Patents

Literature

36results about How to "Good job stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

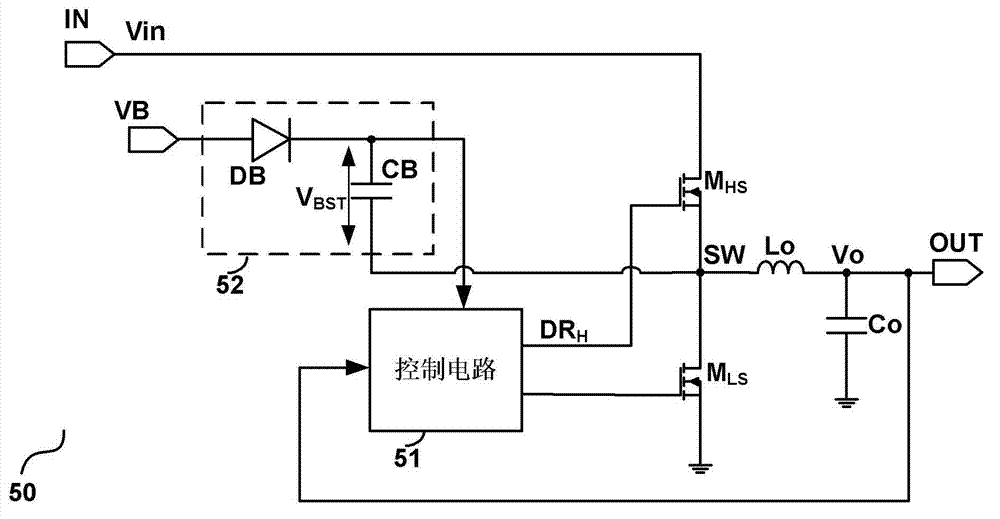

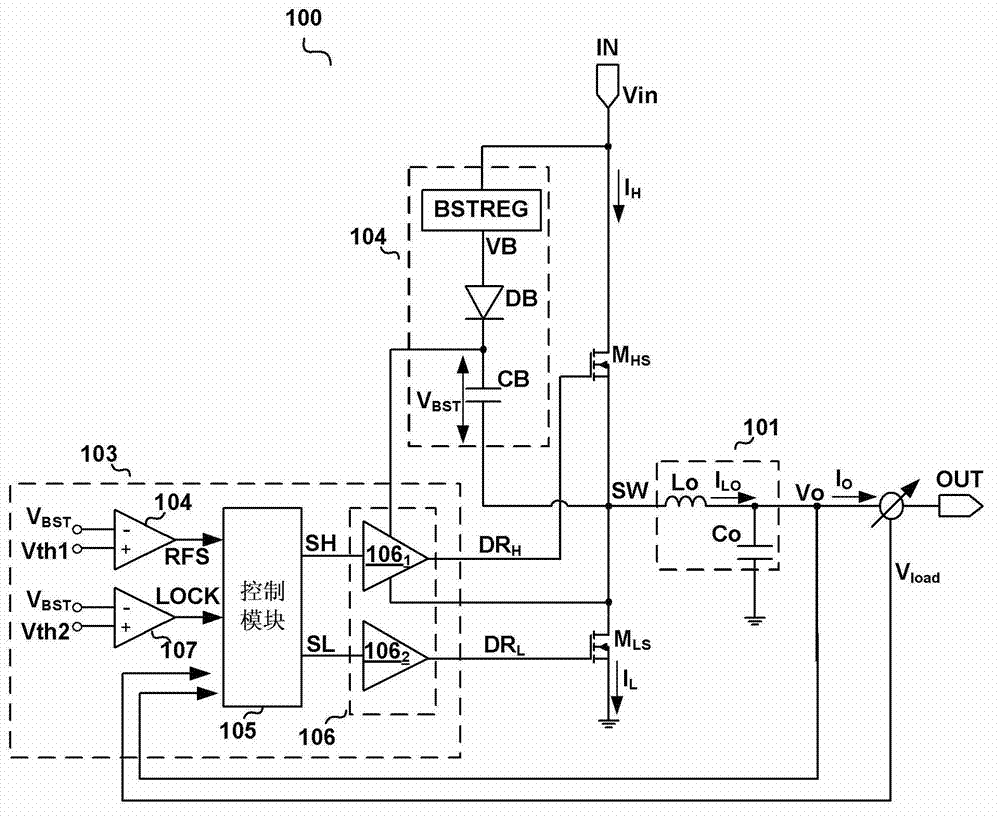

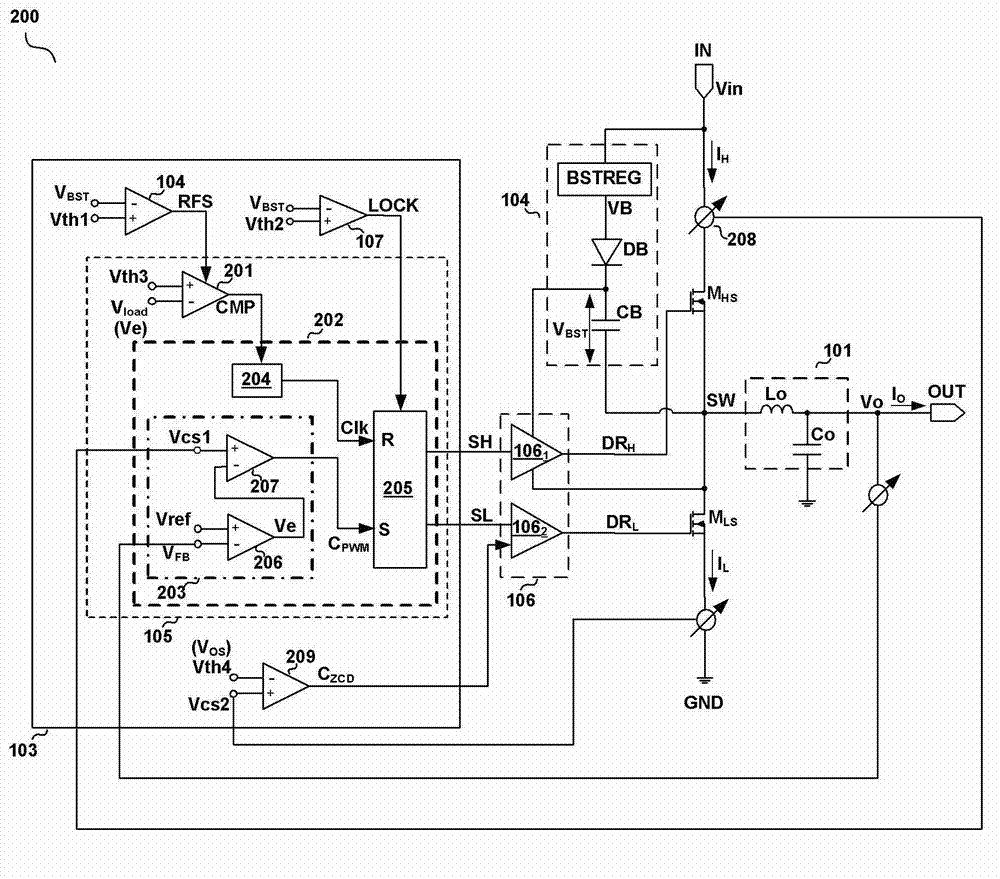

Bootstrap voltage refresh control circuit, voltage converting circuit and relevant control method

ActiveCN102832810AGood job stabilityReduce power consumptionTransistorEfficient power electronics conversionEngineeringVoltage

The invention proposes a bootstrap voltage refresh control circuit, a voltage converting circuit and a relevant control method. The bootstrap voltage refresh control circuit detects the bootstrap voltage in the voltage converting circuit, provides the enhanced on-off driving signal for a high side switch of the voltage converting circuit based on the bootstrap voltage, and controls the charging of the bootstrap voltage through controlling the on-off switch of the high side switch and a low side switch of the voltage converting circuit based on bootstrap voltage. The bootstrap voltage refresh control circuit can recover the bootstrap voltage in time through adjusting the on-off switch of the high side switch and the low side switch when the bootstrap voltage is insufficient, without increasing more switch devices. The voltage converting circuit comprising the bootstrap voltage refresh control circuit has excellent work stability, and the circuit can work normally when the input voltage and the output voltage are closer, and the circuit has smaller power consumption.

Owner:CHENGDU MONOLITHIC POWER SYST

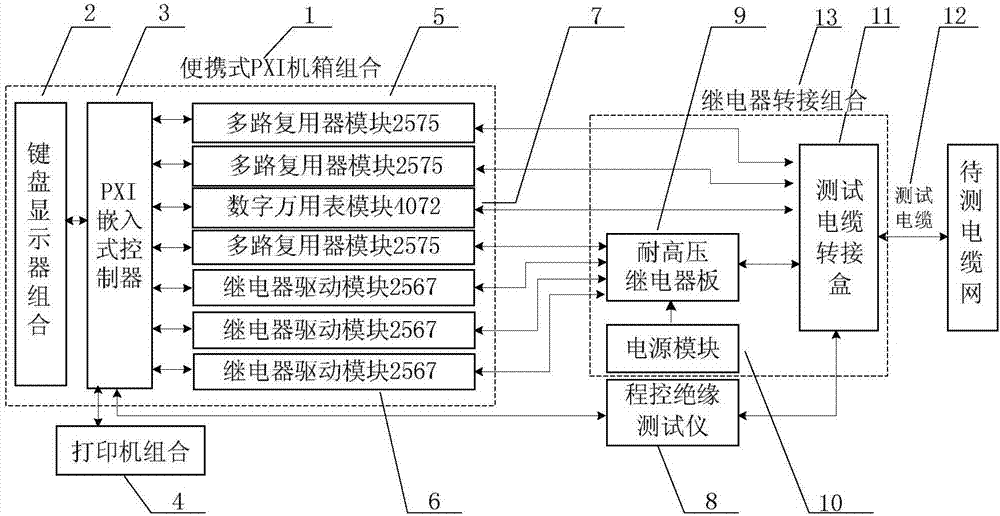

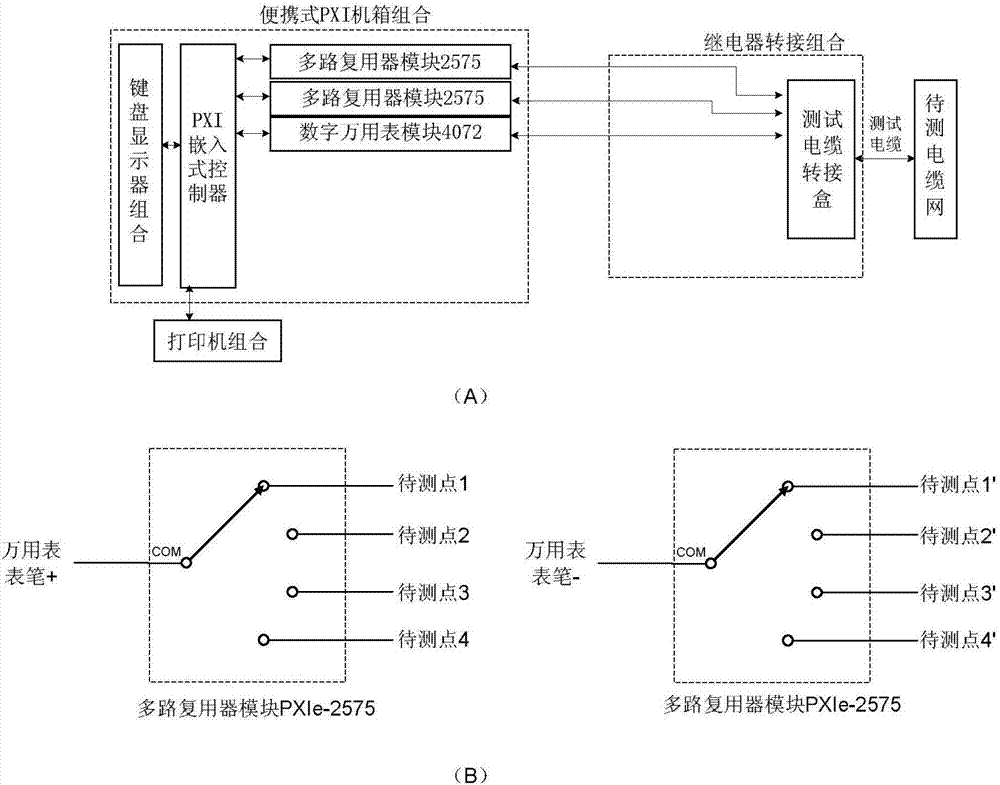

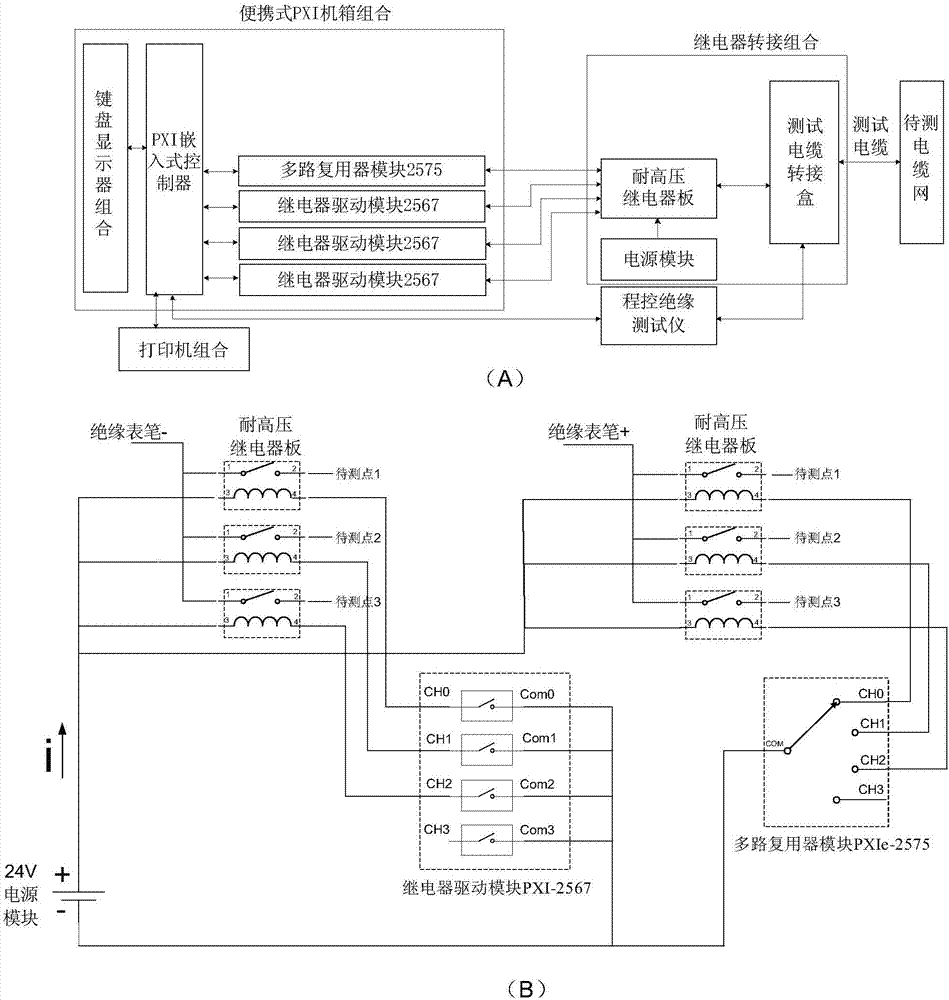

Cable net conduction insulation automatic testing system based on PXI

PendingCN107037326AGood job stabilityImprove test efficiencyFault location by conductor typesComputer printingMultiplexing

The invention provides a cable net conduction insulation automatic testing system based on PXI. The cable net conduction insulation automatic testing system comprises a portable PXI cabinet combination, a relay switching combination, a programmed control insulation tester, a printer, and a testing cable. The portable PXI cabinet combination comprises a PXI embedded type controller, multiplexer modules, relay driving modules, a digital multimeter module, and a keyboard display combination. The relay switching combination comprises a high voltage resistant relay board, a power supply module, and a testing cable switching box. The PXI embedded type controller is the control center of the whole automatic testing system, and switching of conduction to-be-tested points is realized by controlling two multiplexer modules, and the digital multimeter module is used to realize cable net passive conduction testing. The three relay driving modules and the one multiplexer module are used to realize switching of insulation to-be-tested points, and the programmed control insulation tester is used to realize a cable net insulation testing function.

Owner:BEIJING HANGTIAN XINFENG MECHANICAL EQUIP

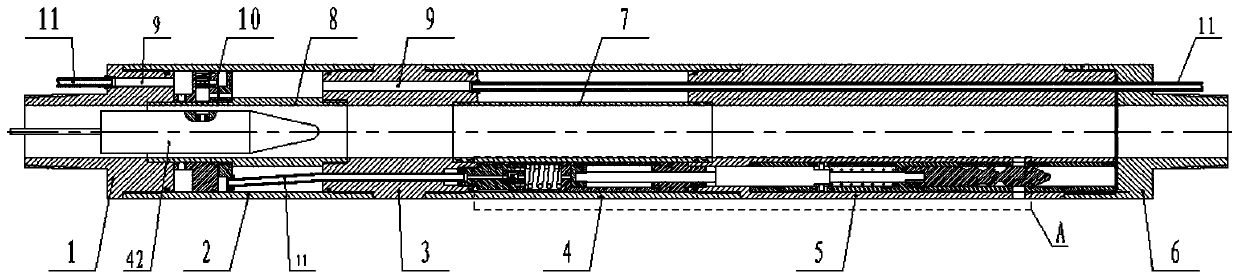

Injection distribution device

The invention belongs to the field of oil field water injection tools, in particular to an injection distribution device, which comprises an upper joint, an upper cylinder, an adapter, a lower cylinder, an installation main body, a lower joint, an upper central pipe and a lower central pipe. The upper joint, the upper cylinder, the adapter and the lower cylinder, the installation main body and thelower joint are sequentially connected through threads from top to bottom to form a shell of the injection distribution device, the upper end of the upper central pipe is inserted into the upper joint, an air pipe connected with the adapter passes through the installation main body and the lower joint and then leads to the outer side of the injection distribution device, two ends of the lower central pipe are respectively inserted between the adapter and the installation main body, a control valve assembly is arranged in the annular space, and a water nozzle assembly is arranged in the installation main body. Compared with a mechanical injection distribution device, the device has the advantages that a tool does not need to be taken off when water is dispensed, and the operation cost is greatly reduced; and compared with an electric control injection distribution device, the device has no strict working condition requirement, so the working stability is better, and the reliability ishigher.

Owner:奥宸科技有限公司

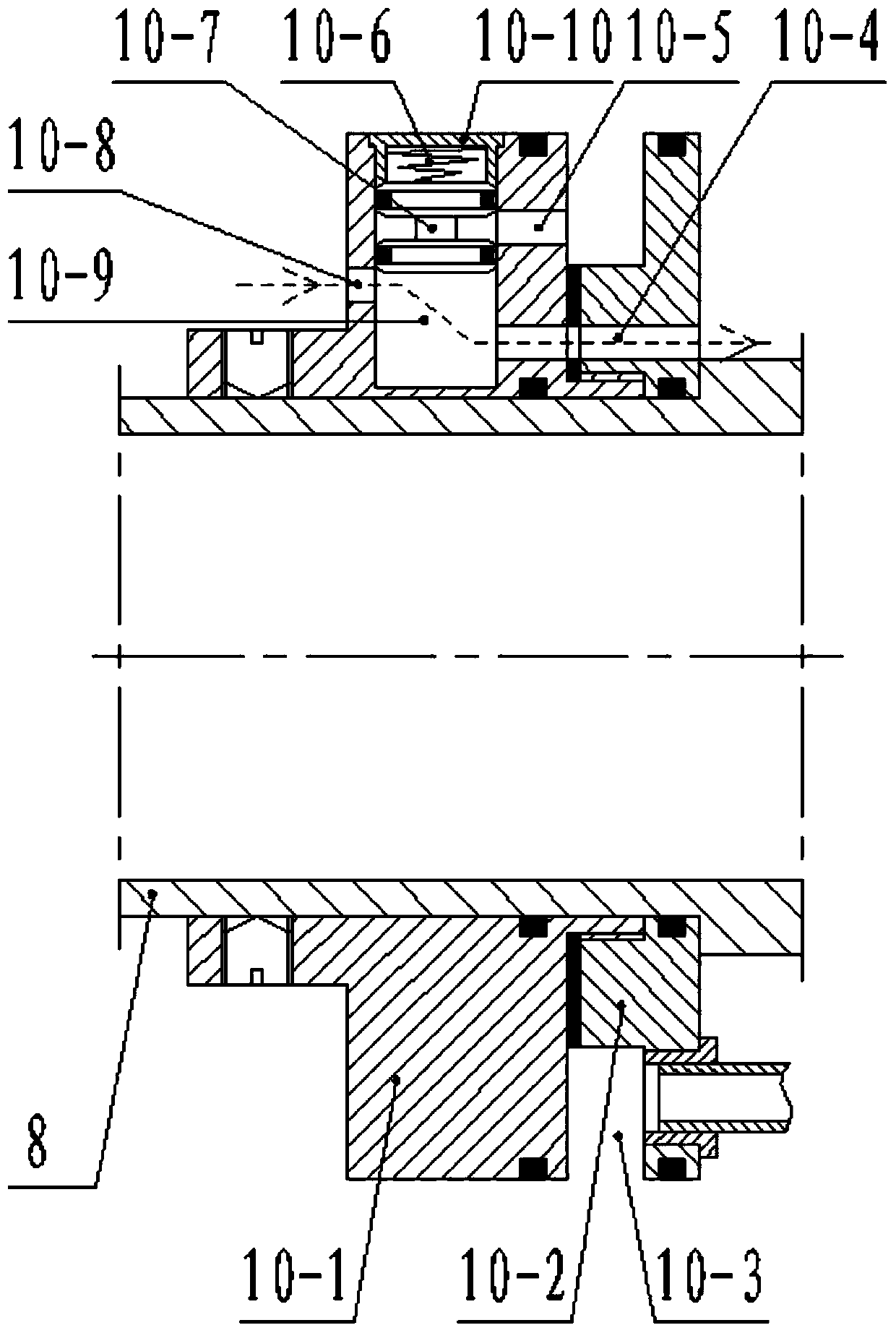

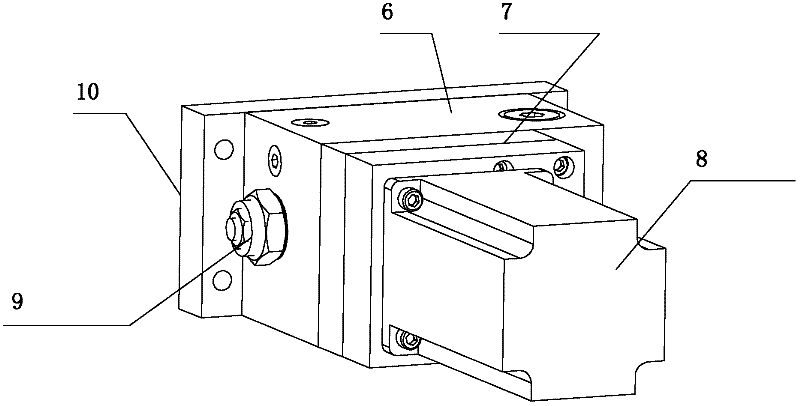

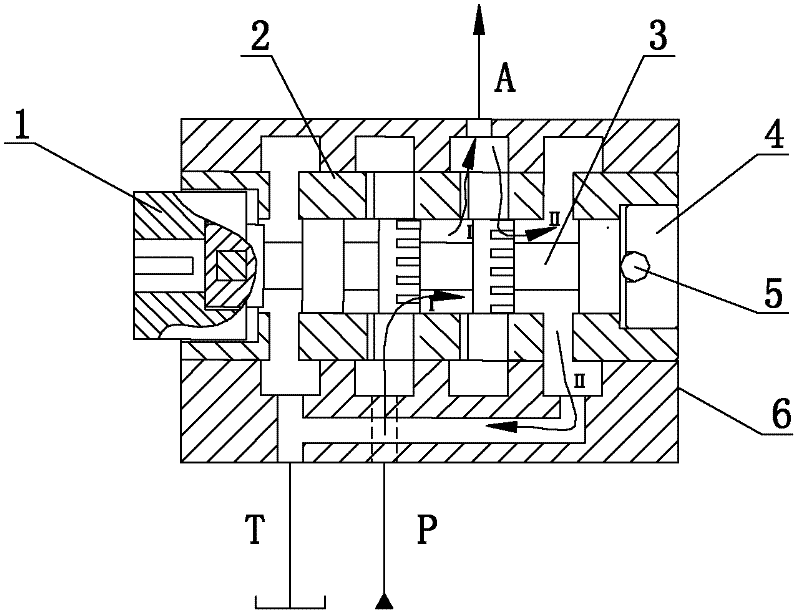

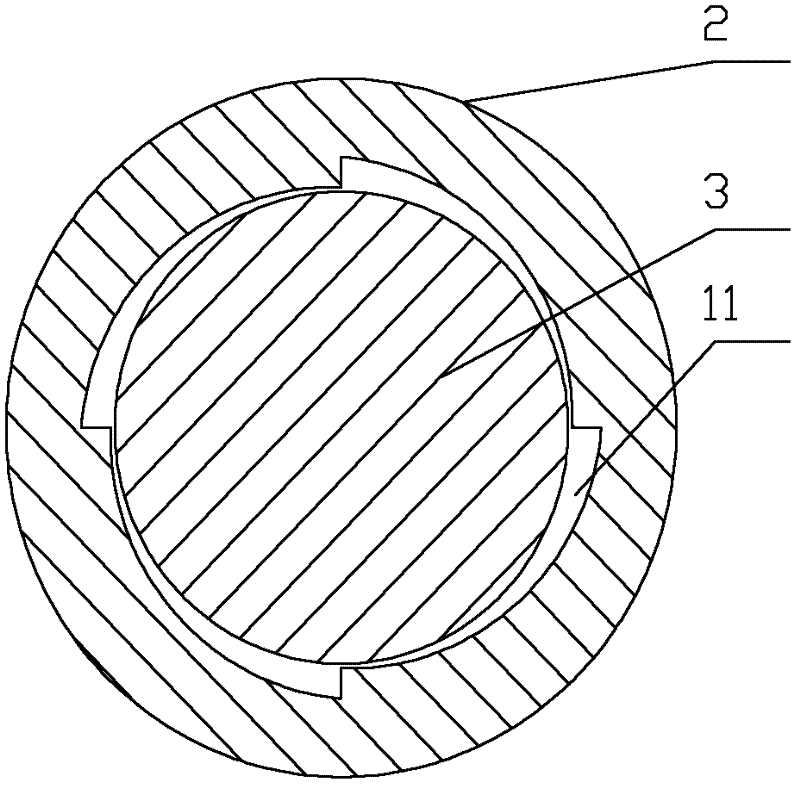

Tee high-frequency electro-hydraulic exciting vibration valve

InactiveCN102537419AAvoid shaft offsetGood job stabilityMultiple way valvesValve housingsElectro hydraulicShuttle valve

