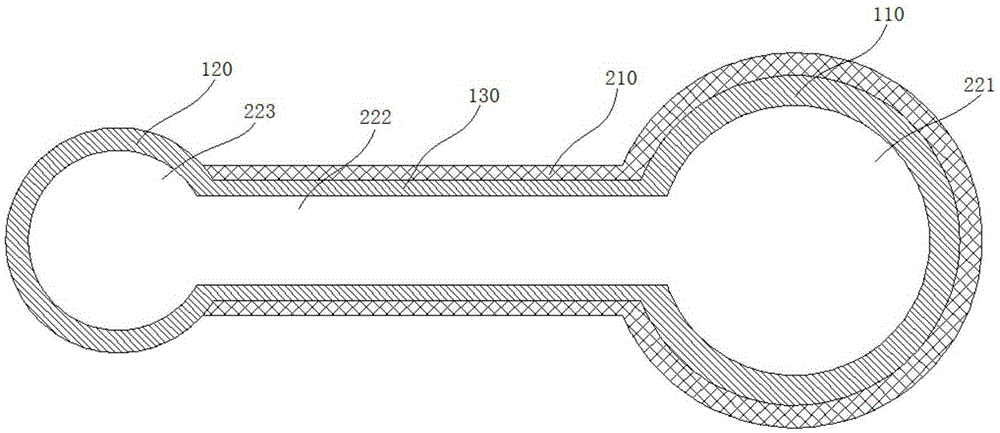

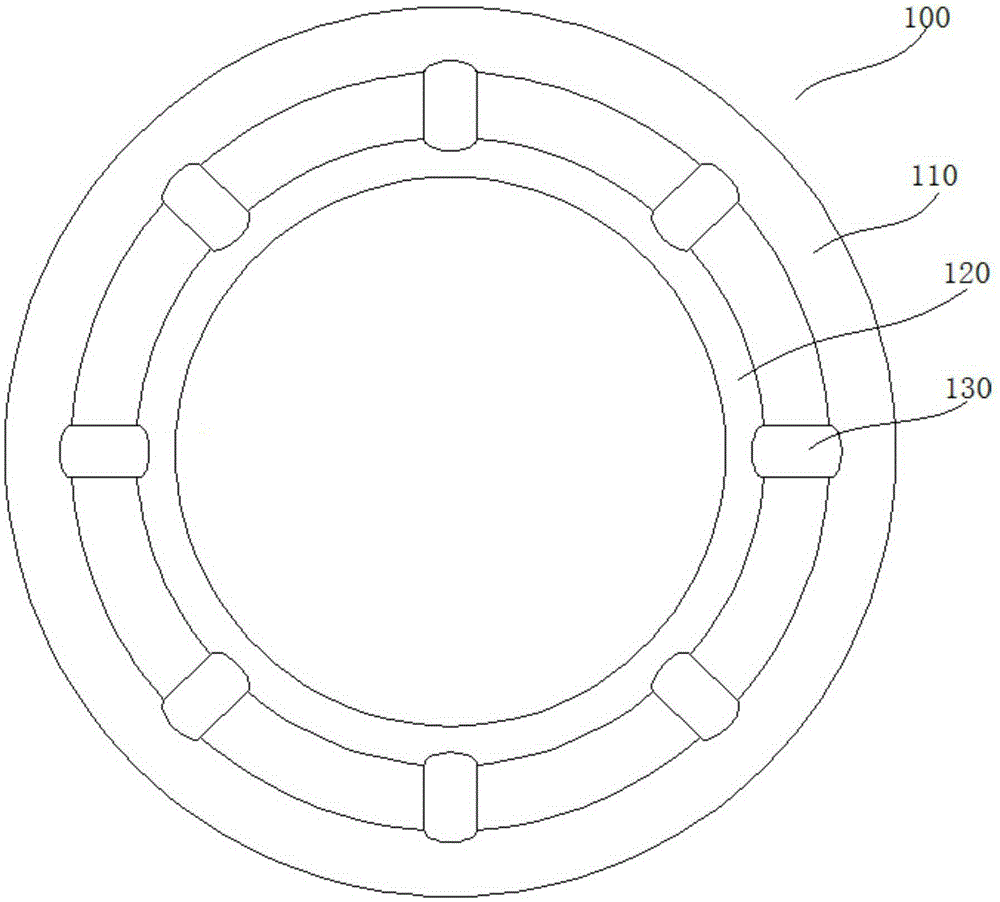

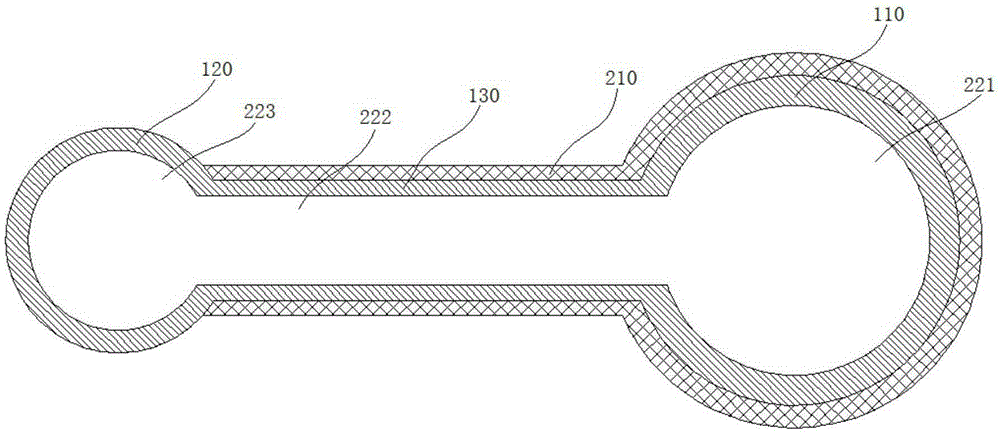

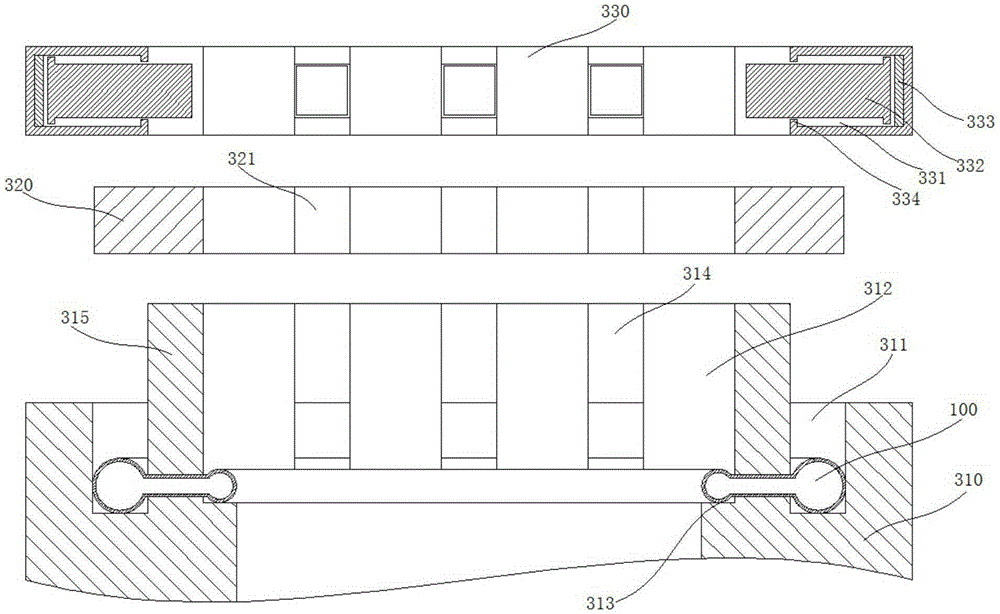

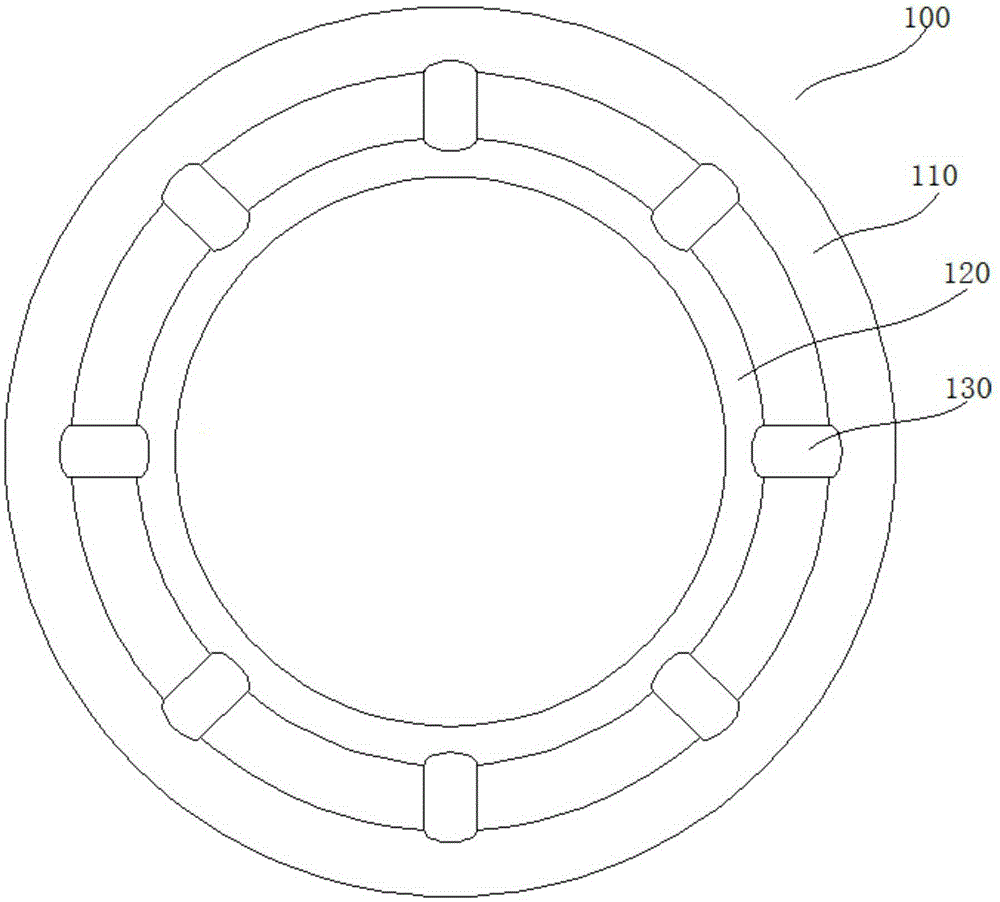

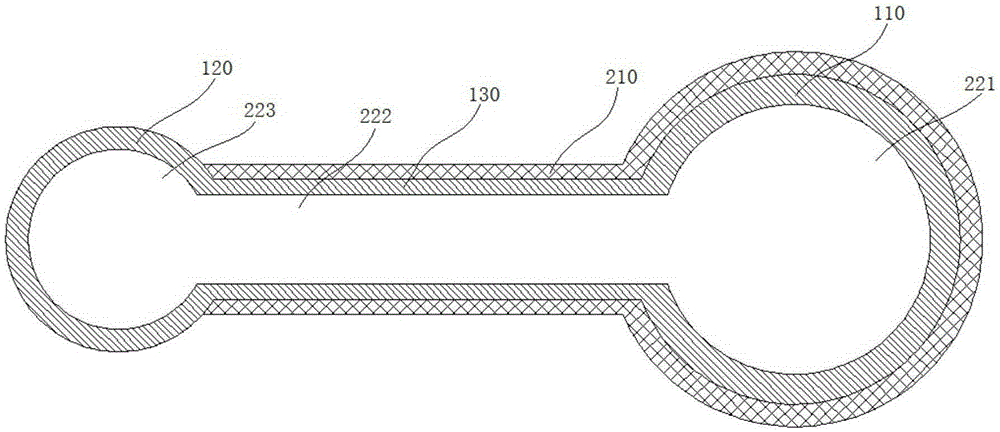

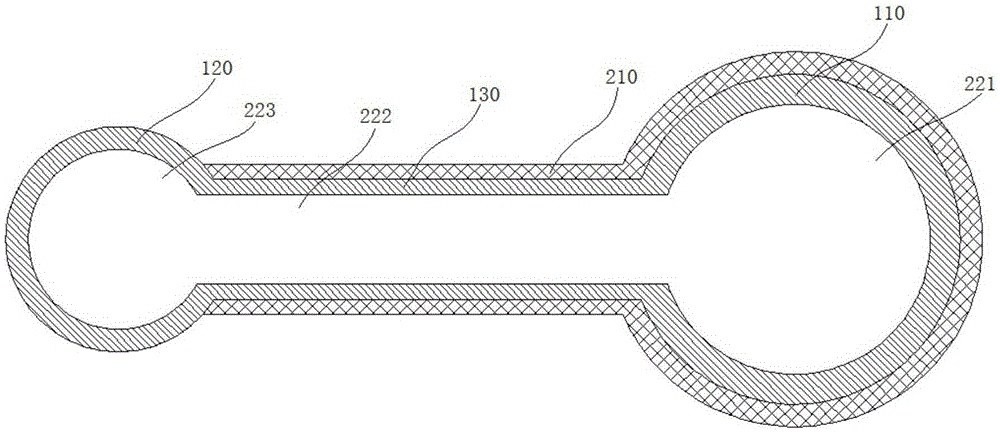

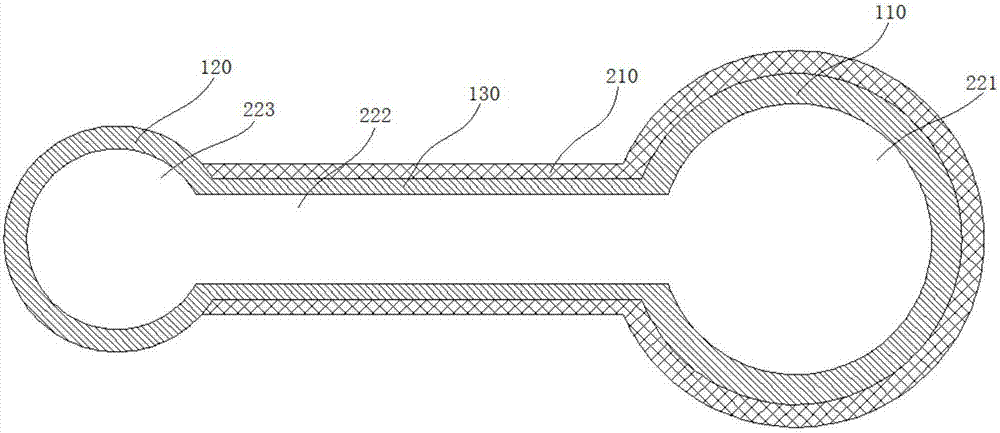

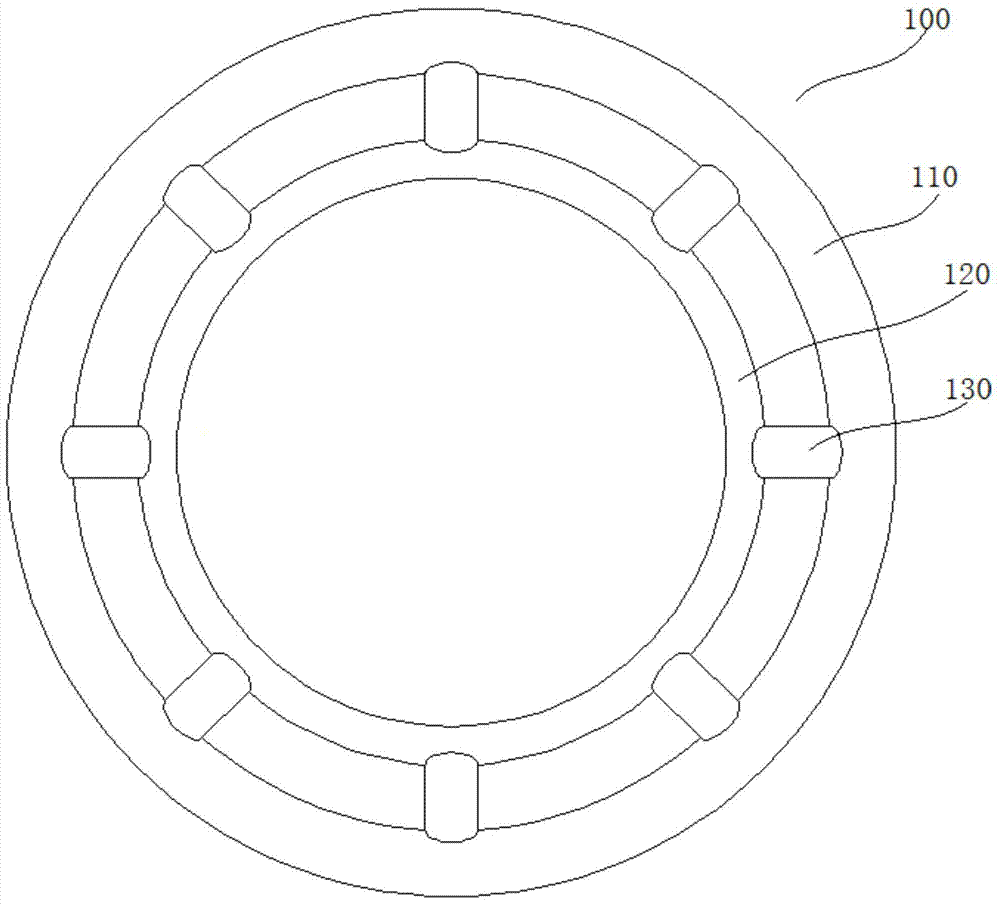

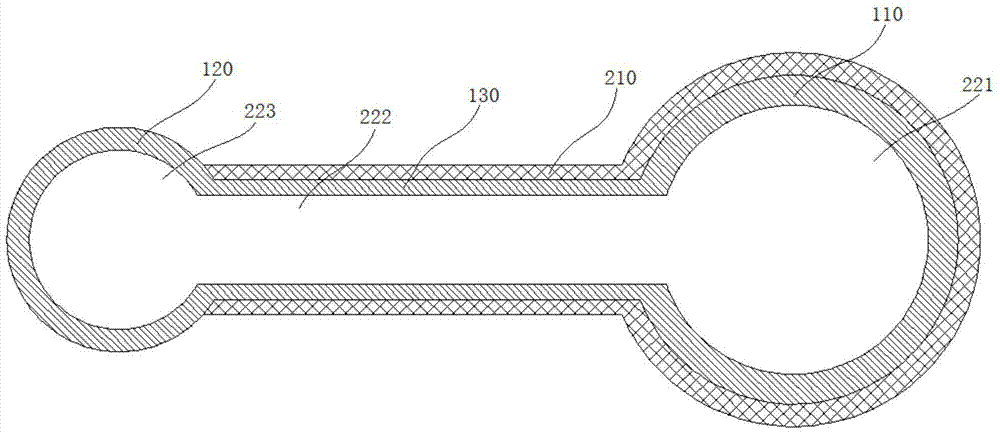

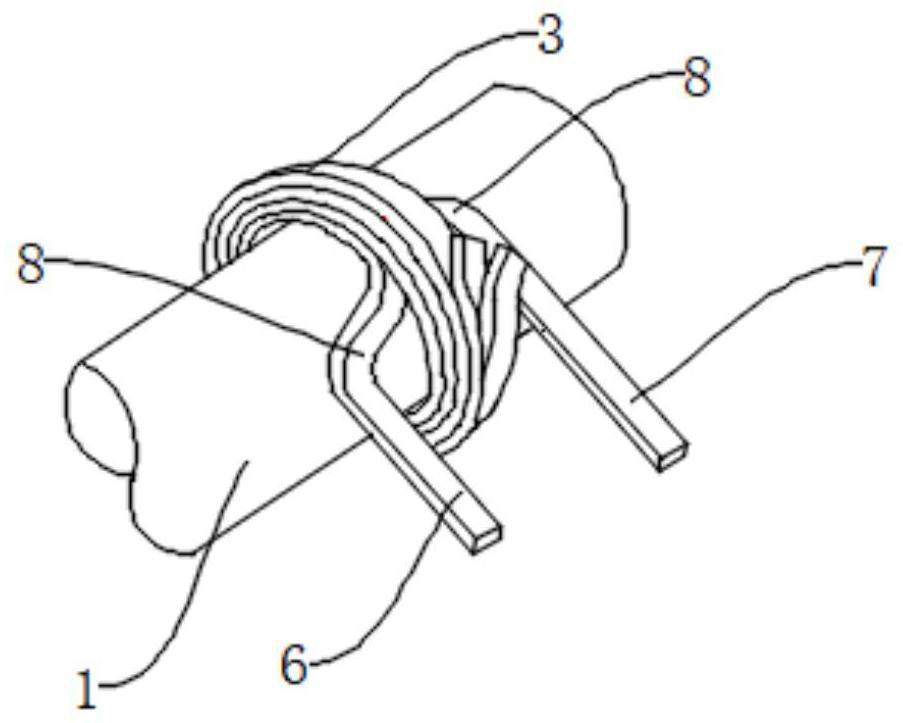

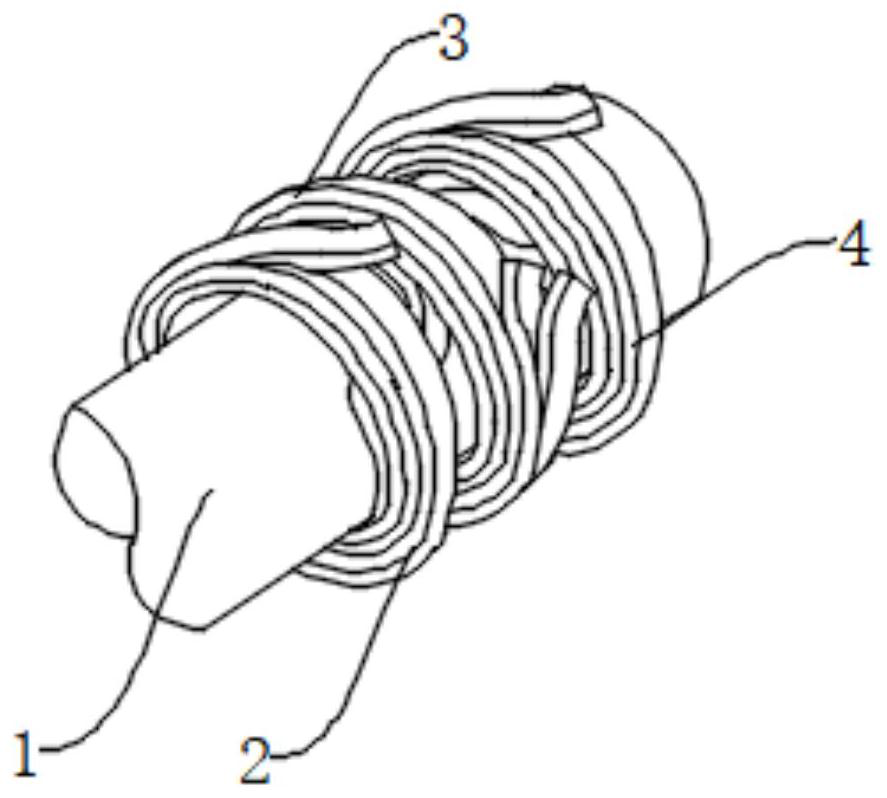

The invention relates to the technical field of neodymium iron boron production equipment, in particular to a sealing ring used for pipe gastight connection. The sealing ring comprises an outer rubber ring and an inner rubber ring which are arranged concentrically. The outer rubber ring and the inner rubber ring are connected to be a whole through at least two connecting pipes uniformly distributed in the circumferential direction. A circular-ring-shaped gas storage cavity is formed in the interior of the outer rubber ring in a hollow mode, a circular-ring-shaped gas collecting cavity is formed in the interior of the inner rubber ring in a hollow mode, and a gas channel used for communicating the gas storage cavity with the gas collecting cavity is formed in the middle of each connecting pipe. The outer rubber ring comprises the following components of natural rubber, butadiene rubber, nitrile butadiene rubber, titanium dioxide, carbon fiber, nano-zinc oxide, paraffin base rubber softening oil, plasticizers and stearic acid. The inner rubber ring comprises the following components of natural rubber, butadiene rubber, active silica powder, carbon black, sulfur, anti-aging agents, accelerants, zinc oxide, magnesium oxide, stearic acid and aromatic oil. The sealing ring used for the pipe gastight connection is good in sealing performance and long in service life.

