Novel 3D printer

A 3D printer, a new type of technology, applied in the direction of 3D object support structure, additive manufacturing, manufacturing tools, etc., can solve the problems of low work efficiency, affecting product quality, poor motion stability of motion mechanism, etc., and achieve high printing efficiency and motion stability Good, good work stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

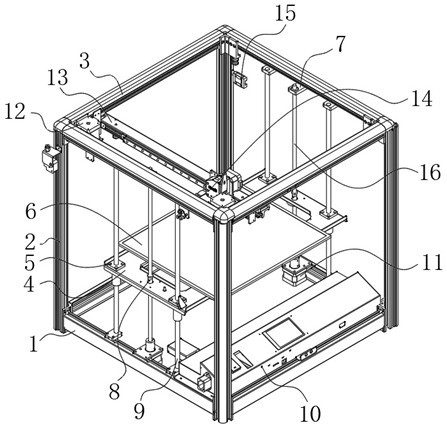

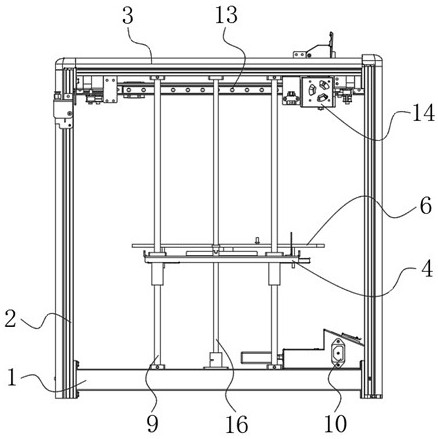

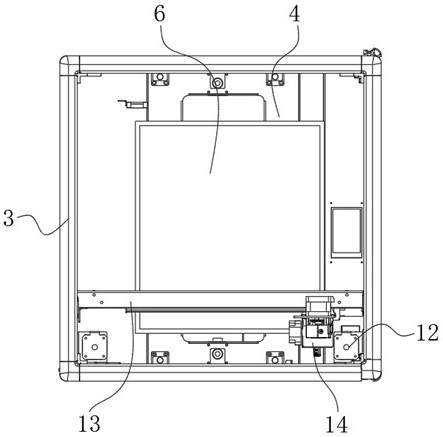

[0022] Attached below Figure 1-4 The specific implementation manner of the present invention will be described in further detail.

[0023] Depend on Figure 1-4 Given, the present invention provides the following technical solutions: a novel 3D printer, comprising a lower frame 1, an upper frame 3 is fixed around the top of the lower frame 1 through a vertical bar 2, and an electric control box 10 is installed on one side of the top of the lower frame 1 The center of the adjacent side of the lower frame 1 and the upper frame 3 is rotatably connected with a first reciprocating screw 16 through a positioning seat 7, and a first servo motor connected to the first reciprocating screw 16 is installed on the bottom of the positioning seat 7 11. The first reciprocating screw rod 16 is meshed with a reciprocating slide seat 8, which is symmetrically installed on the corresponding two sides of the lifting frame 4. A forming plate 6 is installed at the center of the top of the lifting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com