Automatic bamboo root excavator

An excavator and bamboo root technology, applied in the field of automatic bamboo root excavators, can solve the problems of poor stability of bamboo root excavators and inability to guarantee bamboo roots, etc., and achieve the effect of good work stability and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

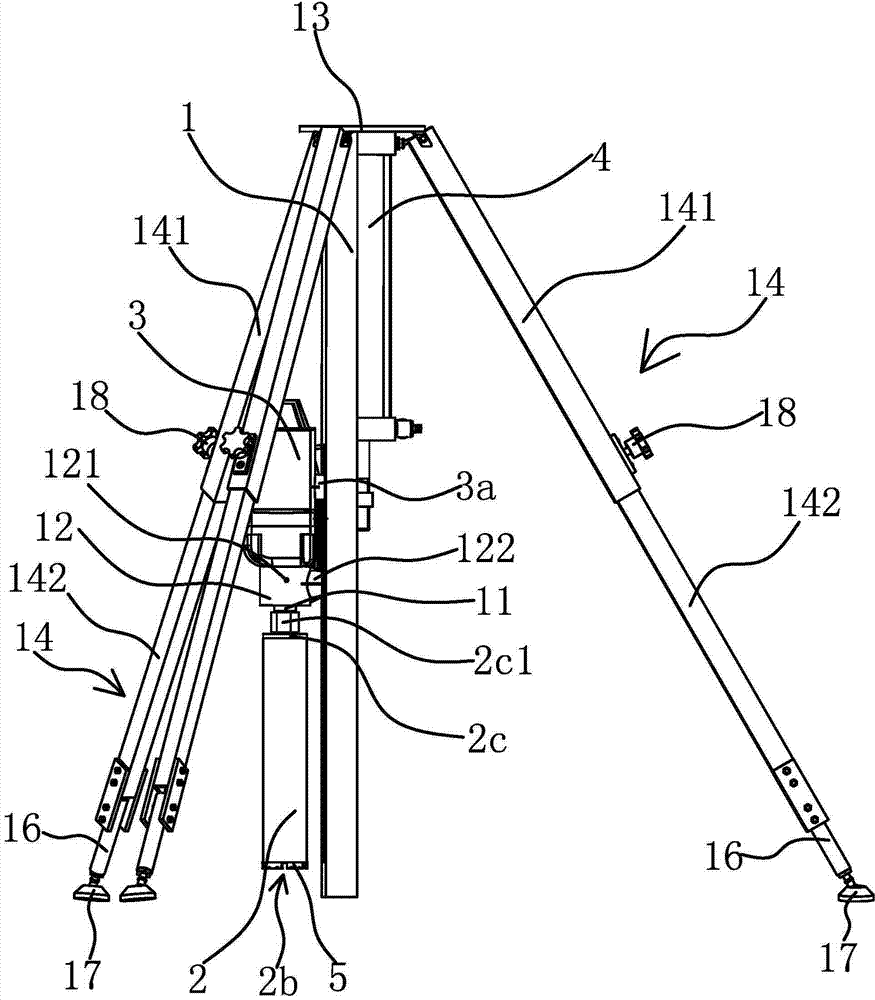

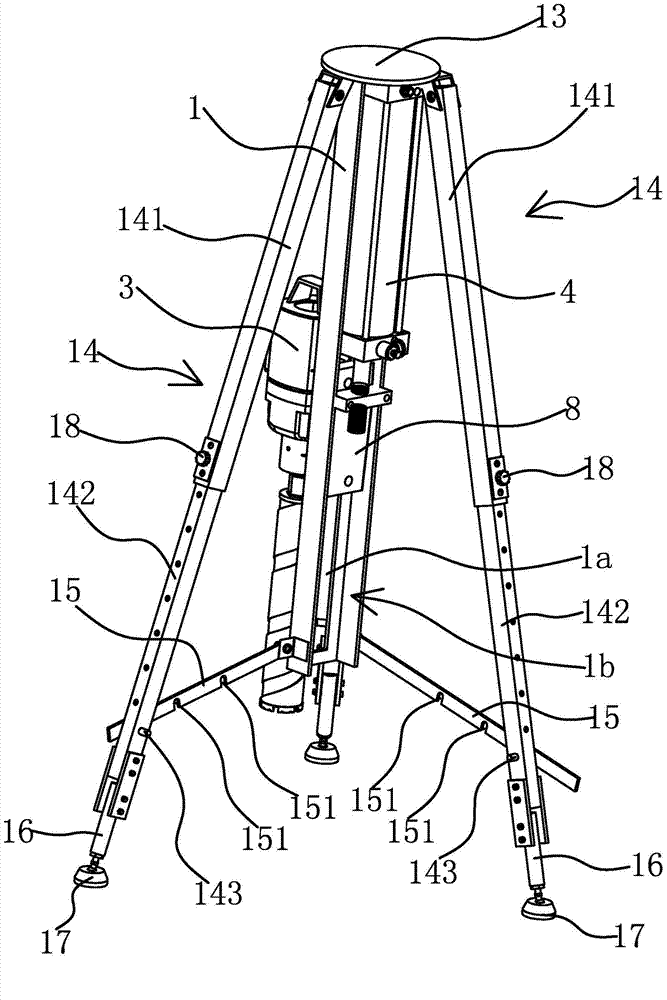

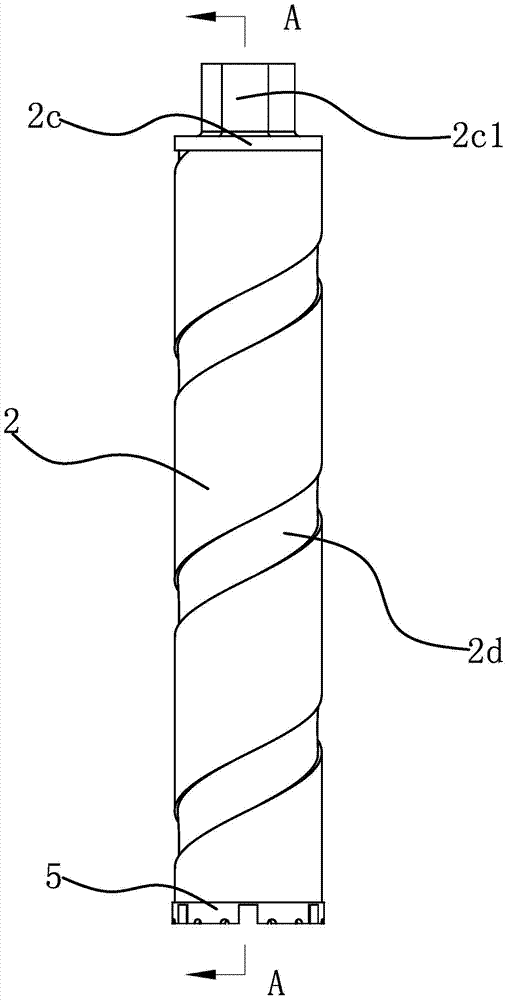

[0034] The automatic bamboo root excavator comprises a mounting frame 1, a cutter barrel 2, a cutter head 5, a push plate 6, a spring 7, a support assembly, a rotating driving source 3, a feeding driving source 4 and a soil-discharging driving mechanism.

[0035] Specifically, as figure 1 with figure 2 As shown, the mounting frame 1 is in the shape of a long strip, and the mounting frame 1 has a through groove 1 a passing through both sides of the mounting frame 1 , and a slider 8 is arranged at the through groove 1 a. The rotation drive source 3 is used to drive the cutter cylinder 2 to rotate, and the feed drive source 4 is used to drive the cutter cylinder 2 to move linearly along the installation frame 1. In this embodiment, the feed drive source 4 is a cylinder, and the rotation drive source 3 is a motor. The cylinder is fixed on one side of the mounting frame 1, the piston rod of the cylinder is connected to the slider 8 by threads, and the motor is located on the othe...

Embodiment 2

[0046] The technical solution in this embodiment is basically the same as that in the first embodiment, the difference is that in this embodiment, the driving mechanism for soil removal includes a vibration generator fixed at the upper end of the cutter barrel 2 . When the push plate 6 could not remove the bamboo root and the soil under the restoring force of the spring 7, the cutter barrel 2 was knocked continuously by the vibration generator, so that the soil near the opening 2b of the cutter barrel 2 could be discharged first, and the cutter barrel 2 The internal soil is separated and loosened under the action of vibration until it is discharged under the operation of the push plate 6 .

Embodiment 3

[0048] The technical solution in this embodiment is basically the same as the technical solution in Embodiment 1, the difference is that in this embodiment, the bracket assembly includes a number of support rods fixed on the mounting frame 1, and the support rods extend toward the mounting frame 1 respectively. The sides are sloped, and the bottom of each support bar has a horizontal support surface. Such a bracket assembly can enable the excavator to be positioned on uneven ground, and has a simple structure and low manufacturing cost.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com