The invention discloses a tee high-frequency electro-hydraulic exciting vibration valve which comprises a valve body, a valve core and a valve sleeve, wherein the valve body is provided with an oil inlet, an oil outlet and an oil return opening, wherein the oil inlet is communicated with a high-pressure oil tank; the oil outlet is communicated with a hydraulic cylinder; the oil return opening is communicated with an oil return oil tank; the valve core and the valve sleeve are positioned in the valve body; the valve sleeve is embedded in a hole of the valve body; the valve core is positioned in the valve sleeve, and is provided with four shoulders, wherein two shoulders at the outer side are support shoulders, and two shoulders in the middle are operating shoulders; grooves are respectively processed axially on the two operating shoulders uniformly, and the grooves of the two operating shoulders are misplaced mutually; valve sleeve windows which are matched with the grooves of the shoulders are uniformly formed circumferentially on the part of the valve sleeve corresponding to the operating shoulders; the distance between the valve sleeve windows is equal to the distance between two operating shoulders; at least three oil wedges are axially formed on the valve sleeve corresponding to the support shoulders at intervals of equal circular arcs; the oil outlet is communicated with a throttle valve; and the throttle valve is installed on the valve body. According to the invention, the shaft diameter deviation is avoided effectively, and the operating stability is good.

Owner:ZHEJIANG UNIV OF TECH

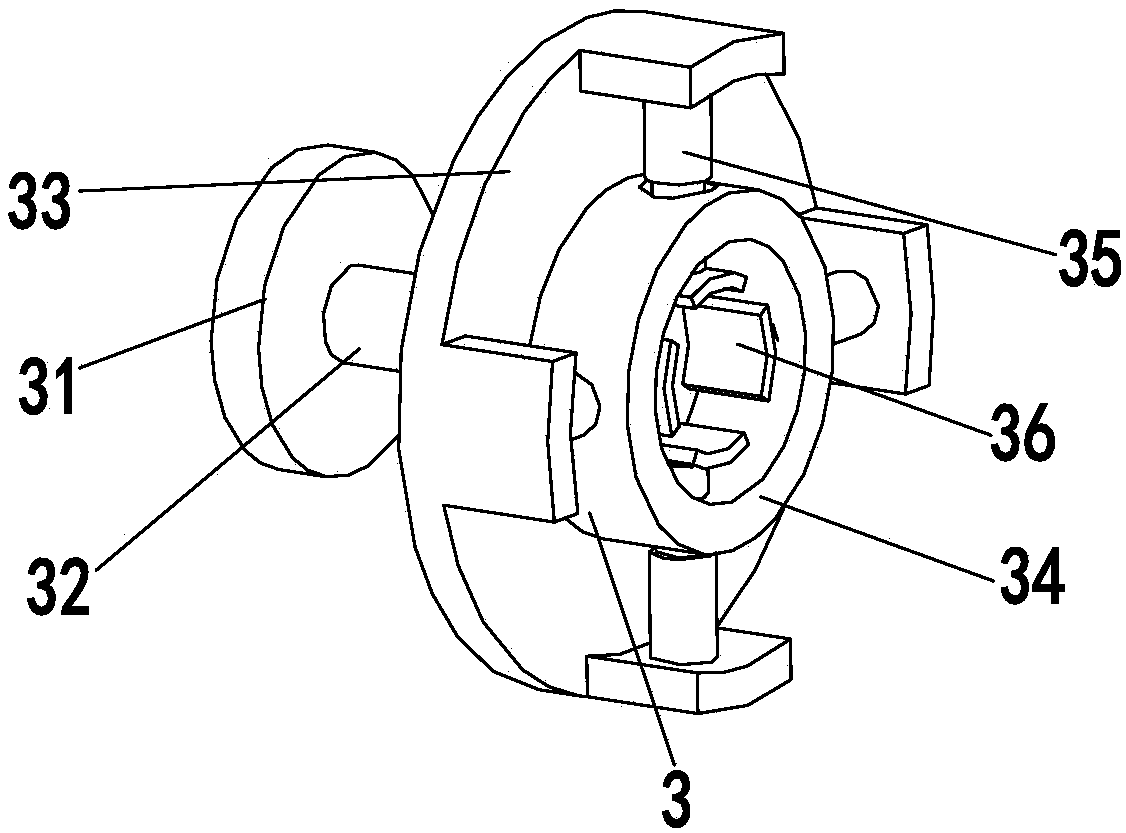

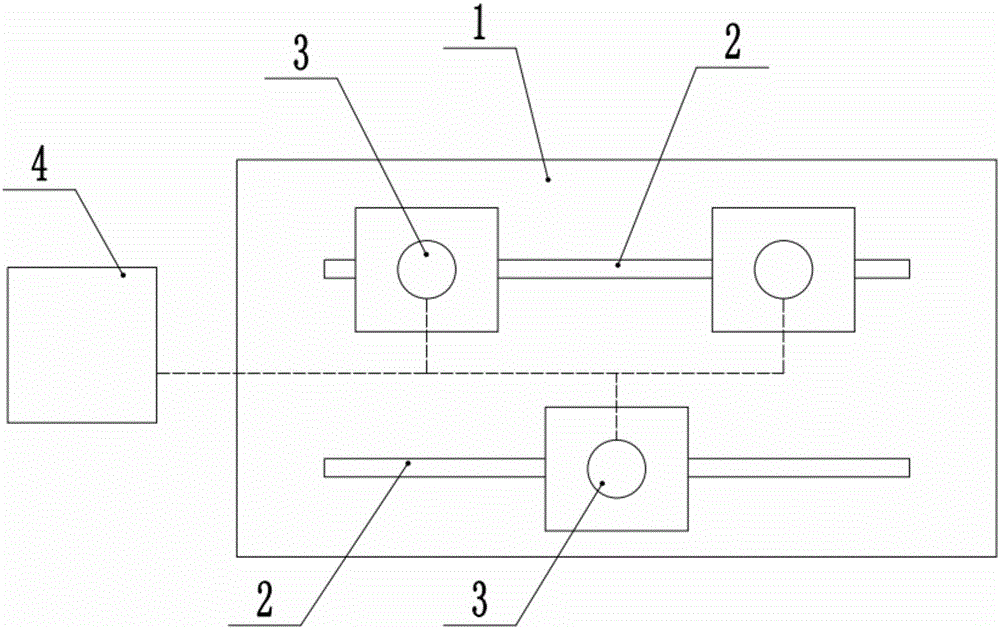

Shaft-class workpiece roundness automatic detection system

ActiveCN109405717AGood job stabilityAccurate recordMechanical counters/curvatures measurementsEngineeringMechanical engineering

The present invention relates to a shaft-class workpiece roundness automatic detection system. The system comprises a bottom plate, an installation rack, a workpice clamping mechanism, a transmissionmechanism, a detection mechanism and an assistance mechanism. The bottom plate is provided with the installation rack, the side wall of the installation rack is provided with the transmission mechanism, the lower end of the transmission mechanism is connected with the workpice clamping mechanism, the upper end of the workpice clamping mechanism is provided with the detection mechanism, the upper end of the workpice clamping mechanism is provided with the assistance mechanism, and the detection mechanism and the assistance mechanism are installed at the side wall of the installation rack. The shaft-class workpiece roundness automatic detection system can solve the problems that a manual handheld tool is needed for detection, the working stability is poor, bulges and depressions at the surfaces of the workpieces cannot be detected and the defect positions are not accurate in record in a current shaft-class workpiece roundness detection process, and can achieve the function of automatic detection of the shaft-class workpiece roundness.

Owner:温州神一轴业股份有限公司

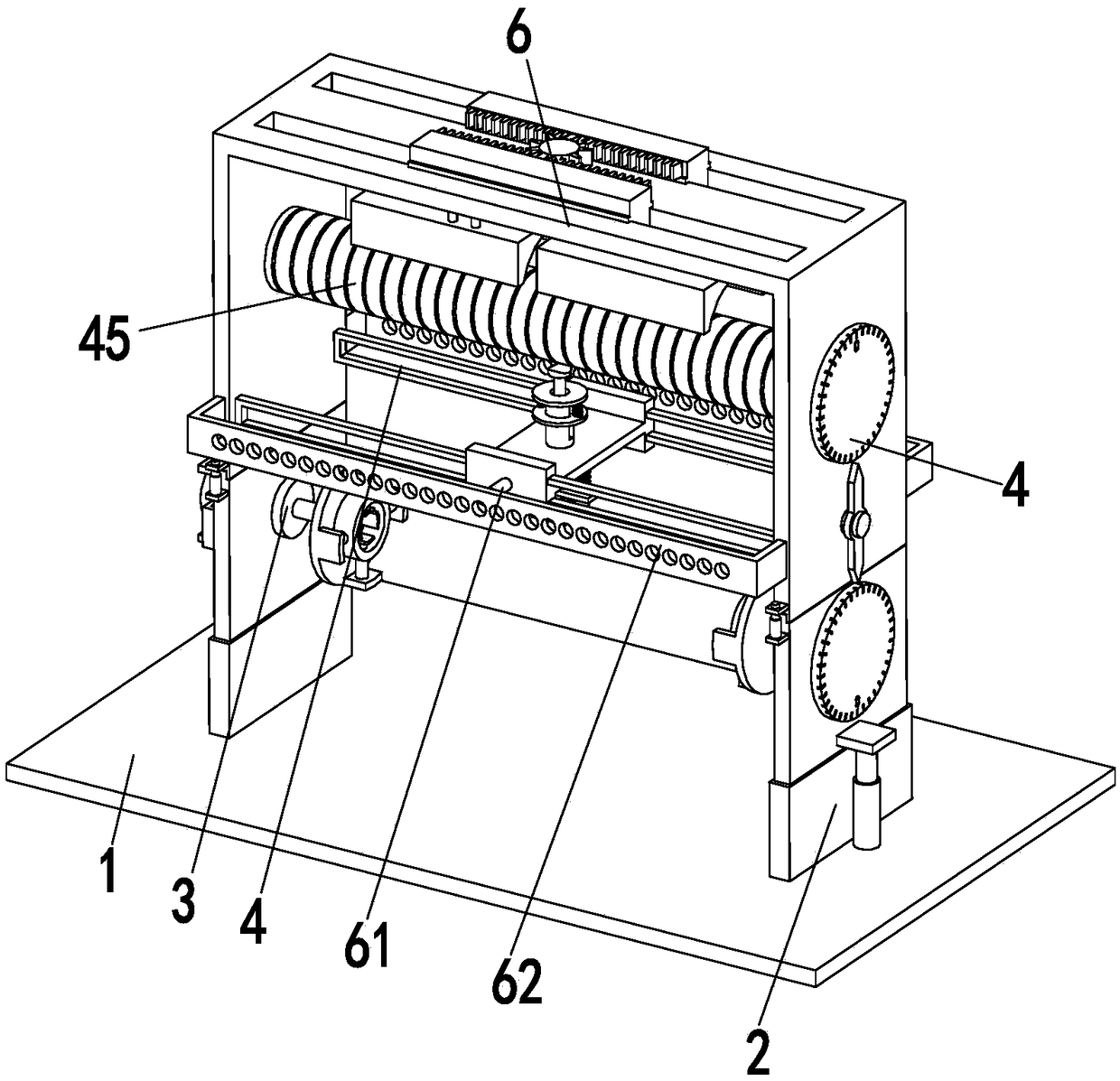

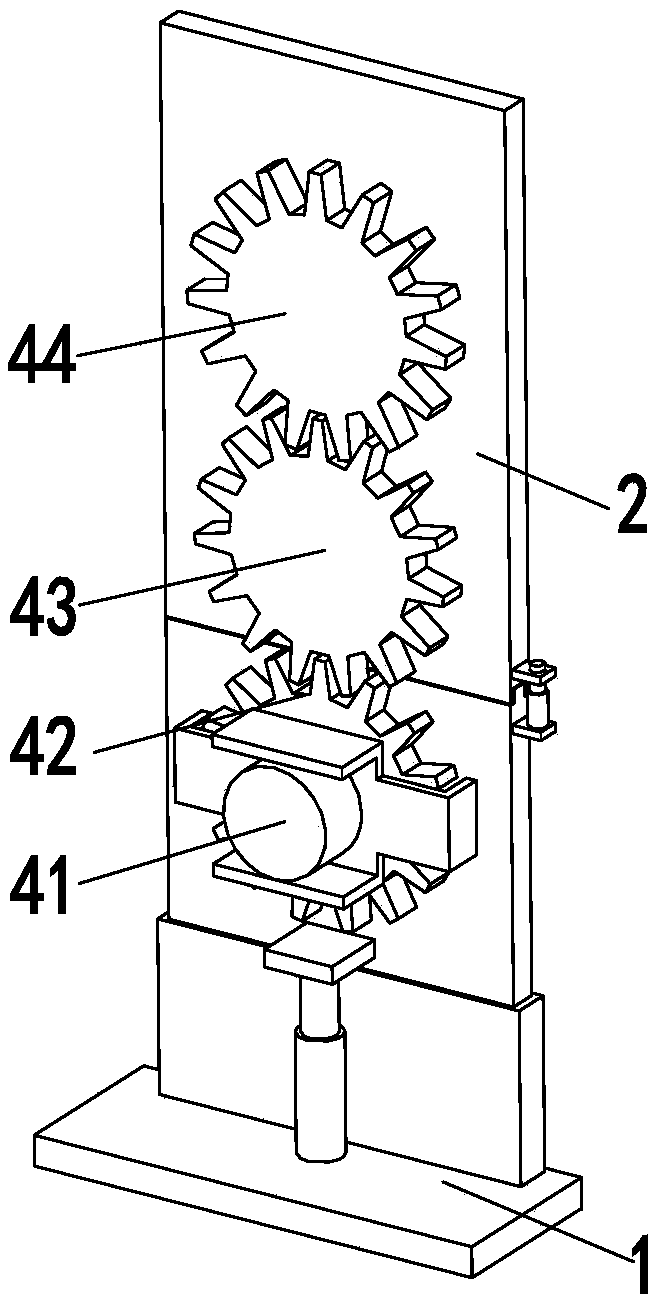

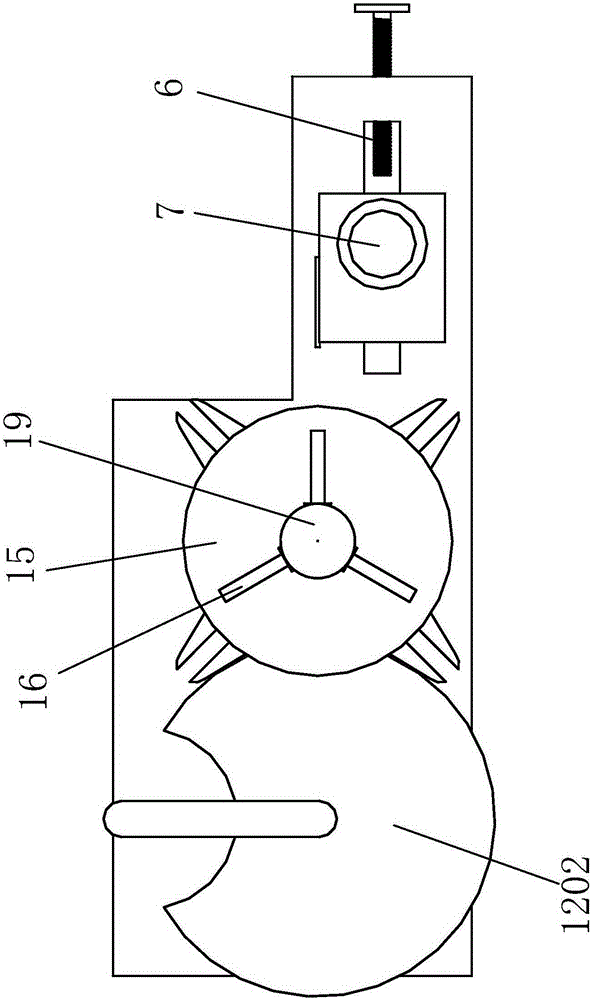

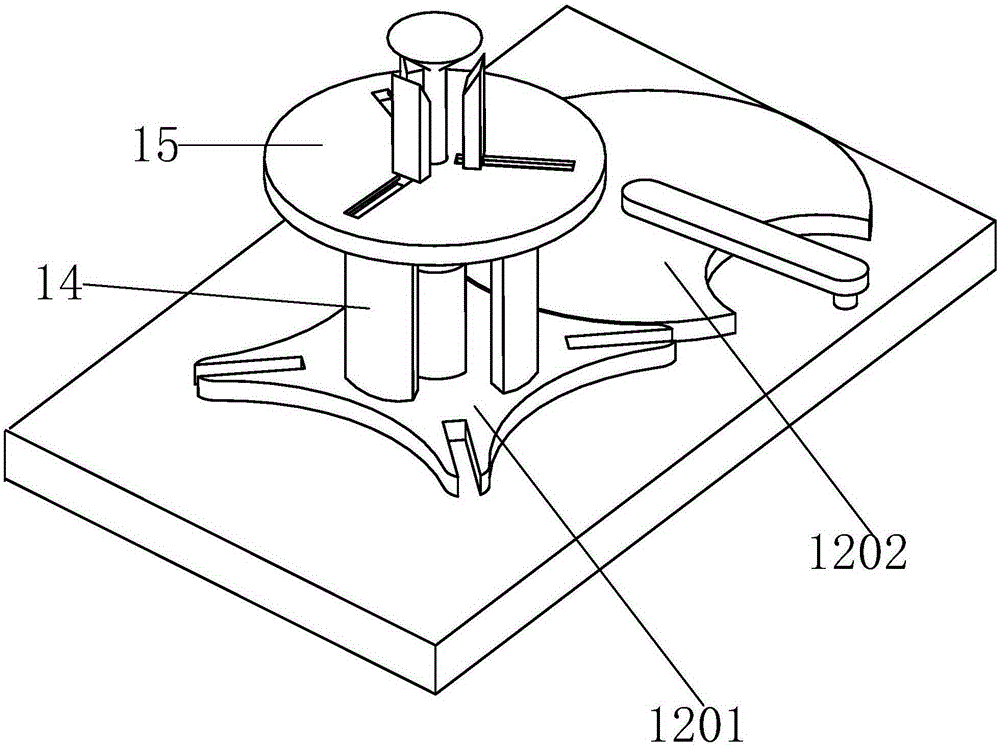

Grooving device for outer surface of lining

ActiveCN105171105ALow costGood job stabilityPrecision positioning equipmentShearing machinesEngineeringSlide plate

The invention relates to a grooving device for the outer surface of a lining. The grooving device comprises a bottom plate. A clamping device is arranged on the left side of the bottom plate. A cutting device is arranged on the right side of the bottom plate and comprises a slideway on the bottom plate, a sliding frame in the slideway, a threaded rod arranged on the right side of the sliding frame, a first air cylinder installed on the upper portion of the sliding frame, an installation plate installed on a shaft of the first air cylinder, a motor installed on the installation plate and a cutting piece installed on a shaft of the motor. A sheave driving mechanism is used for driving a supporting frame used for containing the lining to rotate, intermittent rotation of the supported lining can be realized, and therefore the purpose of evenly grooving the lining is realized. Compared with an existing driving method through a stepping motor, a controller is eliminated, the cost is reduced, and the work stability is good. A sliding plate is pressed through an inverted circular truncated cone pressing block.