Owner:NINGBO LINGKE NEW MATERIAL TECH

Air-sealing mechanism used for neodymium iron boron storage barrel

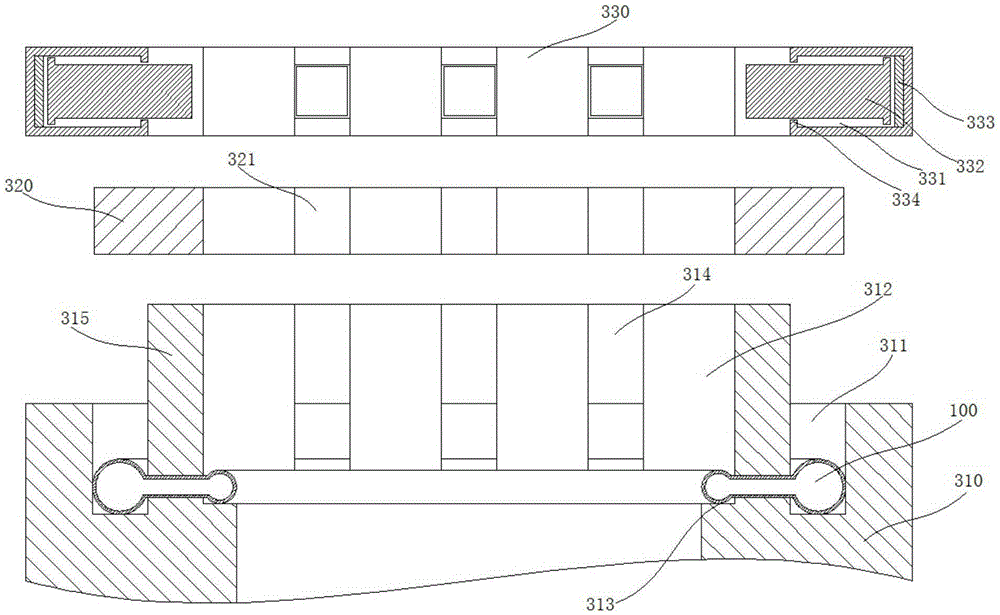

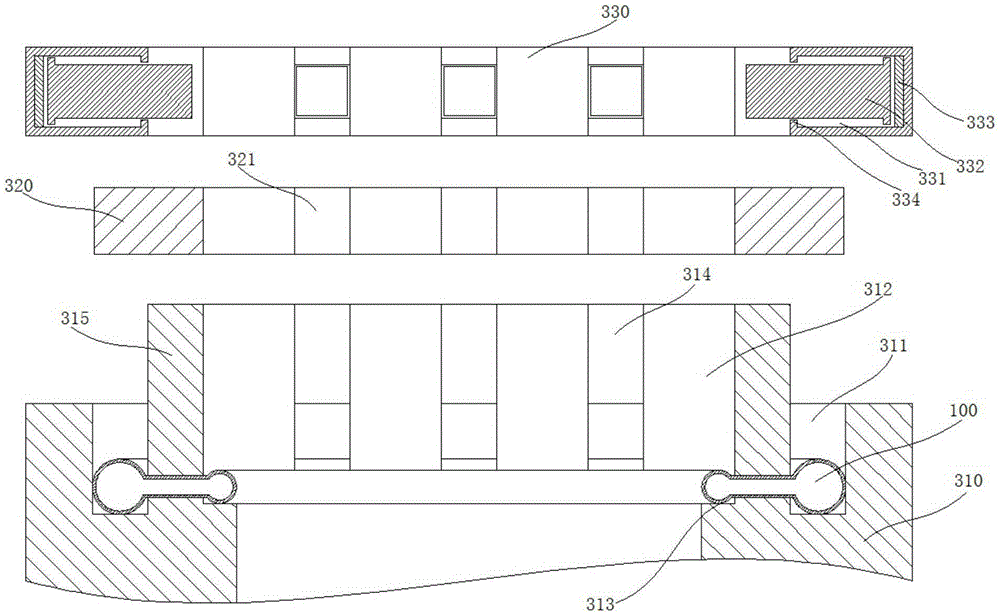

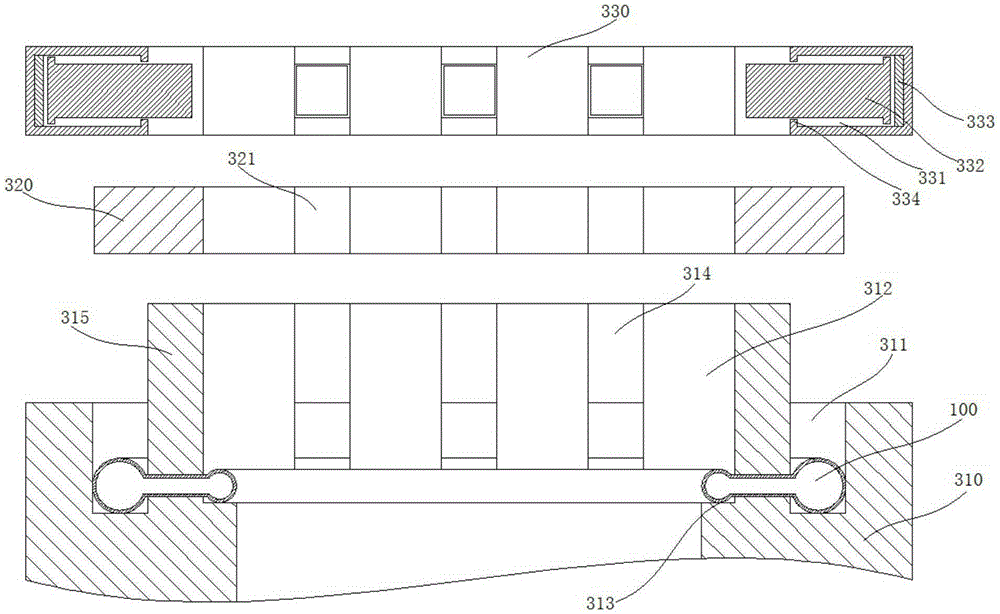

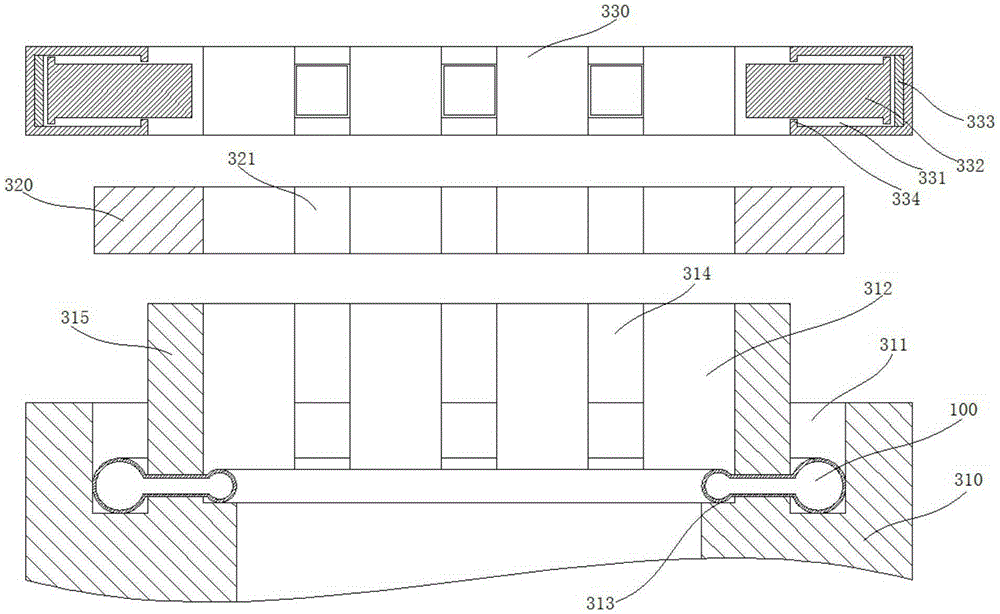

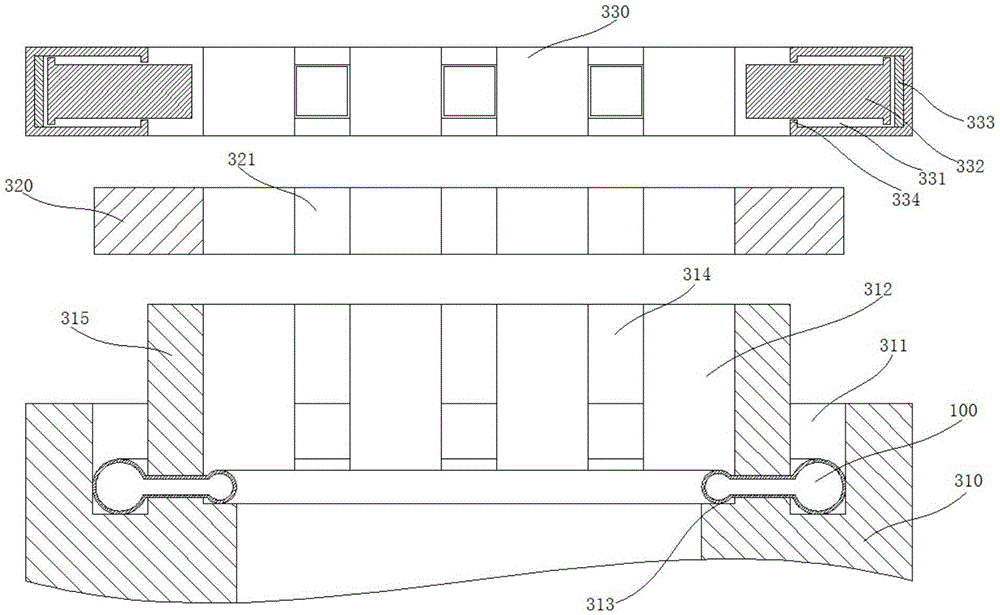

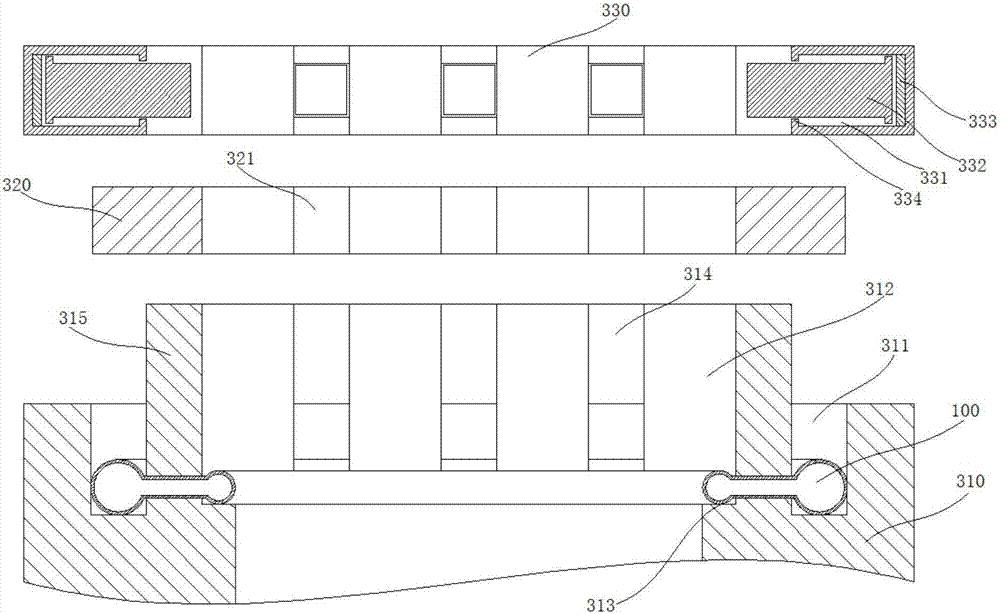

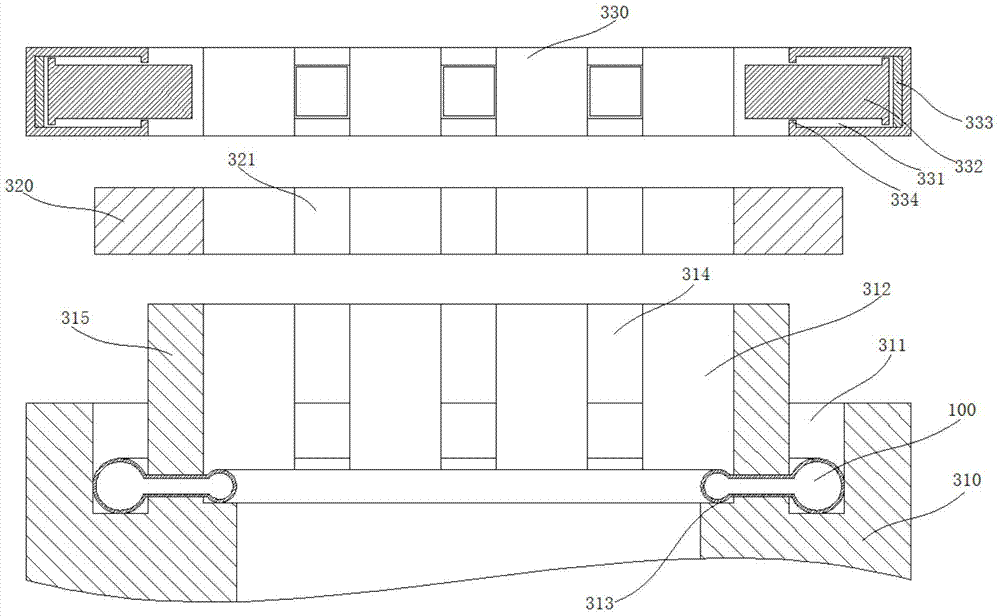

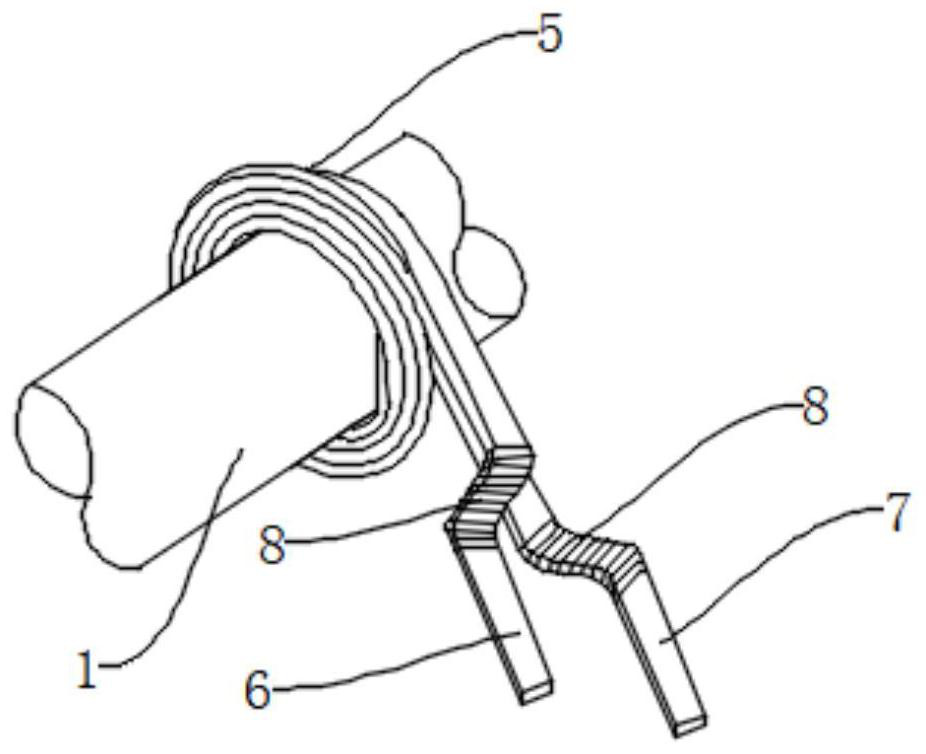

The invention relates to the technical field of neodymium iron boron production devices, in particular to an air- sealing mechanism used for a neodymium iron boron storage barrel. The air- sealing mechanism comprises a barrel opening part arranged on a barrel body, a positioning structure is formed at the open end of the barrel opening part, and a sealing gasket is arranged at the positioning structure; the sealing gasket comprises an outer rubber ring and an inner rubber ring which are concentrically arranged, and the outer rubber ring and the inner rubber ring are connected into a whole through at least two connecting pipes evenly distributed in the circumference direction; the positioning structure comprises a containing groove used for containing the outer rubber ring, containing spaces used for containing the connecting pipes in a one-to-one correspondence mode and a carrying platform used for carrying the inner rubber ring; a pressing ring used for pressing the sealing gasket tightly is arranged at the containing groove, and pressing sheets are arranged in the positions, corresponding to all the containing spaces, of the pressing ring; the barrel opening part further comprises a connecting part, and the outer side of the connecting part is in threaded connection with a fastening ring. According to the air- sealing mechanism used for the neodymium iron boron storage barrel, neodymium iron boron can be received better.

