Automatic quick suction manipulator

A manipulator and fast technology, applied in the field of manipulators, can solve the problems affecting the output speed and output quality of plate reversal, poor work stability, slow board picking speed, etc. workable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

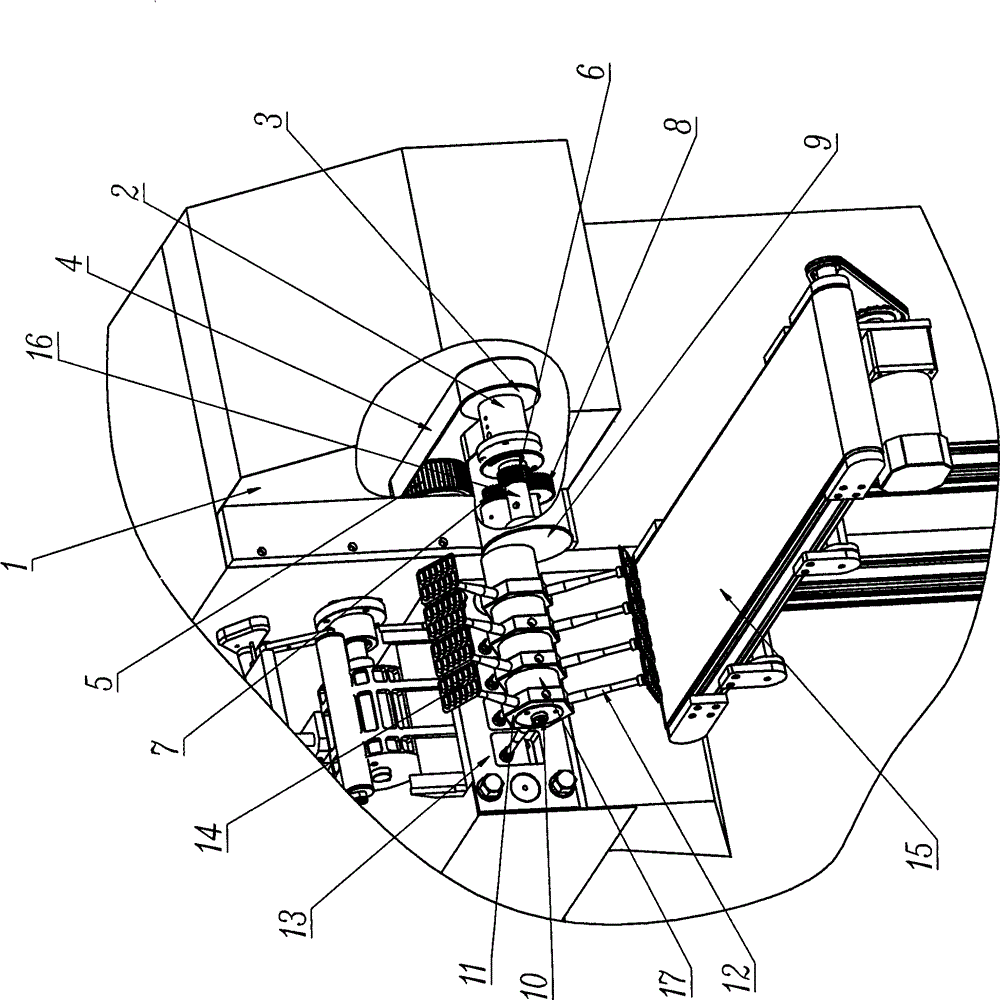

[0008] refer to figure 1 It can be seen that the present invention is applied to the automatic quick-absorbing manipulator between the automatic blister packaging machine and the medicine board cartoning machine, including a straw 12 and a straw holder 11, and the straw holder 11 is connected to the power transmission assembly (installed in the archway 1), the straw seat 11 is equipped with a rotating shaft 10, the inner end of the rotating shaft 10 is equipped with a rotating shaft gear 7, and the rotating shaft gear 7 is connected to the fixed gear 6 through the transition gear 8 installed on the rotating disk 9, The fixed gear 6 (fixed and not rotating) is installed on the eccentric shaft 16 of the power transmission assembly, and the eccentric shaft 16 is connected with the rotating disk 9 . The power transmission assembly includes a connected active synchronous wheel 5, a synchronous belt 4, and a passive synchronous wheel 3 in sequence. Eccentric shaft 16 is contained o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com