Owner:HENAN FEILONG WUHU AUTOMOBILE PARTS

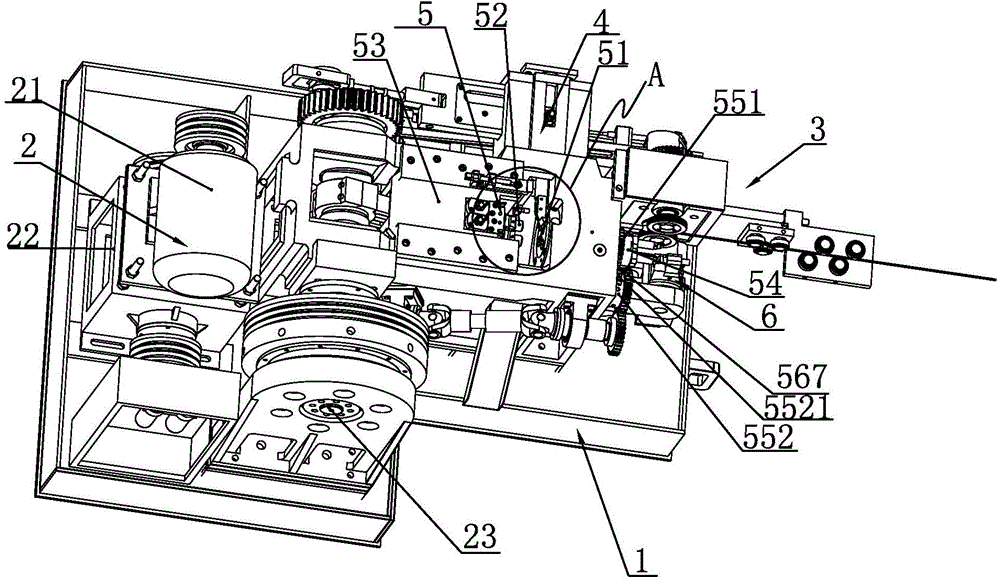

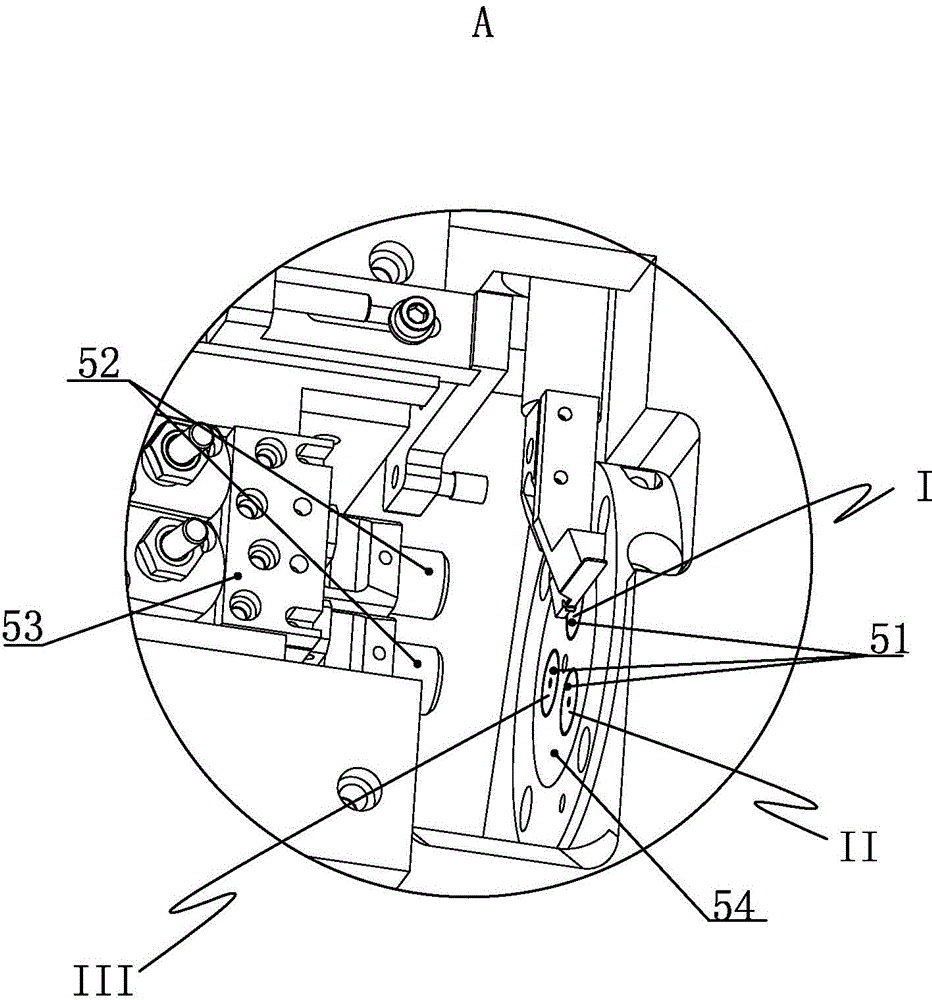

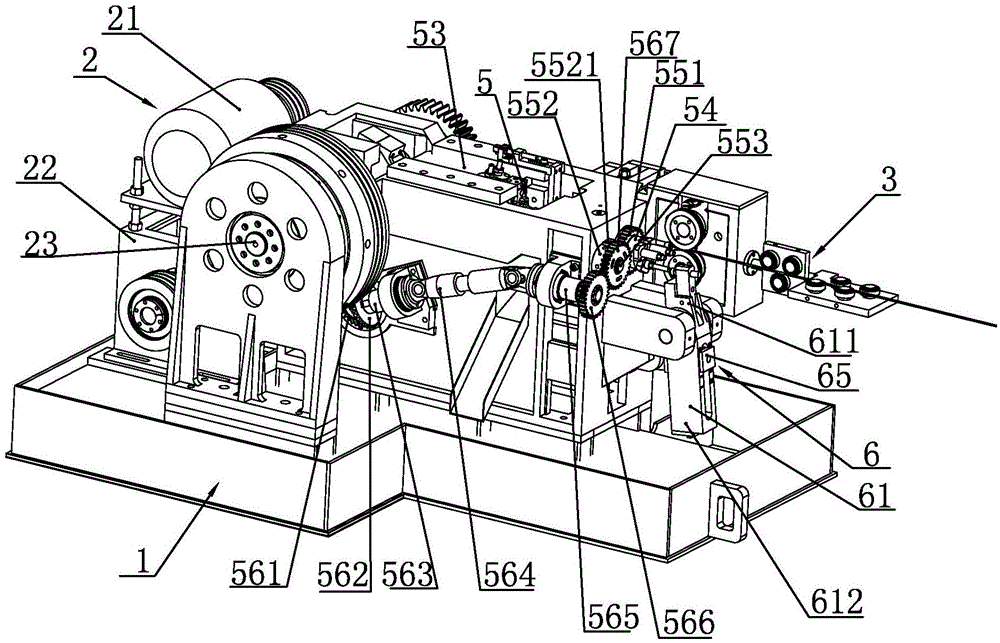

Main die rotary type high-speed cold heading machine

ActiveCN104690202ACompact structureGood job stabilityUpsetting pressesSwagging pressesProcessing accuracyEngineering

The invention relates to a main die rotary type high-speed cold heading machine. A cold heading device further comprises a main die rotary mechanism, wherein the main die rotary mechanism comprises a rotary type main die seat; the main die seat is assembled on a machine body and can rotate; the main die seat is sequentially provided with a plurality of heading working stations corresponding stamping dies one by one, and a material returning working station corresponding to the position of a material returning device; the material returning working station and the heading working stations are uniformly distributed on the same circumference; each working station of the main die seat is correspondingly provided with a main die; the main die seat is connected with an interval indexing device for driving the main die seat to rotate at interval to realize the switching of the working stations of the main die; each stamping die is positioned and mounted on a stamping die slide seat and corresponds to the position of the corresponding cold heading working station. The switching of the working stations is realized by main die rotation; the main die rotary type high-speed cold heading machine has the advantages of compact structure, good production stability, high machining precision and high working efficiency.

Owner:浙江展邦机械有限公司

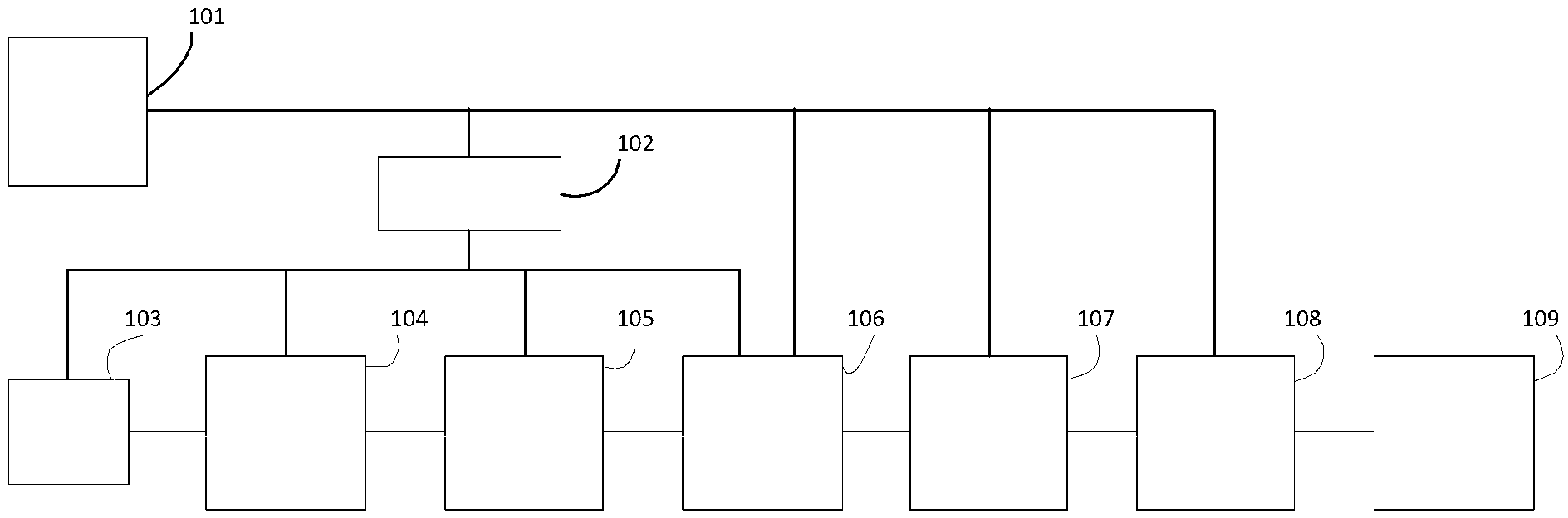

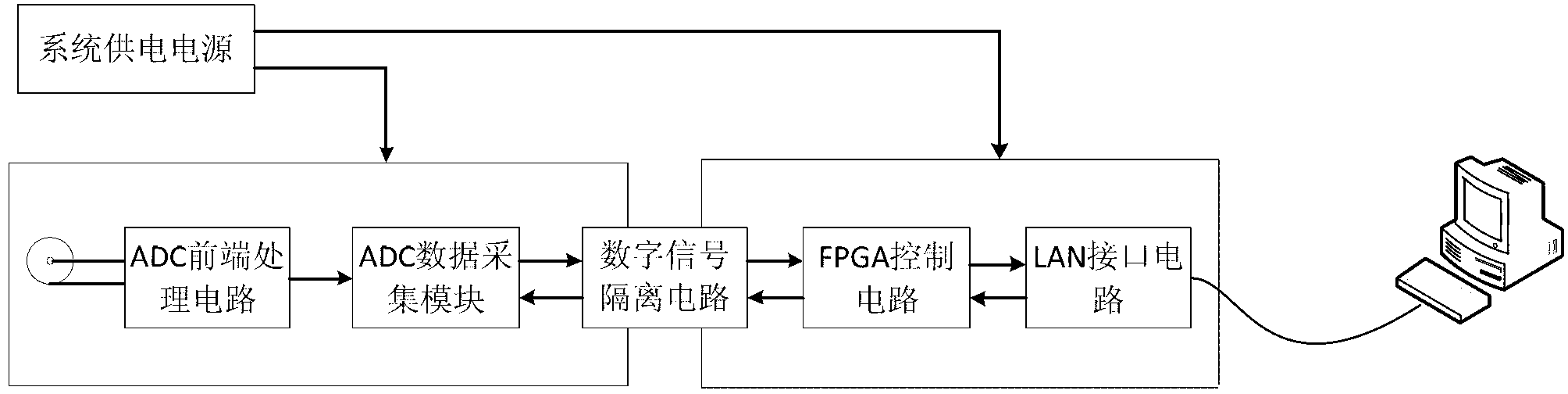

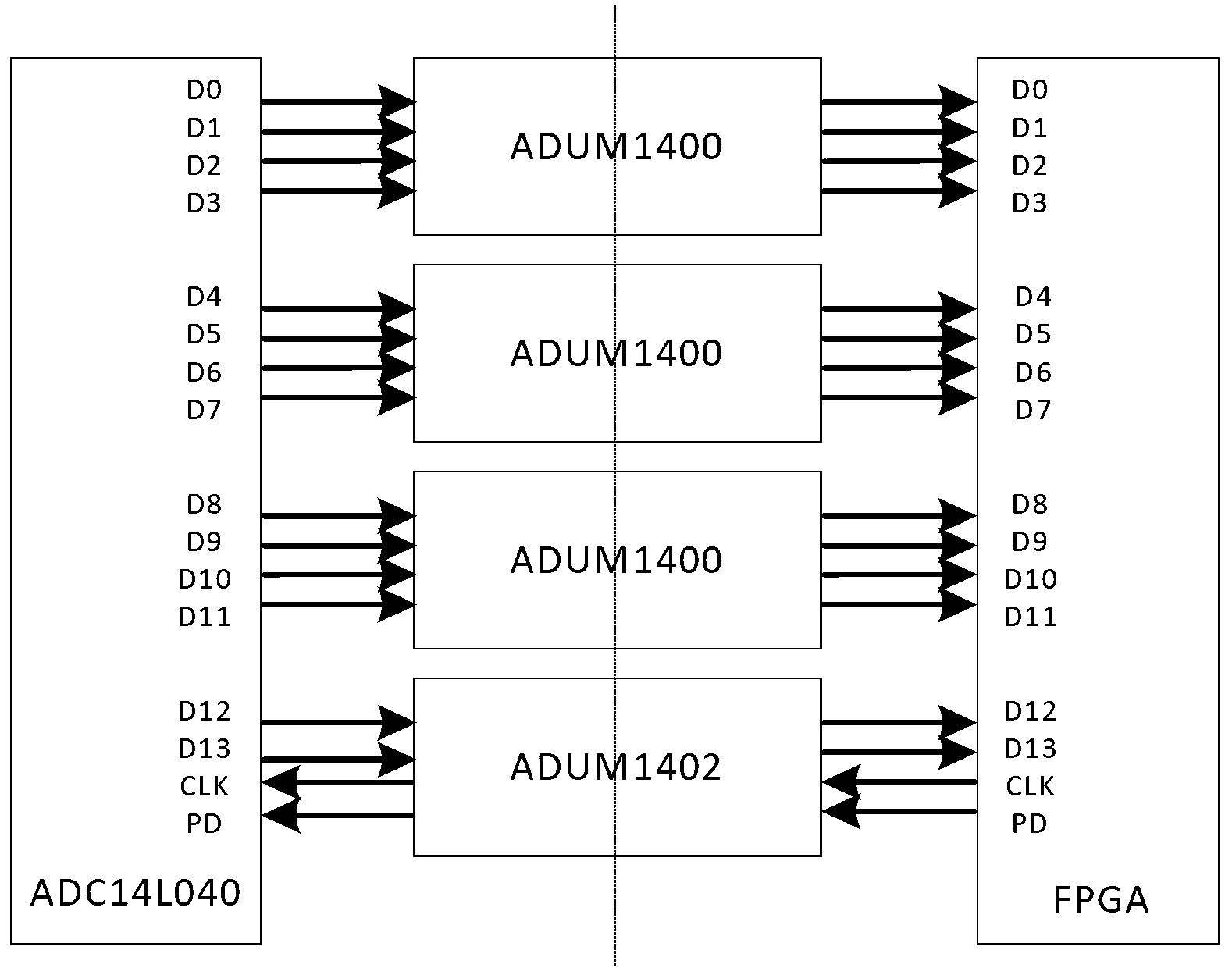

Isolated type high-speed data acquisition card

InactiveCN103226534AGood job stabilityVersatileElectric digital data processingData transmissionIntegrated circuit

The invention discloses an isolated type high-speed data acquisition card, and belongs to the technical field of embedded type measurement. An analog signal to be measured is connected to a gain control circuit (103) through an input interface; an output end of the gain control circuit (103) is connected to a difference drive circuit (104); an output end of the difference drive circuit (104) is connected to an ADC (analog to digital converter) analog-to-digital conversion circuit (105); an output end of the ADC analog-to-digital conversion circuit (105) is connected to a signal isolation circuit (106); an output end of the signal isolation circuit (106) is connected to an FPGA (field programmable gate array) (107); a data processing circuit and an embedded type soft kernel processor are arranged in the FPGA (107); the processor caches the data to an SDRAM (synchronous dynamic random access memory), and the data passes through a network interface circuit (108) and is transmitted to a host computer terminal (109) from the SDRAM; and the kernel processor is a nios processor. According to the isolated type high-speed data acquisition card, the signal acquisition can adopt program control, a signal to be measured is in electric isolation with an external circuit, an internal circuit of a control chip can be programmatically updated, and the stability of data transmission and the flexibility of application are improved.

