Manufacturing method of pneumatic sealing gasket

A technology of sealing gasket and manufacturing method, which is applied in the direction of engine sealing, mechanical equipment, engine components, etc., can solve the problems of NdFeB quality reduction, inability to isolate air, low working temperature, etc., and achieve the best sealing performance and stable operation Performance, avoiding the decline of sealing performance, preventing the effect of swelling seal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

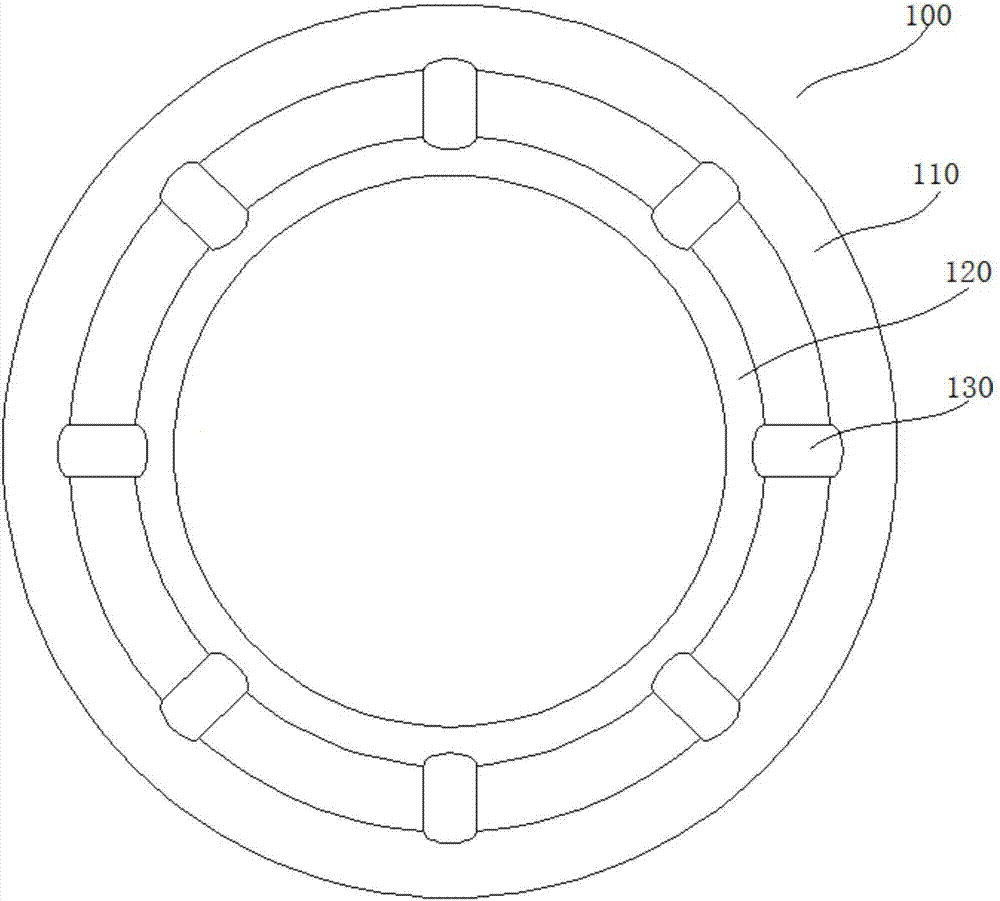

[0115] Such as figure 1 As shown, this embodiment provides a pneumatic sealing gasket. It includes an outer rubber ring 110 and an inner rubber ring 120 arranged concentrically. The outer rubber ring 110 and the inner rubber ring 120 pass through at least two connecting pipes 130 evenly distributed along the circumferential direction (in this embodiment, the number of connecting pipes 130 is 8 A) connected as a whole; the hollow inside of the outer rubber ring 110 is configured as a circular air storage cavity 221, the inside of the inner rubber ring 120 is hollow configured as a circular air collecting cavity 223, and the middle of any connecting pipe 130 is configured for The gas flow channel 222 connecting the gas storage cavity 221 and the gas collection cavity 223.

