Needle plate with insertion sheets for computerized flat knitting machines

A computerized flat knitting and inserting technology, applied in knitting, weft knitting, textiles and papermaking, etc., can solve the problems of equipment yarn breakage, non-standard angle polishing, flying silk, etc., to reduce yarn breakage, save costs, work good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

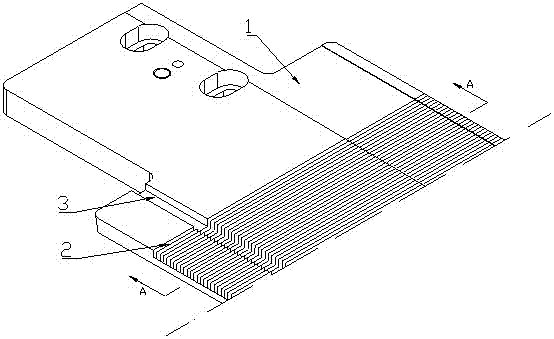

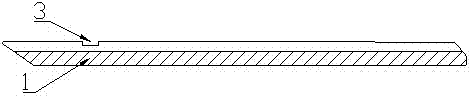

[0017] Below in conjunction with accompanying drawing, structural principle and working principle of the present invention are specifically described: as Figure 1~4 As shown, a needle plate for a computerized flat knitting machine of the present invention includes a motherboard 1 and an insert 4, the motherboard is provided with slots 2 parallel to each other, the slots 2 are equally spaced, and the slots 2 are embedded with The insertion piece 4 forms a needle groove between the insertion piece 4 .

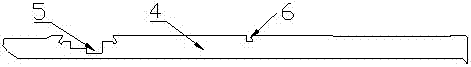

[0018] The motherboard 1 is provided with a positioning groove 3 perpendicular to the slot 2, and the insertion piece 4 is provided with a groove 5 corresponding to the positioning groove 3. Through the cooperation between the positioning groove 3 and the groove 5, the insertion piece 4 can be accurately positioned. It is embedded in the slot 2 of the motherboard; the insert 4 is provided with a steel wire groove 6 for the insertion of the steel wire.

[0019] The inserts 4 are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com