Surface-mounted subminiaturized isolator

A kind of isolator, ultra-miniature technology, applied in the field of surface mount ultra-miniature isolators, can solve the problems of not suitable for surface mount, large structure, not easy to integrate microcircuits, etc., to achieve indicators and high reliability, The effect of reducing the size of the device and reducing the volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

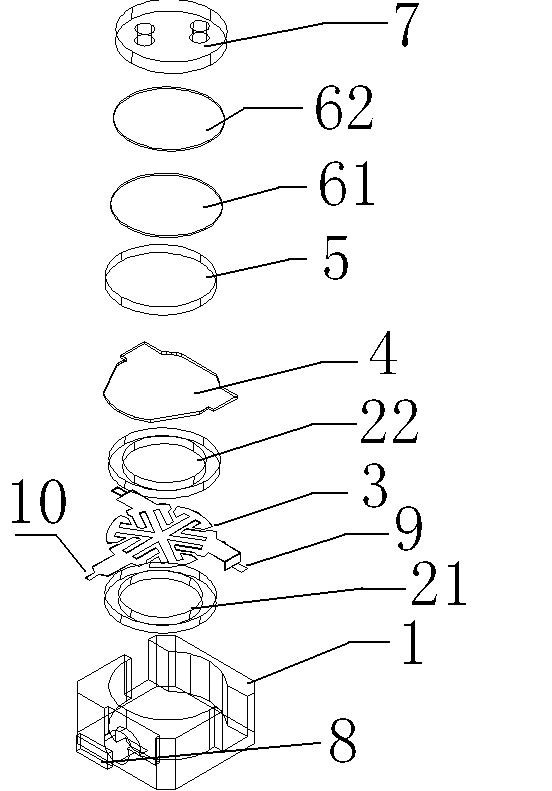

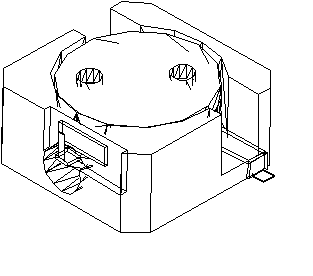

[0014] Example 1: Such as figure 1 and 2 As shown, a surface-mount ultra-miniature isolator includes a cavity 1 and a load chip 8. The length, width and height of the cavity 1 are respectively: 10×10×5.5mm, and the inner surface of the cavity 1 A silver plating layer is provided, and the load chip 8 is welded on the cavity 1 through solder paste.

[0015] A first microwave ferrite 21, a central conductor 3, a second microwave ferrite 22, a shim 4, a permanent magnet 5, and temperature compensation sheets 61, 62 are sequentially placed in the cavity 1; The end of the mouth is covered with a magnetic circuit board 7, and the two pins 9 of the central conductor 3 pass through the port on the cavity 1 and extend to the outside of the cavity and are bent into a step shape along the outer wall of the cavity. The bottom surface of the body 1 is located on the same plane, and the other pin 10 is connected to the welding spot of the load chip 8 by welding.

[0016] Wherein, the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com