Injection distribution device

A technology of injector and converter, which is applied in the direction of mining fluid, wellbore/well components, earthwork drilling and production, etc. It can solve the problems of high sealing performance, poor stability, high temperature resistance performance, etc., and achieve stable work Good performance, low operating cost, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the drawings:

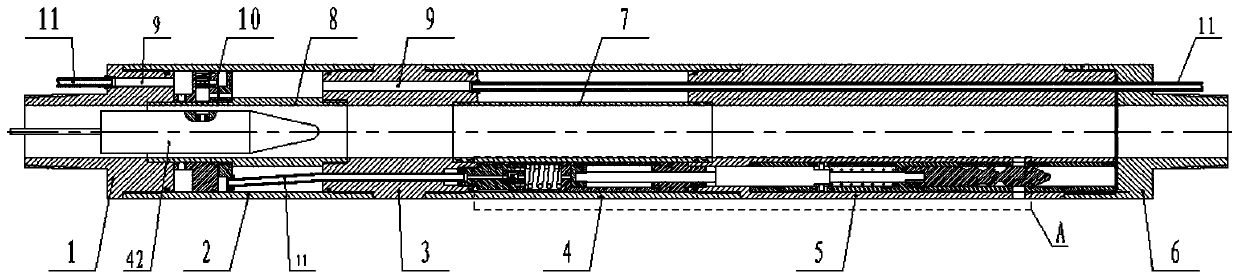

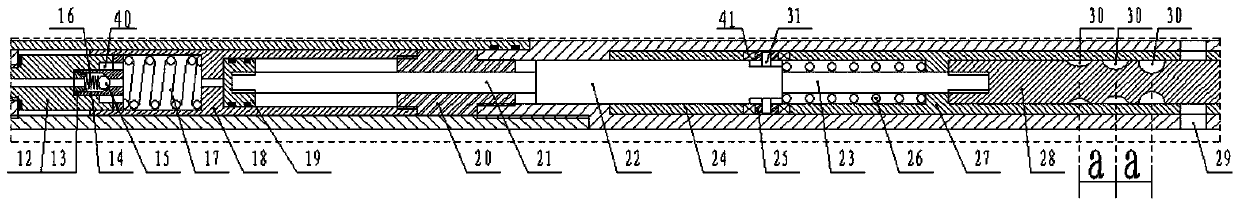

[0034] The present invention includes upper joint 1, upper cylinder 2, adapter 3, lower cylinder 4, mounting main body 5, lower joint 6, upper center tube 8 and lower center tube 7, upper joint 1, upper cylinder 2, adapter 3, lower The barrel 4, the mounting body 5, and the lower joint 6 are sequentially connected by threads from top to bottom, thereby forming the casing of the dispenser.

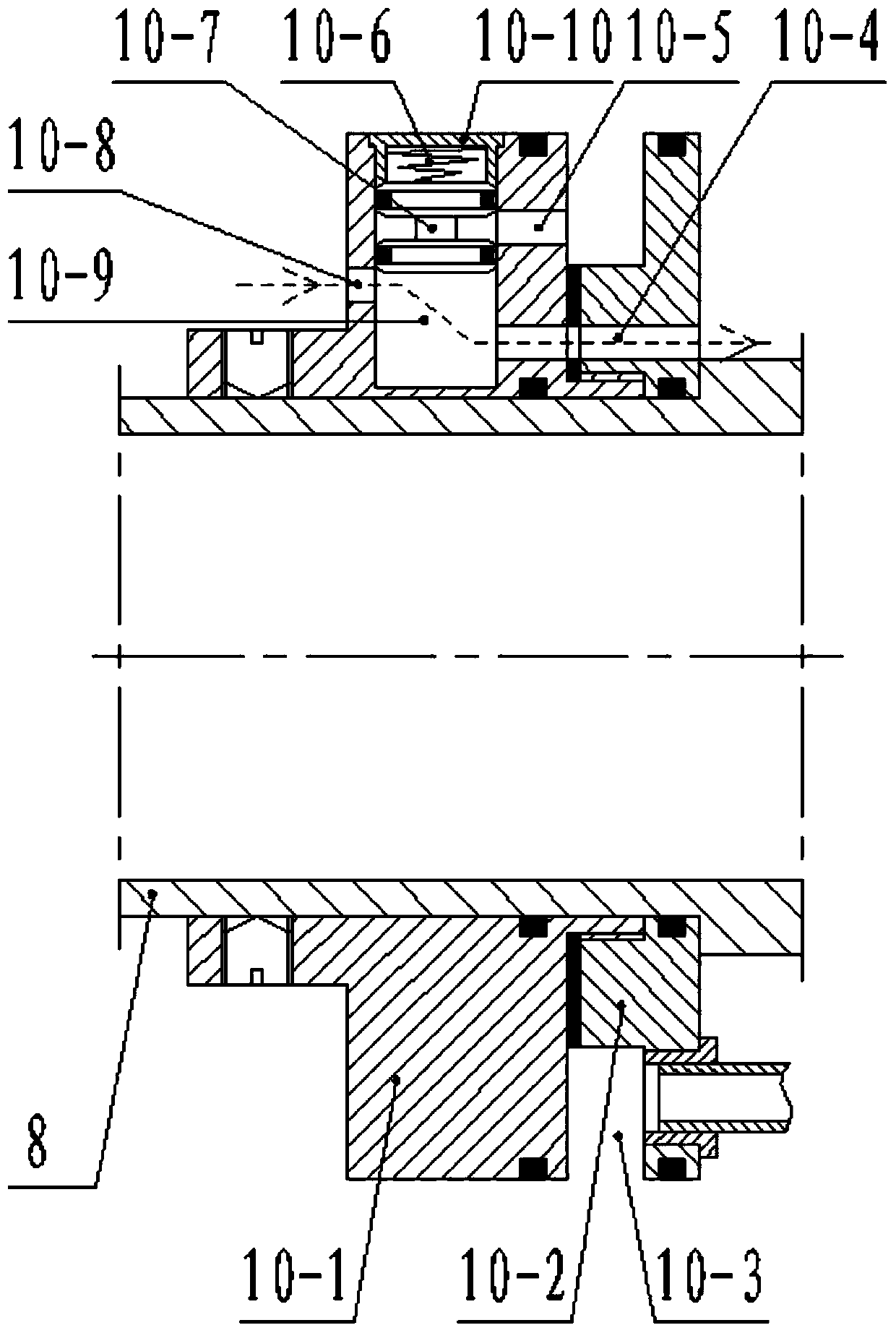

[0035] The upper end of the upper central pipe 8 is inserted into the upper joint 1, and the lower end of the upper central pipe 8 is screwed to the adapter 3, thereby forming an annular space between the upper central pipe 8 and the upper cylinder 2. An air circuit converter 10 is installed in the space, and the air circuit converter 10 is fixed on the upper center tube 8 through a jack wire;

[0036] The upper joint 1 and the adapter 3 are both provided with a linear air passage 9. The upper end sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com