Owner:BEIJING UNIV OF TECH

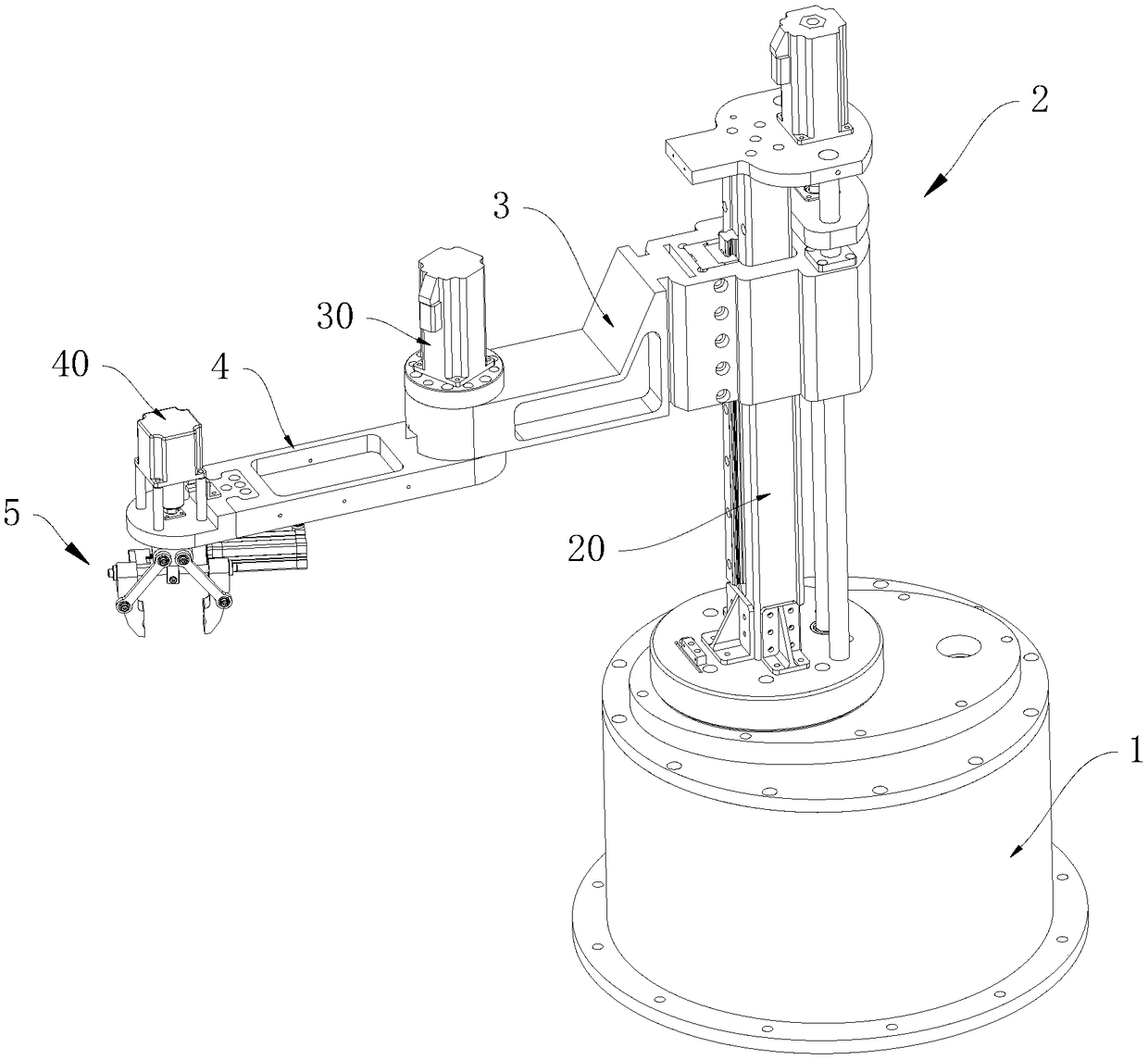

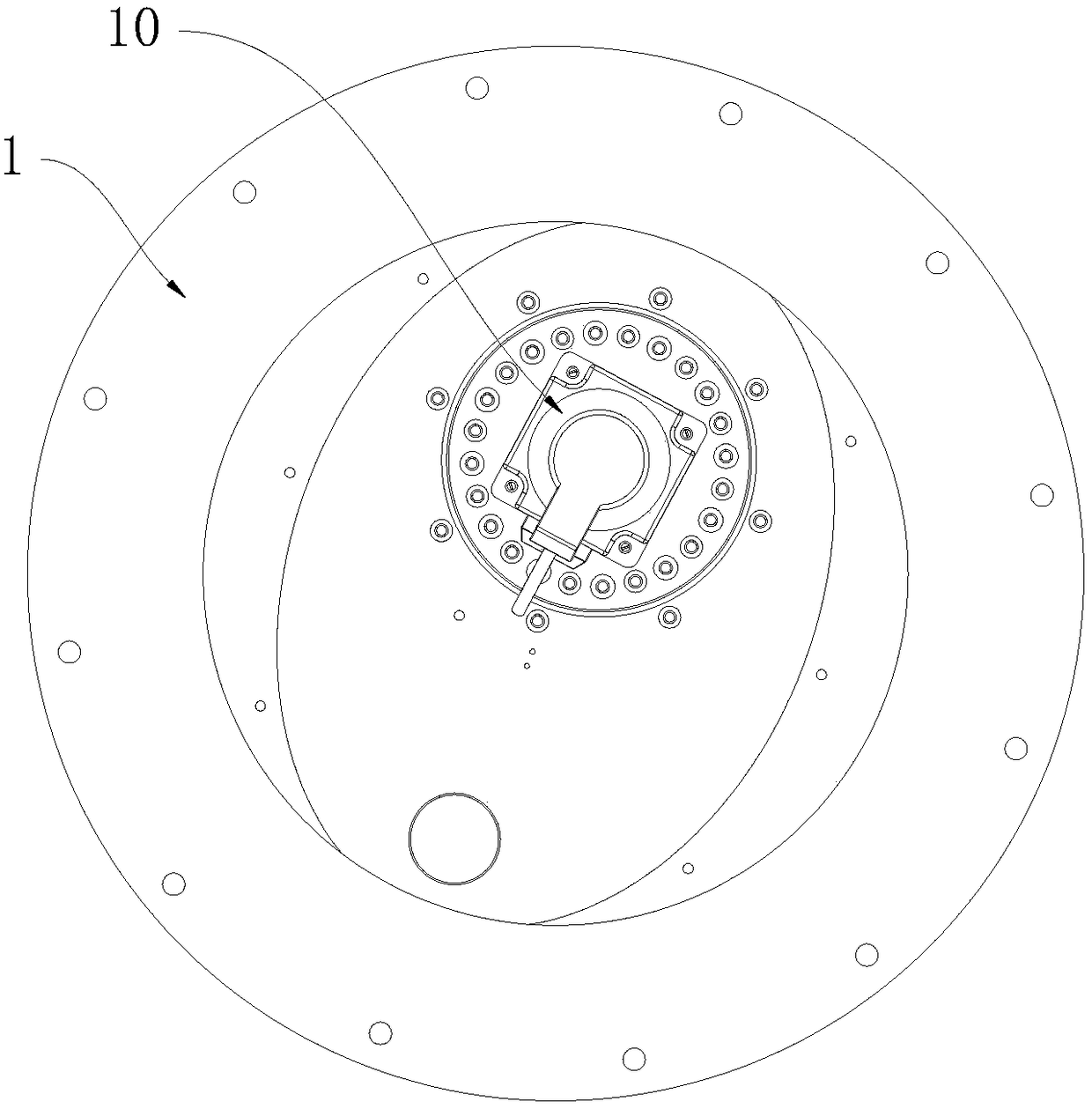

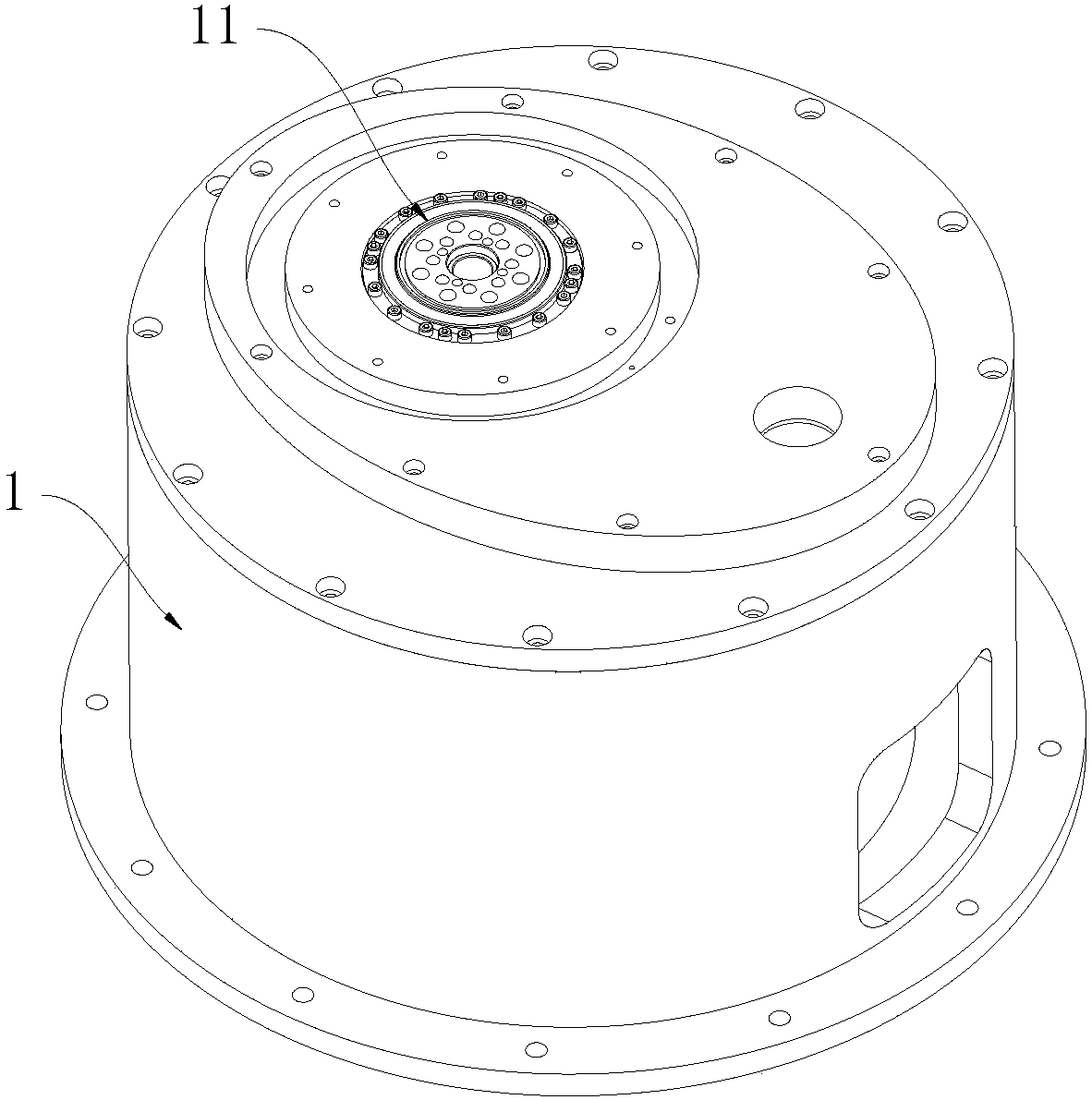

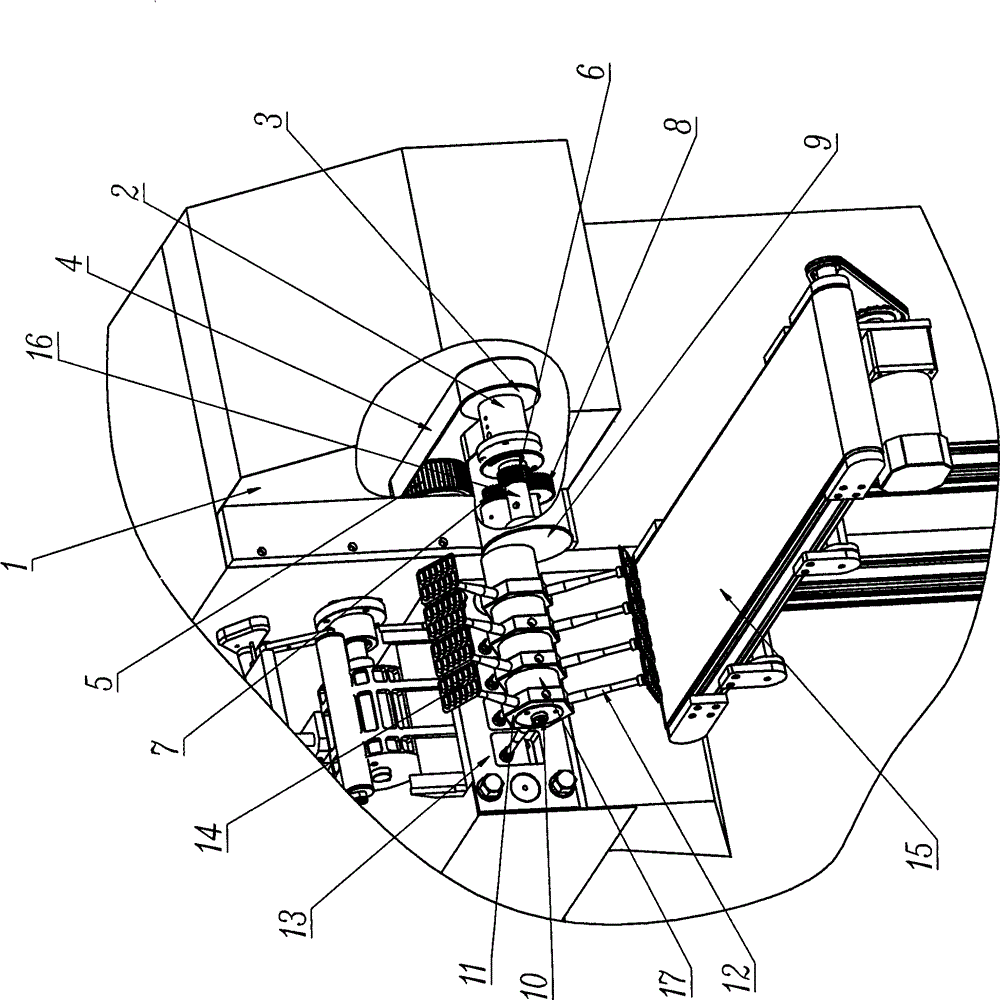

Novel SCARA robot structure

InactiveCN108527342AControl movement precision and accuracyGood job stabilityProgramme-controlled manipulatorSCARAEngineering

The invention disclose a novel SCARA robot structure. The novel SCARA robot structure comprises a base, wherein a lifting mechanism and a base motor which is used for driving the lifting mechanism torotate are arranged on the base, a middle arm is arranged on the lifting mechanism, the middle arm is driven to move up and down by the lifting mechanism, a front arm and a middle arm motor which is used for driving the front arm to rotate are arranged on the middle arm, an actuating mechanism and a front arm motor which is used for driving the actuating mechanism to rotate are arranged on the front arm, and the actuating mechanism is driven to move to a preset position under the driving action of the base motor, the lifting mechanism, the middle arm motor and the front arm motor. The novel SCARA robot structure has the characteristics of the simple structure, easiness in implementation, flexibility, good working stability, high actuating precision and the like, and the movement of the three-dimensional space can be realized.

Owner:深圳市欧力克斯科技有限公司

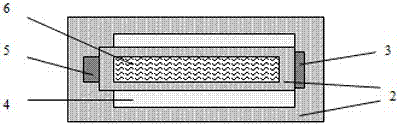

Novel magnetic fluid-piezoelectric film structure device and production method thereof

InactiveCN107991632AHigh sensitivityGood job stabilityDecorative surface effectsSolid-state devicesPhysicsFilm structure

The invention discloses a novel magnetic fluid-piezoelectric film structure device and a production method thereof. The device comprises a piezoelectric sandwich structure and a magnetic fluid layer,wherein the piezoelectric sandwich structure comprises a piezoelectric film layer as well as a top electrode layer and a bottom electrode layer which are arranged on the upper and lower surfaces of the piezoelectric film layer, and a lead (not shown) is arranged between the top electrode layer and the bottom electrode layer; the magnetic fluid layer is located on the top electrode layer. The device is high in magnetic field sensor sensitivity, good in working stability, high in antijamming capability, wireless and passive, and the problem that a probe fails in a long-term working state and isdifficult to repair is solved.

Owner:NINGBO DAHONGYING UNIV

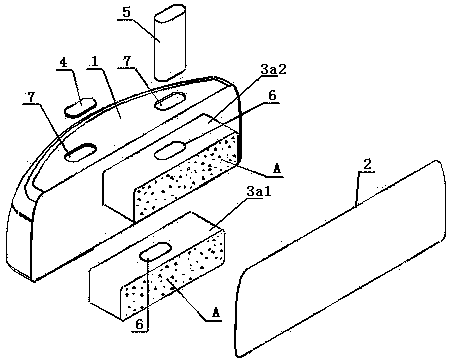

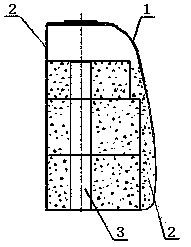

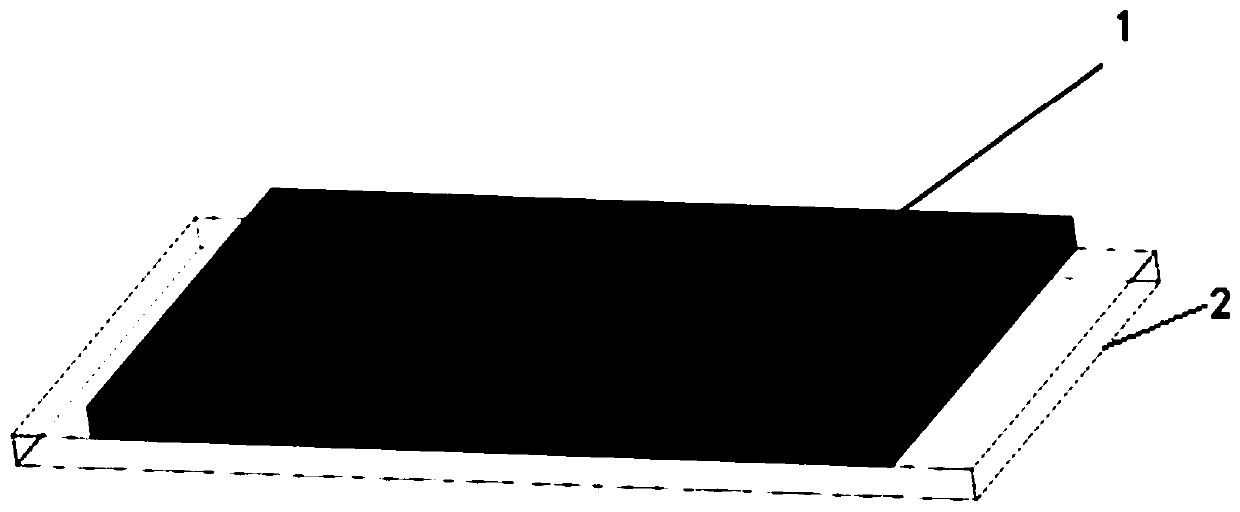

Excavator counter weight and manufacture method thereof

ActiveCN103510563AEvenly filledGood job stabilitySoil-shifting machines/dredgersAssembly lineExcavator

The invention discloses an excavator counter weight and a manufacture method thereof. The excavator counter weight comprises a box body and a cover plate, wherein filling openings are formed in the top of the box body; the box body is welded with the cover plate to form a counter weight housing. The excavator counter weight is characterized in that a plurality of concrete blocks are arranged in the counter weight housing; at least one filling through hole is formed in each concrete block; an upper layer of the concrete blocks is connected with a lower layer of the concrete blocks through connecting shafts. The excavator counterweight has the advantages as follows: the concrete blocks in the excavator counter weight are distributed uniformly; the operation stationarity of an excavator is high when the excavator is in operation; when the excavator counter weight is filled with the concrete blocks, the concrete blocks are prevented from impacting the counter weight housing so as not cause deformation of the counter weight housing; local cavities in the counter weight housing are avoided; the phenomenon that during operation, the counter weight housing is depressed or deformed duo to impacts of external forces is avoided; the manufacture method of the excavator counter weight can adopt an industrial assembly line to effectively improve the production efficiency.

Owner:LIUZHOU LIUGONG EXCAVATORS +2

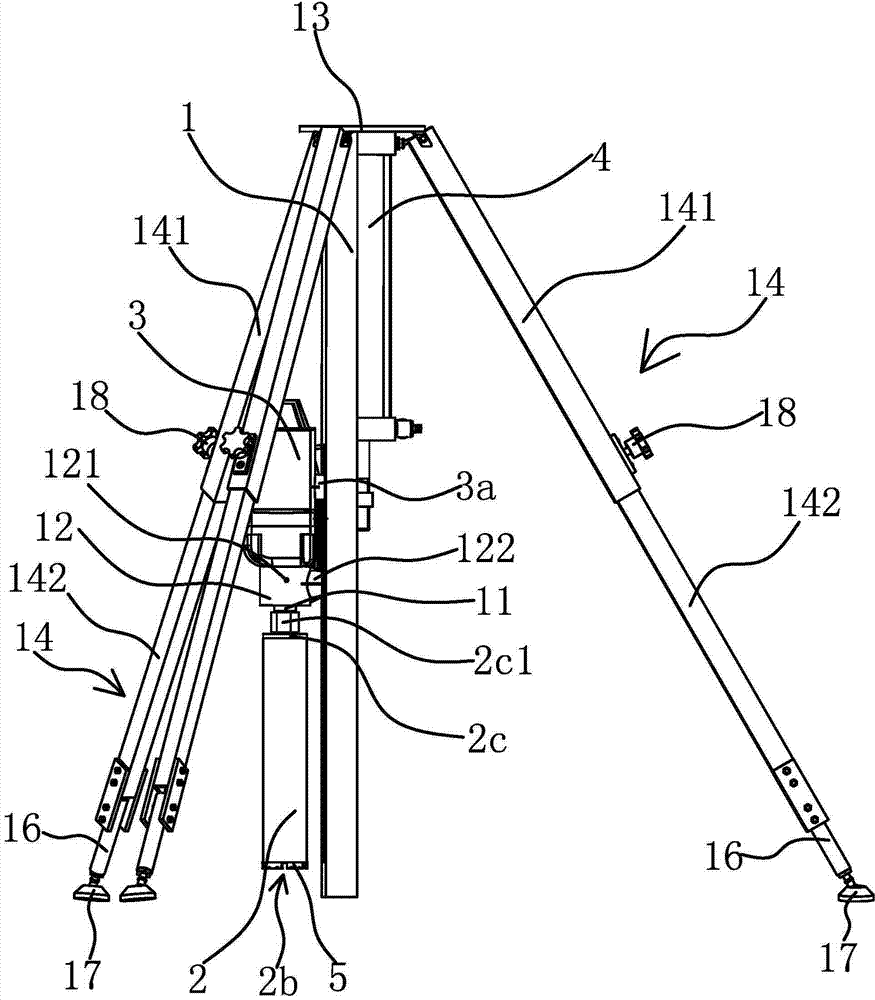

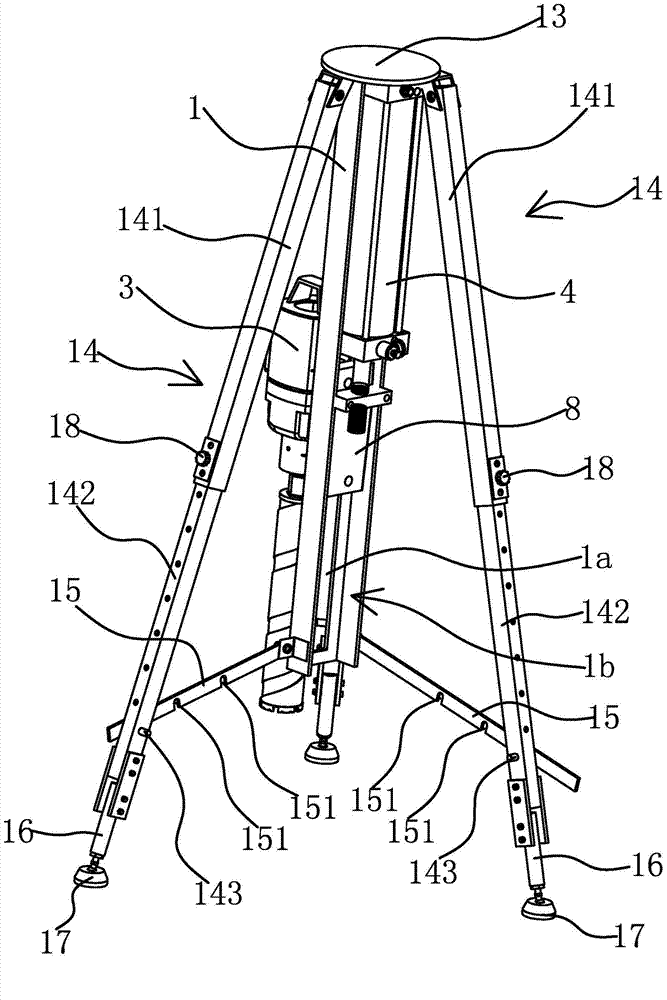

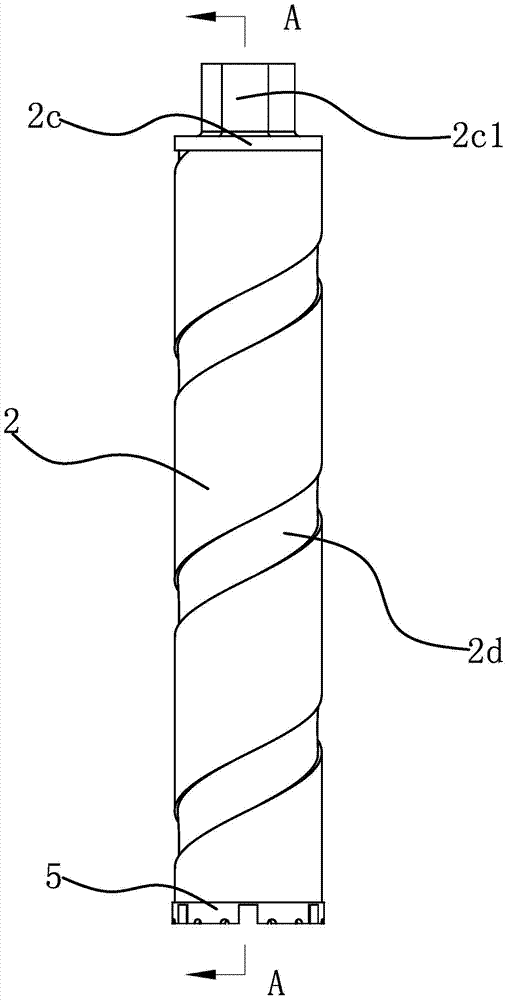

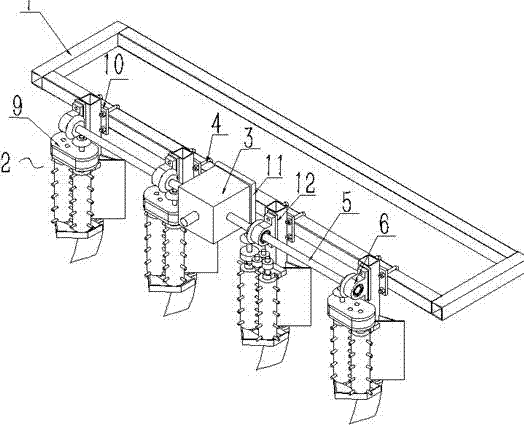

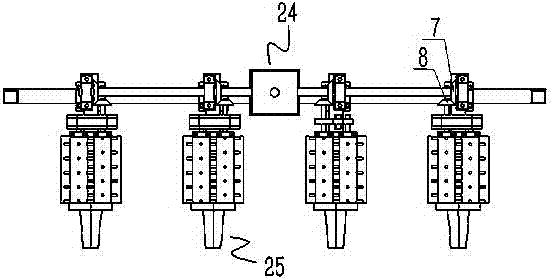

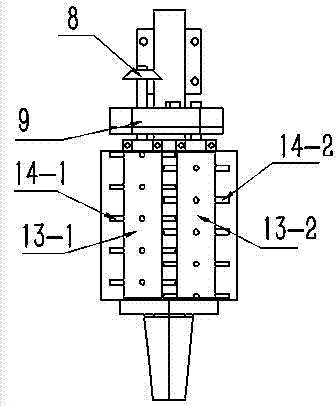

Automatic bamboo root excavator

The invention provides an automatic bamboo root excavator and belongs to the technical field of forestry machinery. The excavator solves the problem that the existing automatic bamboo root excavator is poor in stability. The automatic bamboo root excavator comprises a long-strip-shaped installation frame and a tubular cylinder, a support assembly capable of enabling the installation frame to erect is arranged on the installation frame, a rotating driving source and a feeding driving source are further arranged on the installation frame, a containing cavity is arranged in the cylinder, an opening communicated with the containing cavity is arranged in the lower end portion of the cylinder, a cutter bit is arranged at the opening of the cylinder, a push disc matched with the containing cavity in shape and capable of sliding along the containing cavity is further arranged in the containing cavity of the cylinder, the upper end portions of the push disc and the cylinder are connected through a spring, and a soil discharging driving mechanism is further arranged at the upper end portion of the cylinder. The automatic bamboo root excavator is supported through the support assembly, the rotating driving source and the feeding driving source respectively drive the cylinder to rotate and to be fed, the bamboo root excavator is not required to be centralized and pressed by an operator to be fed in the excavation process, and the working stability is good.

Owner:双登天鹏冶金江苏有限公司

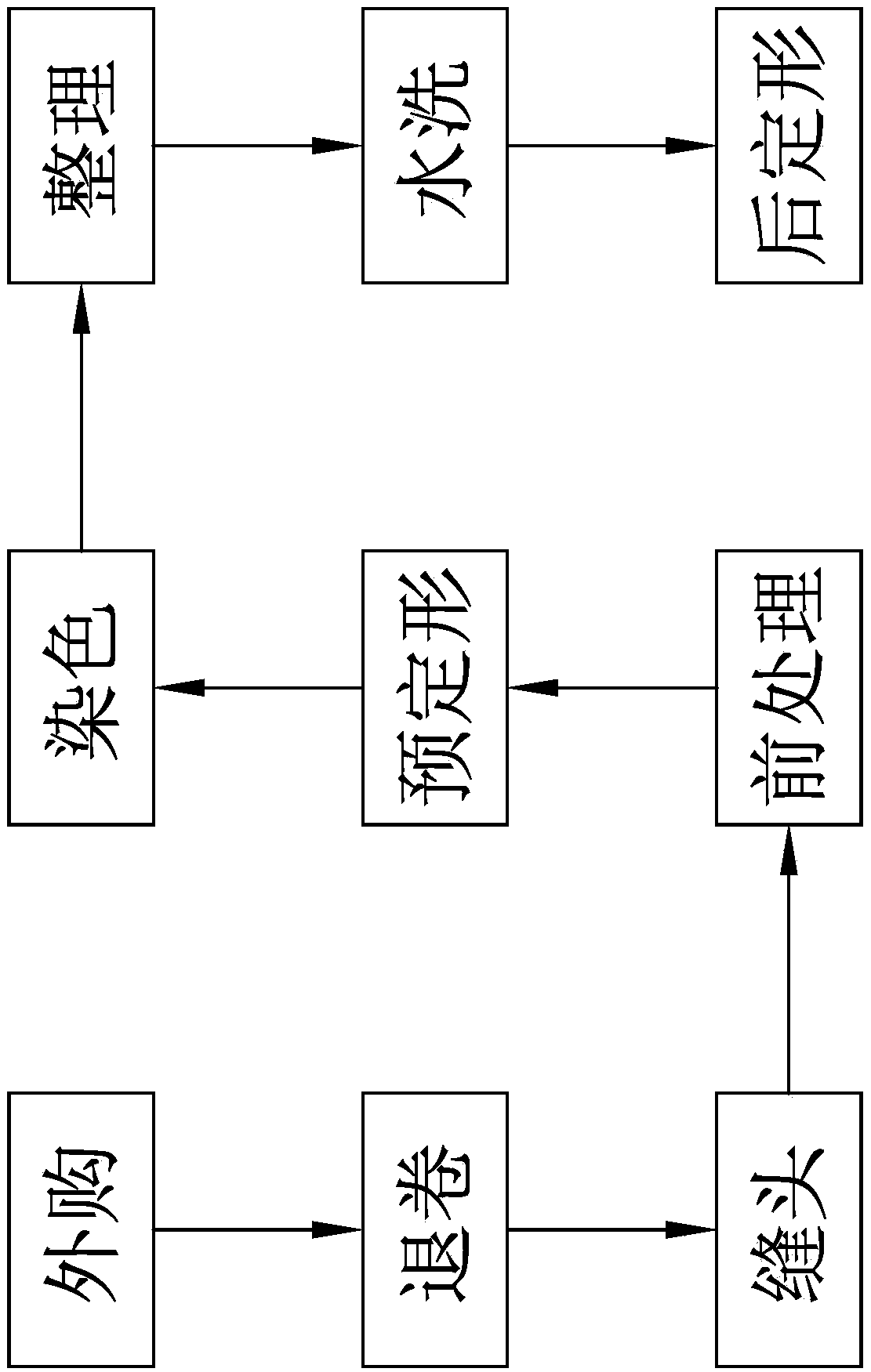

Process for dyeing and finishing swimsuit fabrics

ActiveCN109457504AAvoid harmGood job stabilitySucessive textile treatmentsLiquid/gas/vapor treatment machines driving mechanismsDyeingEngineering

The invention provides a process for dyeing and finishing swimsuit fabrics. By the aid of the process, the technical problems of deficiency of corresponding processes for dyeing and finishing existingswimsuit fabrics, tedious operation and the like can be solved. The process for dyeing and finishing the swimsuit fabrics includes steps of a, carrying out outsourcing, and to be more specific, purchasing existing warp-knitted fabrics on markets; b, carrying out unwinding, to be more specific, placing the warp-knitted fabrics on unwinding machines and unwinding the warp-knitted fabrics; c, carrying out sewing, and to be more specific, carrying out sewing connection on multiple rolls of warp-knitted fabrics by sewing machines; d, carrying out pretreatment; e, carrying out presetting on the warp-knitted fabrics by setting machines; f, carrying out dyeing, to be more specific, placing the warp-knitted fabrics in dyeing devices, dyeing the warp-knitted fabrics and then drying the warp-knittedfabrics by drying ovens; g, carrying out finishing, to be more specific, carrying out padding on the warp-knitted fabrics in finishing agents by padding equipment and then drying the warp-knitted fabrics by drying ovens; h, carrying out washing, to be more specific, placing the warp-knitted fabrics in washing machines and washing the warp-knitted fabrics; i, carrying out post-setting on the warp-knitted fabrics by setting machines to obtain the swimsuit fabrics which are finished products. The process has the advantages of simplicity and convenience.