[0116] The capacity of the gas storage chamber 221 can be 2 to 5 times the capacity of the gas collection chamber 223, the side wall thickness of the gas storage chamber 221 can be 1.5 to 3 times the thickness o...

Embodiment 2

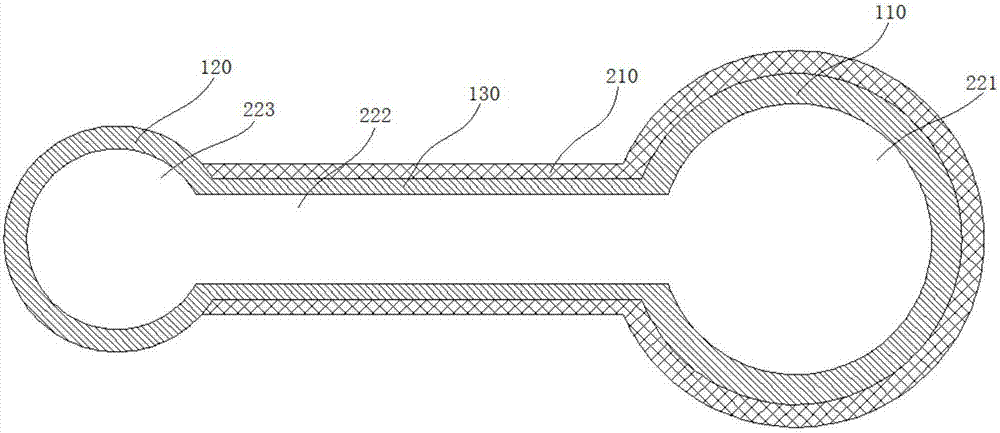

[0118] Such as figure 2 As shown, this embodiment provides a sealing gasket for a neodymium iron boron storage barrel. The difference from embodiment 1 is that the outer rubber ring 110 and the connecting pipe 130 are both constructed with a braid 210.

[0119] In this embodiment, the braided layer 210 is formed by interlacing warp yarns and weft yarns. The warp and weft yarns are made of blended yarns made of nylon fibers and metal fibers, and all warp and weft yarns of the braided layer 210 are spirally wrapped around the outer rubber. The outer surface of the ring 110 and the connecting pipe 130.

[0120] In this embodiment, the nylon fiber in the warp yarn accounts for about 85%, and the metal fiber accounts for about 15%, so that the warp yarn has better elasticity and toughness; the nylon fiber in the weft yarn accounts for about 80%, and the metal fiber accounts for about 20%. Make the warp have better elasticity and strength. In addition, the density of the warp yarn is ...

Embodiment 3

[0122] This embodiment provides a sealing ring for the air-tight connection of pipe fittings. The difference from embodiment 2 is that the material of the outer rubber ring 110 is composed of natural rubber, butadiene rubber, nitrile rubber, Titanium dioxide, carbon fiber, nano zinc oxide, paraffin-based rubber softening oil, plasticizer, stearic acid, composition;

[0123] The material of the inner rubber ring 120 is composed of natural rubber, butadiene rubber, active silicon powder, carbon black, sulfur, antioxidant, accelerator, zinc oxide, magnesium oxide, stearic acid, and aromatic oil.

[0124] In this embodiment, the weight of each component in the outer rubber ring 110 can be any one of the following ranges: 55 to 65 parts of natural rubber, 15 to 25 parts of butadiene rubber, 5 to 10 parts of nitrile rubber, and titanium dioxide 1.5 to 2.5 parts, 1 to 2 parts of carbon fiber, 1 to 1.5 parts of nano zinc oxide, 9 to 11 parts of paraffin-based rubber softening oil, 6 to 7 p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com