Owner:NINGBO LINGKE NEW MATERIAL TECH

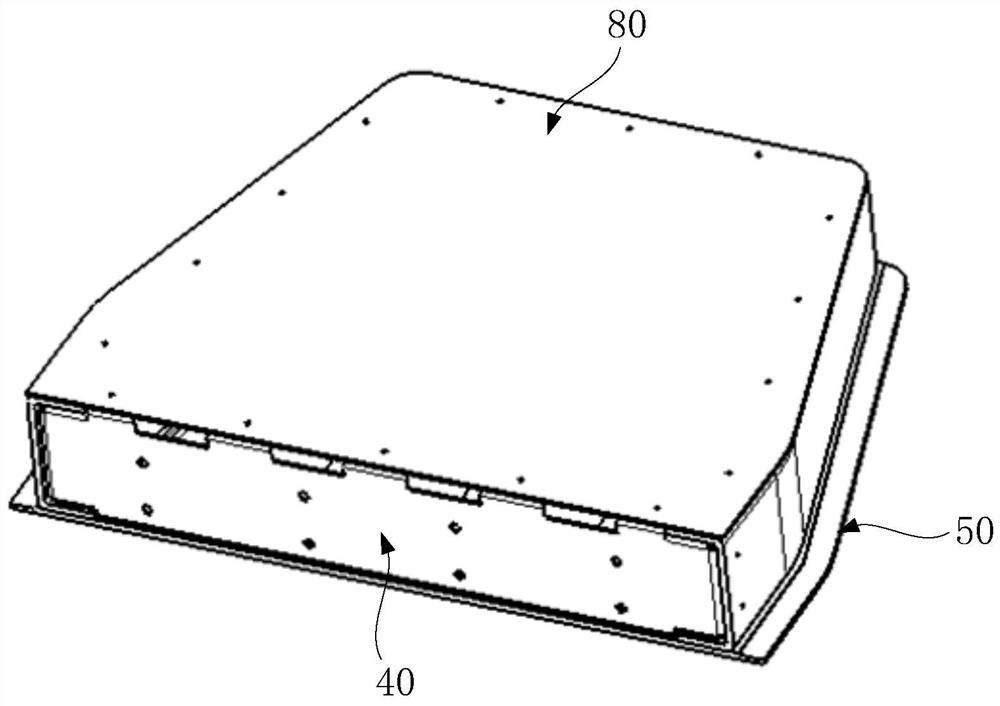

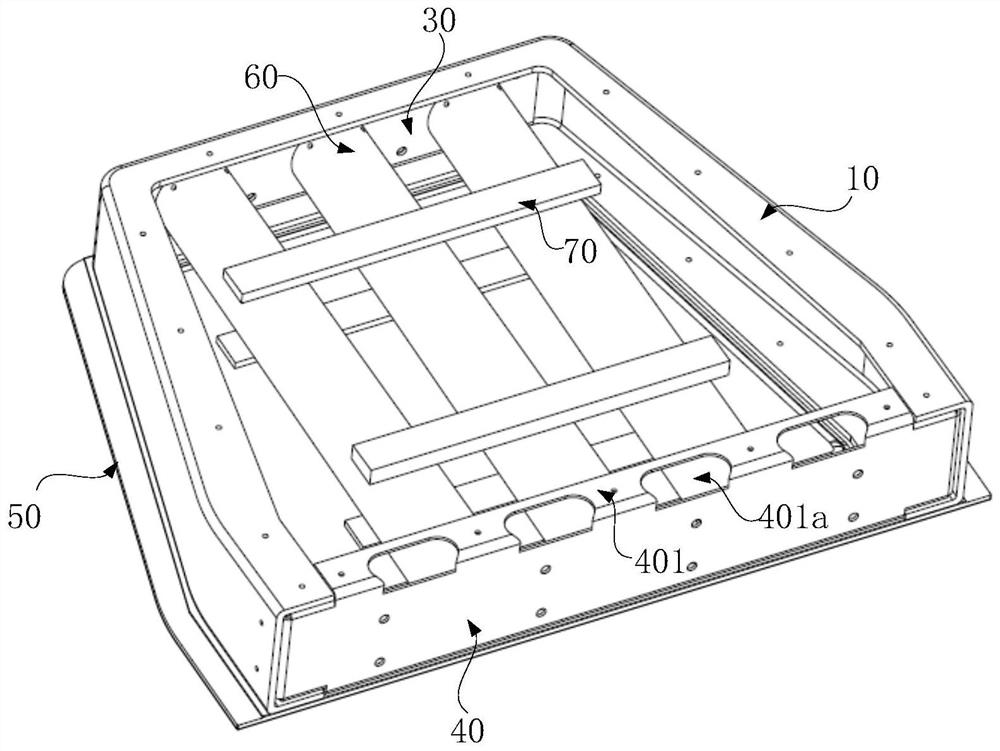

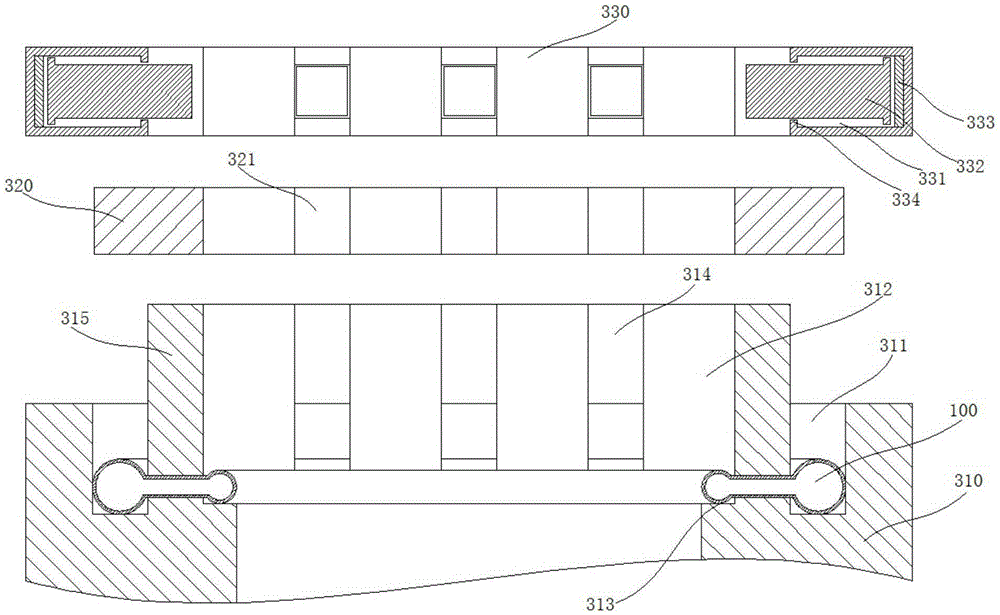

Neodymium iron boron receiving barrel

The invention relates to the technical field of neodymium iron boron production equipment, in particular to a neodymium iron boron receiving barrel. The neodymium iron boron receiving barrel comprises a barrel opening part formed in a barrel body; the opening end of the barrel opening part is provided with a positioning structure, and a sealing gasket is arranged on the positioning structure; the sealing gasket comprises an outer rubber ring and an inner rubber ring which are arranged coaxially, and the outer rubber ring and the inner rubber ring are connected into a whole through at least two connecting pipes uniformly distributed in the circumference direction; the positioning structure comprises a containing groove for containing the outer rubber ring, containing spaces for containing the connecting pipes in a one-to-one correspondence mode and a containing platform for containing the inner rubber ring; a pressing ring for tightly pressing the sealing gasket is arranged in the containing groove, and pressing pieces are arranged in the positions, corresponding to the containing spaces, of the pressing ring; the barrel opening part further comprises a connecting part, a fastening ring is in threaded connection with the outer side of the connecting part, and ejecting rods are arranged in the positions, corresponding to the containing spaces, of the fastening rings. According to the neodymium iron boron receiving barrel, neodymium iron boron can be received well.

Owner:NINGBO LINGKE NEW MATERIAL TECH

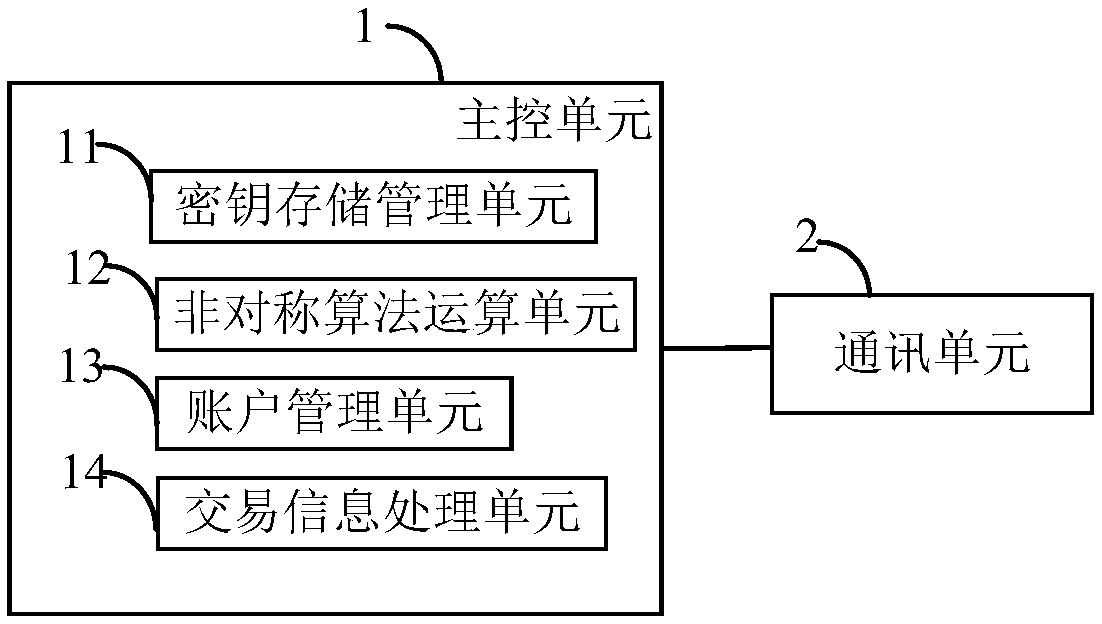

A method for supporting offline transactions by the block chain hard wallet and a hard wallet

The invention discloses a a method for supporting offline transactions by the block chain hard wallet and a hard wallet, relates to the technical field of digital currency, solves the technical problem that the existing hard wallet easily causes equipment locking. The block chain hard wallet comprises a main control unit which is used for account balance recording, transaction signature, decentralized derivation of public keys, signature verification and transaction information recording and is communicated with the outside; And the communication unit is used for performing data interaction with a user side. The method is mainly used for the electronic toll collection system.

Owner:HENGBAO

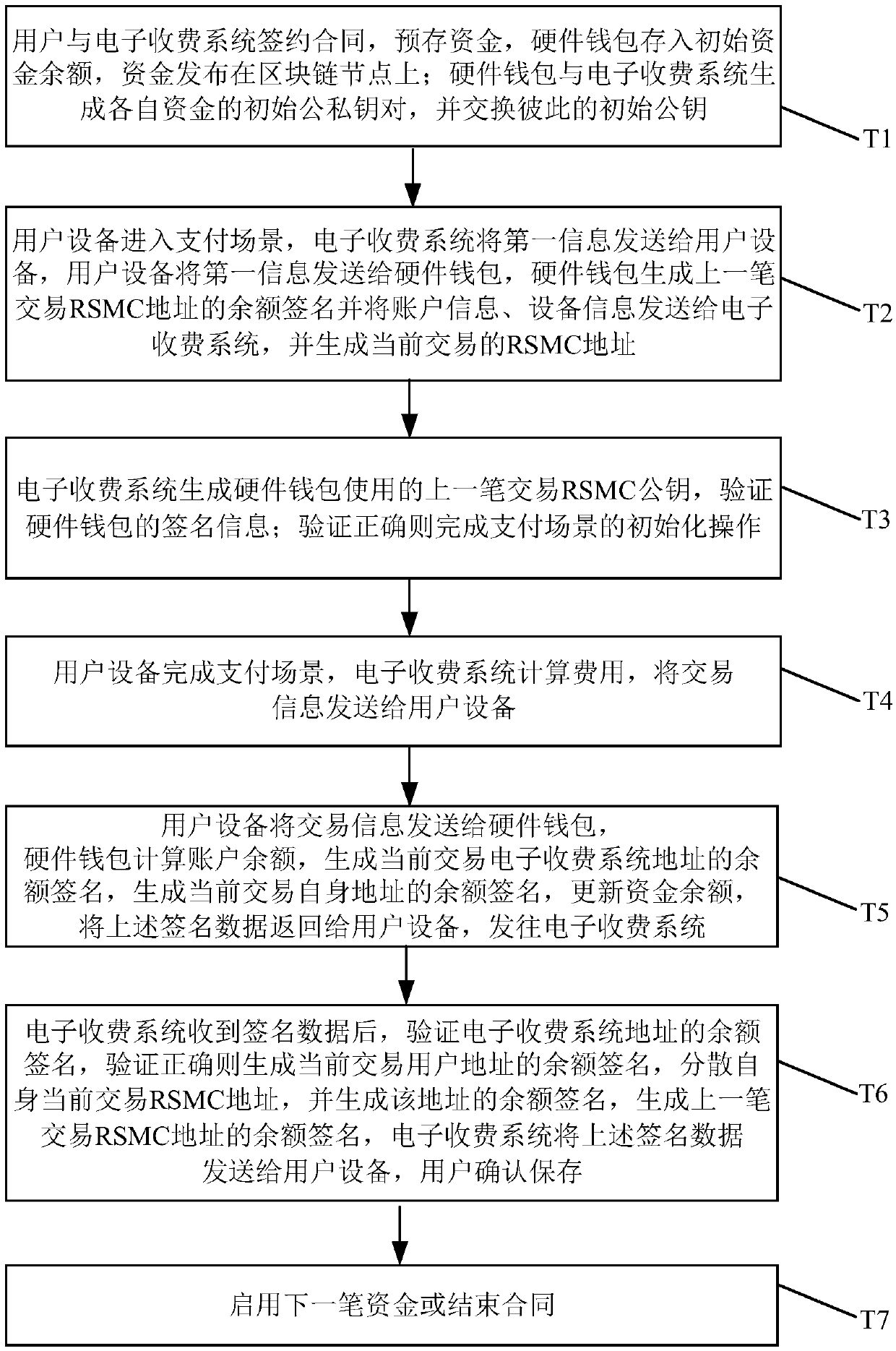

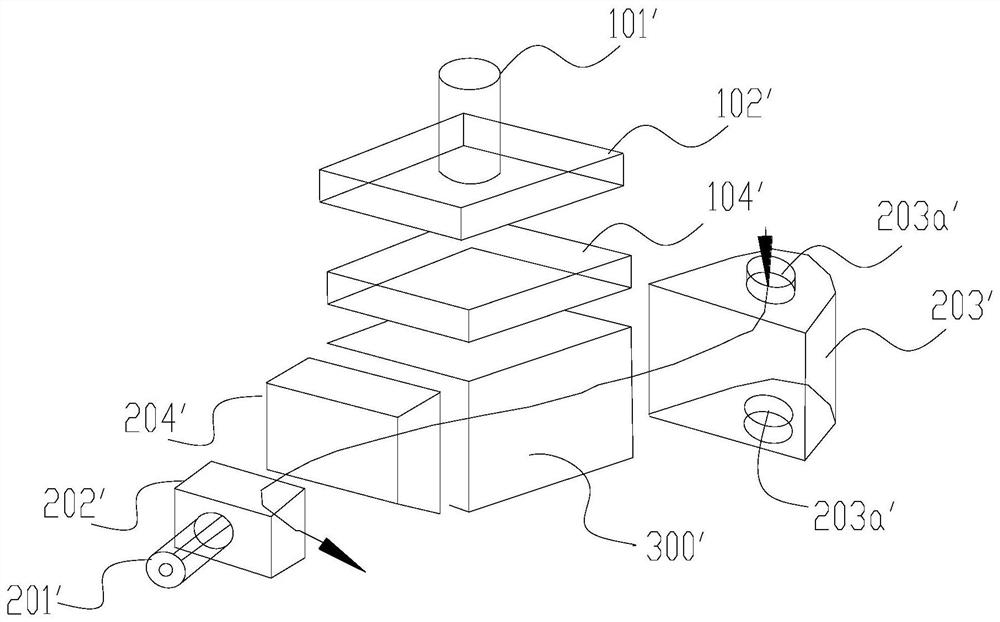

Motor, heat exchange device of shaft system of motor and wind driven generator set

ActiveCN110630454AImprove cooling effectSame technical effectMagnetic circuit rotating partsEngine fuctionsWind drivenEngineering

The invention discloses a motor, a heat exchange device of a shaft system of the motor and a wind driven generator set. The heat exchange device comprises a flexible cavity. A cooling medium can be fed into the flexible cavity. The flexible cavity is located in the inner wall of a motor rotating shaft and used for cooling a motor bearing in the shaft system of the motor. After the cooling medium is poured into the flexible cavity, the cooling environment can be established on the inner wall of the motor rotating shaft, and therefore a heat dissipation channel is formed for the motor bearing which is arranged between the motor rotating shaft and a motor fixed shaft in an encircled mode, and the good cooling effect is achieved.

Owner:BEIJING GOLDWIND SCI & CREATION WINDPOWER EQUIP CO LTD

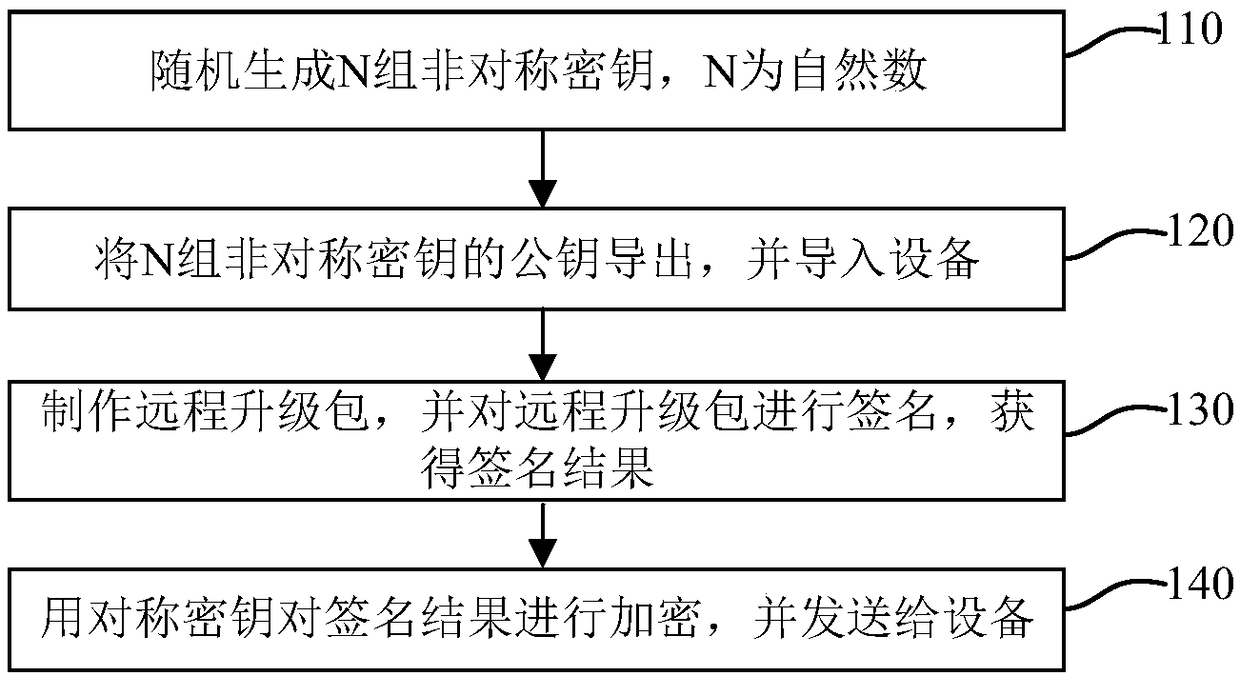

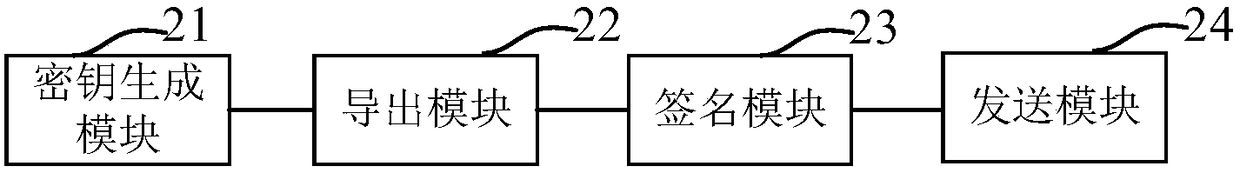

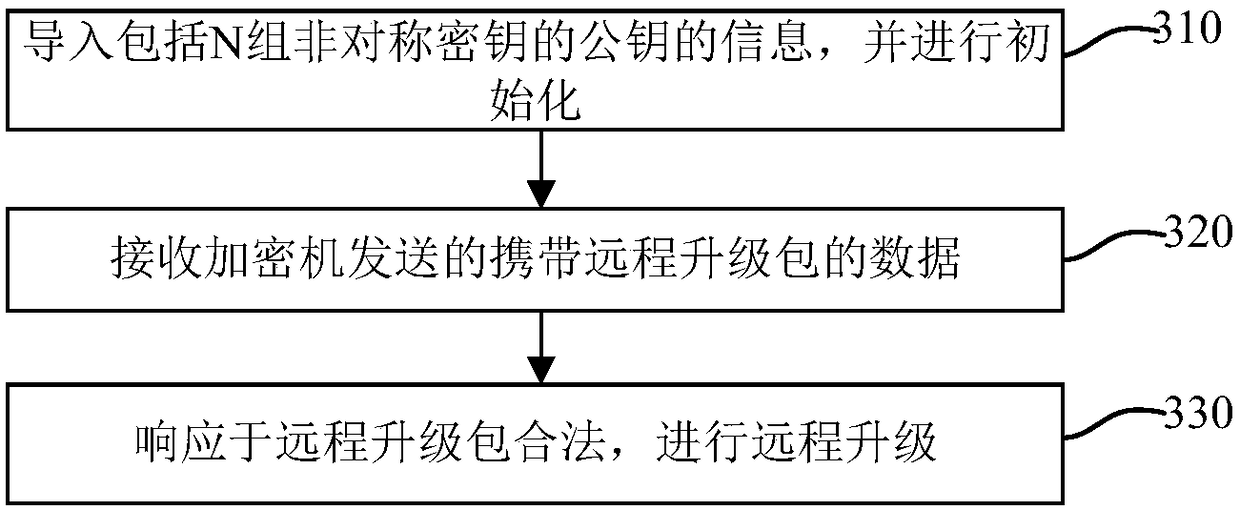

Method and system for remotely upgrading device

InactiveCN108111507AReduce risk of leakageImprove securityKey distribution for secure communicationUser identity/authority verificationUpgradeComputer security

The invention discloses a method and system for remotely upgrading a device, relates to the technical field of remote upgrade, and solves the technical problem of security risks in the remote upgradeof the device in the prior art. The method for remotely upgrading a device according to the application includes the steps of randomly generating N sets of asymmetric secret keys, where N is a naturalnumber; exporting a public key of the N sets of asymmetric secret keys and importing the public key into a device; making a remote upgrade package and signing the remote upgrade package to obtain a signature result; and encrypting the signature result with a symmetric secret key and sending the result to the device. This application is mainly used for device upgrades.