Owner:浙江华昌新材料股份有限公司

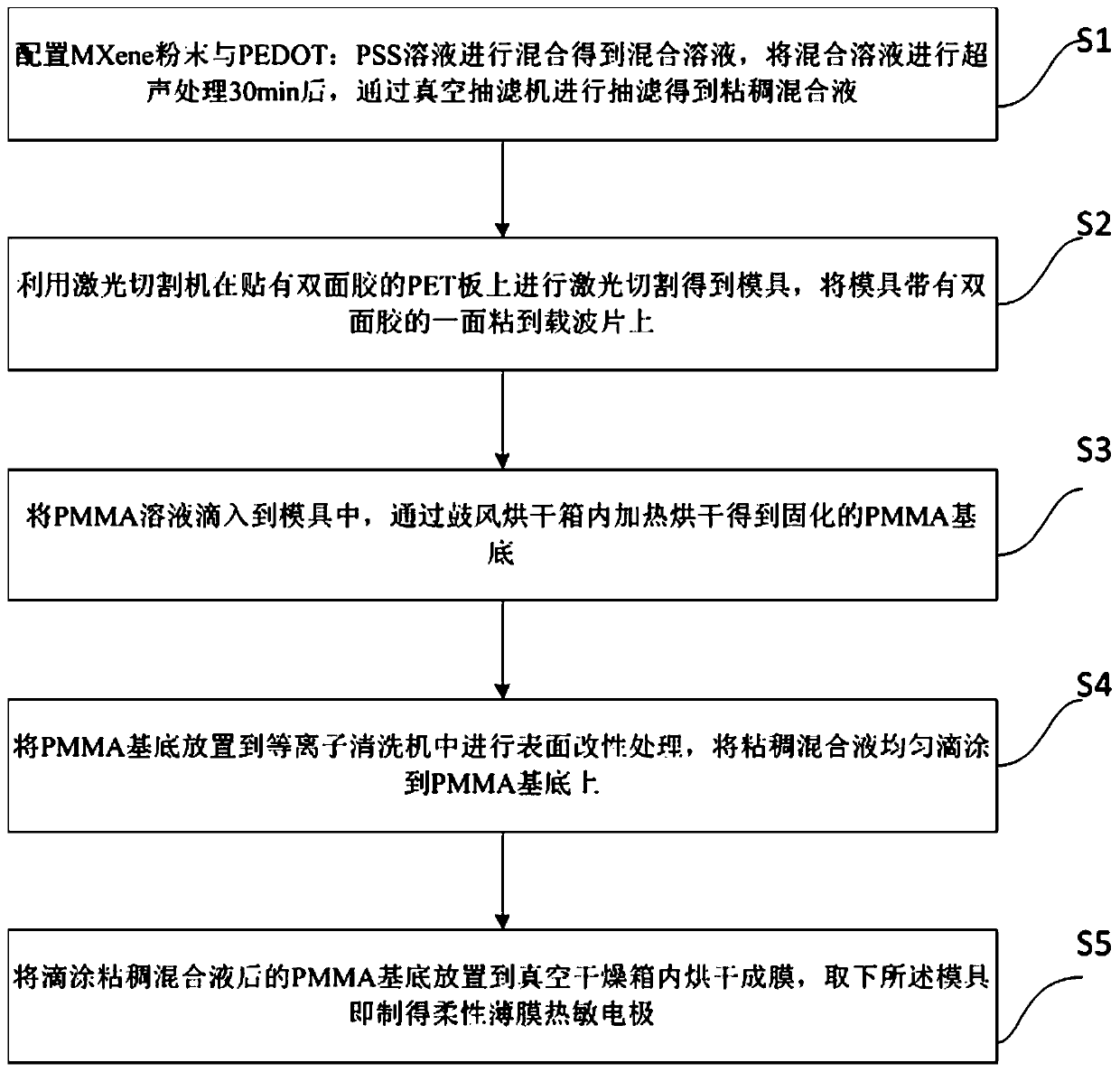

Flexible film thermosensitive electrode with negative temperature coefficient and manufacturing method thereof

InactiveCN111473882AGood job stabilityHigh sensitivityThermometers using electric/magnetic elementsUsing electrical meansThin membraneSurface modification

The invention discloses a flexible thin film thermosensitive electrode with a negative temperature coefficient and a manufacturing method thereof. The manufacturing method includes: preparing and mixing MXene powder and a PEDOT:PSS solution to obtain a mixed solution, the mixed solution being subjected to ultrasonic treatment for 30 min and then subjected to suction filtration through a vacuum suction filter, and obtaining a viscous mixed solution; carrying out laser cutting on the PET plate pasted with the double-sided adhesive tape by using a laser cutting machine to obtain a mold, and pasting one surface, with the double-sided adhesive tape, of the mold on a glass slide; dropwise adding the PMMA solution into a mold, and heating and drying the PMMA solution in a blast drying oven to obtain a cured PMMA substrate; putting the PMMA substrate into a plasma cleaning machine for surface modification treatment, and uniformly dispensing the viscous mixed solution onto the PMMA substrate; and putting the PMMA substrate coated with the viscous mixed solution into a vacuum drying box, drying to form a film, and taking down the mold to obtain the flexible film thermosensitive electrode.

Owner:SUN YAT SEN UNIV

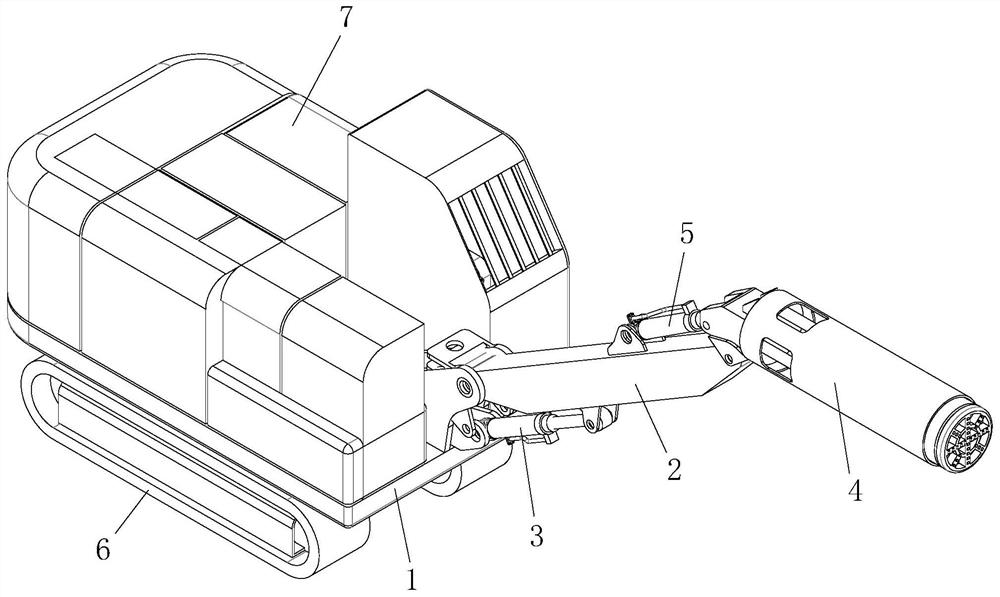

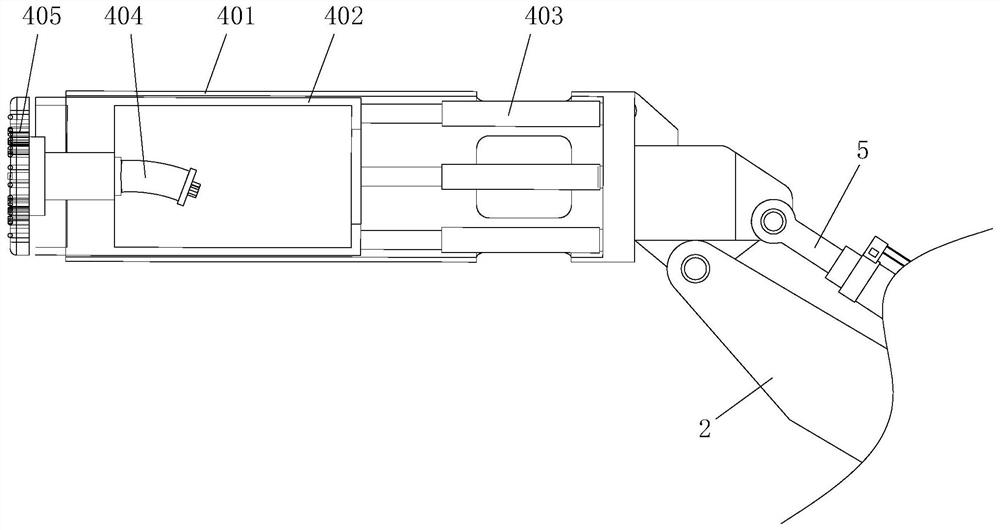

Hydraulic milling and drilling machine and working method thereof

PendingCN112502727AGood job stabilityPowerfulConstructionsDerricks/mastsDrilling machinesThermodynamics

The invention discloses a hydraulic milling and drilling machine and a working method thereof. The hydraulic milling and drilling machine comprises a movable machine body and further comprises a largearm, a swing arm oil cylinder, a milling and drilling assembly and a posture adjusting oil cylinder, the large arm is rotatably connected to the front end of the machine body, the bottom end of the swing arm oil cylinder is rotatably connected with the machine body, the output end of the swing arm oil cylinder is rotatably connected with the large arm, the milling and drilling assembly is rotatably connected to the front end of the large arm, the bottom end of the posture adjusting oil cylinder is rotatably connected with the large arm, and the output end of the posture adjusting oil cylinderis rotatably connected with the milling and drilling assembly. The milling and drilling machine is good in working stability during milling and drilling, is hydraulically driven, is strong in power and high in milling and drilling efficiency, can be suitable for crushing, milling and drilling large-volume rocks, and is low in construction cost and good in construction environment.

Owner:安徽铁创新材料科技有限公司 +1

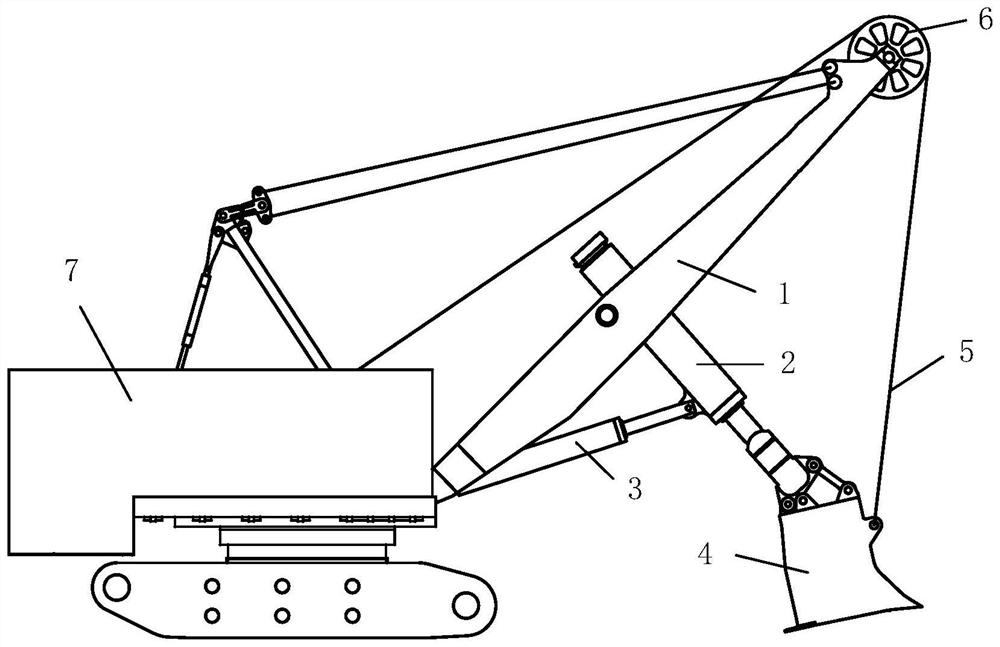

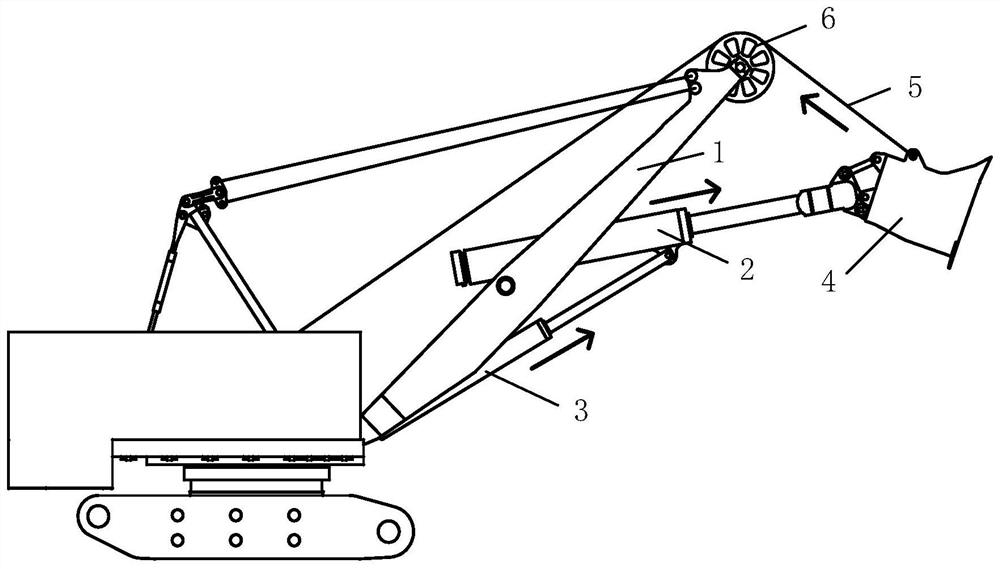

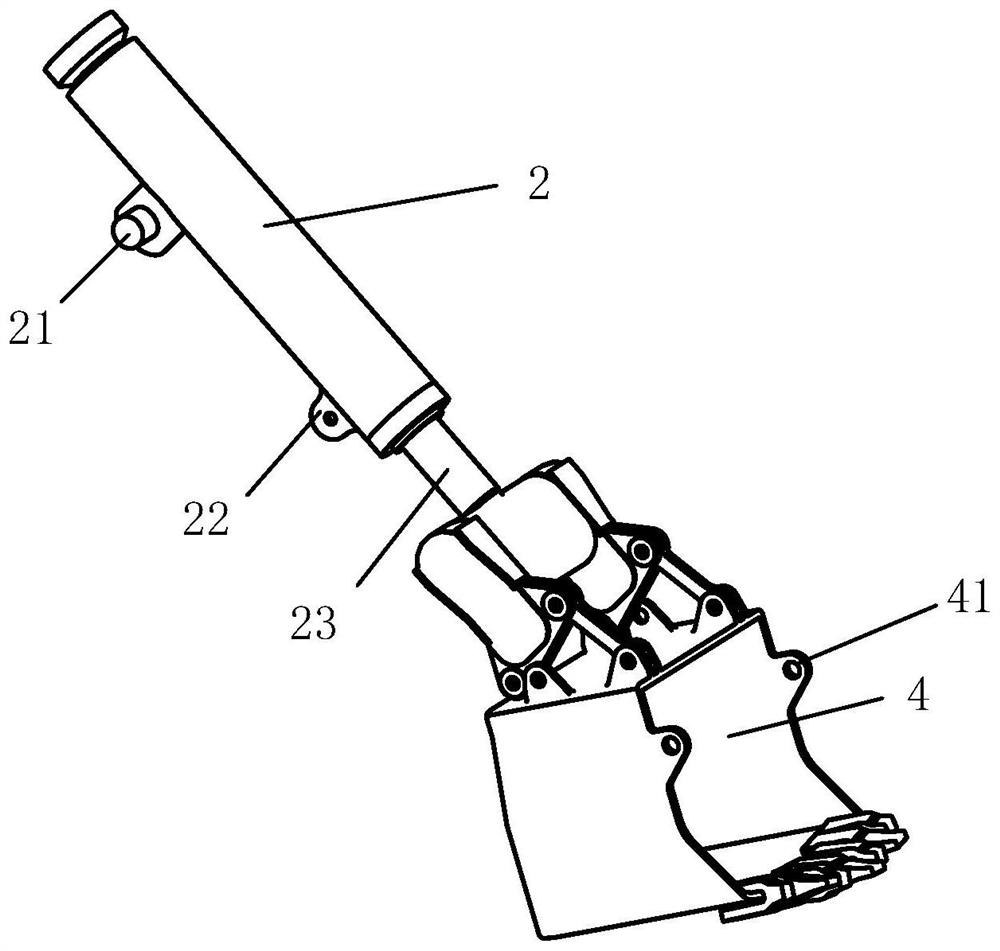

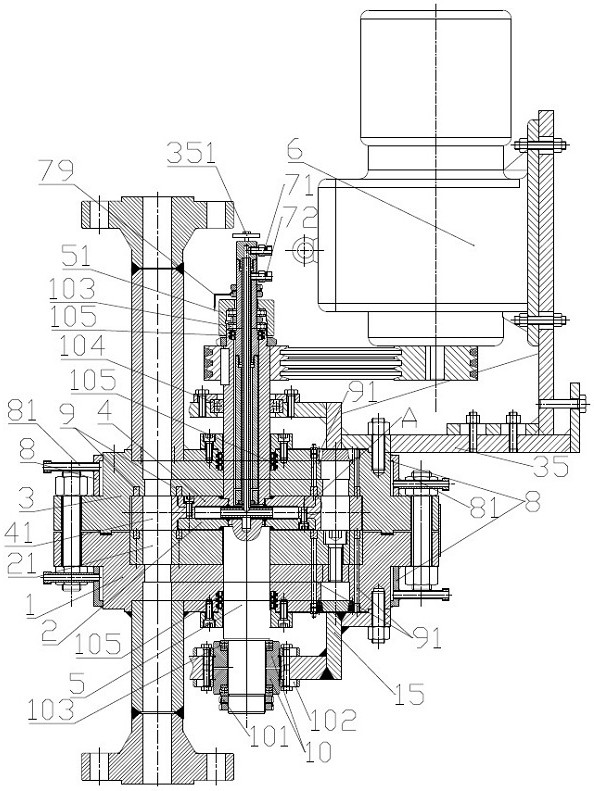

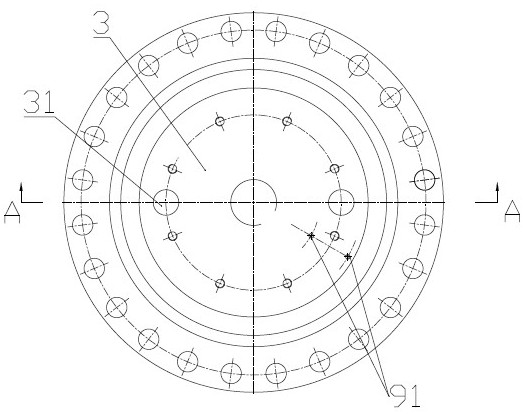

Mining electric shovel working device for electrohydraulic auxiliary operation motion

InactiveCN111962587AImprove stressGood job stabilityMechanical machines/dredgersHydraulic cylinderControl engineering

The invention provides a mining electric shovel working device for electrohydraulic auxiliary operation motion, which belongs to the technical field of mining engineering machinery and aims to solve the problems that energy loss of an existing electric shovel working device is severe, and a lifting force utilization rate of a lifting steel wire rope is low. The mining electric shovel working device is mounted on an electric shovel body with a winding device, and is characterized by comprising a movable arm, a shovel loader, a bucket rod hydraulic rod and an auxiliary hydraulic cylinder. According to the design in the invention, an auxiliary hydraulic cylinder is additionally arranged to assist the bucket rod to lift, so that a steel wire rope stress condition is improved while the bucket rod is too high or too low, lifting force moment and digging force of the bucket rod hydraulic cylinder are improved; the auxiliary hydraulic cylinder can be used for recycling gravitational potentialenergy of the working device, so that energy waste is reduced; and the hydraulic cylinder is taken as a power source to control the bucket rod to extend out and draw back, so that push force of a pushmechanism is increased, and operation stability of the mechanism is improved.

Owner:BEIHANG UNIV

Quick opening mechanism of quick opening high-temperature spherical sealing stop valve

ActiveCN112361025AGood job stabilityGood effect of pressure relief and diversionSpindle sealingsValve members for heating/coolingPhysicsEngineering

The invention discloses a quick opening mechanism of a quick opening high-temperature spherical sealing stop valve, and relates to the field of valves. The quick opening mechanism comprises a valve body, a valve base, a valve cover, a valve clack, a valve rod and a driving device for driving the valve rod to rotate, wherein the valve rod and the valve clack are coaxially arranged and fixedly connected; the valve body and the valve cover are provided with exhaust channels for circulating gas; the valve clack and the valve base are positioned on paths of the exhaust channels; the valve base is fixedly mounted in the valve body, and is provided with a first through hole communicated with the exhaust channels; the valve clack is provided with a second through hole corresponding to the first through hole; and the exhaust channels have three states of opening when the first through hole is overlapped with the second through hole during rotating of the valve clack, half opening when part of the first through hole is overlapped with the second through hole and closing when the first through hole is not overlapped with the second through hole. The quick opening mechanism has the advantage of good pressure relief and shunting effects.

