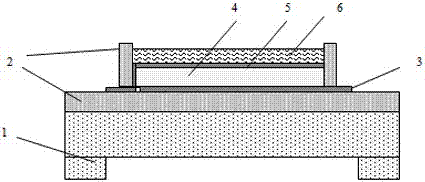

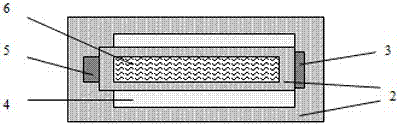

Novel magnetic fluid-piezoelectric film structure device and production method thereof

A technology of piezoelectric film and manufacturing method, applied in the field of new magnetic fluid-piezoelectric film structure device and its manufacturing, to achieve the effects of avoiding difficult maintenance, good working stability and strong anti-interference ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

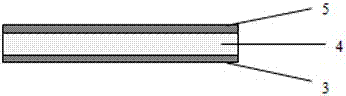

[0053] 1. Select silicon wafer as the substrate layer, and clean and dry the silicon wafer for later use;

[0054] 2. Using low-pressure chemical vapor deposition to grow a layer of low-stress SiO with a thickness of 2 µm on the surface of the silicon wafer 2 Film, as the support layer of the piezoelectric film layer;

[0055] 3. The bulk silicon etching process is used to remove most of the silicon on the back of the silicon substrate layer to release the piezoelectric sandwich structure;

[0056] 4. Deposit metal Al with a thickness of 2nm as the lower electrode layer and pattern it;

[0057] 5. Using the magnetron sputtering method, deposit a 3μm ZnO piezoelectric film layer with a preferred orientation parallel to the c axis, and pattern the leads of the lower electrode layer to be exposed;

[0058] 6. Deposit metal Al with a thickness of 2nm as the upper electrode layer and pattern it, and lead the upper electrode layer to the plane of the lower electrode layer to connect to the ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com