Grooving device for outer surface of lining

An outer surface and bushing technology, which is applied in the field of auto parts processing equipment, can solve the problems of affecting the cooling efficiency of the water pump, reducing the rotation speed of the impeller, and the difficulty of processing and clamping, etc., to achieve flexible adjustment, uniform support, and work good stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to make the technical means and creative features realized by the present invention easy to understand, the present invention will be further elaborated below.

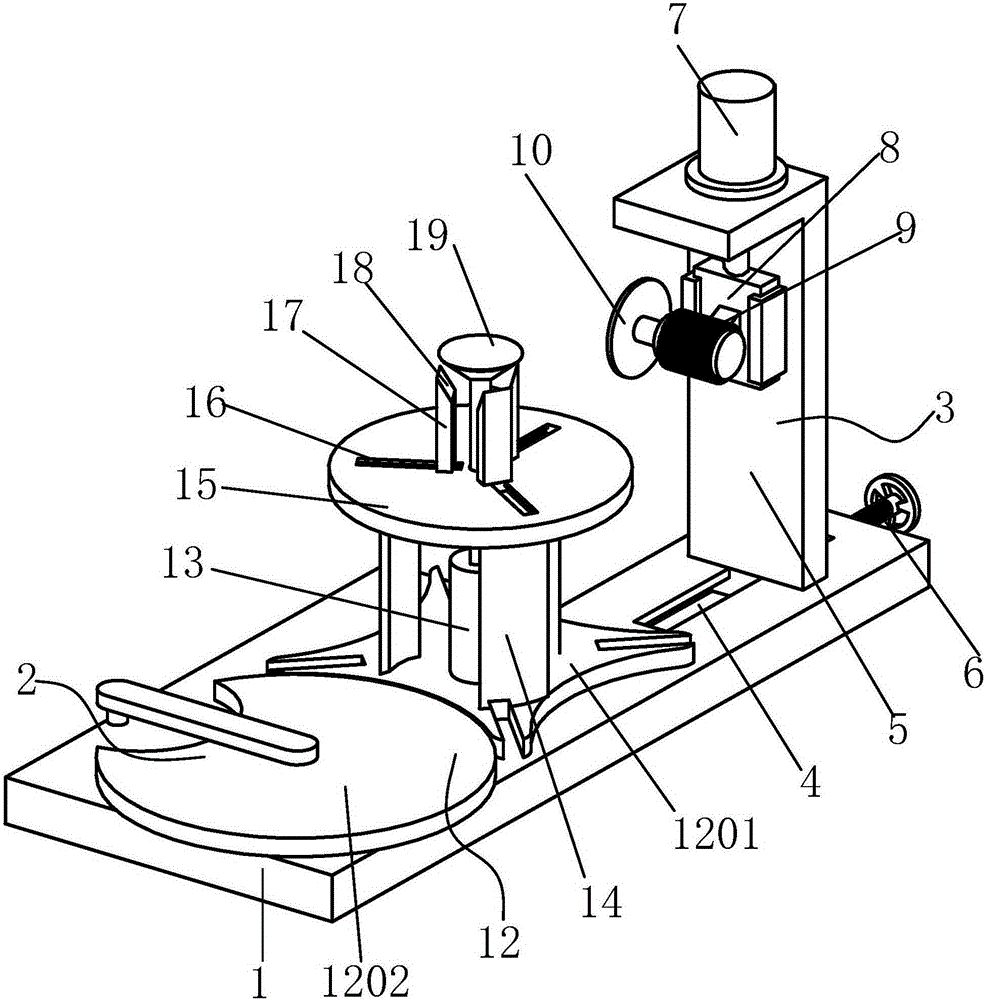

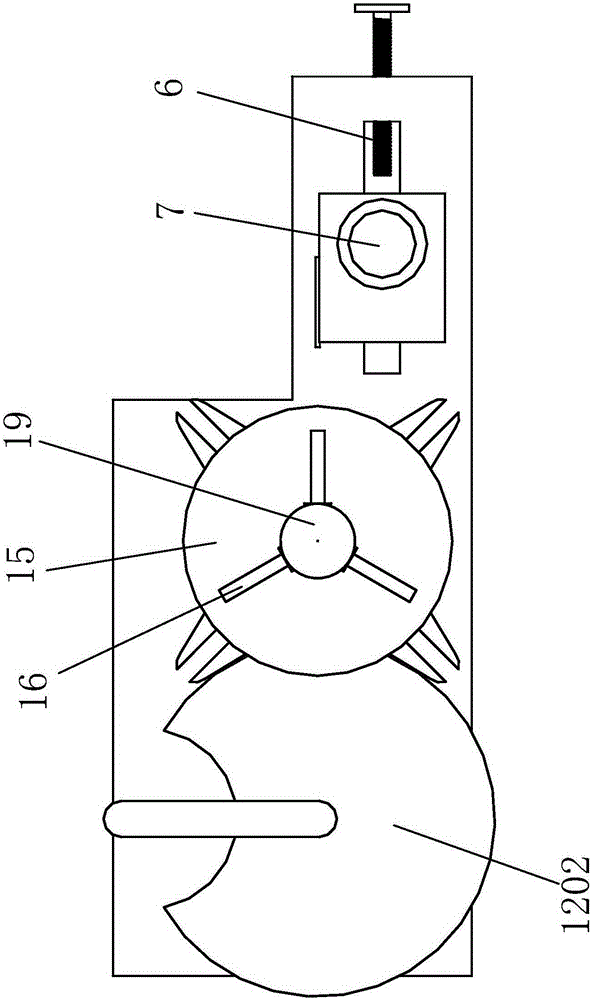

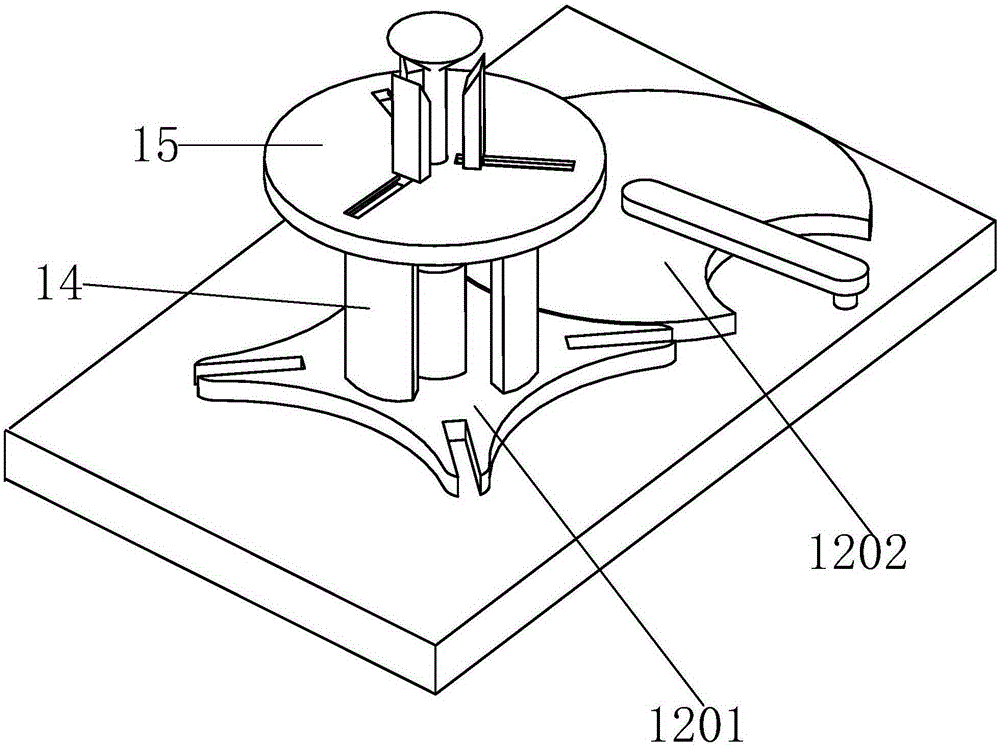

[0017] like Figure 1 to Figure 4 As shown, a device for opening grooves on the outer surface of a bushing includes a base plate 1 , a clamping device 2 is provided on the left side of the base plate 1 , and a cutting device 3 is provided on the right side of the base plate 1 .

[0018] The cutting device 3 includes a slideway 4 arranged on the base plate 1, a slide frame 5 arranged in the slideway 4, a threaded rod 6 arranged on the right side of the slide frame 5, a No. 1 air cylinder 7 installed on the top of the slide frame 5 , a mounting plate 8 mounted on the shaft of the No. 1 cylinder 7, a motor 9 mounted on the mounting plate 8, and a cutting blade 10 mounted on the shaft of the motor 9. The right end of described sliding frame 5 is provided with groove 11, and the left end of described threa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com