Owner:ZHEJIANG PETROCHEMICAL VALVE CO LTD

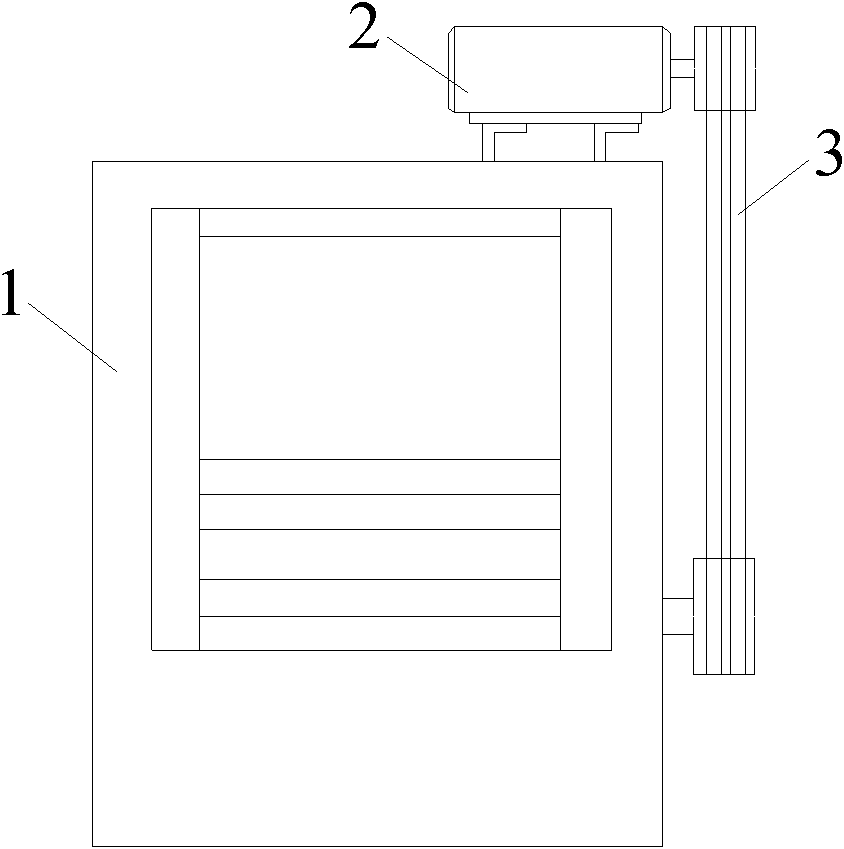

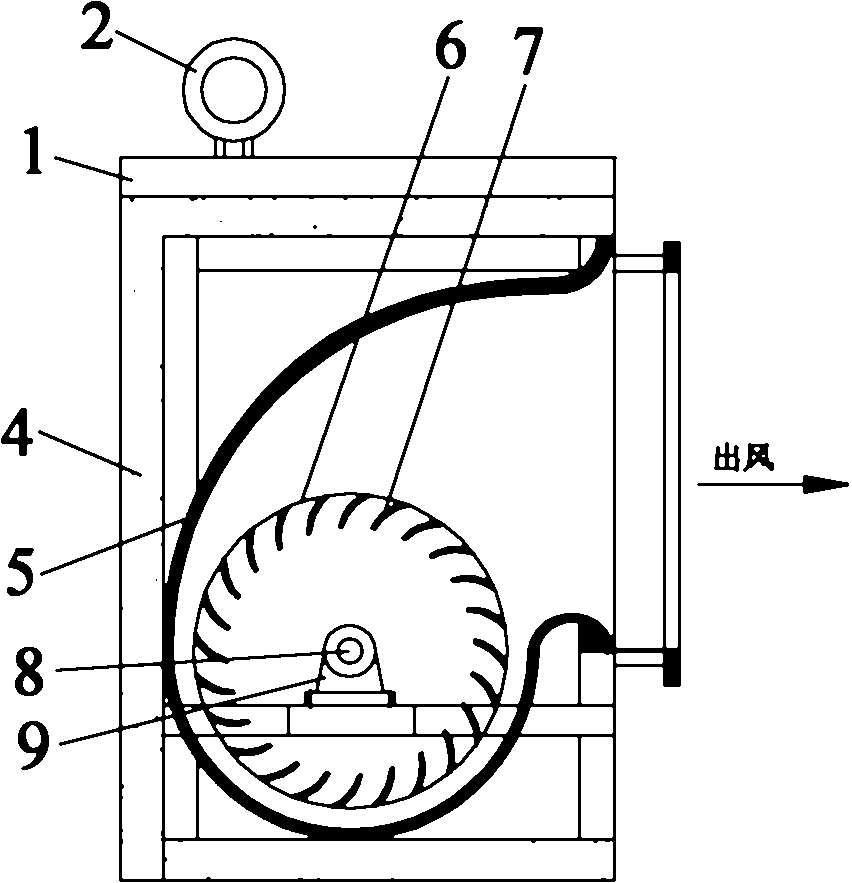

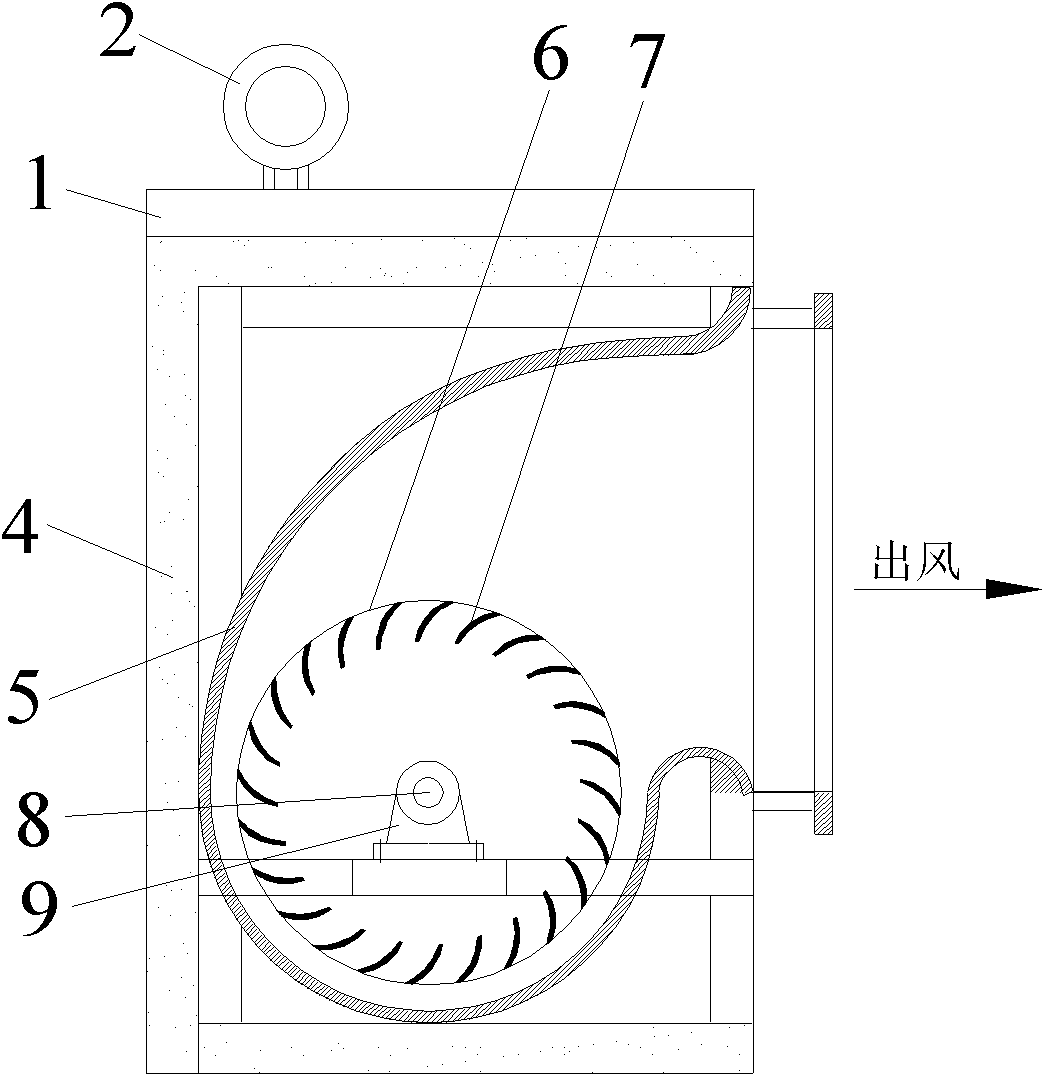

Fire-fighting centrifugal fan

The invention discloses a fire-fighting centrifugal fan, which comprises a box body with an air inlet and an air outlet, wherein a scroll case is arranged in the box body; a motor is fixedly arranged on the box body; the motor drives an impeller in the scroll case to rotate by a triangle belt; impeller blades are distributed on the inner circumference of the impeller uniformly; the box body has a duplex plate structure; and a heat-insulating layer is arranged in a duplex plate. The fire-fighting centrifugal fan has high operating stability, and can run continuously at the high temperature of 300 DEG C for over 60 minutes.

Owner:黄山市大华消防空调设备有限公司

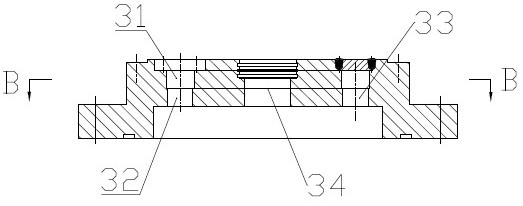

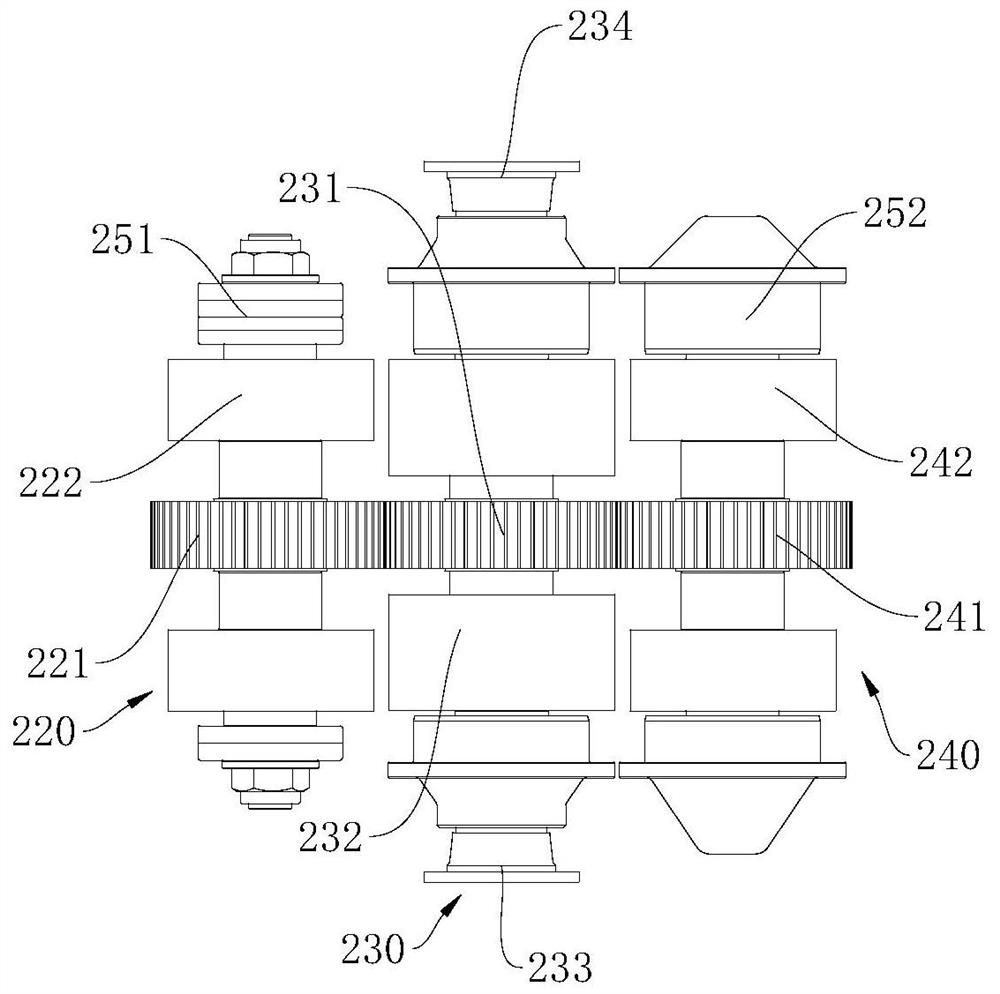

Multi-point supporting weighing mechanism

InactiveCN106644001AGood job stabilityReduce vibrationWeighing apparatus with automatic feed/dischargeEngineeringMulti point

Owner:M & J MACHINERY ENGINEER

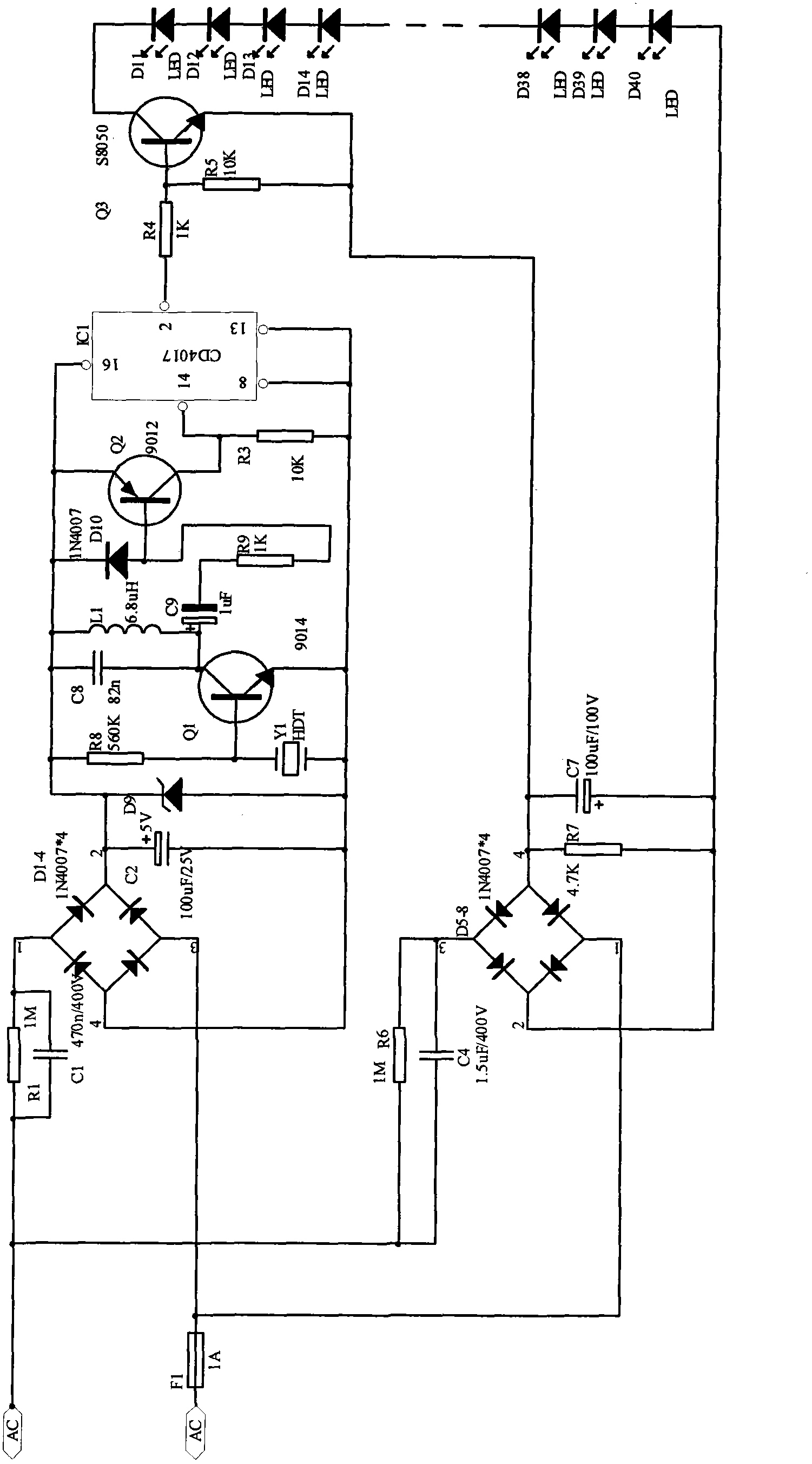

Sub-ultrasonic voice energy-saving lamp

InactiveCN103228081AGood job stabilityLow energy consumptionElectric light circuit arrangementTelecommunicationsRadiation

The invention discloses a sub-ultrasonic voice energy-saving lamp which consists of a lighting circuit and a voice sub-ultrasonic control circuit. No switch is required for control; a sub-ultrasonic air bag and voice freely control switching of LEDs (Light Emitting Diodes) within 5m; and the sub-ultrasonic voice energy-saving lamp has the advantages of good working stability, low energy consumption, long service life, low cost, no radiation, and the like.

Owner:TIANCHANG JINLING ELECTRONICS

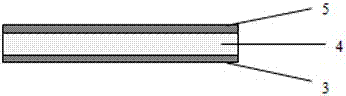

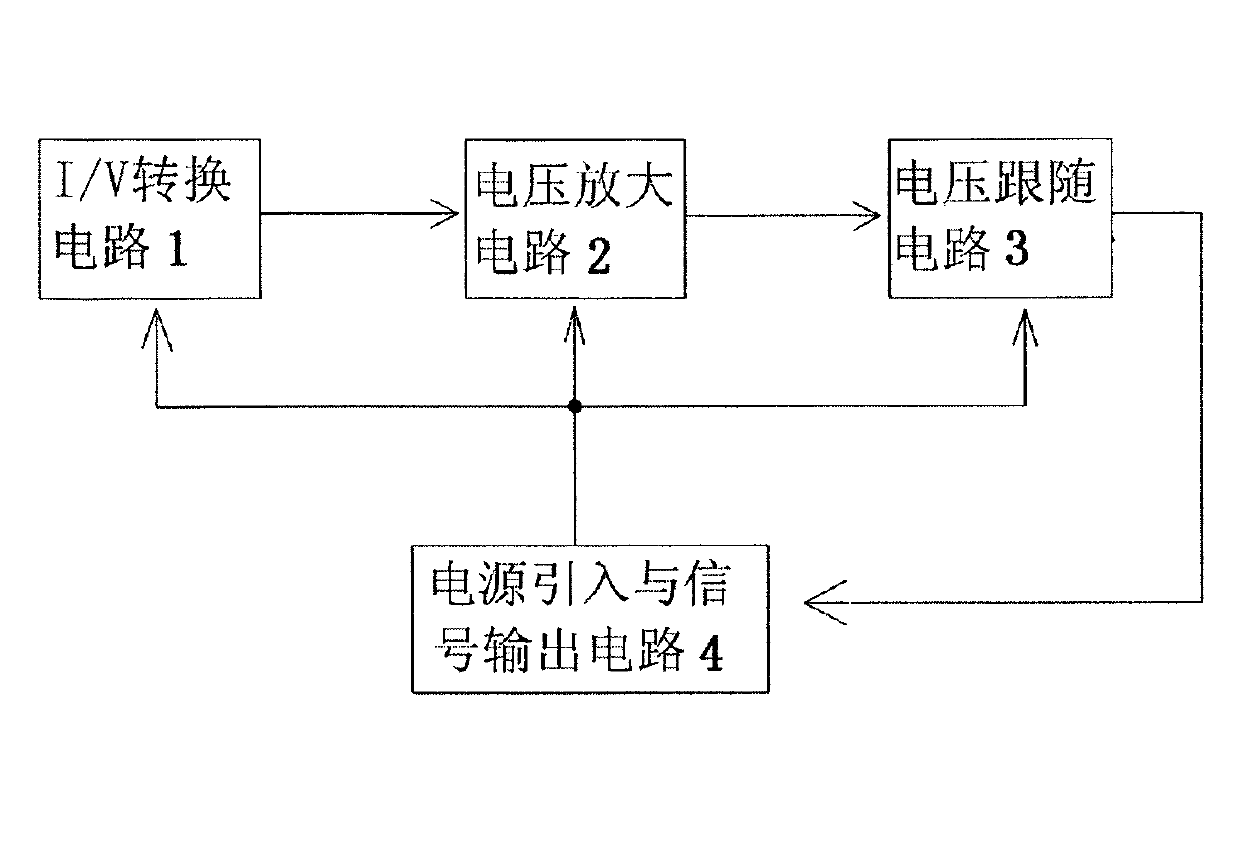

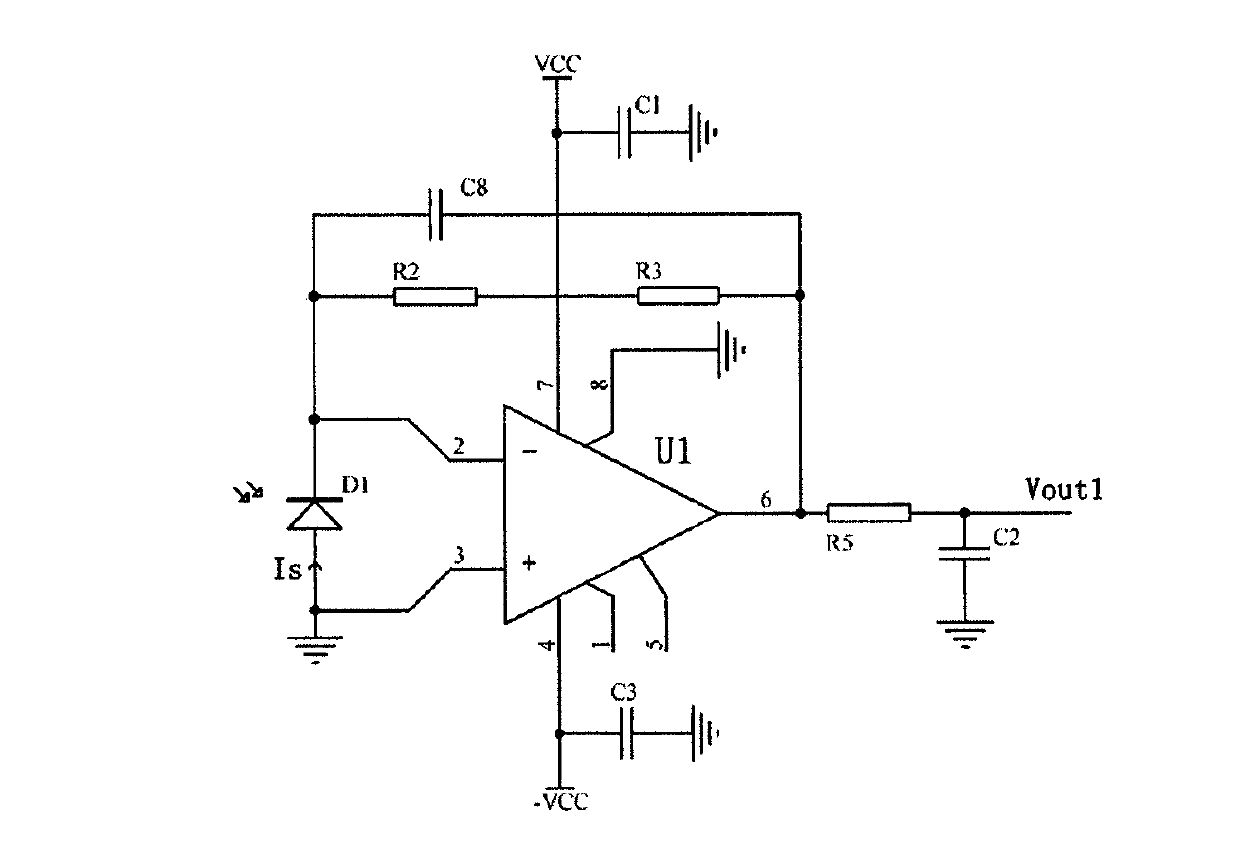

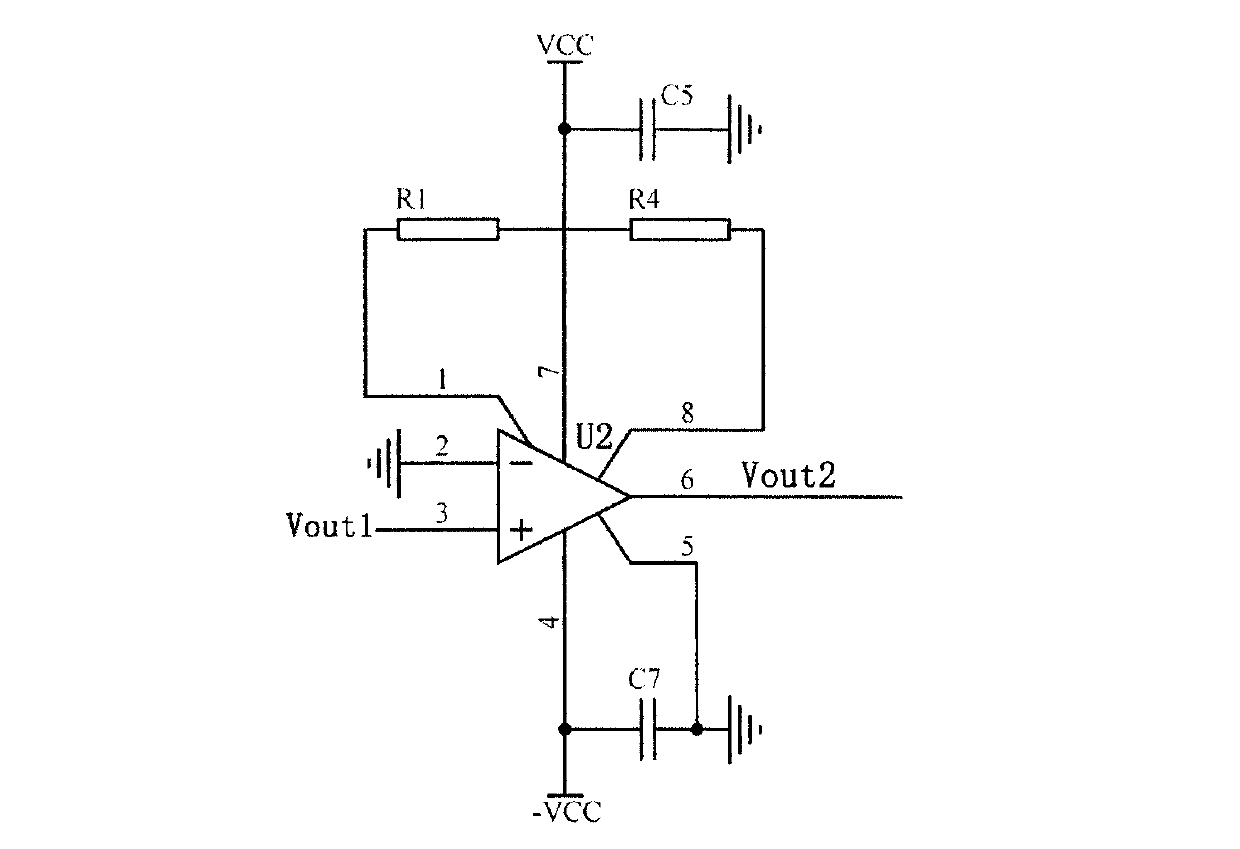

Optoelectronic signal acquisition and conversion device for optical sensor used for detecting dust concentration

InactiveCN102854154AGood job stabilityStrong anti-interference abilityColor/spectral properties measurementsPhysicsAnti jamming

The invention provides an optoelectronic signal acquisition and conversion device for an optical sensor used for detecting dust concentration, which belongs to the technical field of measuring electronics. The optoelectronic signal acquisition and conversion device comprises an I / V conversion circuit, a voltage amplifier circuit, a voltage follower circuit and a power lead-in and signal output circuit, wherein the output terminal of the power lead-in and signal output circuit is connected with the I / V conversion circuit, the voltage amplifier circuit and the voltage follower circuit, the output terminal of the I / V conversion circuit is connected with the voltage amplifier circuit, the output terminal of the voltage amplifier circuit is connected with the voltage follower circuit, the output terminal of the voltage follower circuit is connected with the power lead-in and signal output circuit, and the voltage follower circuit comprises capacitors C4 and C6, a resistor R6 and a bipolar operational amplifier U3. The optoelectronic signal acquisition and conversion device has the advantages of good working stability, strong anti-interference ability, accurate acquisition data, etc.

