Tee high-frequency electro-hydraulic exciting vibration valve

A technology of exciting valves and high-frequency electricity, which is applied in the direction of multi-way valves, valve details, valve devices, etc., can solve problems such as poor working stability and shaft diameter deviation, and achieve reduced friction, extended service life, and working stability good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings.

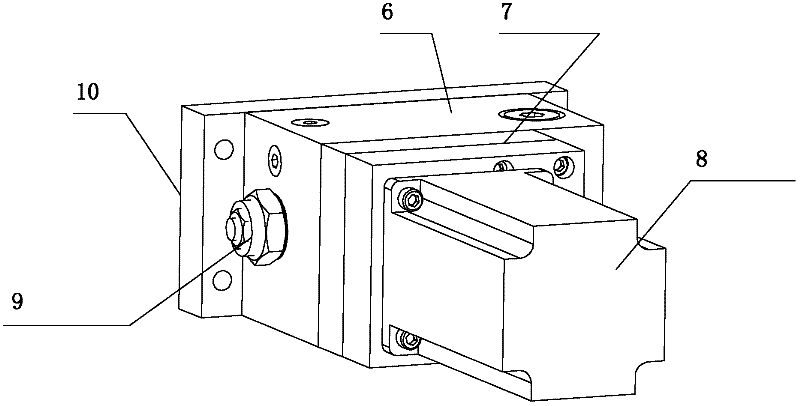

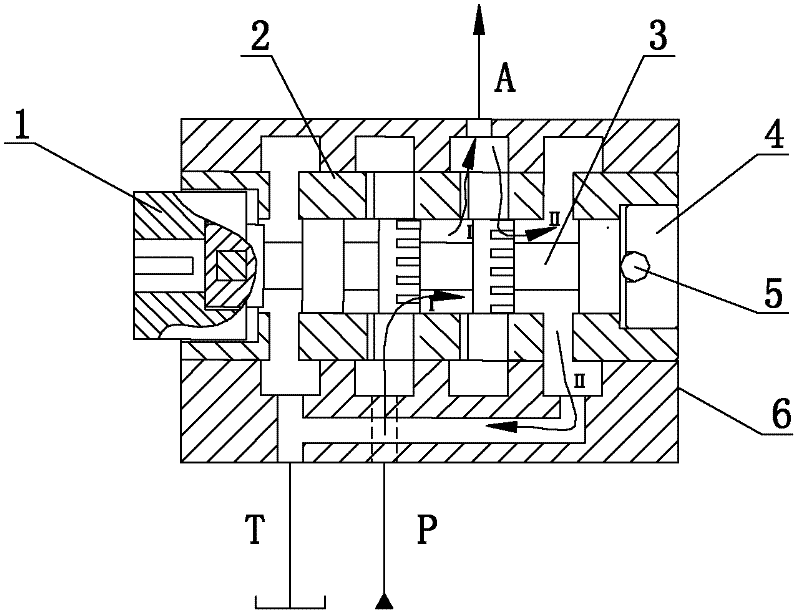

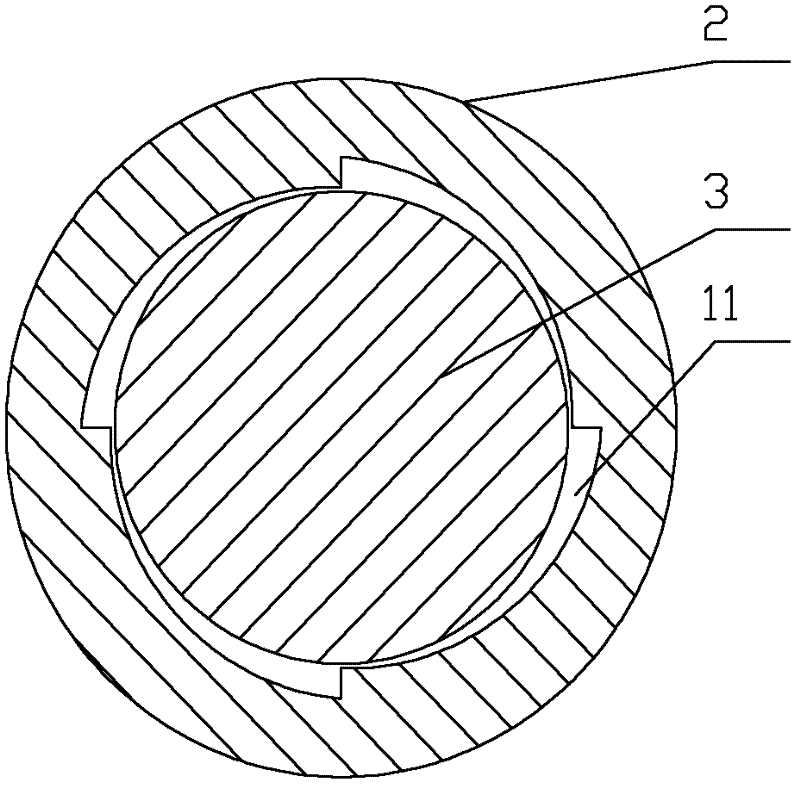

[0014] refer to Figure 1 ~ Figure 3 , a three-way high-frequency excitation valve, including a valve body 6, a valve core 3 and a valve sleeve 2, the valve body 6 is provided with an oil inlet P connected with a high-pressure oil tank, and an oil outlet connected with a hydraulic cylinder Port A, the oil return port T connected to the oil return tank; the valve core 3 and the valve sleeve 2 are located in the valve body 6, the valve sleeve 2 is nested in the valve body hole, the valve core 3 is in the valve sleeve 2, and the valve core There are 4 shoulders on 3, of which the outer two shoulders are supporting shoulders, the middle two shoulders are working shoulders, and the two working shoulders are evenly processed with Z grooves in the circumferential direction, and the two shoulders The grooves on the sleeve are misaligned with each other, and the position of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com