Owner:HENGBAO

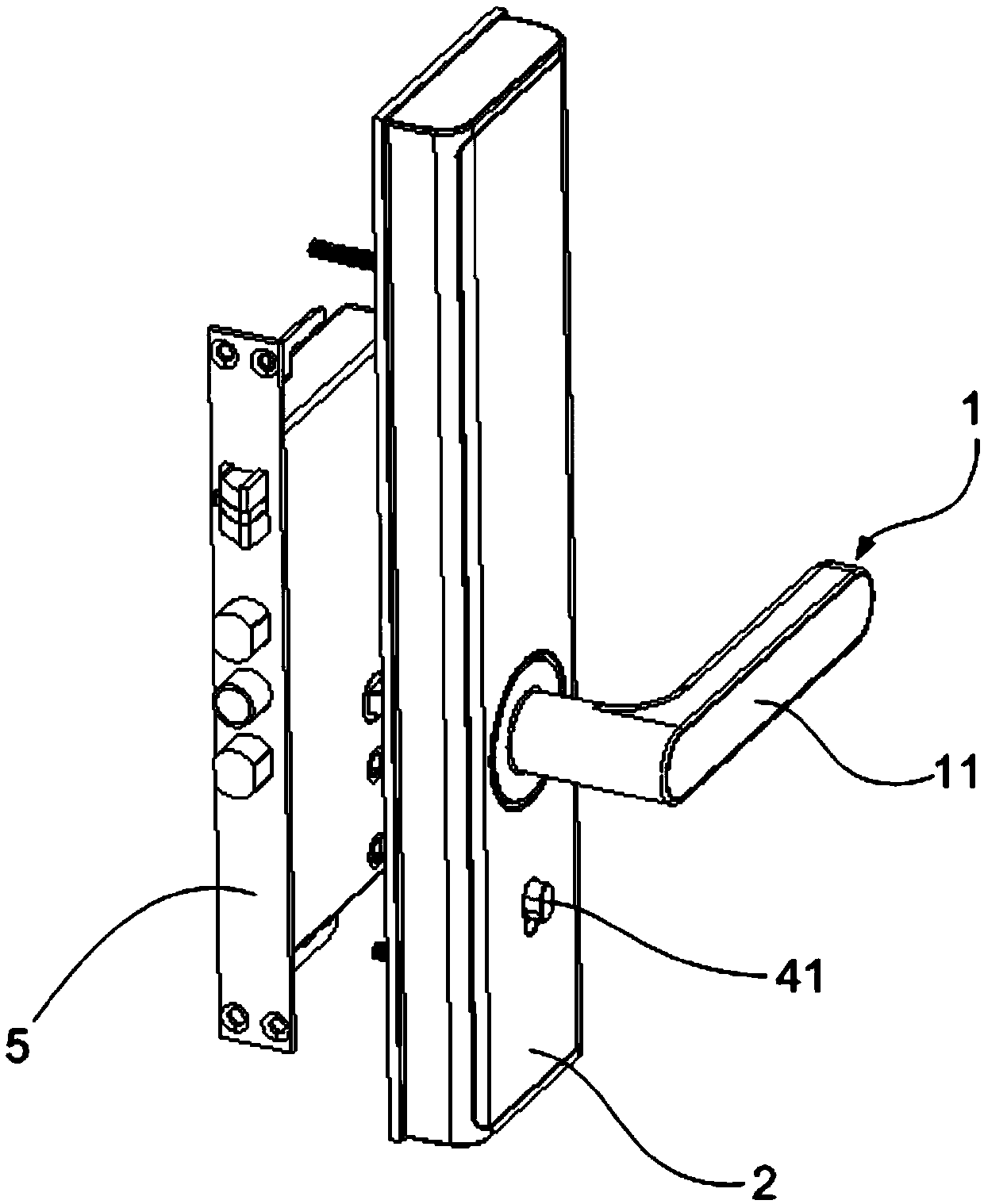

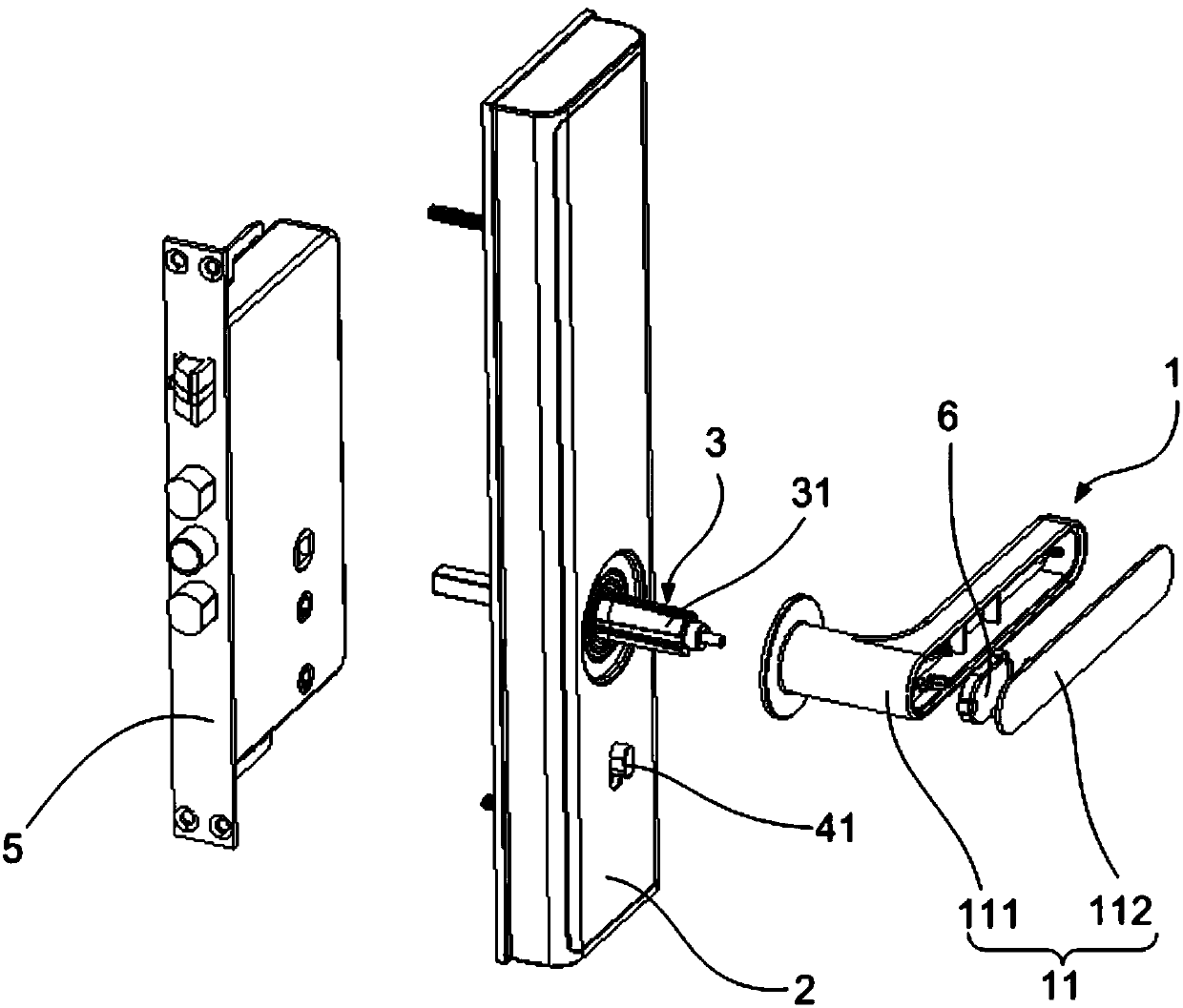

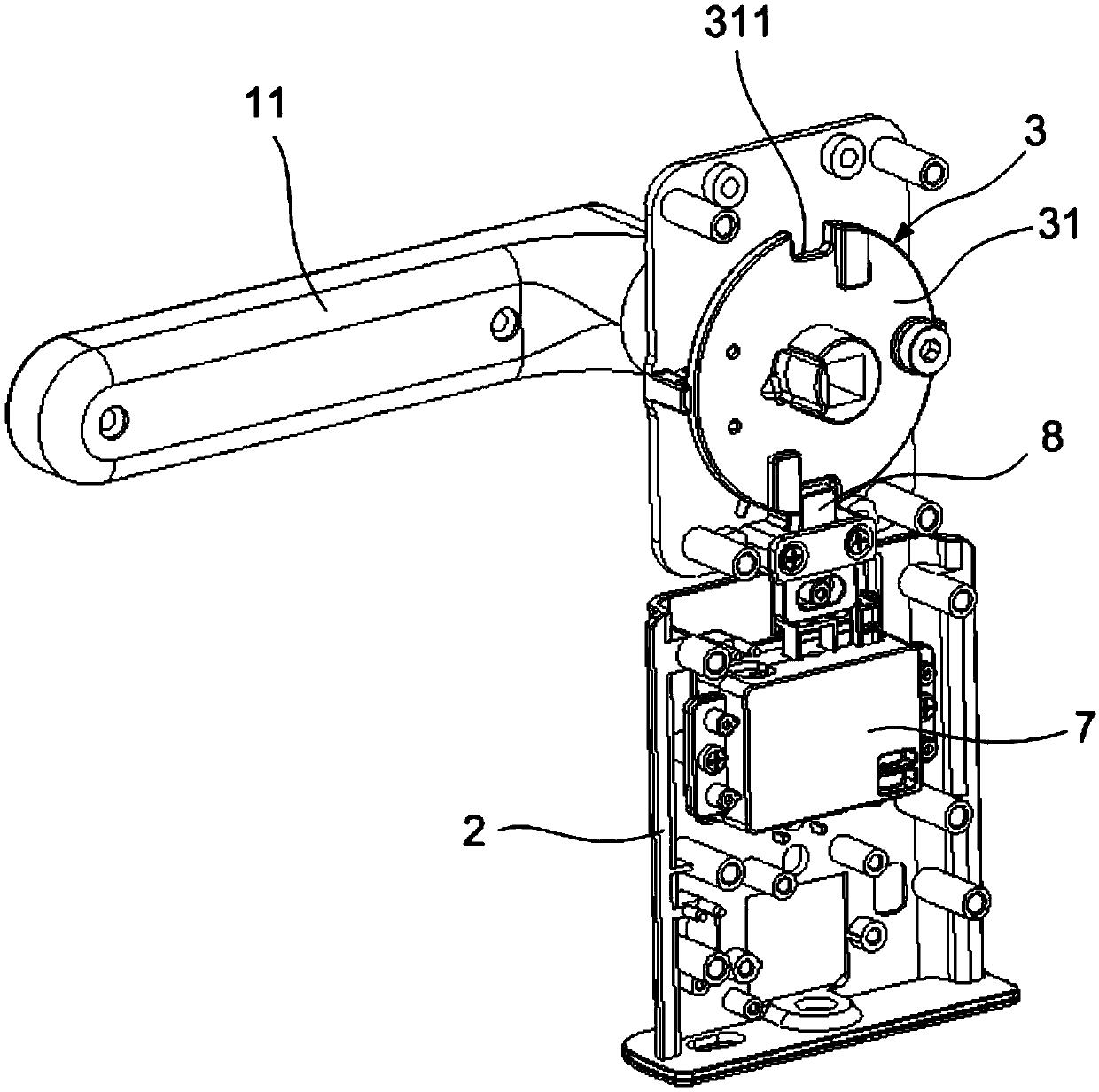

Handle device capable of preventing unlocking from cat eye and door lock

PendingCN111321943AAvoid situations where it is not enabledImprove securityNon-mechanical controlsKeyhole guardsControl engineeringStress sensors

The invention discloses a handle device capable of preventing unlocking from a cat eye and a door lock. The handle device comprises a handle provided with a pressure sensor for detecting a pressing force, a handle linkage member connected to the handle and acting along with movement of the handle, and a clutch mechanism, wherein a clutch end of the clutch mechanism is in clutch limiting fit with the handle linkage member, and a drive controller of the clutch mechanism is connected to the pressure sensor. When the pressure sensor detects the pressing force on the handle, the drive controller receives a pressure signals transmitted by the pressure sensor, and controls the clutch mechanism to act, so that the clutch end and the handle linkage member are deviated from limiting fit, and the handle is allowed to perform an unlocking motion; and after the handle is reset to a locked position, the drive controller controls the clutch end to reset to a position in limiting fit with the handle linkage member. The handle device can perform an unlocking action only needing to be held in a hand; and after the hand releases, the action of the handle is automatically limited, so that the safety is improved, and meanwhile, unlocking is convenient and fast.

Owner:YUNDING NETWORK TECH BEIJING

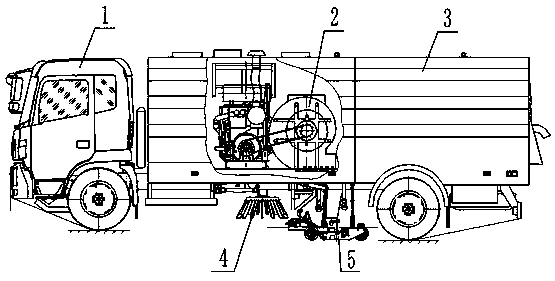

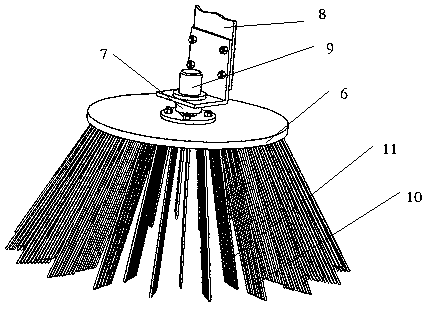

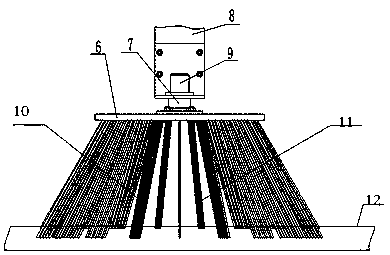

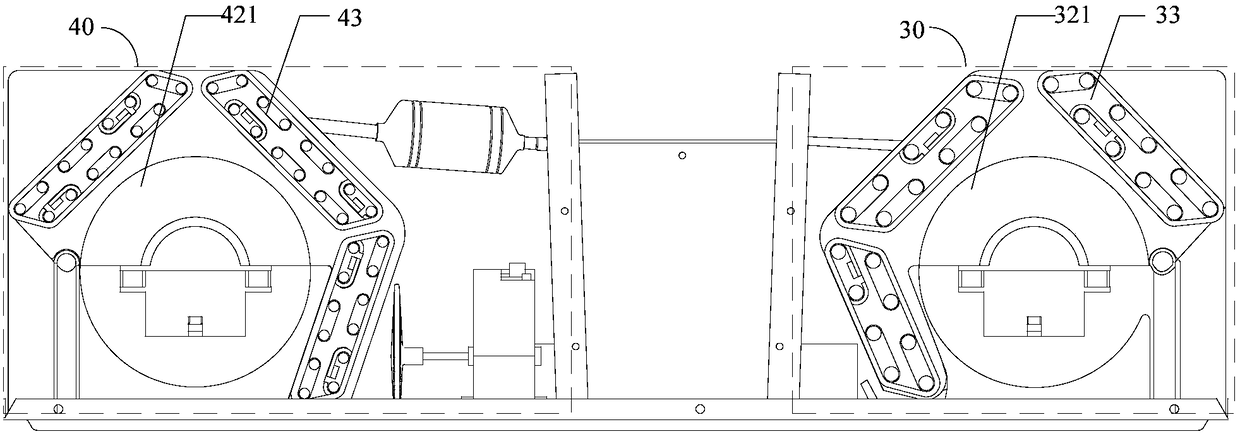

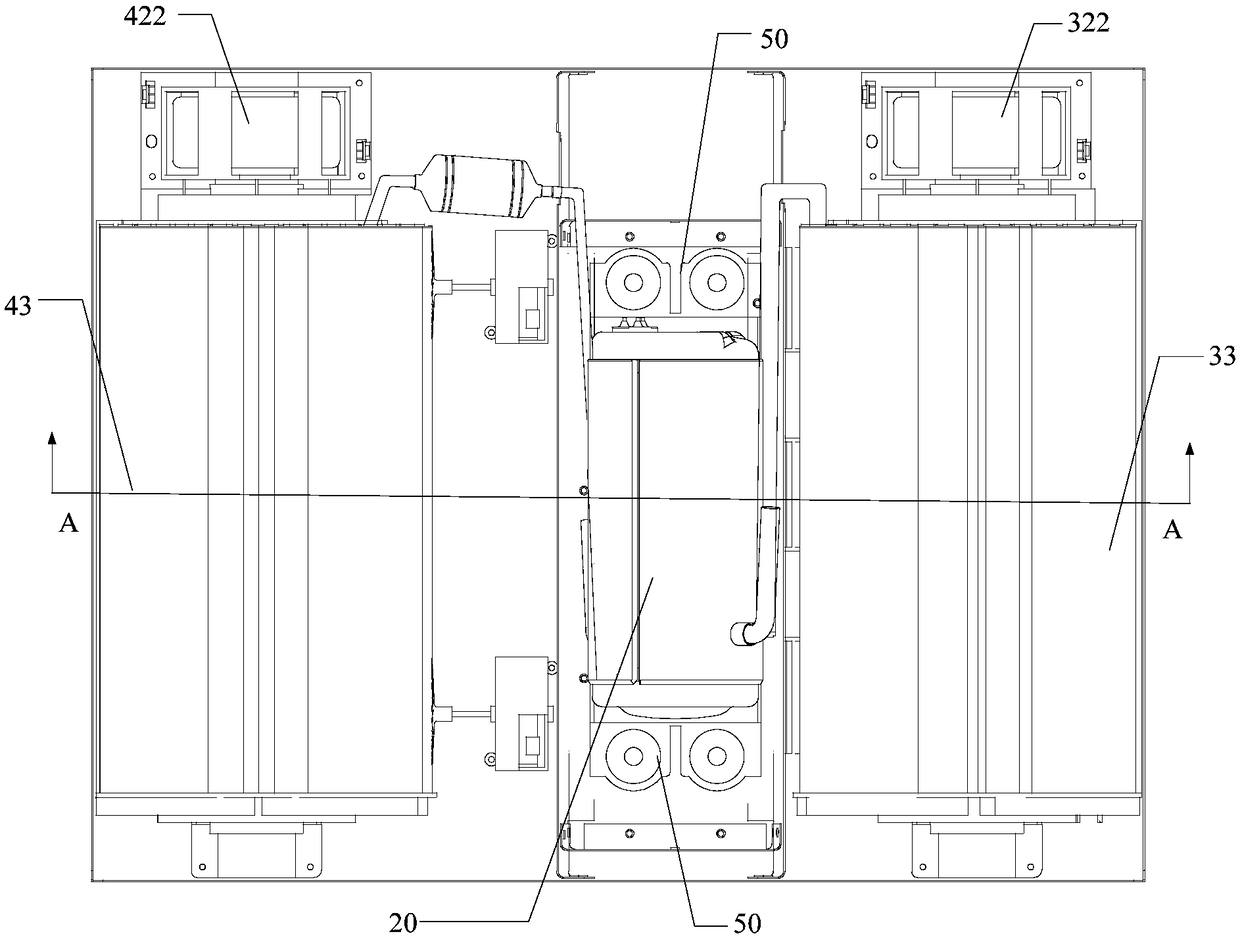

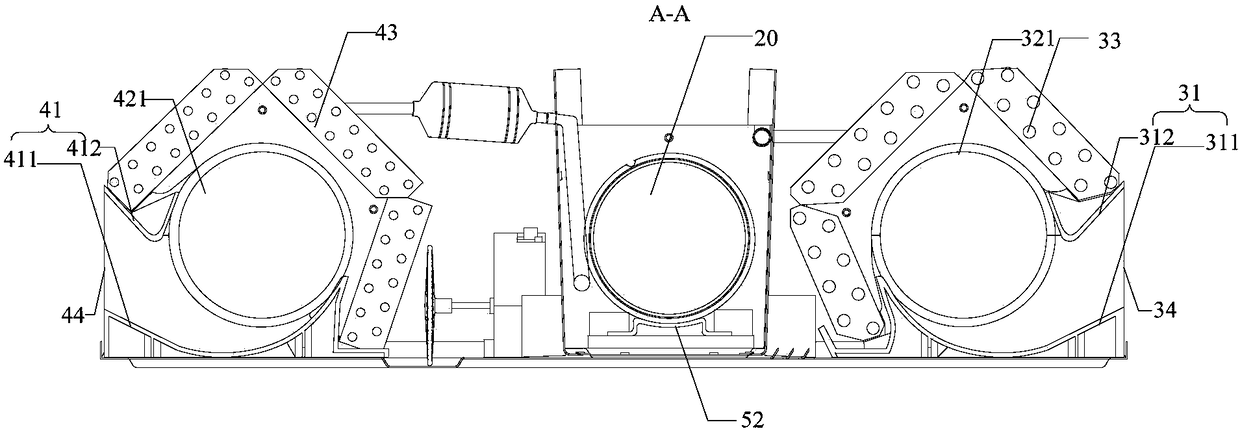

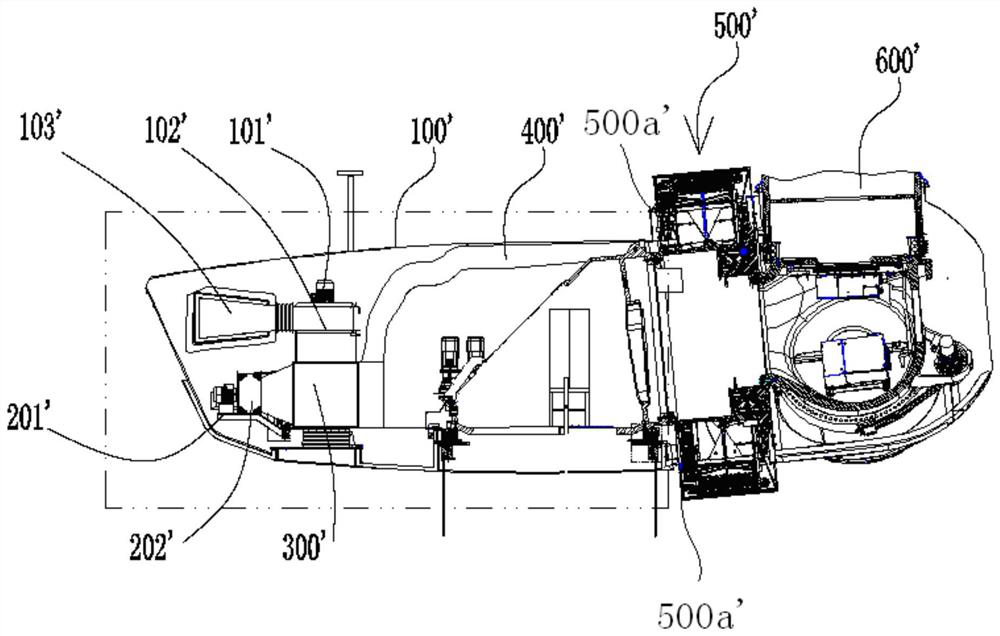

Sweeping vehicle and disc brush device thereof

The invention relates to a sweeping vehicle and a disc brush device thereof and aims to solve that problems that in the prior art, melted water of a snow melting car remains on the road surface to cause secondary freezing, and then traffic safety is affected. The sweeping vehicle comprises a vehicle body and the disc brush device on the bottom of the vehicle body, wherein the disc brush device comprises a mixed disc brush, and the mixed disc brush comprises an installation plate, soft bristle units and hard bristle units. The soft bristle units and the hard bristle units are alternatively installed on the bottom face of the installation plate, each soft bristle unit comprises at least one bunch of soft bristles, and each hard bristle unit comprises at least one bunch of hard bristles. Thesoft bristles are used for clearing away water and floating dust, and the hard bristles are used for clearing away road garbage and broken ice. The sweeping vehicle with the disc brush device followsthe snow melting car by a certain distance for combined operation, snow water remaining on the road surface when the snow melting car works can be cleared away, the garbage and the broken ice on the road surface can be cleared away, it is ensured that the road surface is clean, no accumulated water remains, and the situation that secondary freezing is generated to affect the traffic safety is avoided.

Owner:HENAN SENYUAN HEAVY IND

Manufacturing method for air-pressure type sealing gasket

The invention relates to the technical field of neodymium iron boron production devices, in particular to a manufacturing method for an air-pressure type sealing gasket. The manufacturing method comprises the following steps that 1, a first rubber raw material is prepared; 2, a second rubber raw material is prepared; 3, an outer rubber ring is prepared from the first rubber raw material; 4, an inner rubber ring is prepared from the second rubber raw material; 5, a connecting pipe is prepared from the second rubber raw material; and 6, assembling is conducted. By means of the manufacturing method for the air-pressure type sealing gasket, the sealing gasket with good sealing performance and long service life can be prepared.