Owner:常熟市德虞矿山机电有限公司

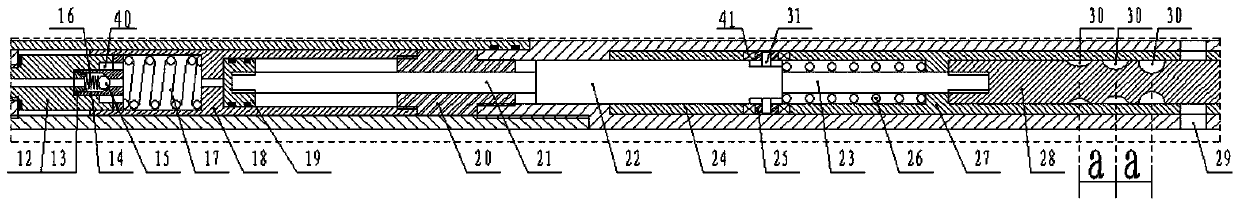

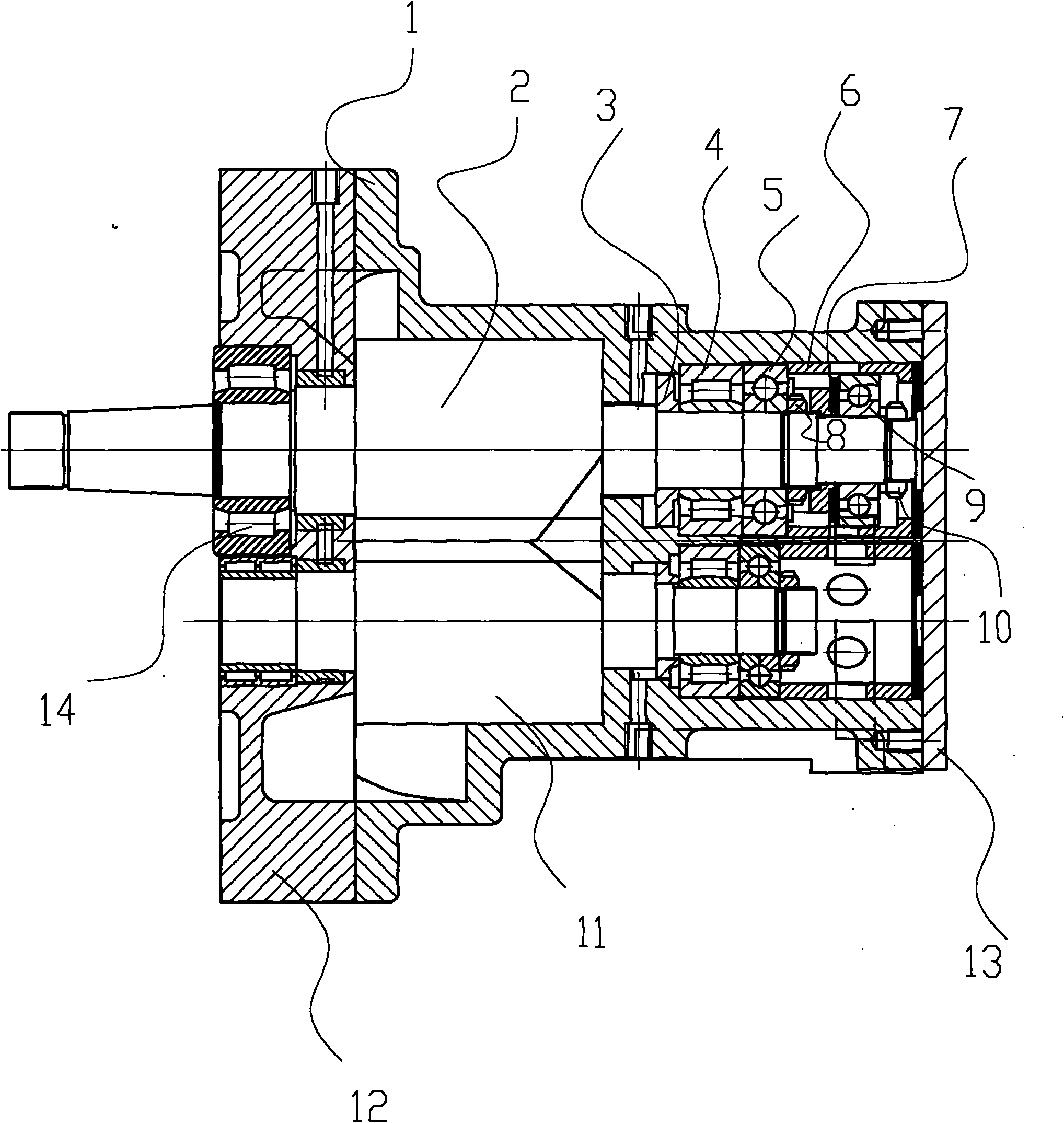

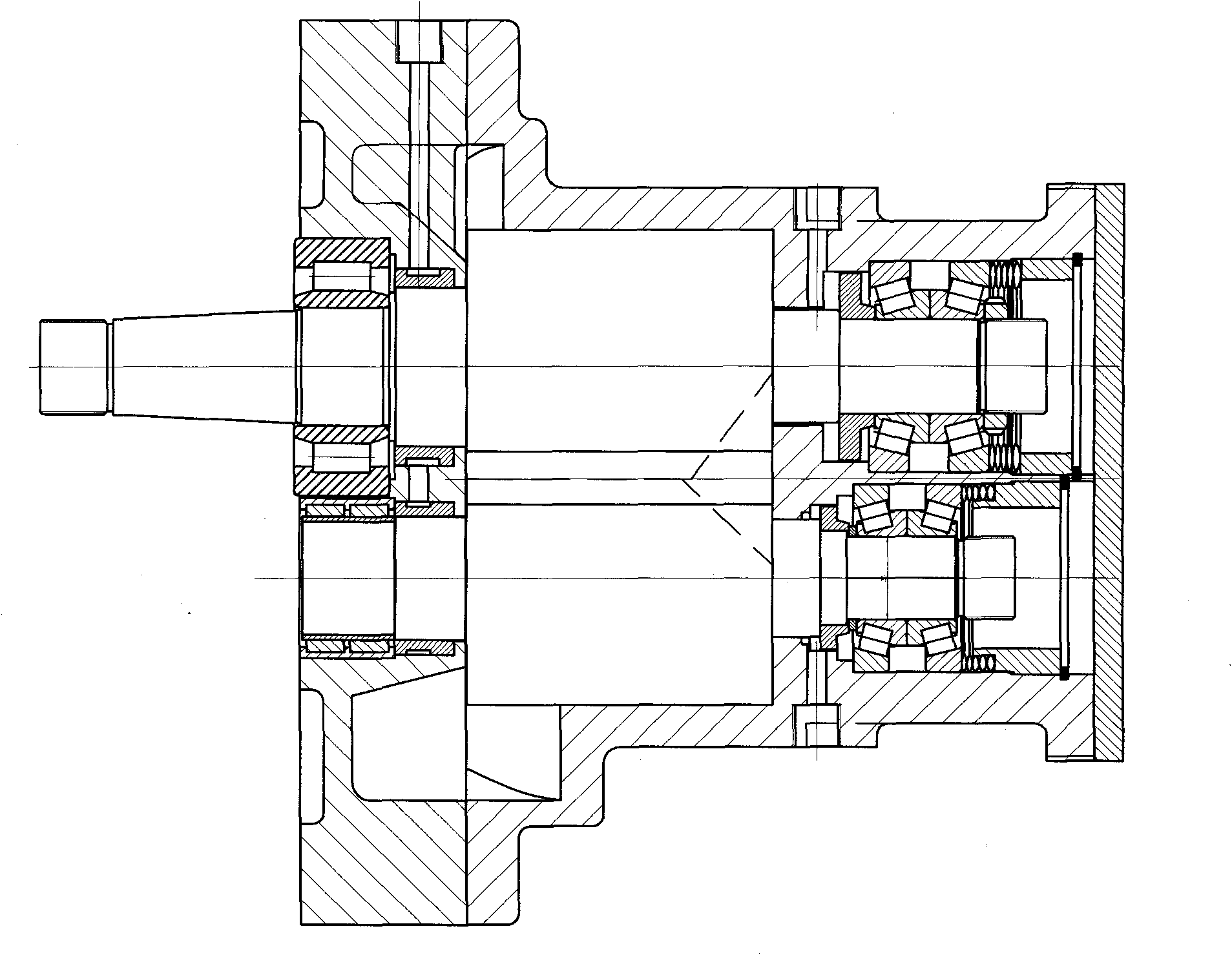

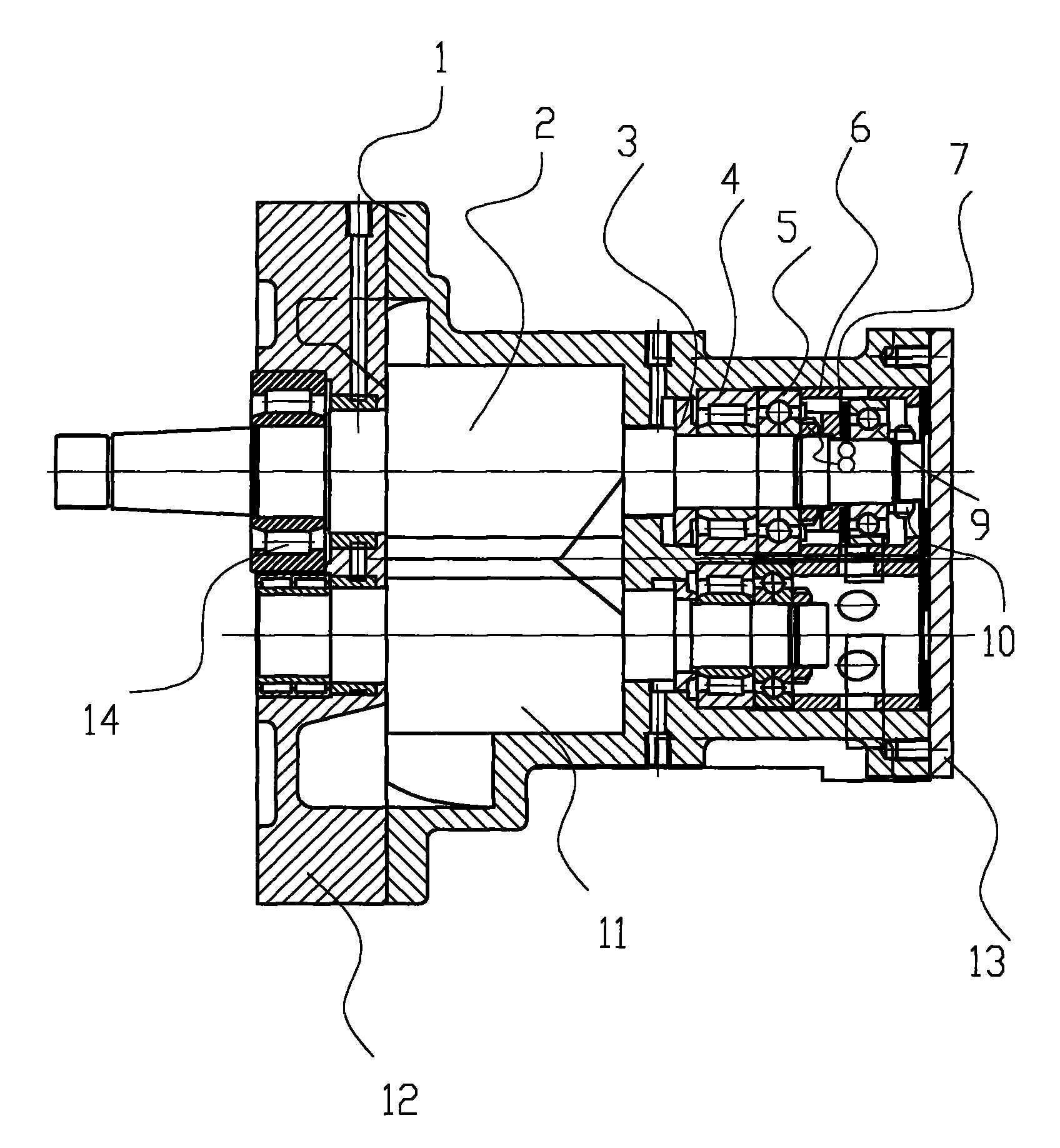

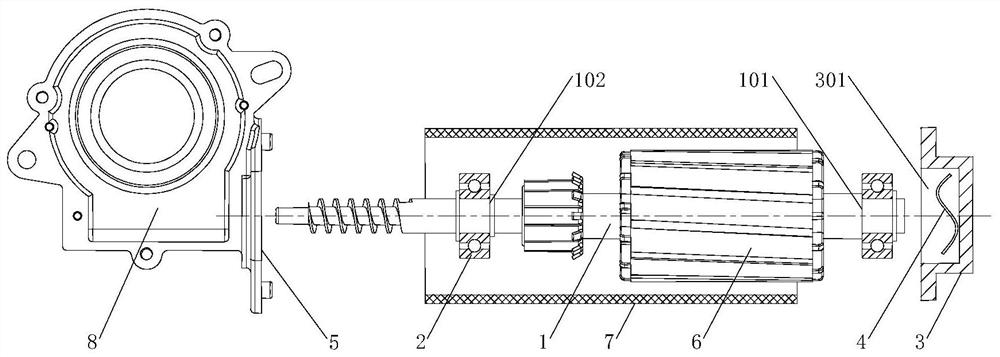

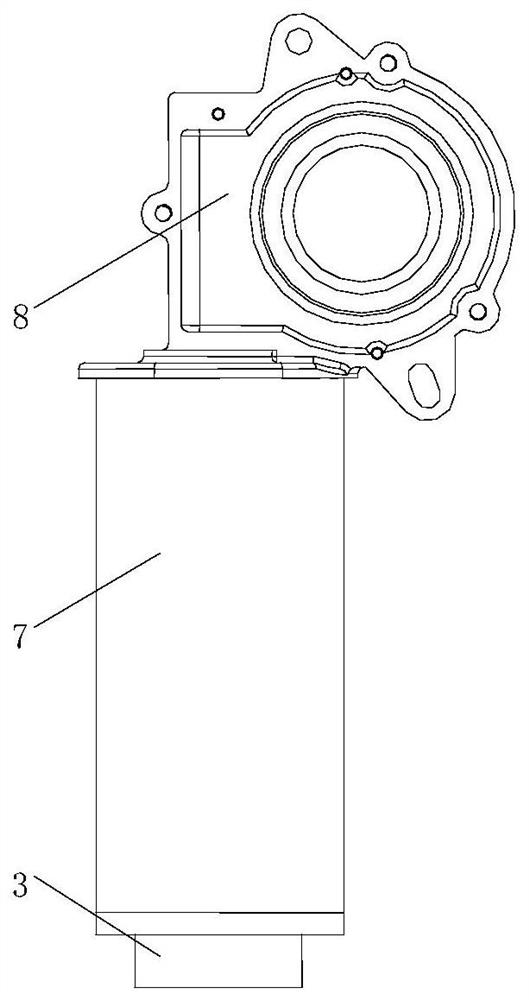

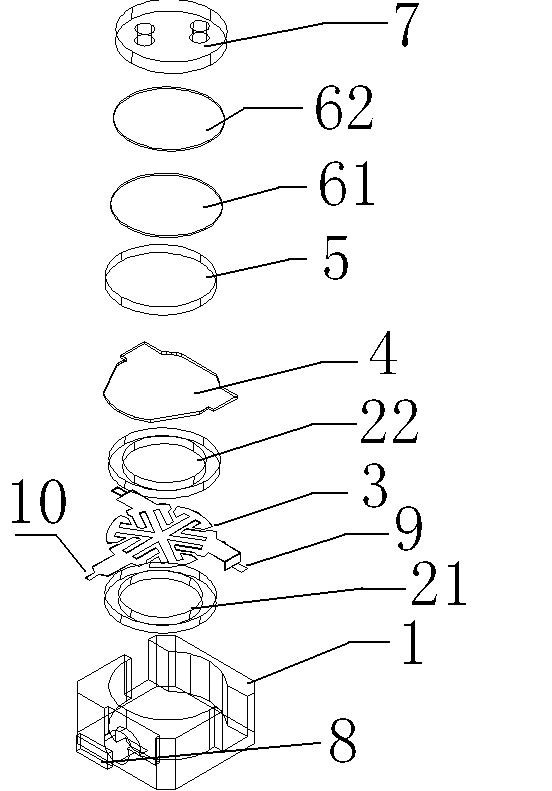

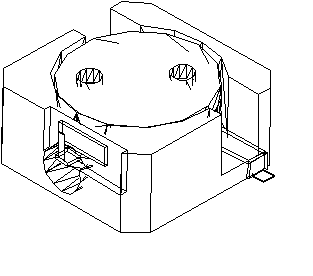

Spindle bearing device of rotary screw rod compressor

ActiveCN101776080AHigh running precisionGood job stabilityRotary/oscillating piston pump componentsLiquid fuel engine componentsStructural rigidityBearing surface

The invention relates to a spindle bearing device of a rotary screw rod compressor, which comprises a shell and a pair of rotors which are mutually meshed, wherein one rotor forms a spindle, and the rear end thereof is provided with two journal bearing surfaces with different diameters, wherein a heavy radial roller bearing and a four-point contact ball bearing are sequentially lined and deployed on the large-diameter journal bearing surface and the outer diameters thereof are fixed on a shell supporting hole, and an angle contact ball bearing is deployed on the small-diameter journal bearing surface; the outer side of the outer diameter of the four-point contact ball bearing is provided with an isolation cover; the outer side of the isolation cover is provided with a butterfly spring; the angle contact ball bearing is arranged on the outer side of the butterfly spring, and is connected with the spindle of the screw rod compressor through a second set nut; the device has the advantages of good structural rigidity and motion rigidity, higher radial and axial integrated bearing capability, and good work stability; and secondly, the operation efficiency is higher, and the operation precision and the service life can be significantly improved.

Owner:NINGBO BAOSI ENERGY EQUIP

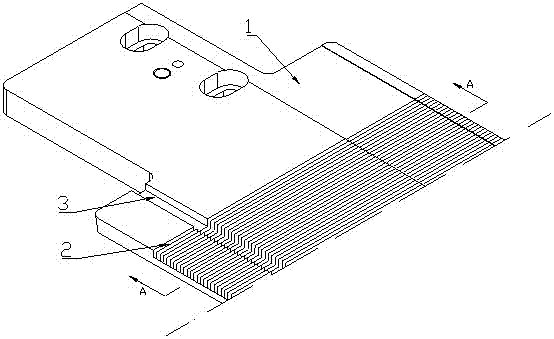

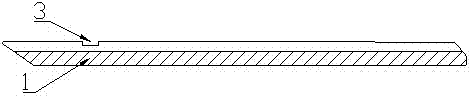

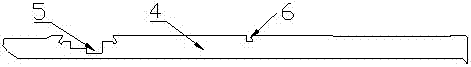

Needle plate with insertion sheets for computerized flat knitting machines

The invention discloses a needle plate with insertion sheets for computerized flat knitting machines. The needle plate comprises a parent plate and the insertion sheets. Insertion grooves which are parallel to one another are formed in the parent plate, the insertion sheets are embedded in the insertion grooves, and needle grooves are formed in positions between the insertion sheets. The needle plate has the advantages that the needle plate is good in work stability and further can be repaired, the cost can be saved, and phenomena of broken yarns, flying threads and uneven cloth surfaces can be reduced.

Owner:ZHONGSHAN LONGZU AUTOMATION TECH CO LTD

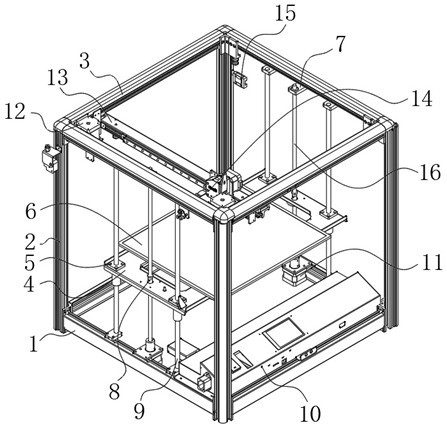

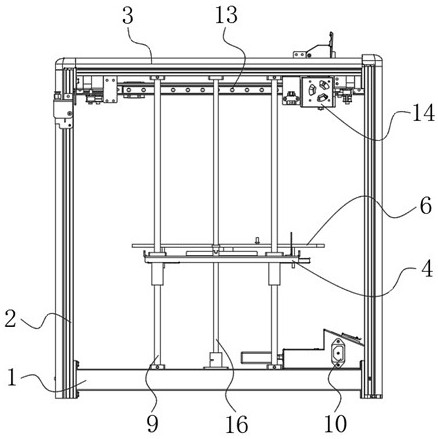

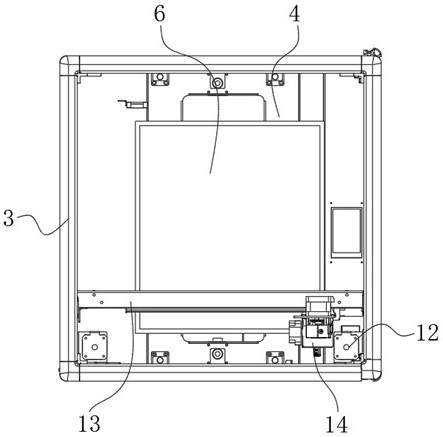

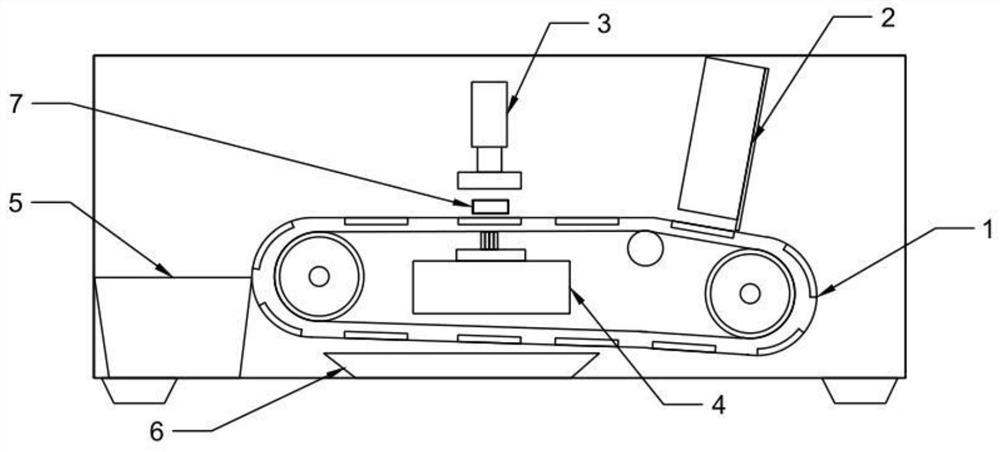

Novel 3D printer

InactiveCN111823585AImprove printing efficiencyGood job stabilityAdditive manufacturing apparatus3D object support structuresStructural engineeringElectrical and Electronics engineering

The invention discloses a novel 3D printer. The novel 3D printer comprises a lower frame, wherein an upper frame is fixed on the periphery of the top of the lower frame through vertical rods, an electric cabinet is mounted on one side of the top of the lower frame, first reciprocating lead screws are rotatably connected to the centers of the adjacent sides of the lower frame and the upper frame through positioning seats, a first servo motor which is in driving connection with each first reciprocating lead screw is mounted at the bottom of the corresponding positioning seat, each first reciprocating lead screw is connected with a reciprocating sliding seat in a meshing mode, the reciprocating sliding seats are symmetrically arranged on two corresponding sides of a lifting frame, a forming plate is arranged at the center of the top of the lifting frame, and X-axis driving assemblies are arranged on the two corresponding sides of the bottom of the upper frame. The novel 3D printer is novel in structure and ingenious in concept, the forming plate gradually moves downwards under the action of the first reciprocating lead screws in the 3D printing process, the layer-by-layer forming of printed articles is facilitated, the printing efficiency is high, the working stability is good, and the quality of the formed products is good.

