Flexible film thermosensitive electrode with negative temperature coefficient and manufacturing method thereof

A negative temperature coefficient, flexible film technology, used in thermometers, thermometers with directly sensitive electrical/magnetic components, and heat measurement, which can solve the problems of being easily affected by environmental humidity and low working stability of flexible film electrodes. , to solve the problem of low work stability, good work stability and high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

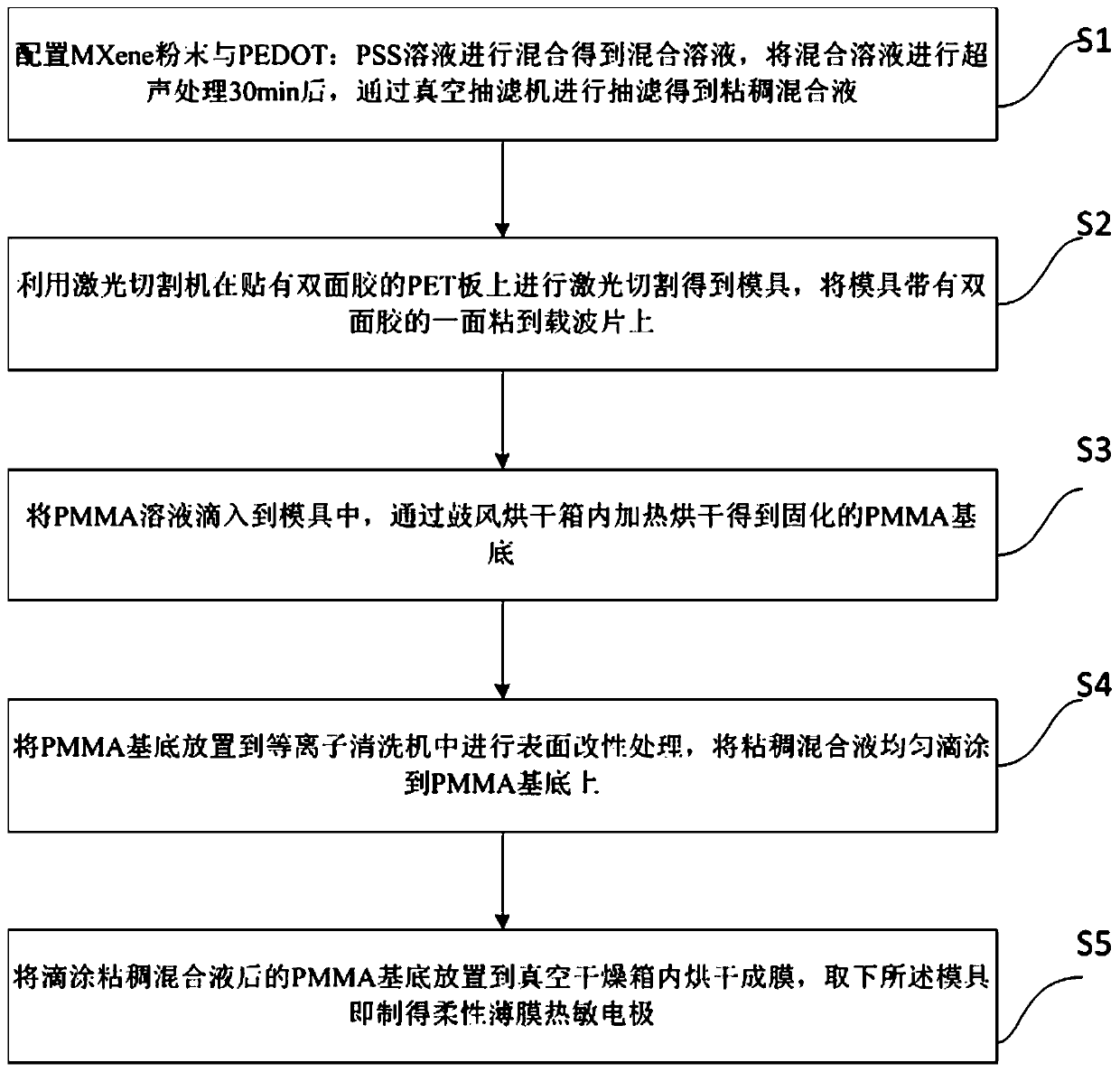

[0032] Fabrication method of flexible thin film thermosensitive electrode with negative temperature coefficient, such as figure 1 shown, including the following steps:

[0033] S1. Configure MXene powder and PEDOT:PSS solution to mix to obtain a mixed solution. After the mixed solution is ultrasonically treated for 30 minutes, it is filtered by a vacuum filter to obtain a viscous mixed solution;

[0034] S2. Utilize a laser cutting machine to carry out laser cutting on the PET plate with double-sided adhesive to obtain a mold, and stick the side of the mold with double-sided adhesive to the carrier film;

[0035] S3. drop the PMMA solution into the mould, and obtain a solidified PMMA substrate by heating and drying in a blower oven;

[0036] S4. The PMMA substrate is placed in a plasma cleaning machine for surface modification, and the viscous mixed solution is evenly drip-coated on the PMMA substrate;

[0037] S5. Place the PMMA substrate after dripping the viscous mixed so...

Embodiment 2

[0039] S1. Configure the mixed solution obtained by mixing the MXene powder with a mass ratio of 3:1 and the PEDOT:PSS solution. After the mixed solution is ultrasonically treated for 30 minutes, filter paper with a pore size of 0.45 μm is used for suction filtration through a vacuum filter. Obtain a viscous mixture; in this step, ultrasonic treatment for 30 minutes can fully mix the MXene powder and PEDOT:PSS solution; the use of filter paper with a pore size of 0.45 μm can ensure the suction filtration effect and have a suitable suction filtration speed. (PEDOT:PSS is easy to pass through the filter paper when the pore size of the filter paper is too large, and the filtration speed is too slow if the pore size of the filter paper is too small);

[0040] S2. Utilize a laser cutting machine to carry out laser cutting on a PET plate with double-sided adhesive tape to obtain a mold, and stick the side of the mold with double-sided adhesive tape on the carrier film; wherein the th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com