Owner:NINGBO LINGKE NEW MATERIAL TECH

Bucket mouth structure for neodymium-iron-boron storage bucket

The invention relates to the technical field of neodymium-iron-boron production equipment, in particular to a bucket mouth structure for a neodymium-iron-boron storage bucket. The bucket mouth structure for the neodymium-iron-boron storage bucket comprises a bucket mouth part which is arranged on a bucket body. A positioning structure is arranged at the open end of the bucket mouth part. A sealing gasket is arranged in the position of the positioning structure. The sealing gasket comprises an outer rubber ring and an inner rubber ring, wherein the outer rubber ring and the inner rubber ring are arranged concentrically and connected into a whole through at least two connecting pipes which are evenly distributed in the circumferential direction. The positioning structure comprises a containing groove used for containing the outer rubber ring, containing gaps used for containing the connecting pipes in a one-to-one correspondence mode, and a containing table used for containing the inner rubber ring. A pressing ring used for tightly pressing the sealing gasket is arranged in the position of the containing groove. Pressing pieces are arranged in the positions, corresponding to all the containing gaps, of the pressing ring respectively. The bucket mouth part further comprises a connecting part. A fastening ring is connected to the outer side of the connecting part in a threaded mode. Ejector rods are arranged in the positions, corresponding to all the containing gaps, of the fastening ring respectively. By the adoption of the bucket mouth structure for the neodymium-iron-boron storage bucket, neodymium-iron-boron materials can be received quite excellently.

Owner:NINGBO LINGKE NEW MATERIAL TECH

Storage device for collecting neodymium-iron-boron magnetic powder

The invention relates to the technical field of neodymium-iron-boron production equipment, in particular to a storage device for collecting neodymium-iron-boron magnetic powder. The storage device for collecting the neodymium-iron-boron magnetic powder comprises a bucket mouth part which is arranged on a bucket body. A positioning structure is arranged at the open end of the bucket mouth part. A sealing gasket is arranged in the position of the positioning structure. The sealing gasket comprises an outer rubber ring and an inner rubber ring, wherein the outer rubber ring and the inner rubber ring are arranged concentrically and connected into a whole through at least two connecting pipes which are evenly distributed in the circumferential direction. The positioning structure comprises a containing groove used for containing the outer rubber ring, containing gaps used for containing the connecting pipes in a one-to-one correspondence mode, and a containing table used for containing the inner rubber ring. A pressing ring used for tightly pressing the sealing gasket is arranged in the position of the containing groove, and pressing pieces are arranged in the positions, corresponding to all the containing gaps, of the pressing ring respectively. The bucket mouth part further comprises a connecting part. A fastening ring is connected to the outer side of the connecting part in a threaded mode. Ejector rods are arranged in the positions, corresponding to all the containing gaps, of the fastening ring respectively. By the adoption of the storage device, neodymium-iron-boron materials can be received excellently.

Owner:NINGBO LINGKE NEW MATERIAL TECH

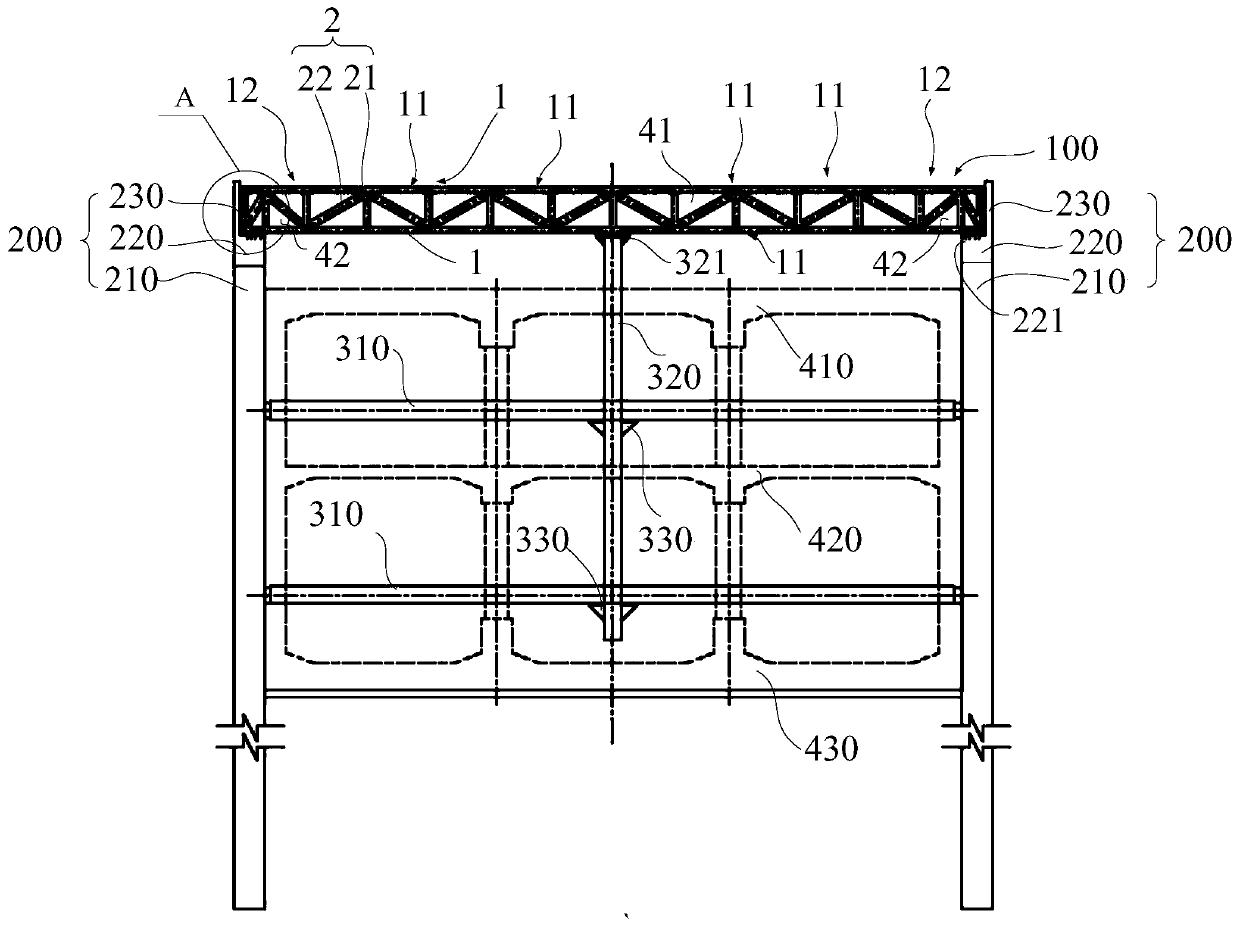

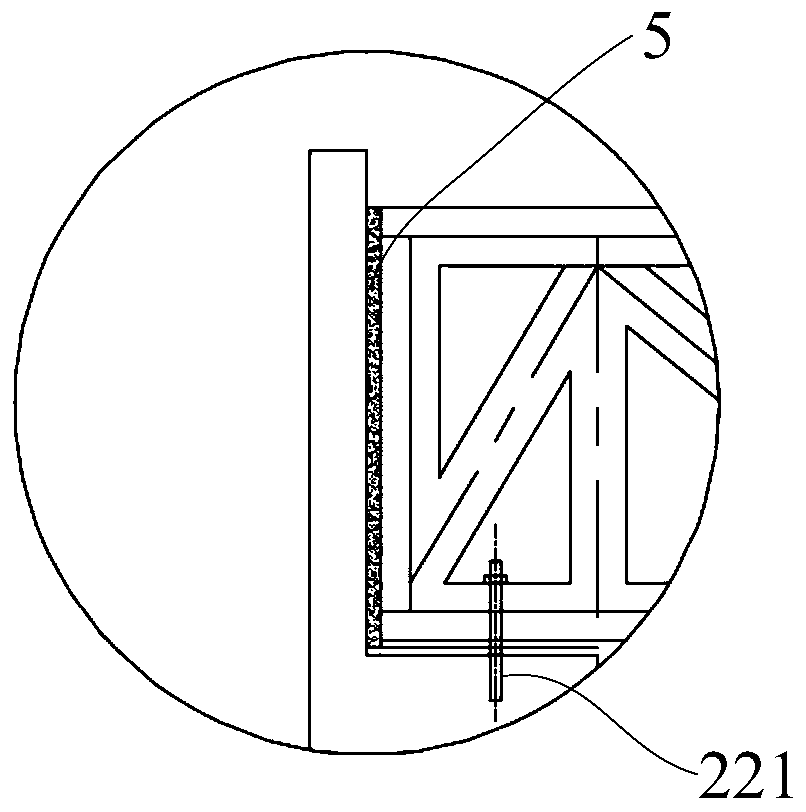

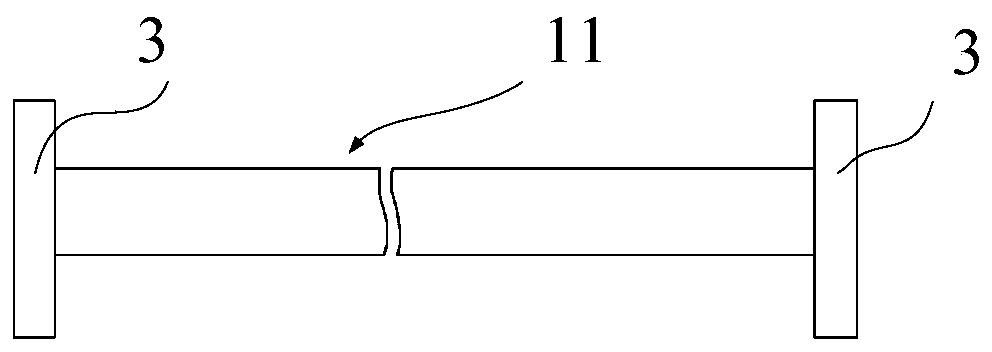

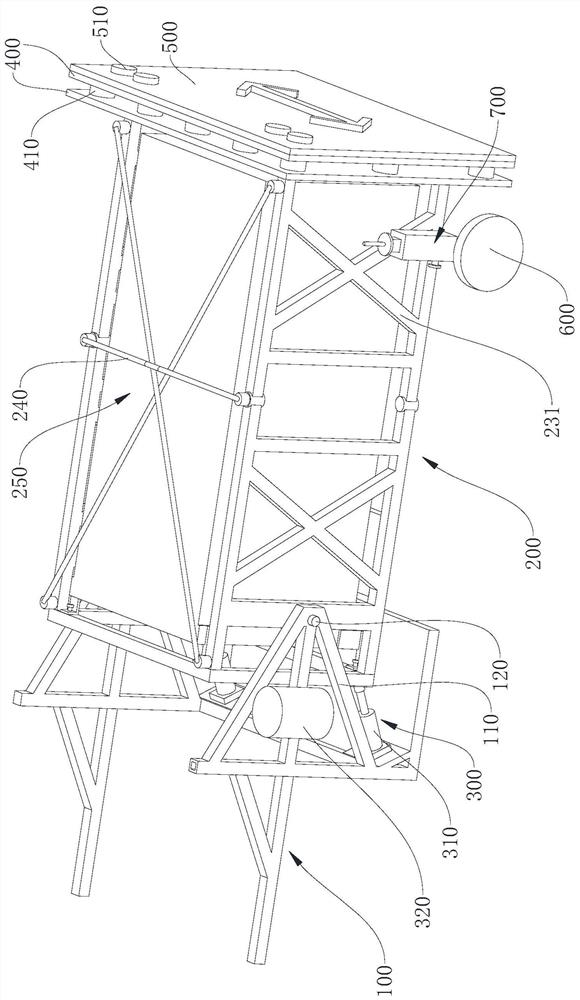

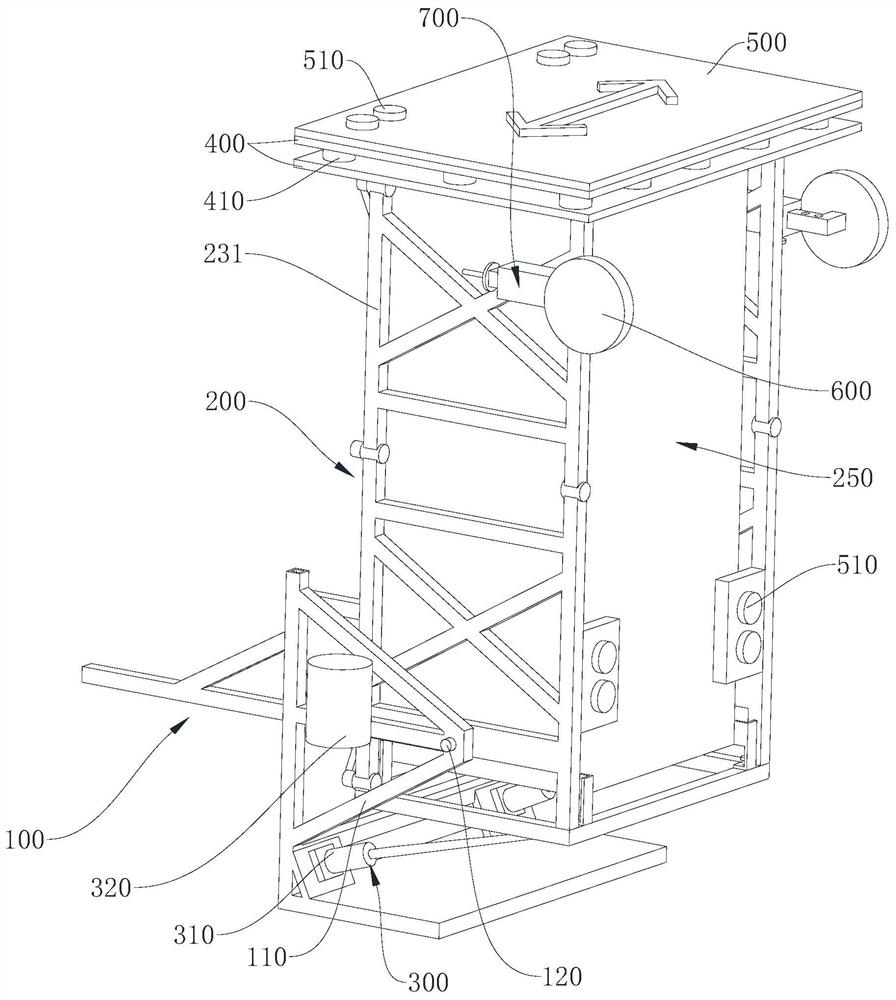

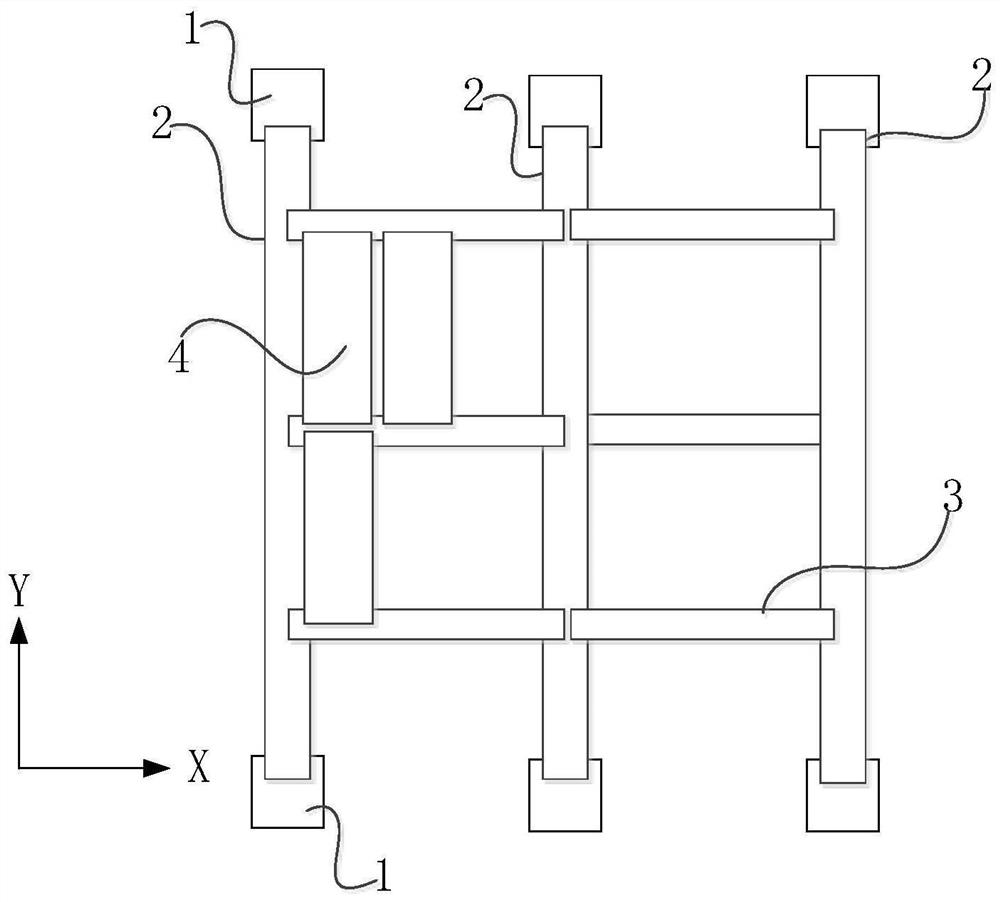

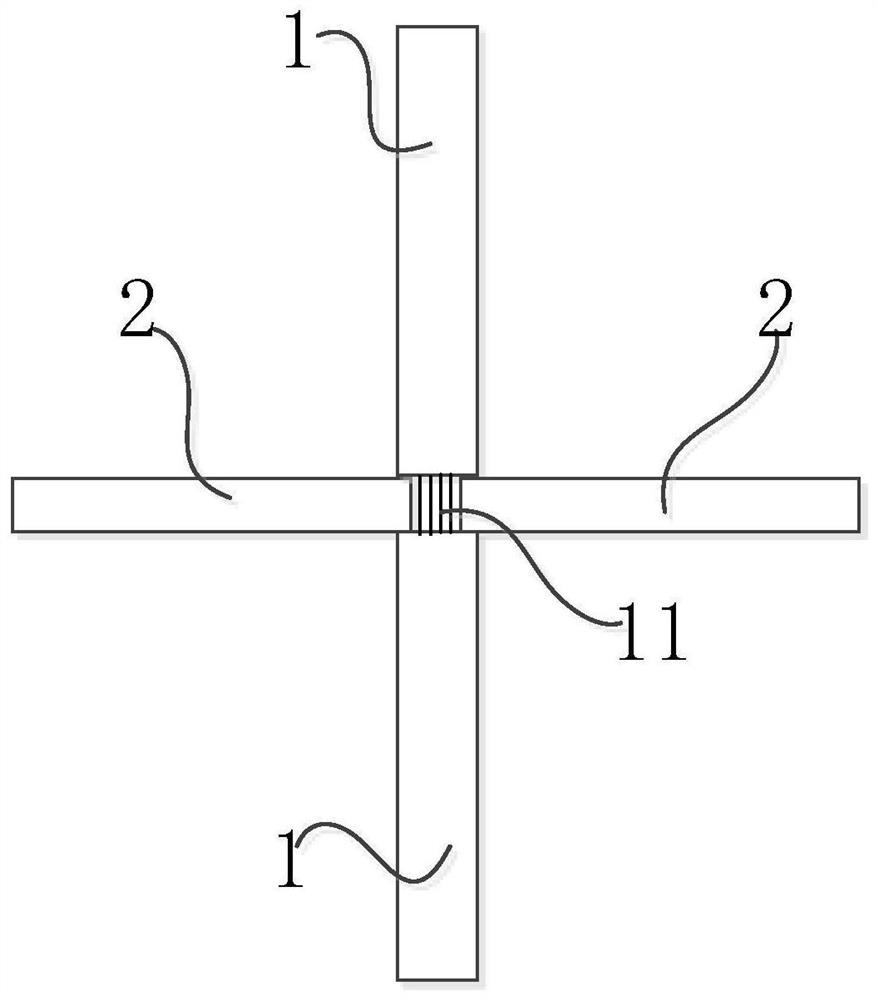

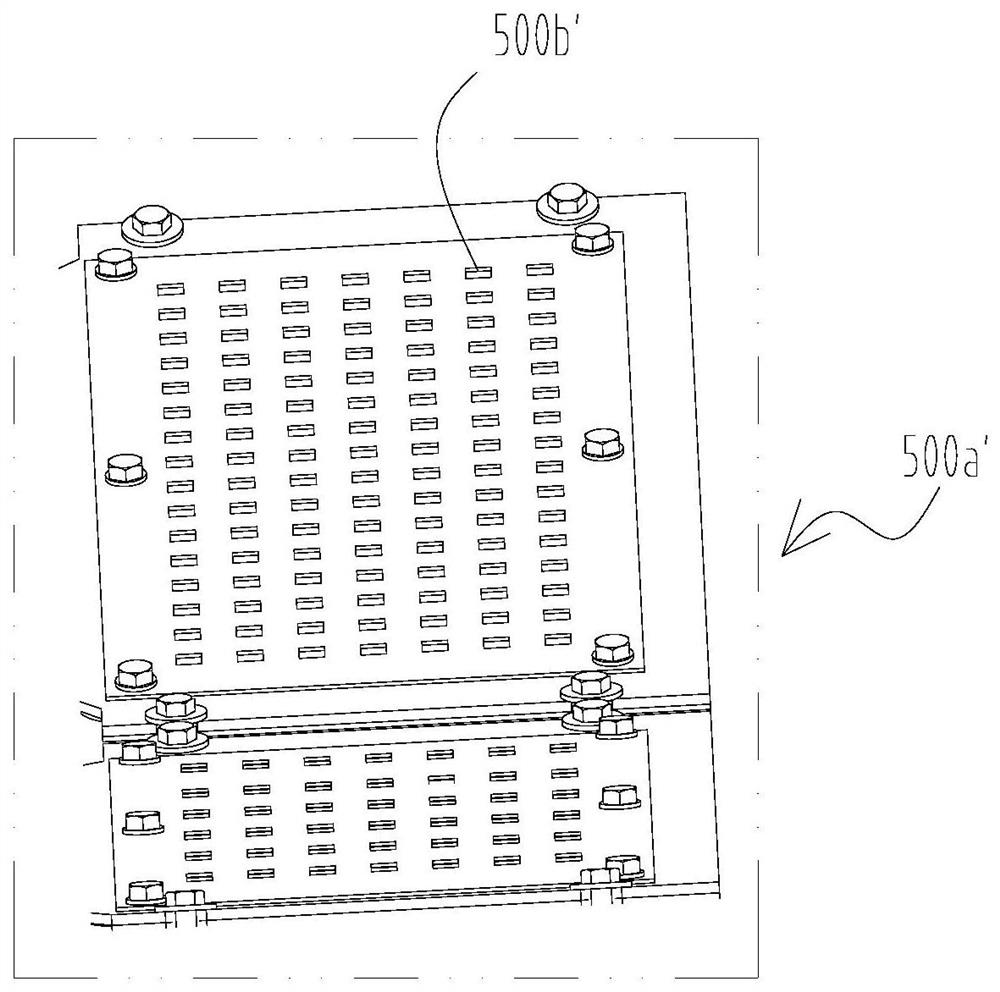

Supporting truss capable of being recycled, foundation pit supporting system and subway station construction method