Owner:浙江飞熊智能科技有限公司

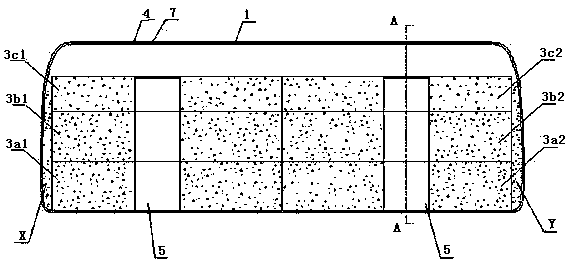

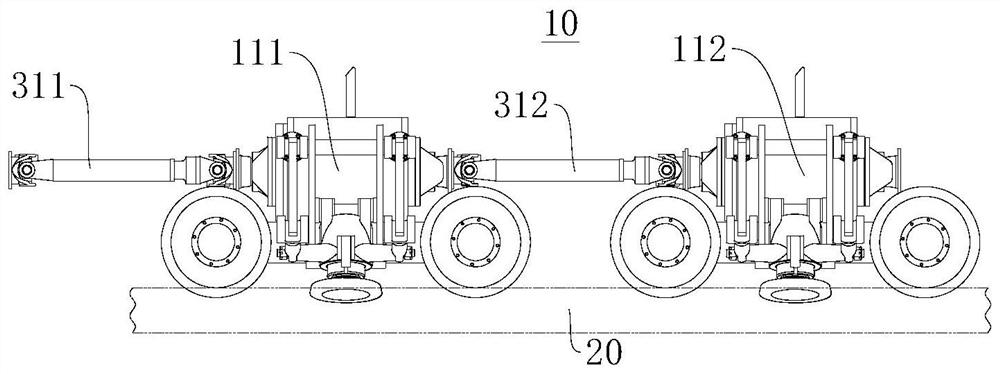

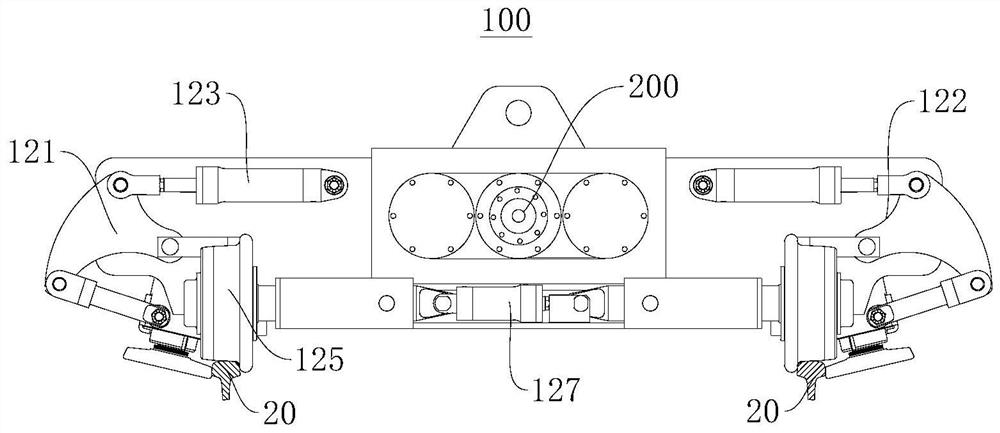

Vibration exciter, stabilizing device, stabilizing equipment and track maintenance vehicle

The embodiment of the invention provides a vibration exciter, a stabilizing device, stabilizing equipment and a track maintenance vehicle, and relates to the technical field of equipment for track maintenance. The vibration exciter provided by the embodiment of the invention comprises a first vibration excitation shaft, a second vibration excitation shaft and a third vibration excitation shaft which are in transmission connection and are arranged in parallel. The first vibration excitation shaft is provided with a first eccentric block, the second vibration excitation shaft is provided with a second eccentric block, the third vibration excitation shaft is provided with a third eccentric block, when the vibration exciter is used, the whole vibration exciter only generates horizontal vibration excitation force through the first eccentric block, the second eccentric block and the third eccentric block, the horizontal vibration excitation force acts on a steel rail, and the stability of the rail is improved. The plane formed by the axes of two of the first vibration excitation shaft, the second vibration excitation shaft and the third vibration excitation shaft is obliquely arranged relative to the vertical plane, and compared with the height of an existing vertically-distributed three-shaft type vibration exciter, the height of the vibration exciter is effectively reduced, namely, the gravity center of the vibration exciter is reduced, and then the stability effect and the stability during operation can be improved.

Owner:CHANGZHOU RUITAI ENG MASCH CO LTD +1

Driving differential-velocity counter-rotating no-tillage anti-blocking device

ActiveCN107182319APrevents tangling and cloggingGood job stabilitySpadesPloughsPloughPower transmission

The invention provides a driving differential-velocity counter-rotating no-tillage anti-blocking device with excellent capabilities of weeding and preventing winding, and a great anti-blocking effect. The device includes a rack, a deceleration box, a power transmission assembly and a plurality of furrow opener assemblies, wherein each furrow opener assembly comprises a furrow opener poling arranged on the rack and a furrow opener blade plough installed on the furrow opener poling; each furrow opener assembly is provided with a differential-velocity counter-rotating anti-blocking assembly which is composed of a differential-velocity transmission unit and two weeding wheels; each weeding whee is provided with a plurality of weeding rods; the weeding rods of the two weeding wheels are mutually arranged in spatial crossing mode; the two weeding wheels are axially parallel to each other and disposed on the furrow opener polings; the input end of the differential-velocity transmission unit is connected to the power transmission assembly, and the output end of the power transmission assembly is connected to the two weeding wheels separately for driving the two weeding wheels to rotate reversely.

Owner:SHANDONG ACADEMY OF AGRI MACHINERY SCI

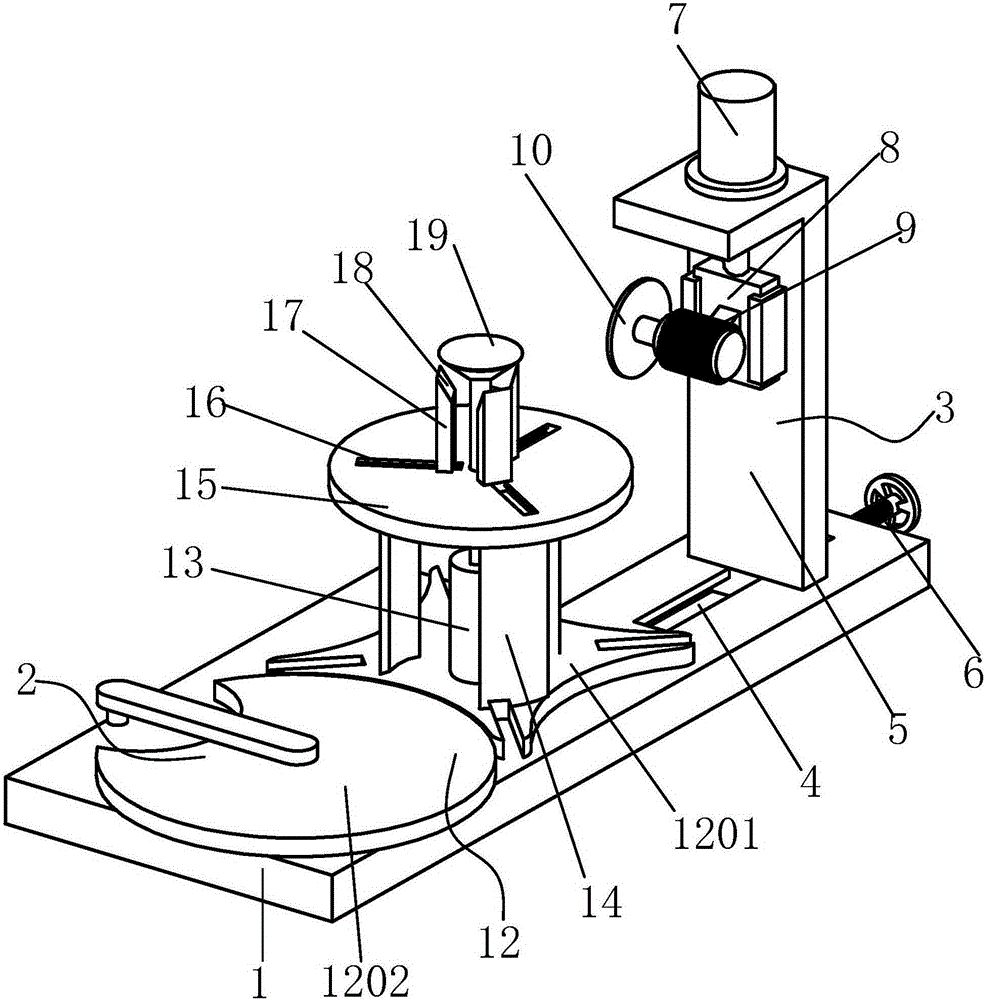

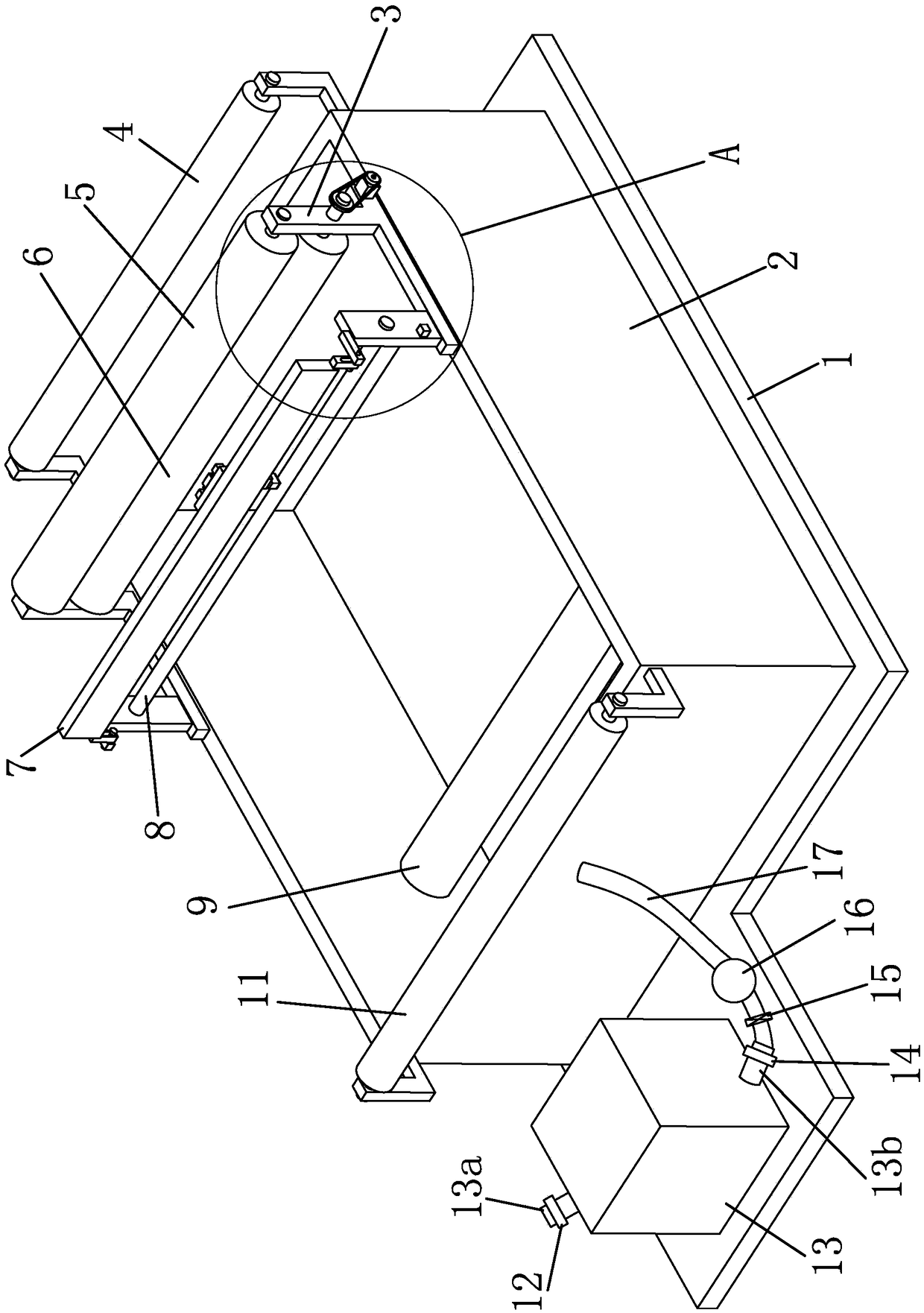

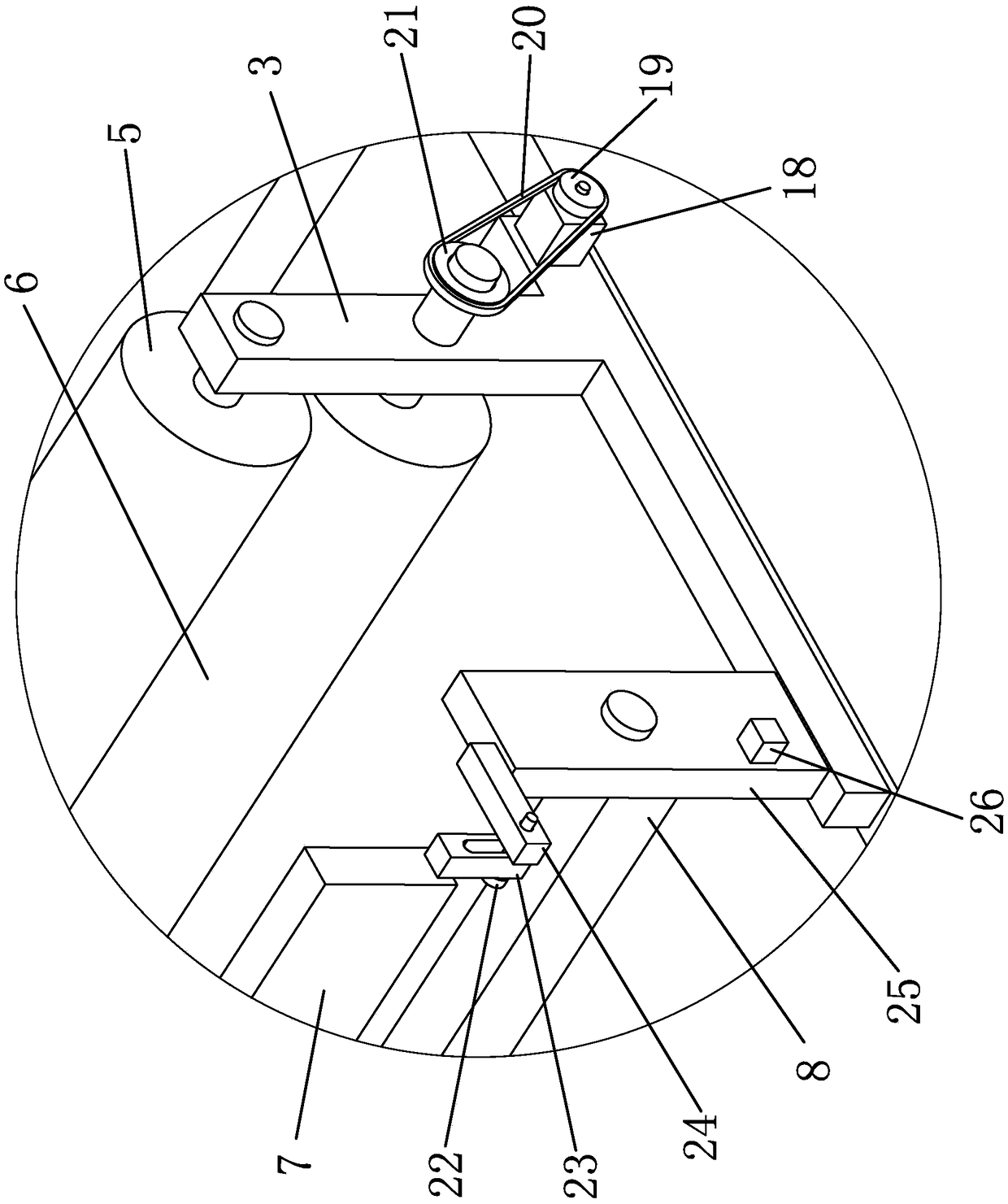

Automatic quick suction manipulator

The invention discloses an automatic quick suction manipulator which comprises suction pipes (12) and a suction pipe base (11). The suction pipe base (11) is connected with a power transmission assembly by a turntable (9), a rotary shaft (10) is arranged in the suction pipe base (11), a rotary shaft gear (7) is arranged at an inner end of the rotary shaft (10) and is connected with a fixed gear (6) by a transition gear (8), the transition gear (8) is arranged on the turntable (9), the fixed gear (6) is arranged on an eccentric shaft (16) of the power transmission assembly, and the eccentric shaft (16) is connected with the turntable (9). The automatic quick suction manipulator has the advantages that the automatic quick suction manipulator is excellent in work stability, low in noise, high in plate fetching conveying speed, convenient to operate, feasible in operation and simple and practical in structure, and the plate turn sequence outputting speeds can be increased.

Owner:WENZHOU XIAOJIANG MACHINERY TECH

Batch detection equipment for SIM cards

PendingCN113731829AImprove detection efficiencyGood job stabilitySortingHigh level techniquesEmbedded systemEngineering

Owner:STATE GRID ZHEJIANG ELECTRIC POWER CO LTD JINHUA POWER SUPPLY CO

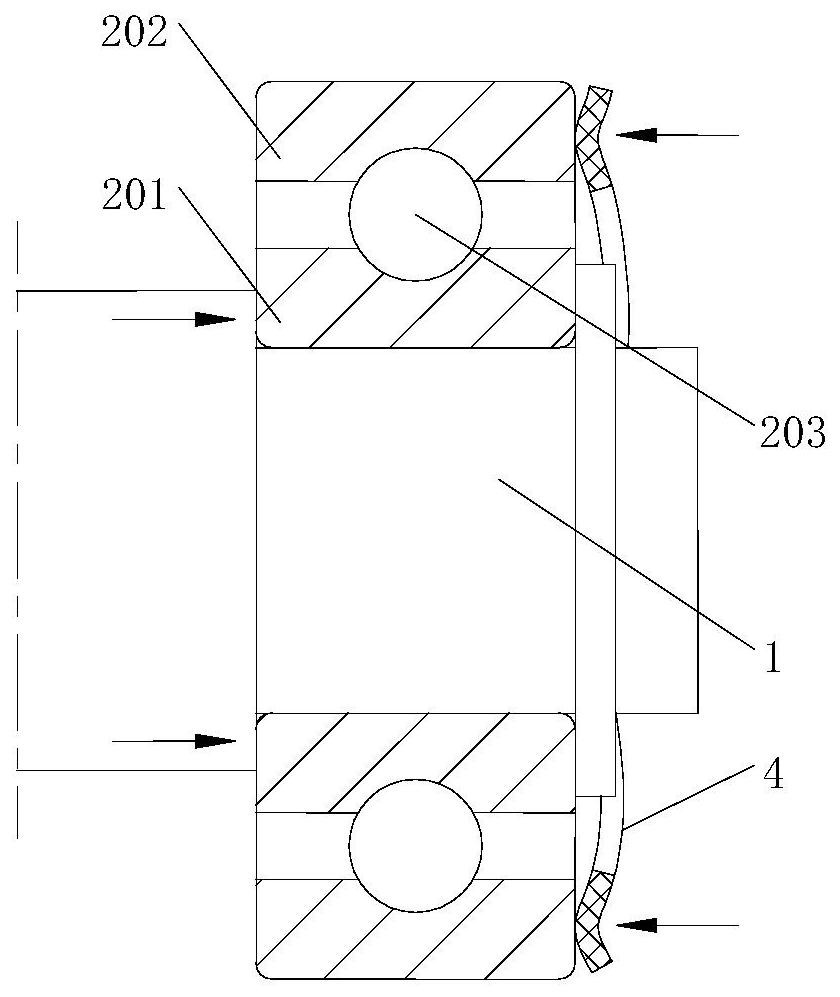

Double-side clamping type motor self-locking mechanism and self-locking motor

PendingCN113824245AReduce heatGood job stabilityMechanical energy handlingSupports/enclosures/casingsPhysicsElectric machinery

The invention discloses a double-side clamping type motor self-locking mechanism and a self-locking motor. The double-side clamping type motor self-locking mechanism comprises a rotating shaft (1), wherein a ball bearing (2) is arranged on the rotating shaft (1), the outer side of the ball bearing (2) is connected with an extrusion part, and an inner ring (201) and an outer ring (202) of the ball bearing (2) apply axial pressing force to balls (203) after being extruded by the extrusion part. According to the double-side clamping type motor self-locking mechanism, the self-locking effect on the rotating shaft is realized through frictional resistance formed by mutual fitting of the balls in the ball bearing with the inner ring and the outer ring after the balls are subjected to axial pressure, so that the heating temperature of the motor in the working process is reduced, and the self-locking mechanism has the advantages of simple structure and good self-locking stability.

Owner:浙江美茵电机有限公司

Surface-mounted subminiaturized isolator

InactiveCN103022607ASmall device sizeGood job stabilityWaveguide type devicesPhysicsHigh dielectric permittivity

The invention discloses a surface-mounted subminiaturized isolator which comprises a cavity. A load chip is fixed onto the cavity, and a first microwave ferrite, a central conductor, a second microwave ferrite, a shimming sheet, a permanent magnet and temperature compensation sheets are sequentially placed in the cavity; and a magnetic circuit plate covers an opening end of the cavity, two pins of the central conductor penetrate through a port on the cavity, extend out of the cavity and are bent into steps along the walls of the cavity, ends of the two pins and the bottom surface of the cavity are positioned on the same plane, and another pin of the central conductor is connected with the load chip. The surface-mounted subminiaturized isolator has the advantages that the ceramic loop ferrites with high dielectric constants are adopted, and the size of the surface-mounted subminiaturized isolator is reduced; the pins of the central conductor are bent to be parallel to the bottom surface of the cavity, and accordingly the surface-mounted subminiaturized isolator is suitable to be mounted on a surface; and the temperature compensation sheets are made of iron-nickel alloy, and accordingly the surface-mounted subminiaturized isolator is good in working stability at an extreme temperature, has high indexes and is high in reliability.

Owner:南京广顺电子技术研究所有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com