Excavator counter weight and manufacture method thereof

A manufacturing method and excavator technology, applied in the direction of earth mover/shovel, construction, etc., can solve the problems of local cavity, box concave deformation, uneven weight distribution, etc., to achieve uniform filling and improve production Good efficiency and machine operation stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

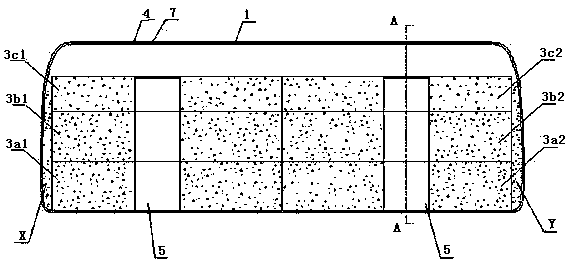

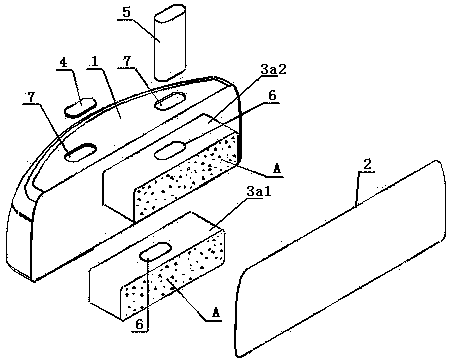

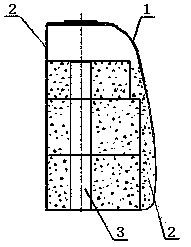

[0030] Such as figure 1 , 2 , 3, the counterweight housing includes a box body 1 and a cover plate 2, the cover plate 2 is located on the side of the box body 1, concrete blocks are placed in the counterweight housing, calculated according to the hollow shape of the box body 1 The quantity and assembly method of small concrete blocks, as well as the shape and size of each small concrete block, in order to ensure that the combined structure of several small concrete blocks after assembly is compact, the thickness of small concrete blocks on the same layer is usually the same, such as figure 1 As shown, the number of small concrete blocks calculated according to the hollow shape of the counterweight shell is 6, the thickness of the small concrete blocks 3a1 and 3a2 of the bottom layer is the same, the thickness of the small concrete blocks 3b1 and 3b2 of the middle layer is the same, and the small concrete blocks of the upper layer The blocks 3c1 and 3c2 have the same thickness...

Embodiment 2

[0046] Such as image 3 , 4As shown, on the basis of Embodiment 1, the filling hole 6 is cylindrical. The manufacturing method of Example 2 is basically the same as that of Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com