PendingCN111270685AReduce the difficulty of disassemblyShorten the construction periodArtificial islandsExcavationsSupporting systemArchitectural engineering

The application provides a supporting truss capable of being recycled, a foundation pit supporting system and a subway station construction method. The supporting truss is used in the foundation pit supporting system of a construction subway station and comprises two chord members and a web member, the two chord members are arranged at interval and in an up and down mode, and the two ends of eachchord member are detachably connected to an enclosure body of the foundation pit supporting system; and the web member is connected between the upper chord member and the lower chord member. Accordingto the supporting truss, the supporting truss is spliced by using the prefabricated chord members and the web member, so that the construction process of cast-in-place concrete forming of the supporting truss is omitted, after the supporting work is completed, direct detaching can be conducted, the construction difficulty of the supporting truss is reduced accordingly, and meanwhile, the construction period is also shortened.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

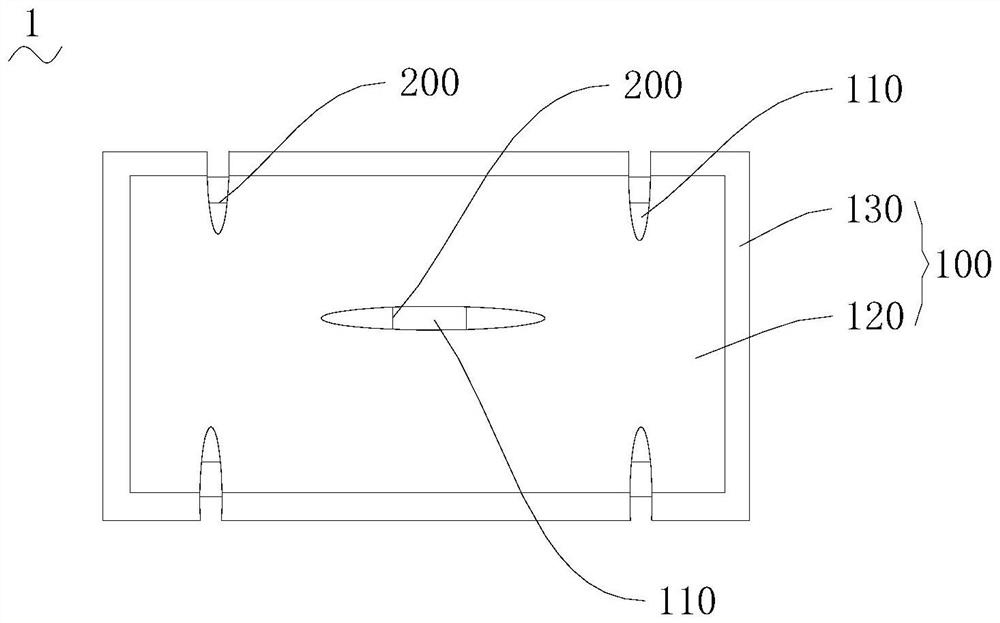

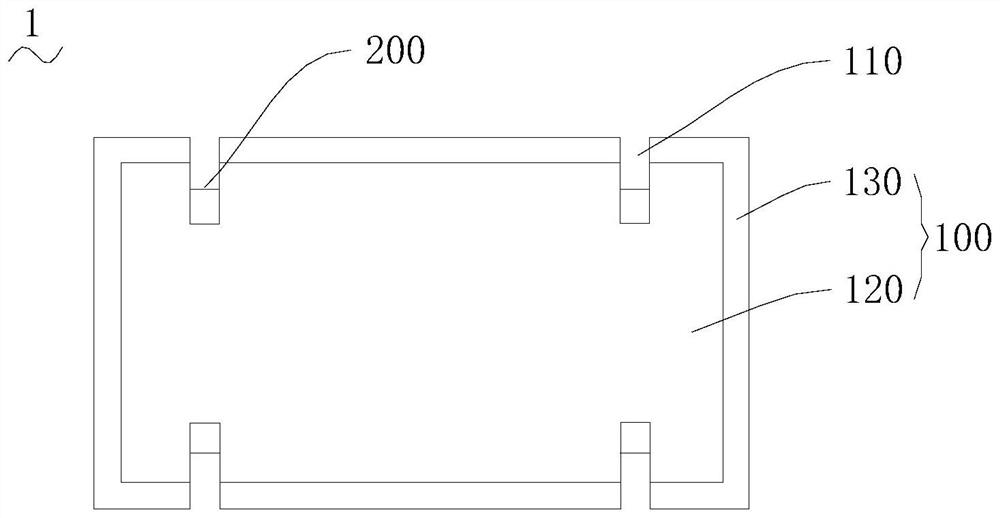

Pneumatic type sealing gasket

The invention relates to the technical field of NdFeB production equipment, in particular to a pneumatic type sealing gasket. The pneumatic type sealing gasket comprises an outer rubber ring and an inner rubber ring arranged concentrically, wherein the outer rubber ring and the inner rubber ring are connected into a whole through at least two connecting pipes evenly distributed in the peripheral direction; the inside of the outer rubber ring is hollow to form an annular air storage cavity; the inside of the inner rubber ring is hollow to form an annular air collecting cavity; an air runner used for communicating the air storage cavity with the air collecting cavity is formed in the middle of any connecting pipe. The pneumatic type sealing gasket is easy and convenient to use and capable of achieving good sealing performance.

Owner:NINGBO LINGKE NEW MATERIAL TECH

Rear buffer device of engineering truck and anti-collision engineering truck

InactiveCN112406752APrevent being hitAvoid car crashesOptical signallingCrash attenuatorsTruckMechanical engineering

The invention provides a rear buffer device of an engineering truck and the anti-collision engineering truck, and belongs to the technical field of vehicle engineering. The rear buffer device comprises a connecting frame, a buffer frame and a power support assembly. When the engineering truck runs, the power support assembly is started, the buffer frame is turned upwards by 90 degrees to be lifted, and the engineering truck can run conveniently; when the engineering truck is suspended and carries out construction, the power support assembly is closed, the buffer frame is turned downwards by 90degrees to fall down, the buffer frame is horizontally placed at the rear end of the engineering truck, and the engineering truck is prevented from being collided. The buffer frame can contract in the running direction of the engineering truck, when the engineering truck is paused and conducts construction and an a vehicle behind cannot brake in time to collide with the buffer frame, the buffer frame is stressed to contract in the collision direction to conduct buffering, so that the collision force of the vehicle is counteracted, and the engineering truck is effectively prevented from beingcollided; and a buffer space can be provided for the rear vehicle, so that major accidents of vehicle damage and casualty of the rear vehicle are avoided.

Owner:河北惠众汽车传动轴制造股份有限公司 +2

Integral type air conditioner

PendingCN108469076ASame technical effectLighting and heating apparatusNoise suppressionMiniaturizationStructural engineering

The invention provides an integral type air conditioner. The integral type air conditioner comprises an air conditioner shell body, a horizontal type compressor and at least two fixing supports, wherein the horizontal type compressor is fixedly arranged inside the air conditioner shell body, the fixing supports are arranged on a bottom plate of the air conditioner shell body, two of the fixing supports are correspondingly arranged at the two ends of the horizontal type compressor so as to fix the horizontal type compressor. According to the technical scheme of the integral type air conditioner, the fixing supports are arranged at the two ends of the horizontal type compressor, so that the horizontal size of a part of the horizontal type compressor part is small, then the length of the whole air conditioner in the horizontal direction of the horizontal type compressor is reduced, and the miniaturization design is facilitated.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD +1

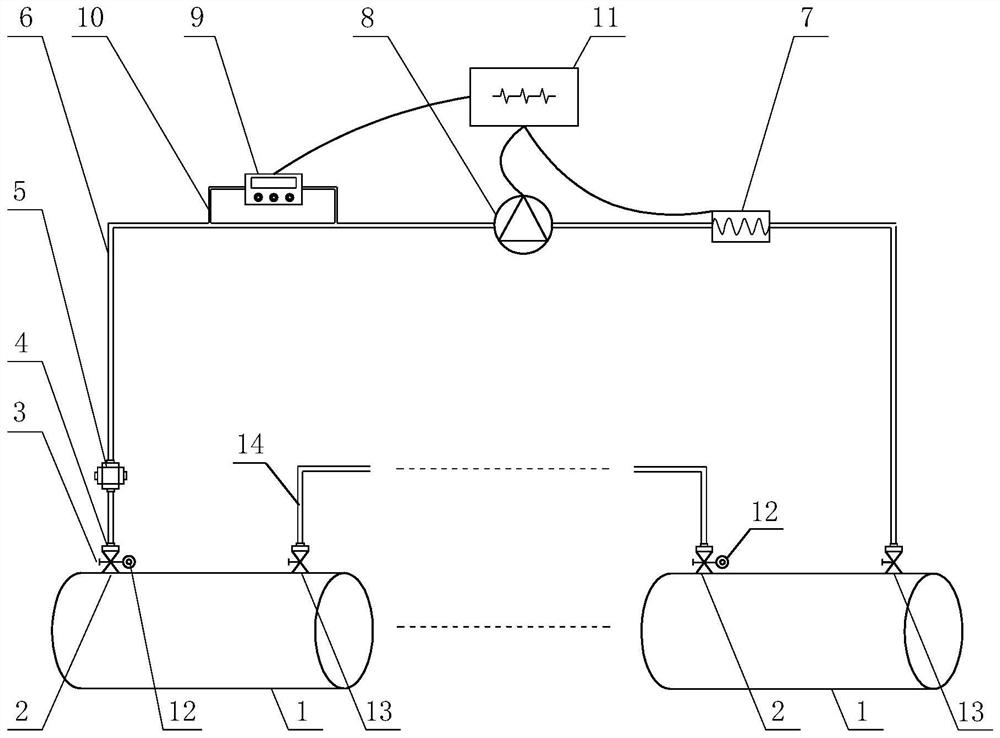

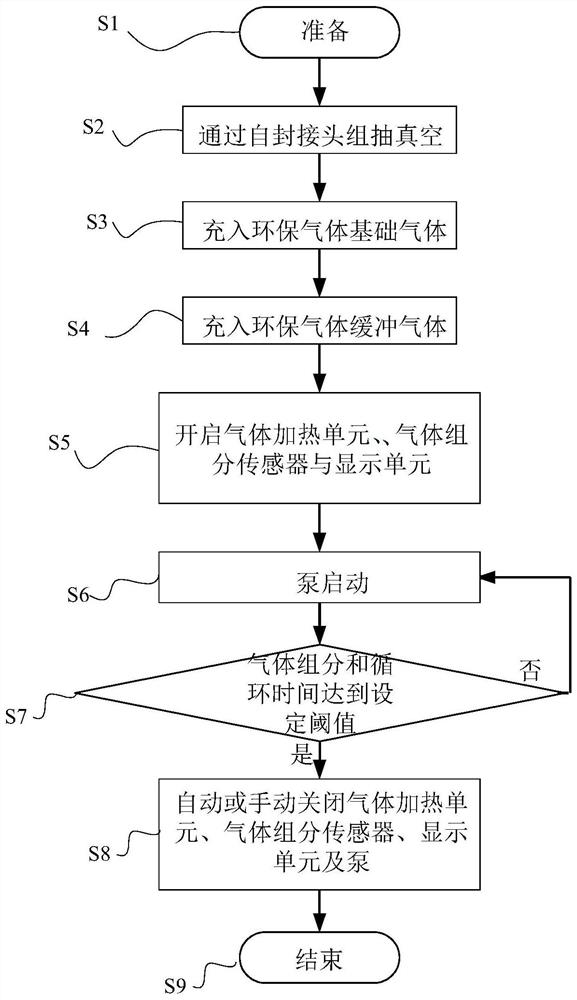

Gas mixing device and gas mixing method

PendingCN112180033AWell mixedGuaranteed mixing effectTransportation and packagingPreparing sample for investigationThermodynamicsSwitchgear

The invention discloses a gas mixing device and a gas mixing method. The gas mixing device comprises a gas guide pipe used for connecting a gas outlet and a gas inlet of a switch equipment gas chamberstructure, wherein the switch equipment gas chamber structure is provided with a plurality of gas ports, and the plurality of gas ports comprise the gas outlet and the gas inlet; a pump arranged on the gas guide pipe and used for driving gas in the gas guide pipe to flow towards the gas outlet end of the gas guide pipe along the gas inlet end of the gas guide pipe, wherein the gas inlet end of the gas guide pipe is a connecting end for connecting the gas guide pipe with the gas outlet, and the gas outlet end of the gas guide pipe is a connecting end for connecting the gas guide pipe with thegas inlet; a joint group arranged on the gas guide pipe and used for inflating and deflating the switch equipment gas chamber structure through the gas guide pipe; and a gas component sensor arrangedon the gas guide pipe and used for detecting all gas components of the mixed gas in the gas guide pipe. The gas mixing device provided by the invention effectively ensures the mixing effect.

Owner:XIAN XD SWITCHGEAR ELECTIC CO LTD +1

Energy absorption structure, cowcatcher device and railway vehicle

ActiveCN112744253AImprove energy absorptionEasy to installRailway wheel guards/bumpersEnergy absorptionControl theory

The invention discloses an energy absorption structure, a cowcatcher device and a railway vehicle, wherein the energy absorption structure comprises a U-shaped frame and energy absorption pipes which are made of composite materials, and comprises an energy absorption pipe front seat and an energy absorption pipe rear seat which are made of meta; the energy absorption pipe front seat is fixed on the inner side of the front part of the U-shaped frame, and the two ends of the energy absorption pipe rear seat are respectively fixed with the two tail ends of the U-shaped frame; the energy absorption pipes are fixed between the energy absorption pipe front seat and the energy absorption pipe rear seat; and moreover, the energy absorption pipe front seat and the energy absorption pipe rear seat are both provided with metal bosses, and the energy absorption pipes and the metal bosses are mutually nested and fixed. According to the scheme, the energy absorption requirements of different vehicle types are met by adjusting the number and length of the energy absorption pipes, and the application range is wider; the U-shaped frame made of the composite material serves as a main body, the energy absorption pipe front seat and the energy absorption pipe rear seat are made of metal and serve as a framework, and on the basis of certain structural strength, the weight can be effectively reduced; the metal bosses and the energy absorption pipes are fixed in a nested mode, and reliable installation of the energy absorption pipes made of the composite material is achieved.

Owner:CRRC QINGDAO SIFANG CO LTD

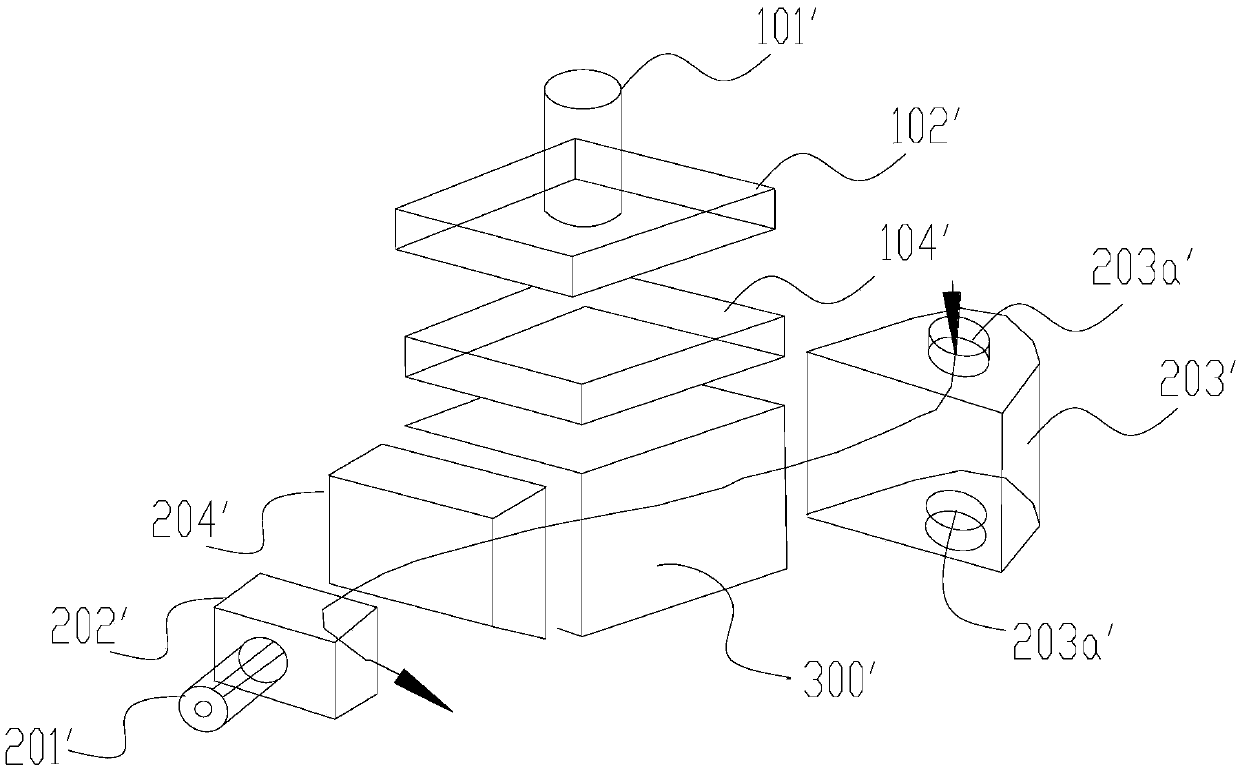

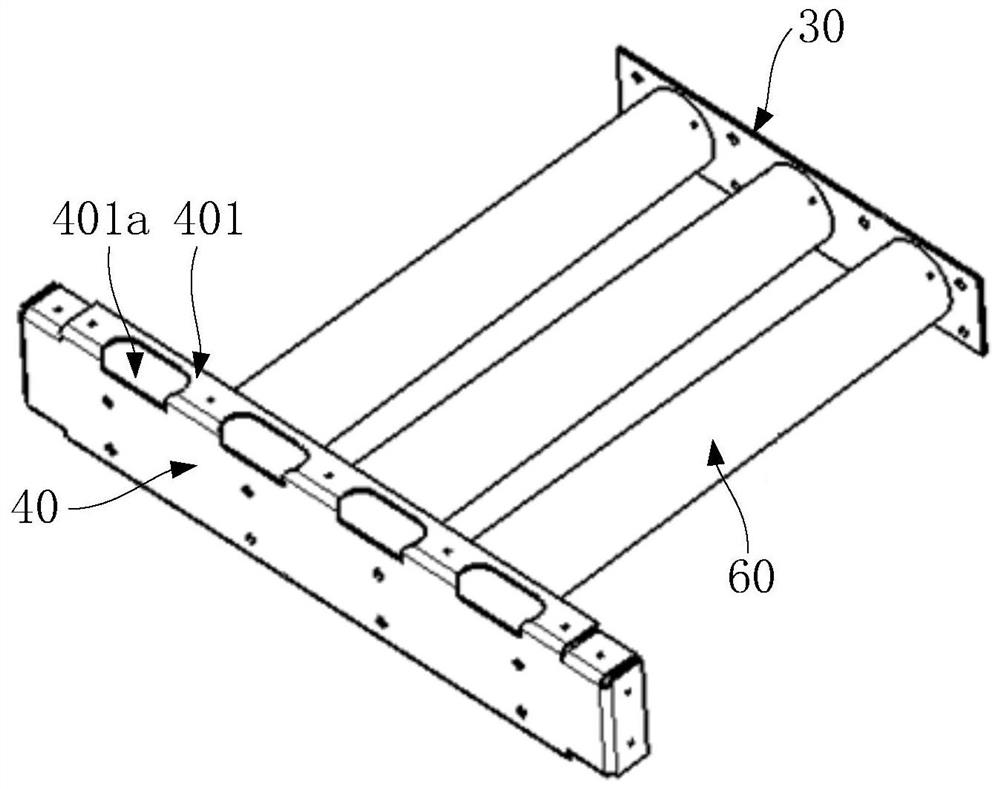

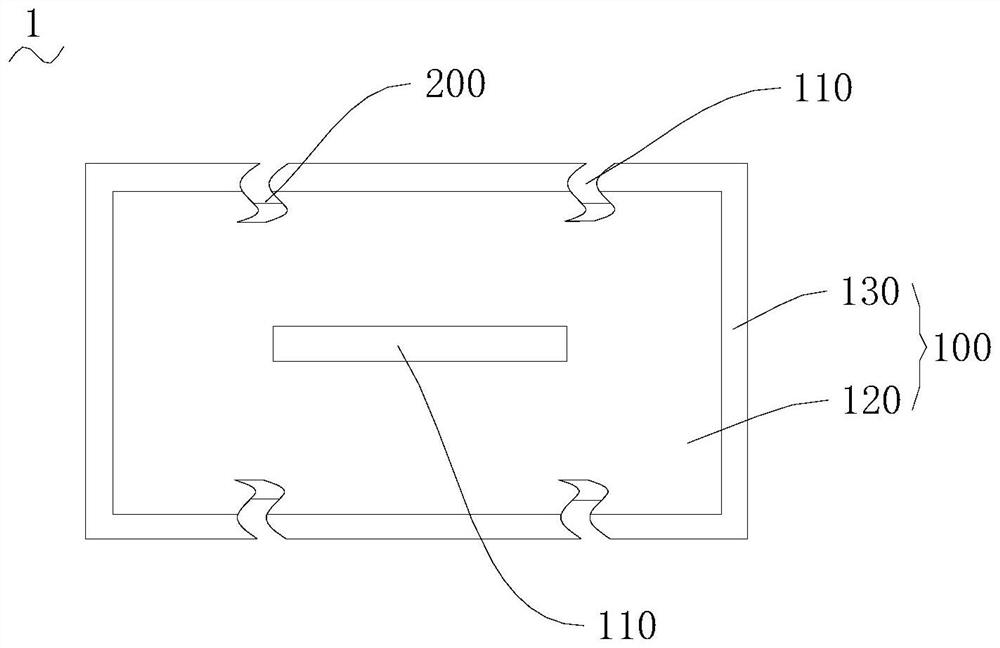

Material receiving apparatus for easily oxidized powder

InactiveCN105418987AImprove sealingPromote swellingEngine sealsLoading/unloadingRubber ringEngineering

The present invention relates to the technical field of neodymium iron boron production equipment, and in particular relates to a material receiving apparatus for easily oxidized powder. The material receiving apparatus comprises a barrel mouth portion arranged on a cylinder, wherein a positioning structure is structured at an open end of the barrel mouth portion, and a sealing gasket is arranged at the positioning structure; the sealing gasket comprises concentrically arranged outer rubber ring and inner rubber ring, wherein the outer rubber ring and the inner rubber ring are integrally connected by at least two connection pipes which are evenly distributed along the circumferential direction; the positioning structure comprises a seat groove for seating the outer rubber ring, a seat gap for seating the connection pipe one to one, and a seat table for seating the inner rubber ring; wherein a press ring for compacting the sealing gasket is arranged in the seat groove, and a tablet is arranged in any seat gap corresponding to the press ring; and the barrel mouth portion also comprises a connection portion, wherein an outer side of the connection portion is in threaded connection with a fastening ring, and an ejector pin is arranged in any seat gap corresponding to the fastening ring. By adopting the apparatus provided by the present invention, material receiving for a variety of easily oxidized powders comprising the neodymium iron boron material can be preferably performed.

