Double-side clamping type motor self-locking mechanism and self-locking motor

A self-locking motor and side clamp technology, applied in electrical components, electromechanical devices, electric components, etc., can solve the problems of output shaft jamming, reduce motor rotational stability, self-locking effect, and hidden safety hazards, and improve self-locking. Stability, excellent working stability, avoid the effect of self-locking force change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

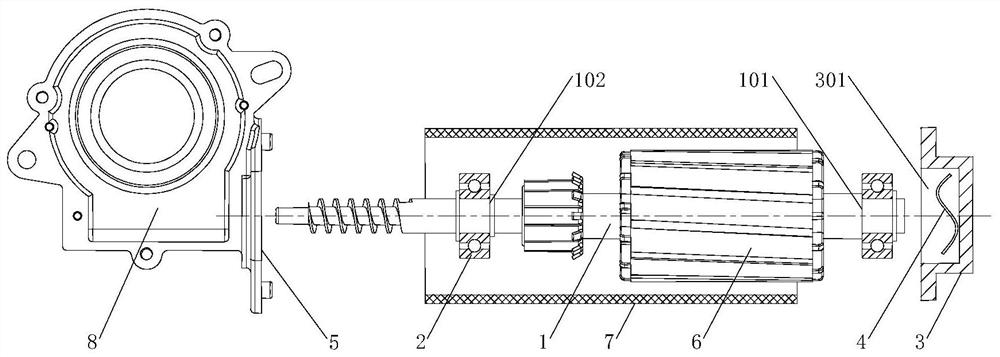

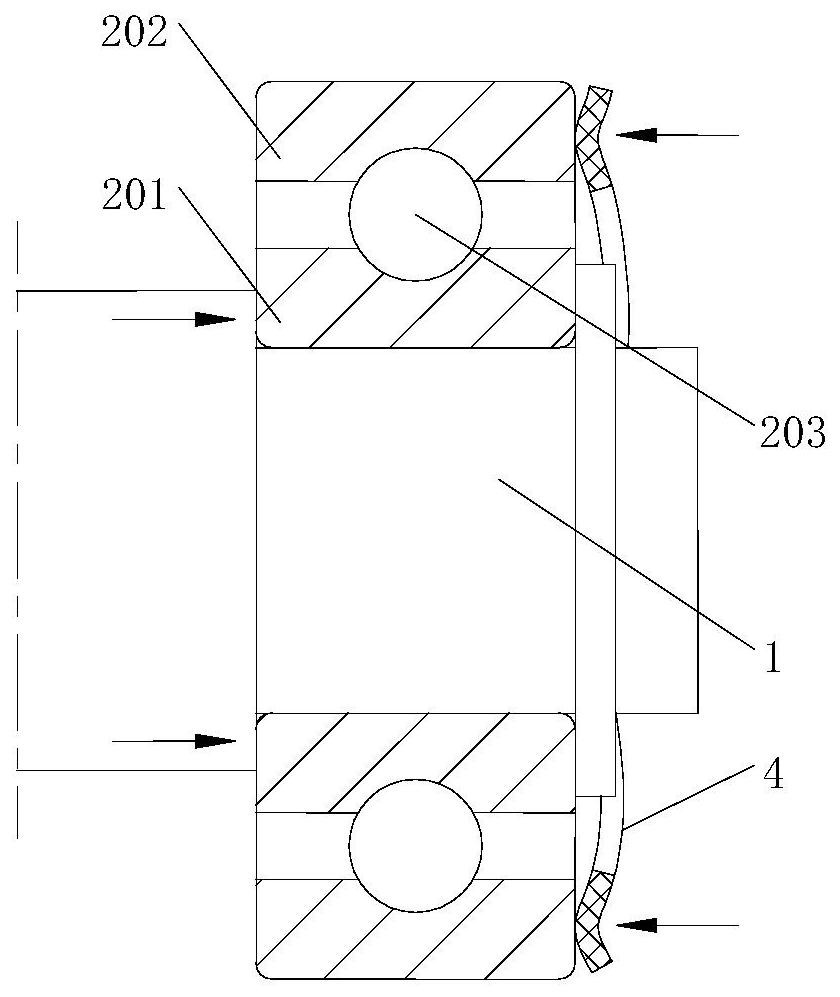

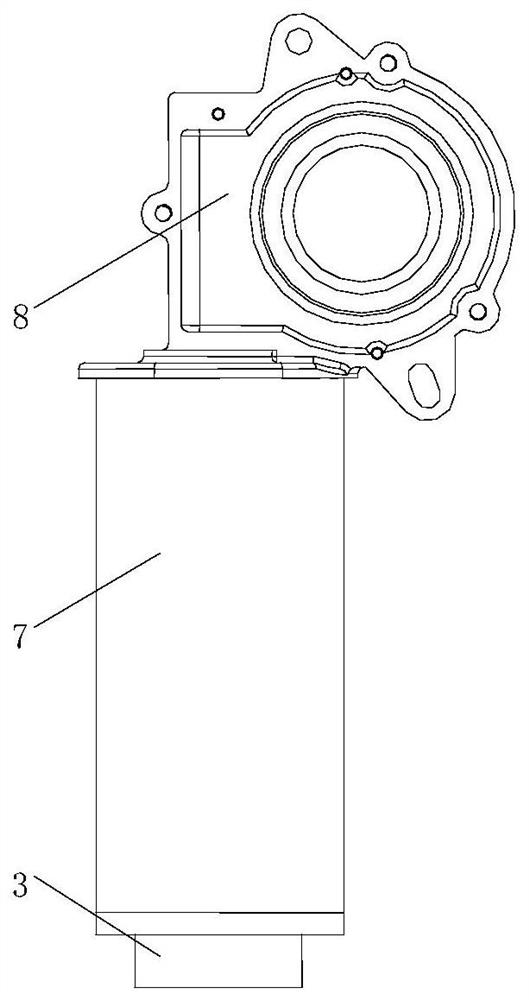

[0030] Example 1. A double-sided clamping motor self-locking mechanism, which is composed of Figure 1-2 As shown, the rotating shaft 1 is included, and the ball bearing 2 is arranged on the rotating shaft 1. The ball bearing 2 is a conventional bearing with an inner ring 201, an outer ring 202 and balls 203. The outer side of the ball bearing 2 is connected with an extruded part. The ball bearing The inner ring 201 and the outer ring 202 of 2 respectively exert axial pressing force on the balls 203 after being squeezed by the extrusion part.

[0031] The directions in which the inner ring 201 of the ball bearing 2 and the outer ring 202 of the ball bearing 2 exert pressure on the balls 203 are opposite to each other.

[0032] The number of the ball bearings 2 is two, and the two ball bearings 2 are respectively arranged on the left and right sides of the rotating shaft 1; the extruding part includes a first extruding group and a second extruding group, the first extruding gr...

Embodiment 2

[0043] Example 2. A single-side clamping motor self-locking mechanism, which is composed of figure 2 As shown, the rotating shaft 1 is included, and the ball bearing 2 is arranged on the rotating shaft 1. The ball bearing 2 is a conventional bearing with an inner ring 201, an outer ring 202 and balls 203. The outer side of the ball bearing 2 is connected with an extruded part. The ball bearing The inner ring 201 and the outer ring 202 of 2 respectively exert axial pressing force on the ball 203 after being squeezed by the extrusion part.

[0044] The directions in which the inner ring 201 of the ball bearing 2 and the outer ring 202 of the ball bearing 2 exert pressure on the balls 203 are opposite to each other.

[0045] The ball bearing 2 is arranged on one side of the rotating shaft 1 .

[0046] The extrusion part includes a cover plate 3 and a first extrusion surface 101 located on the rotating shaft 1, the cover plate 3 and the outer ring 202 on one side of the ball be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com