Cable net conduction insulation automatic testing system based on PXI

An automatic test system and insulation tester technology, applied in the direction of detecting faults and fault locations according to conductor types, can solve problems such as difficulty in meeting cable network batch production testing, inability to meet batch production testing tasks, and poor work stability. Achieve the effect of improving the level of automated testing and testing efficiency, convenient debugging, and high testing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

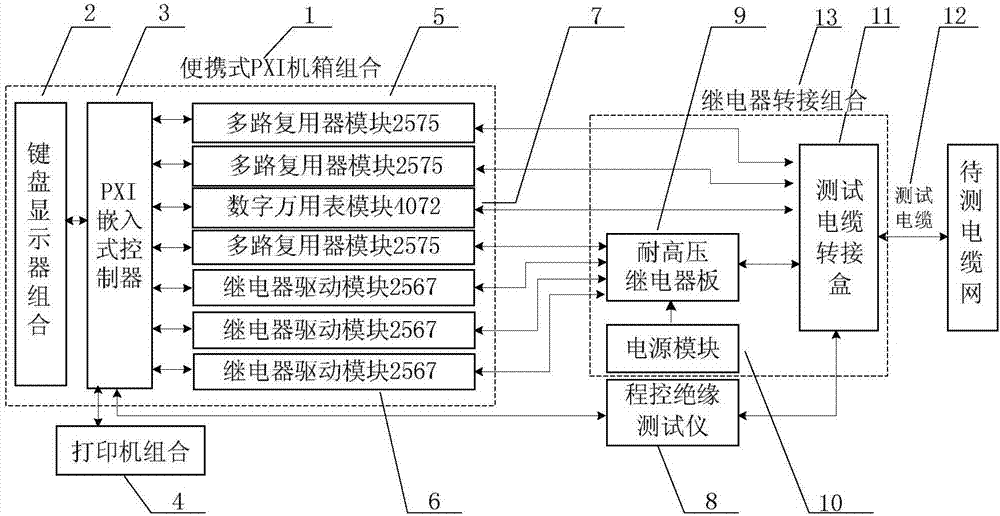

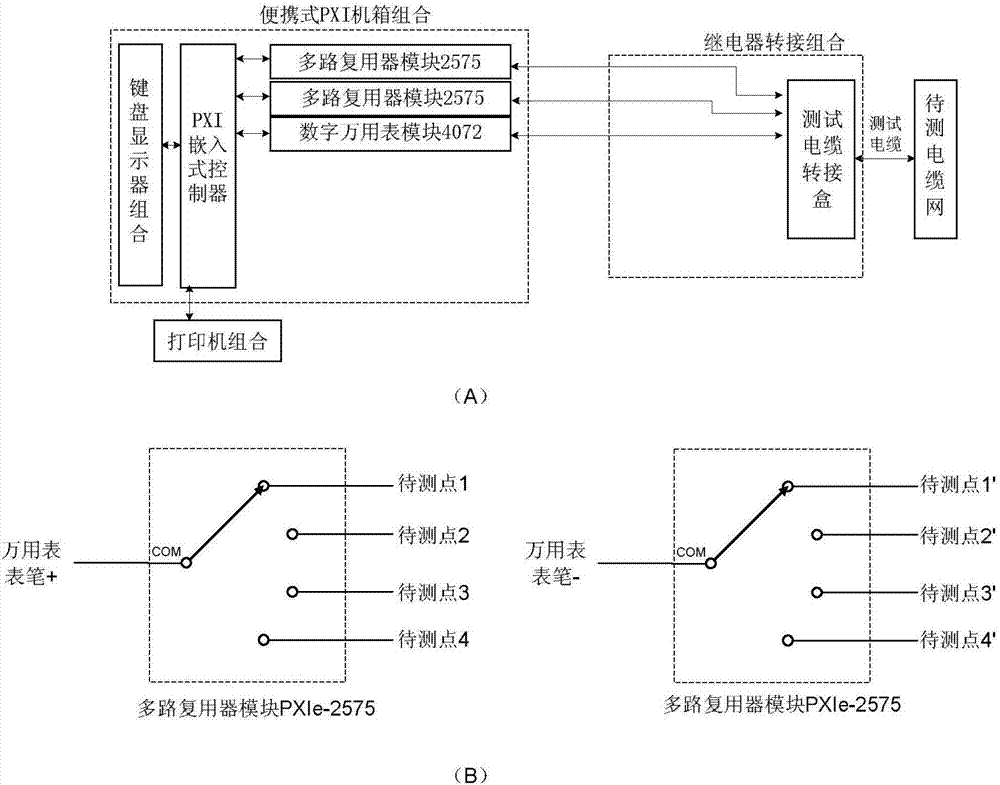

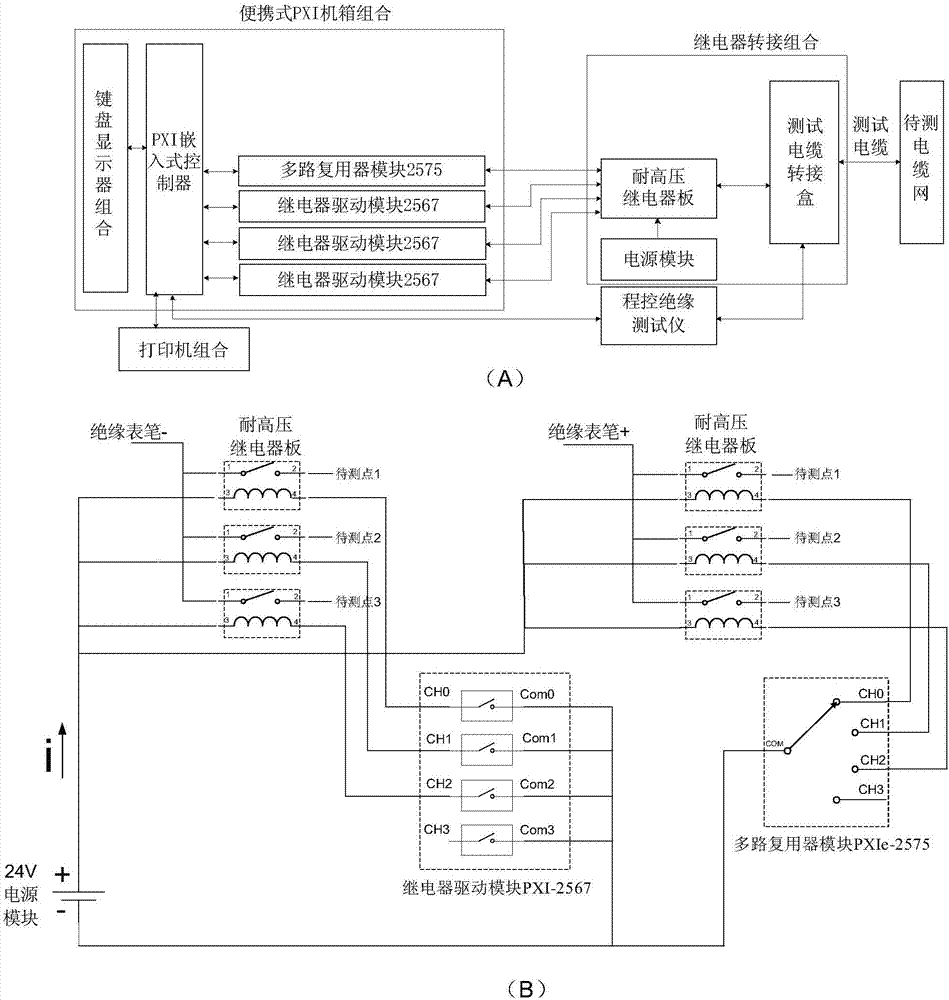

[0025] In order to further illustrate the specific implementation of the patent of the present invention, the technical solution of the patent of the present invention will be discussed in detail below in conjunction with the accompanying drawings.

[0026] Such as figure 1 As shown, the patent of the present invention adopts a modular design scheme, including a portable PXI chassis combination, a relay transfer combination, a program-controlled insulation tester, a test cable, a printer, etc., wherein the PXI chassis combination includes a PXI embedded controller, 3 multi-channel Multiplexer module PXIe-2575, 3 relay drive modules PXI-2567, digital multimeter module PXI-4072 and keyboard display combination and other modules, relay transfer combination includes high-voltage resistant relay board, power supply module and test cable transfer box, etc.

[0027] Keyboard and display combination: it is the interactive interface between the test operator and the PXI embedded contro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com