Owner:NINGBO LINGKE NEW MATERIAL TECH

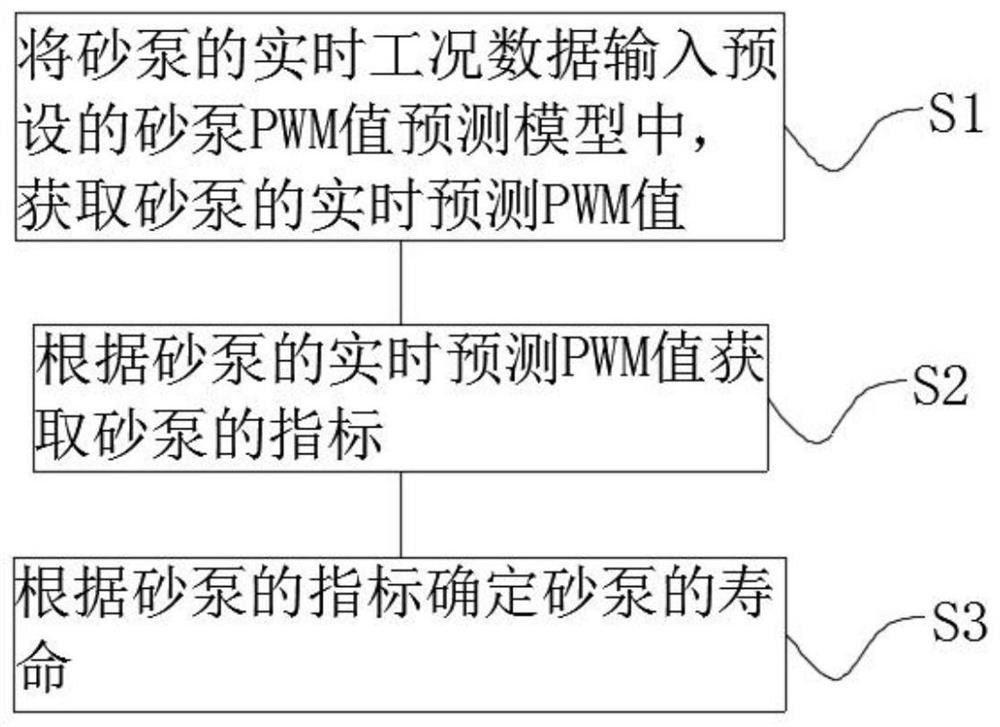

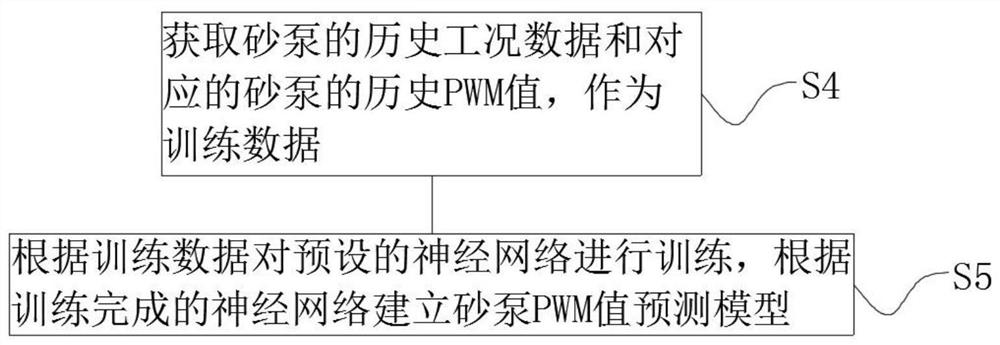

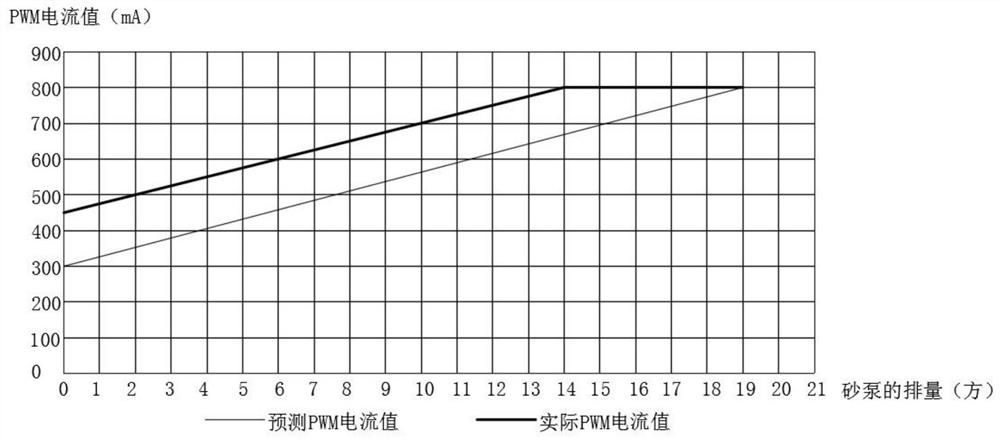

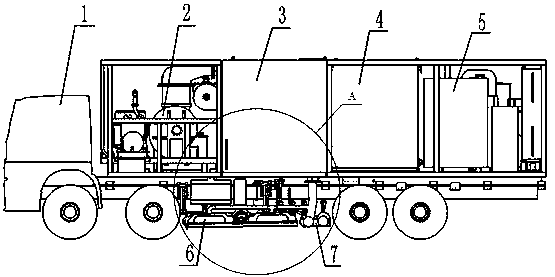

Service life prediction method and device for sand pump of fracturing blender truck

PendingCN113570160ADetermination of lifeAccurate determination of lifetimeForecastingResourcesTruckReal time prediction

The invention relates to the technical field of sand pumps, in particular to a service life prediction method and device for a sand pump of a fracturing blender truck. The service life prediction method for the sand pump of the fracturing blender truck comprises: inputting real-time working condition data of the sand pump into a preset sand pump PWM value prediction model, and obtaining a real-time prediction PWM value of the sand pump; obtaining indexes of the sand pump according to the real-time predicted PWM value of the sand pump; and determining the service life of the sand pump according to the indexes of the sand pump. By inputting the real-time working condition data of the sand pump into the PWM value prediction model, the real-time prediction PWM value of the sand pump is obtained, and the obtaining process of the real-time prediction PWM value of the sand pump is simplified. An index of the sand pump is calculated according to the real-time predicted PWM value of the sand pump, and the service life of the sand pump is determined according to the index of the sand pump. Therefore, in the operation process of the fracturing blender truck, the working condition data of the sand pump are detected in real time, the service life of the sand pump can be accurately determined, and constructors can arrange work conveniently and complete operation on time conveniently.

Owner:SANY PETROLEUM INTELLIGENT EQUIP CO LTD

Manufacturing method of pneumatic sealing gasket

Owner:NINGBO LINGKE NEW MATERIAL TECH

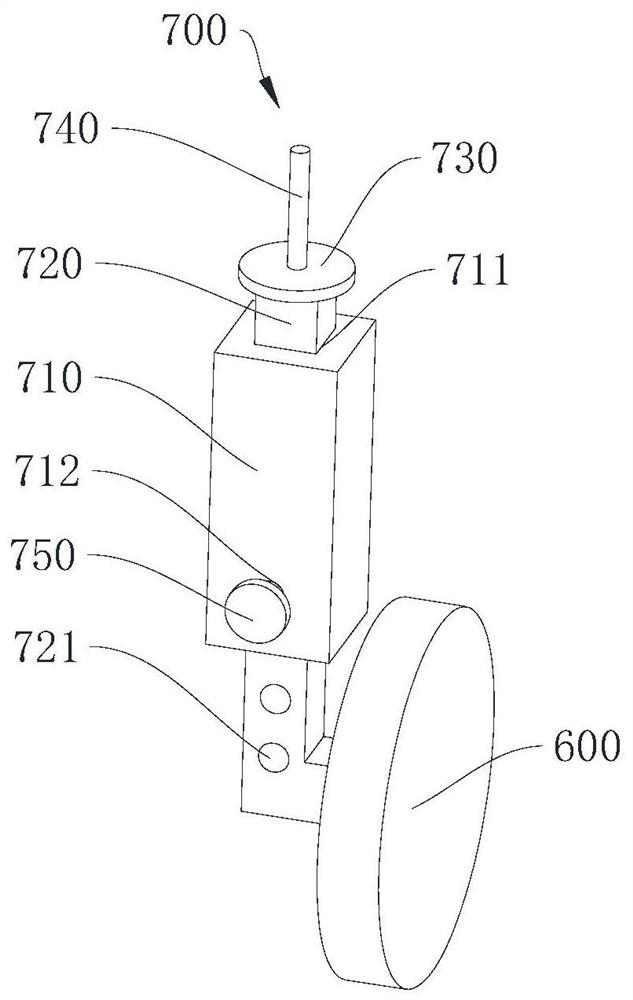

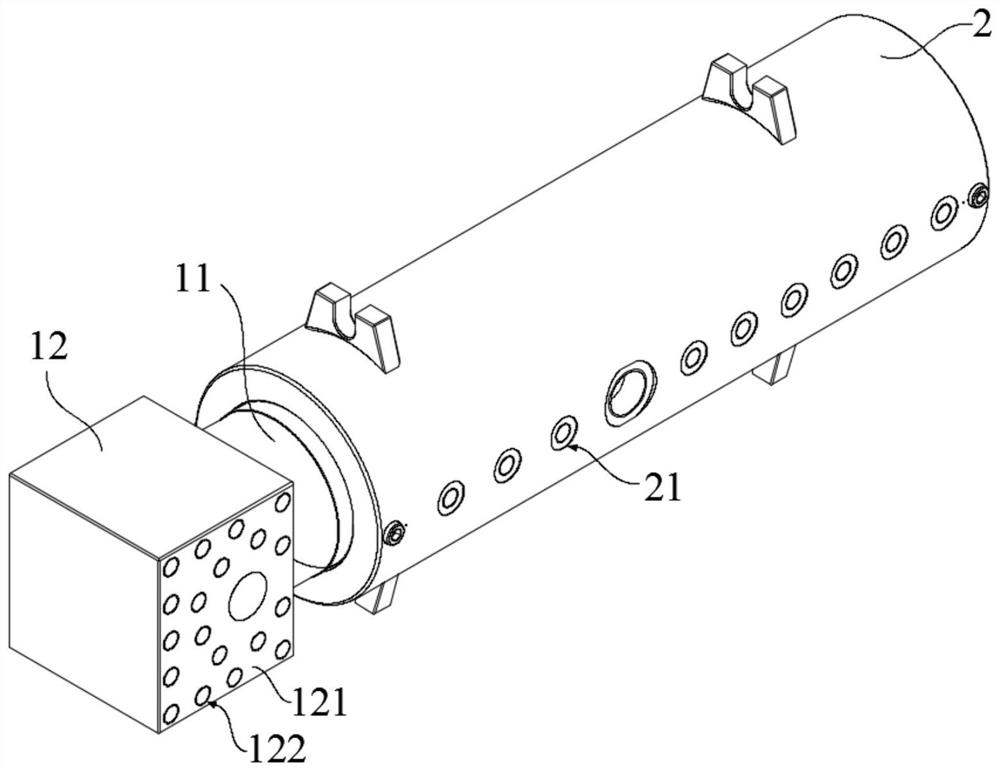

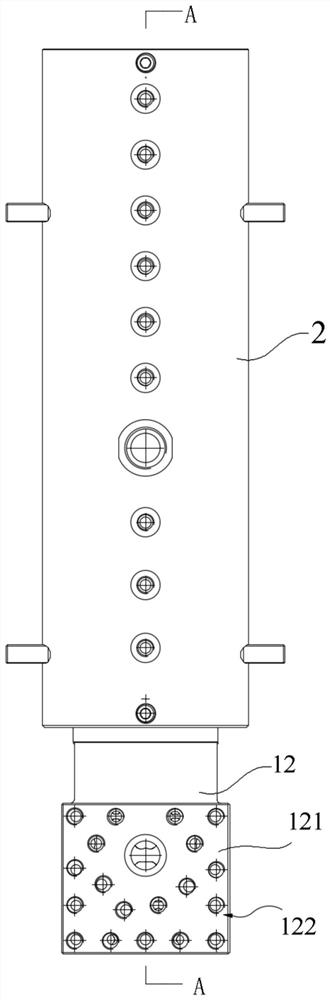

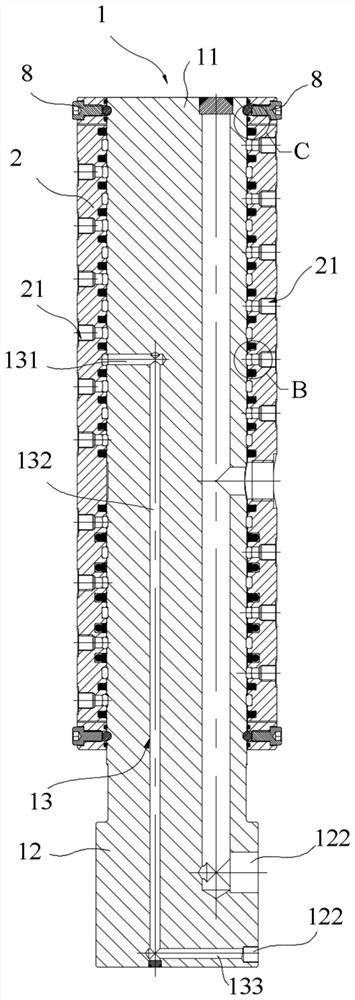

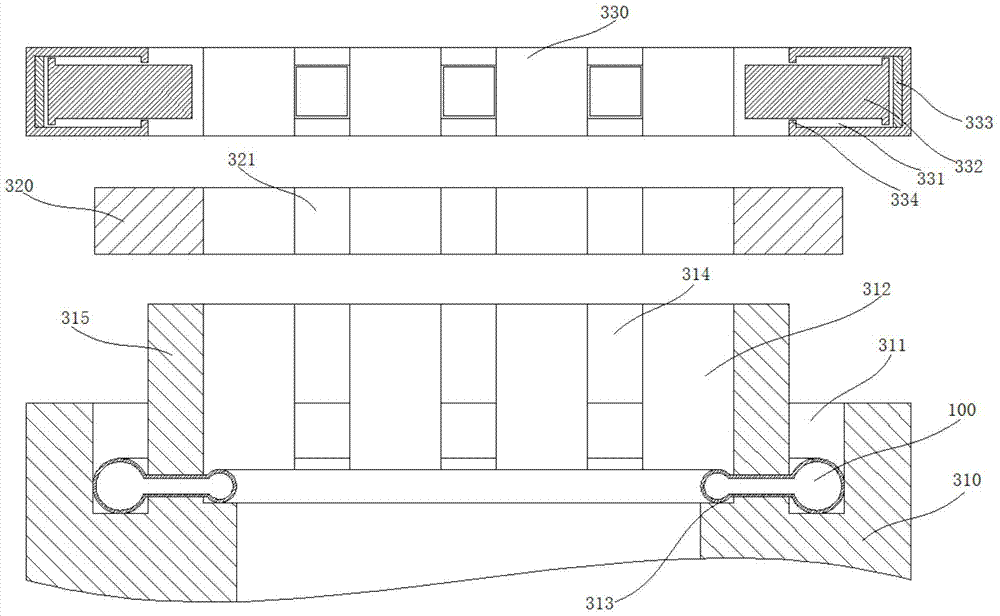

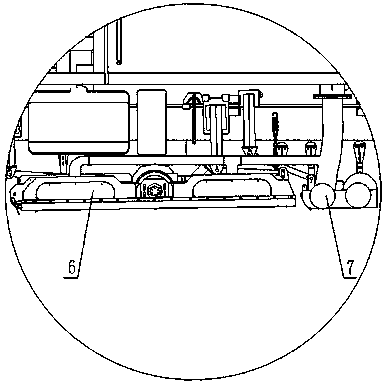

Central rotary joint, pipe winder and continuous pipe operation equipment

PendingCN111981233AThe main structure is compactSmall cross sectionAdjustable jointsBranching pipesControl theoryMechanical engineering

The invention provides a central rotary joint, a pipe winder and continuous pipe operation equipment. The central rotary joint comprises a mandrel and a rotor. The mandrel comprises a sleeving part and a mounting part formed at one end of the sleeving part, one side of the mounting part is provided with a mounting surface, and a plurality of first liquid ports are formed in the mounting surface. Second liquid ports in one-to-one correspondence with the first liquid ports are formed in the rotor. A plurality of flow channels are formed on the mandrel, a plurality of ring cavities are formed between the sleeving part and the rotor, and each first liquid port communicates with the corresponding ring cavity through the corresponding flow channel. The flow channels comprise the first flow channel, the second flow channel and the third flow channel, and the distance between the axis of at least part of the third flow channel and the axis of the second flow channel communicating with the third flow channel is larger than zero. According to the central rotary joint, the distance between the axis of at least part of the third flow channel and the axis of the second flow channel communicating with the third flow channel is larger than zero, so that the structure of the central rotary joint is more compact, and the installation requirement of all pipelines on the first liquid ports can bemet.

Owner:HUNAN SHUANGDA ELECTROMECHANICAL CO LTD

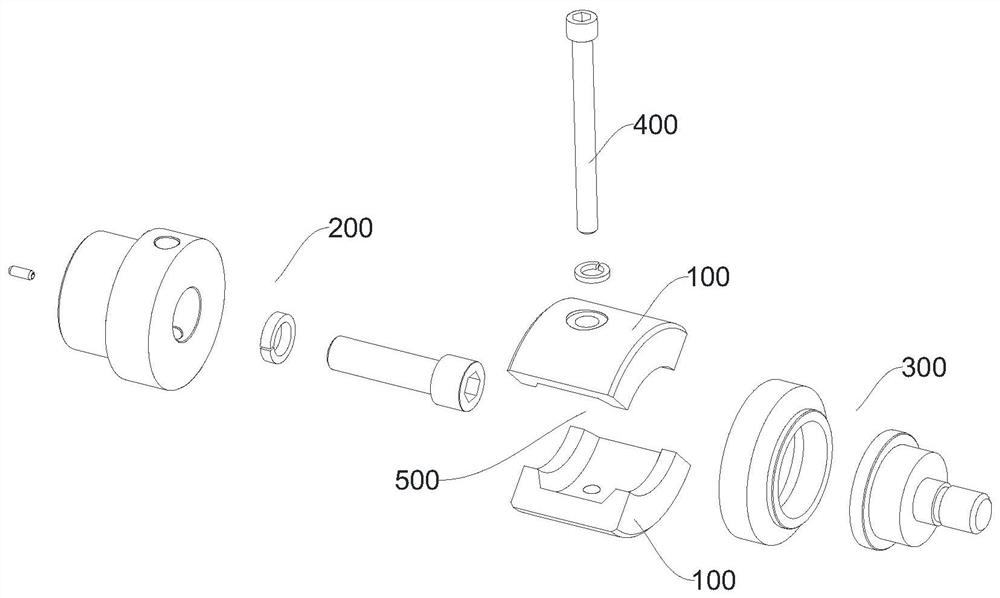

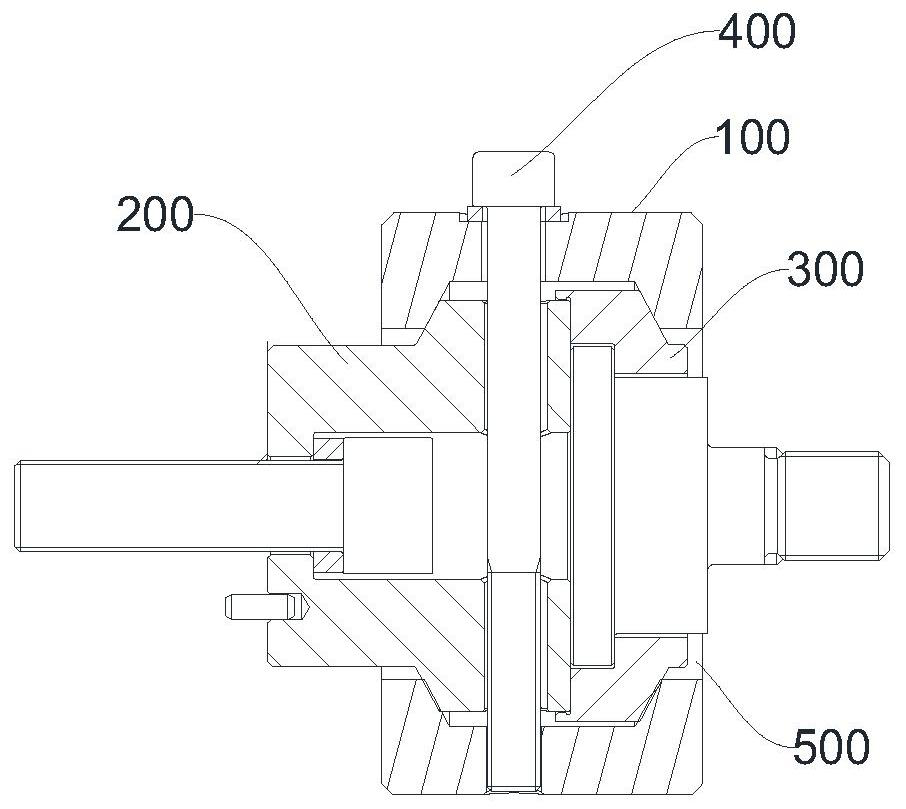

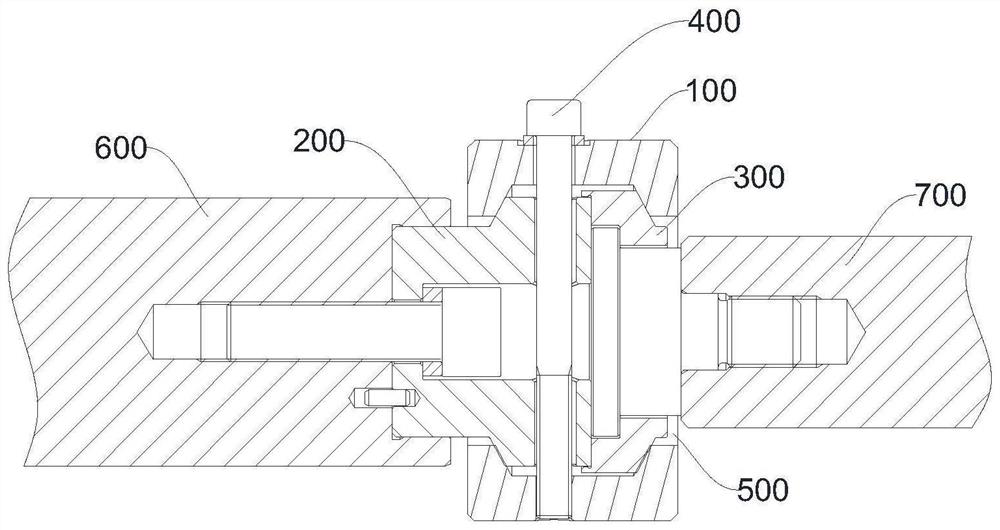

Connecting structure and plunger pump

PendingCN113530811ASame technical effectPositive displacement pump componentsLiquid fuel engine componentsPhysicsPlunger pump

The invention relates to the technical field of plunger pumps, in particular to a connecting structure and a plunger pump. The connecting structure and the plunger pump are used for solving the problems that a plunger and a pull rod are likely to wear and loosen in the prior art. The connecting structure is used for connecting a first component and a second component. The connecting structure comprises at least two oppositely-arranged clamping pieces, a first connecting assembly, a second connecting assembly and a locking piece. An installation space is defined by the at least two oppositely-arranged clamping pieces. One part of the first connecting assembly is located in the installation space, and the other part of the first connecting assembly is located outside the installation space and connected with the first component. One part of the second connecting assembly is located in the installation space, and the other part of the second connecting assembly is located outside the installation space and connected with the second component. The parts, located in the installation space, of the first connecting assembly and the second connecting assembly abut against each other. The locking piece is connected with the clamping pieces and used for fixing the clamping pieces to the first connecting assembly and the second connecting assembly. The connecting structure is applied to the plunger pump.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH

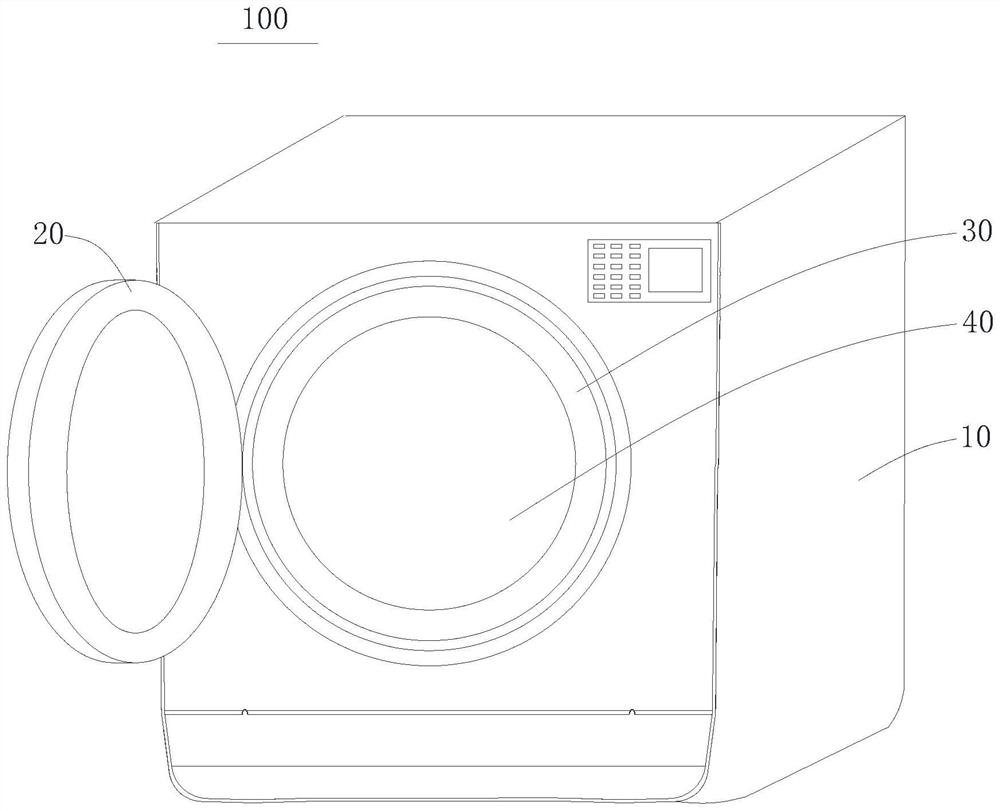

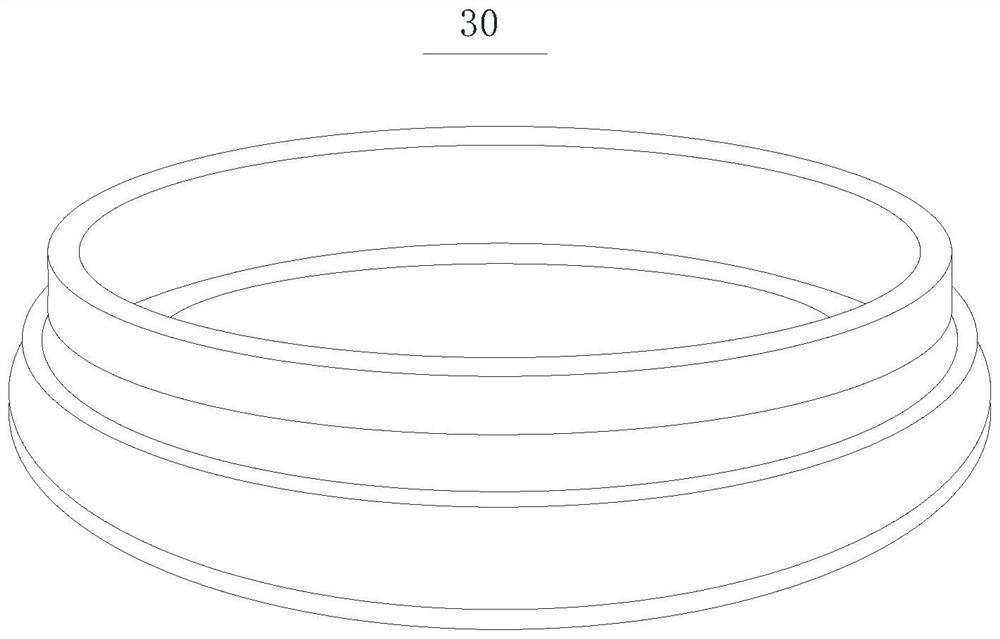

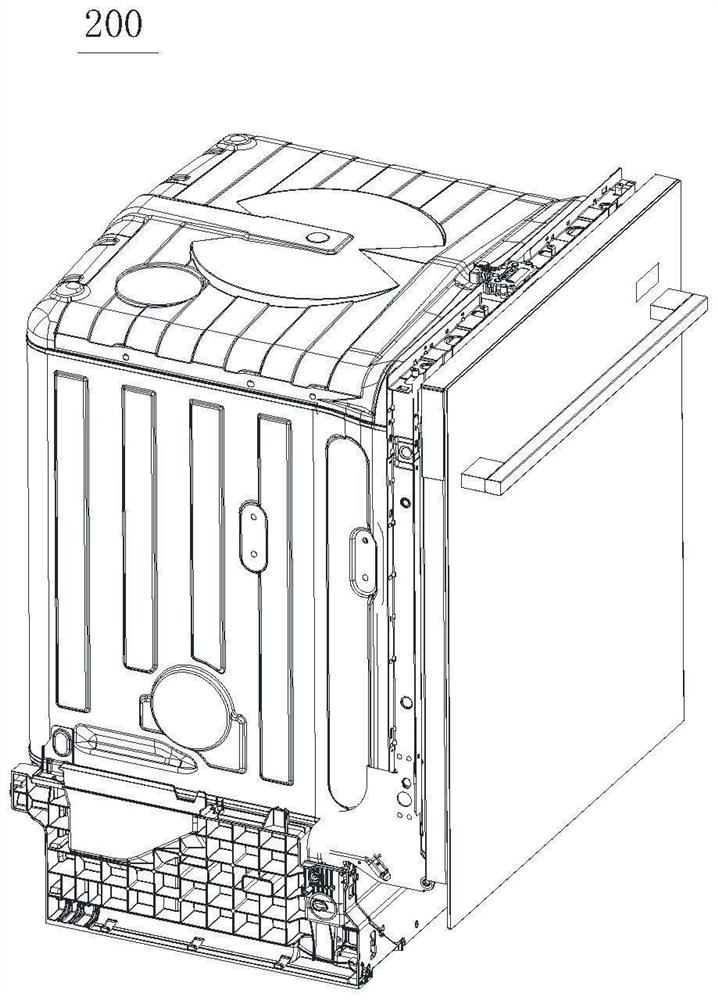

Door seal material and preparation method thereof, door seal ring and household appliance

The invention relates to the technical field of household appliances, in particular to a door seal material, a preparation method thereof, a door seal ring and a household appliance. The invention relates to a door seal material, and aims to solve the problem of poor heat resistance of a door seal ring. The door seal material comprises 100 parts of styrene-ethylene-butylene-styrene block copolymer, the door seal material further comprises 40-60 parts of polypropylene, 10-20 parts of polyphenyl ether, 100-130 parts of extending oil, 10-20 parts of inorganic filler, 1-2 parts of a slipping agent, 0.1-1 part of a surface modifier, 0.1-1 part of pigment, 0.1-0.5 part of an antibacterial and mildew-proof agent, 0.1-1 part of an antioxidant, 0.1-1 part of a heat stabilizer, 0.1-1 part of a light stabilizer and 0.1-0.5 part of a lubricant. The door seal material is used for household appliances.

Owner:HISENSE(SHANDONG)REFRIGERATOR CO LTD

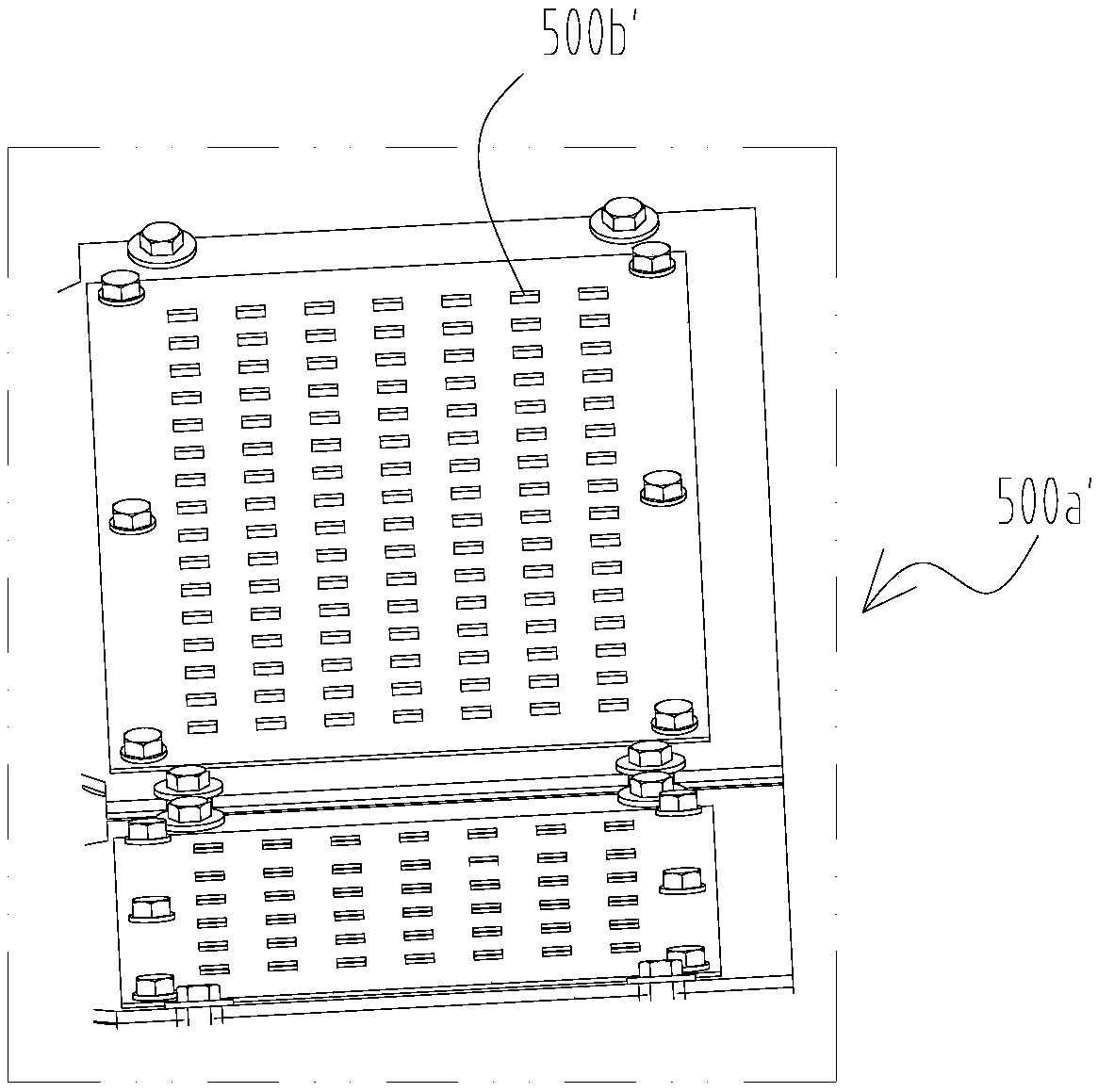

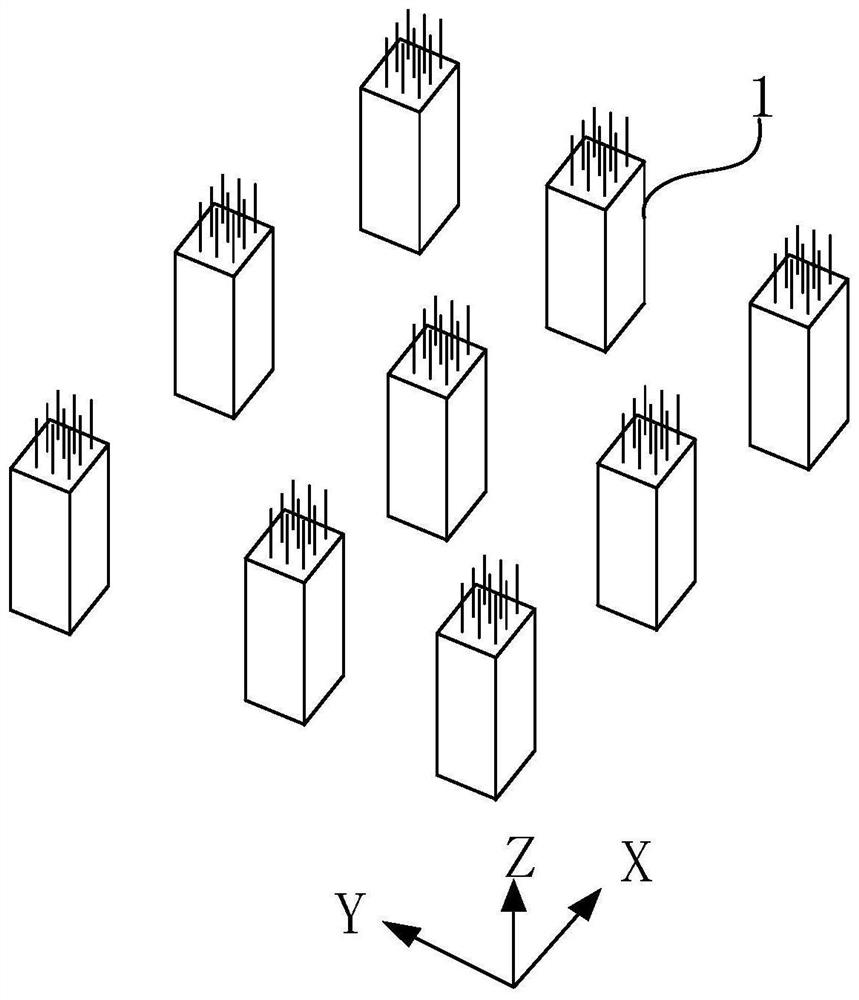

Assembly system and construction method thereof

The invention discloses an assembly system and a construction method thereof, relates to the technical field of buildings, and aims to solve the problem of node connection. The assembly system comprises prefabricated columns, prefabricated main beams, prefabricated secondary beams and prefabricated floor slabs. The prefabricated main beams are arranged in the first direction and connected with the two adjacent prefabricated columns, and the prefabricated main beams partially extend into the prefabricated columns. The prefabricated secondary beams are arranged in the second direction, the second direction is perpendicular to the first direction, and the ends of the prefabricated secondary beams are connected with the prefabricated main beams. The ends of the prefabricated floor slabs are connected with the prefabricated secondary beams. The assembly system and the construction method thereof is used for a multi-layer fabricated building.

Owner:CCDI INT SHENZHEN DESIGN CONSULTANTS

Air pressure gasket

Owner:NINGBO LINGKE NEW MATERIAL TECH

OLED screen body and phototherapy device

PendingCN114028733AExcellent adhesionAvoid tearingElectrical apparatusElectroluminescent light sourcesLight treatmentEngineering

The invention provides an OLED screen body and a phototherapy device, and belongs to the technical field of phototherapy equipment, and the OLED screen body comprises a screen body and a plurality of elastic stretching lines; wherein a plurality of adaptive openings is formed in the thickness direction of the screen body, one elastic stretching line is arranged between two opposite point positions of the circumferential contour of at least one adaptive opening, and the elastic stretching line is configured with pulling force for tensioning the circumferential contour of the adaptive opening. The phototherapy device comprises an OLED screen body. According to the OLED screen body and the phototherapy device provided by the invention, when the OLED screen body is attached to a knee joint, a wrist joint and other parts, the adaptive port can realize a better attachment effect and reduce the conditions of upwarp, non-attachment and the like, and meanwhile, the elastic stretching line can prevent the condition of tearing caused by excessive stretching in the adaptive attachment process.

Owner:GUAN YEOLIGHT TECH CO LTD

Interface structure for NdFeB storage tank

InactiveCN105366166BSame technical effectContainer/bottle contructionRigid containersEngineeringMechanical engineering

The invention relates to the technical field of NdFeB production equipment, in particular to an interface structure for an NdFeB storage tank. It includes a barrel mouth arranged on the barrel body, the opening end of the barrel mouth is constructed with a stepped connection part, and the outer side of the connection part is threaded with a fastening ring; the connection part is provided with a gap in the axial direction, and the fastening ring is placed There is a ejector rod in the gap; the internal structure of the fastening ring has an accommodation chamber for placing the ejector rod, the inner wall of the fastening ring is provided with a telescopic opening connected with the accommodation chamber, and the ejector rod is telescopically constructed in the accommodation chamber from the telescopic opening; The side wall of the cavity opposite to the expansion port is provided with a top rail in the circumferential direction. The gap between the top rail and the expansion port gradually becomes smaller in the direction of rotation of the fastening ring. The top rail is used to follow the rotation of the fastening ring to change the diameter of the ejector rod. up position. Through the present invention, the NdFeB storage barrel can be preferably fixedly connected to the corresponding discharge port.

Owner:NINGBO LINGKE NEW MATERIAL TECH

Manufacturing method and structure of three-cake entangled reverse unit and transformer

ActiveCN112951585AAvoid truncated welding operationsImprove affordabilityCoils manufactureTransformerMechanical engineering

The invention provides a manufacturing method of a three-cake entangled reverse unit, and belongs to the technical field of transformers. During winding, 2k wires jointly wind two continuous wire cakes and an entangled wire cake located between the two continuous wire cakes, the 2k wires are wound in parallel to a specified number of turns to obtain a temporary wire cake, the 2k wires are averagely divided into two groups, namely a first group wire and a second group of wires, the first group of wires and the second group of wires are transposed in the left direction and the right direction and temporarily fixed, temporary wire cakes are scattered, wire cakes are turned between the first group of wires and the second group of wires to obtain entangled wire cakes to be fixed, and temporary fixing of the first group of wires and the second group of wires is relieved; the first continuous wire cake and the second continuous wire cake are obtained by winding the two sides of the entangled wire cake to the specified number of turns respectively, the turn number adjusting range is large, large impulse voltage can be borne, the phenomenon of breakdown short circuit is avoided, the coil structure is optimized, and the use safety is improved.

Owner:BAODING TIANWEI GROUP TEBIAN ELECTRIC

Heat exchange devices for motors and their shafting, wind turbines

ActiveCN110630454BSame technical effectMagnetic circuit rotating partsEngine fuctionsElectric machineCooling effect

The invention discloses a heat exchange device for a motor and its shaft system, and a wind power generator set. The heat exchange device includes a flexible cavity capable of inputting a cooling medium, and the flexible cavity is located on the inner wall of the motor shaft. The flex chamber cools the motor bearings in the motor shaft. After the cooling medium is injected into the flexible cavity, a cooling environment can be established on the inner wall of the motor rotating shaft, thereby opening up heat dissipation channels for the motor bearings enclosed between the motor rotating shaft and the fixed shaft of the motor, and achieving a better cooling effect.

Owner:BEIJING GOLDWIND SCI & CREATION WINDPOWER EQUIP CO LTD

Snow melting vehicle and snow melting cover device thereof

The invention relates to a snow melting vehicle and a snow melting cover device thereof, and aims to solve the problems that in the prior art, the driving vision is affected due to overflowing of steam, secondary icing is caused due to transverse flow of melted water, and then the driving safety is affected. The snow melting vehicle comprises a vehicle body and the snow melting cover device mounted at the bottom of the vehicle body, the snow melting cover device comprises a snow melting cover, the snow melting cover is provided with a snow melting chamber, and the snow melting cover is correspondingly provided with sewage suction chambers on the left side and the right side of the snow melting chamber. According to the snow melting vehicle and the snow melting cover device thereof, when the snow melting vehicle conducts snow melting operation, hot steam and snow water which overflow to the sewage suction chambers can be absorbed through the snow melting vehicle, so that the situation that the steam continuously overflows and then the driving vision is affected is prevented, moreover, the phenomenon that the melted snow water transversely flows and is iced up again can be avoided, and the driving safety is ensured.

Owner:HENAN SENYUAN HEAVY IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com