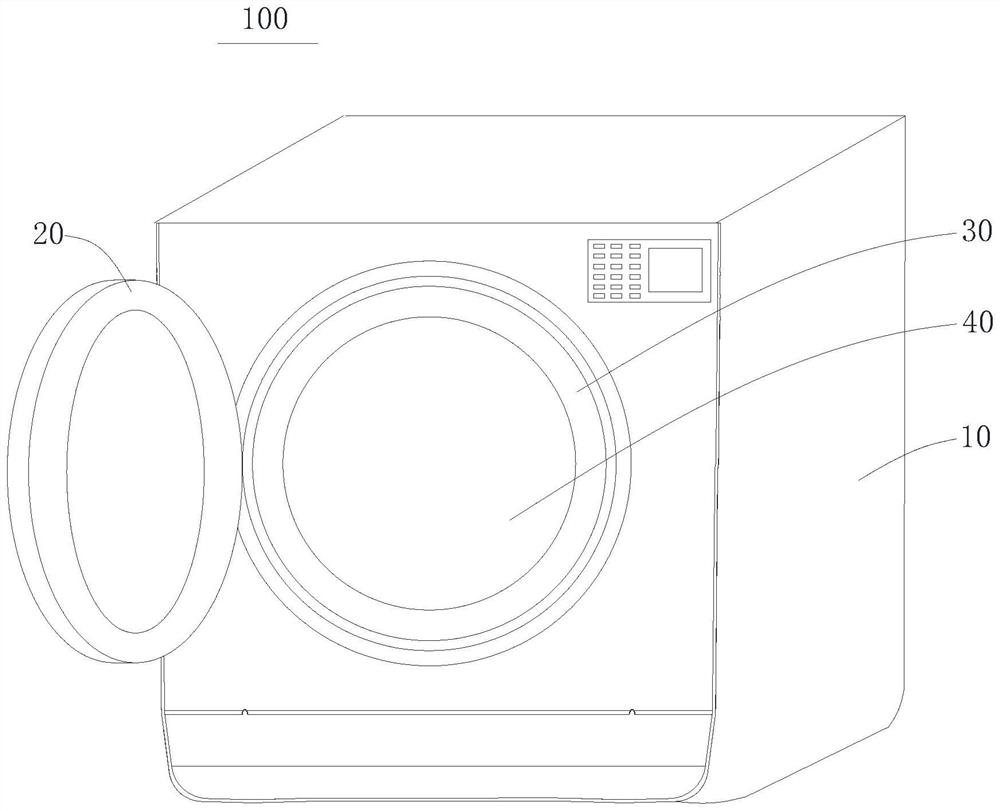

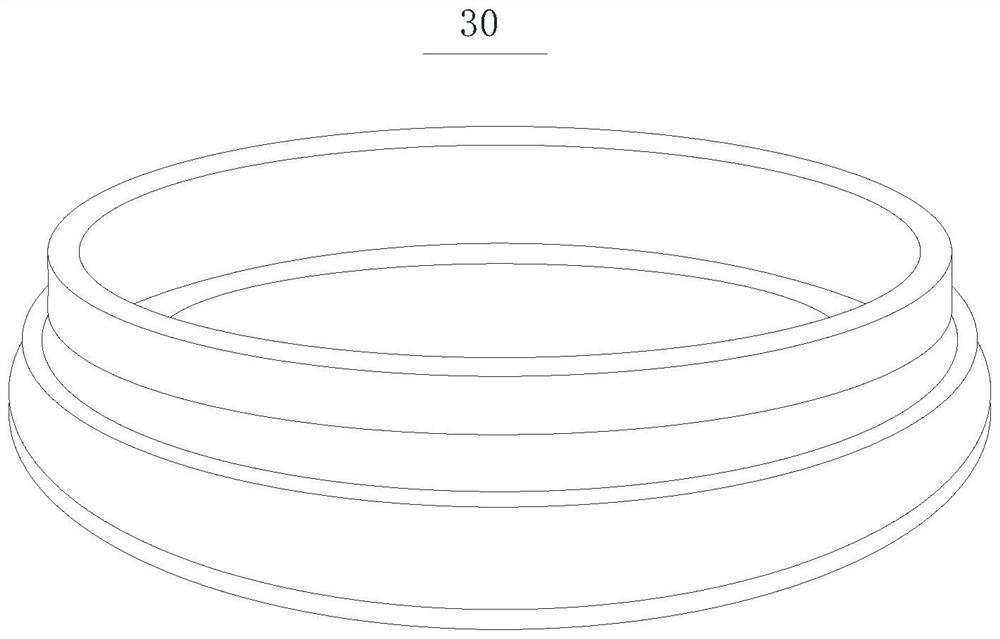

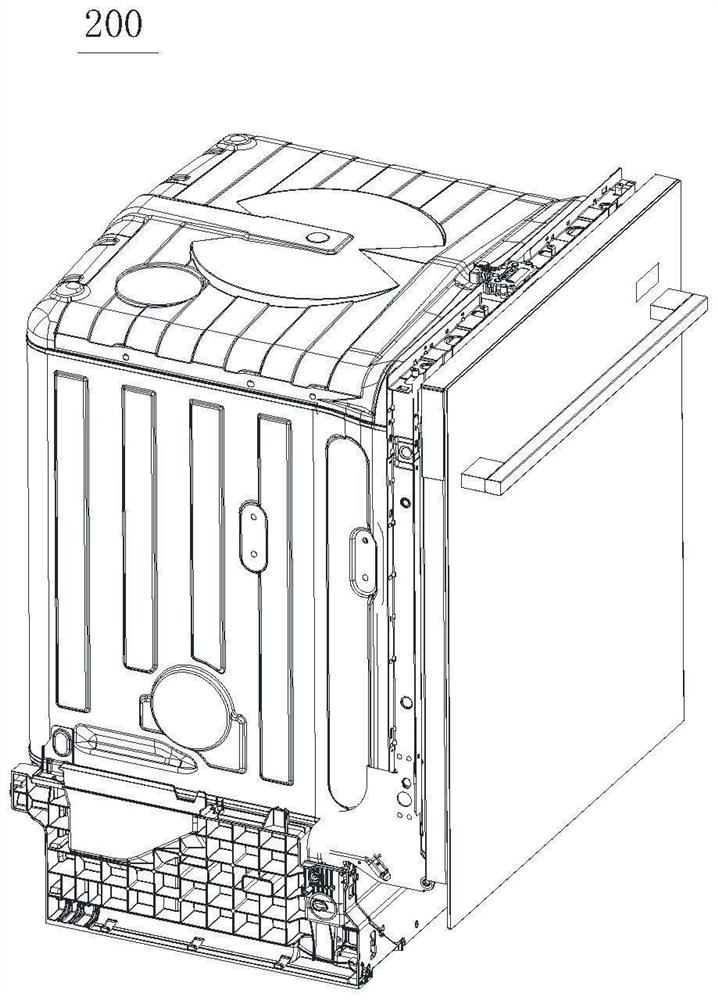

Door seal material and preparation method thereof, door seal ring and household appliance

A door seal ring and inorganic filler technology, applied in the field of household appliances, can solve problems such as difficult to clean stains, easy to deform, poor heat resistance of door seal rings, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0076] An embodiment of the present application provides a method for preparing a door sealing material, comprising the following steps:

[0077] S1. Weigh the following raw materials in parts by weight: 100 parts of styrene-ethylene-butylene-styrene block copolymer, 40-60 parts of polypropylene, 10-20 parts of polyphenylene ether, 100-130 parts of filler oil, and inorganic filler 10-20 parts, 0.1-1 part of surface modifier, 0.1-1 part of pigment, 0.1-0.5 part of antibacterial and antifungal agent, 1-2 parts of slip agent, 0.1-1 part of antioxidant, 0.1-1 part of heat stabilizer 1 part, 0.1-1 part of light stabilizer and 0.1-0.5 part of lubricant, for use;

[0078] S2. Dry the antioxidant and inorganic filler for use;

[0079] S3. Dissolving the surface modifier in anhydrous ethanol, then adding it to the dried inorganic filler, stirring and mixing, and drying to remove the anhydrous ethanol to obtain the pretreated inorganic filler;

[0080] S4. Mix the styrene-ethylene-but...

Embodiment 1

[0089] like Figure 5 Shown, S11, take by weighing the following weight raw materials: styrene-ethylene-butylene-styrene block copolymer (styrene content is 20%, number average molecular weight is 100000g / mol, hydrogenation amount is 90%, purchased from Sinopec Baling Petrochemical Co., Ltd. YH-503) 100g, polypropylene (random copolymer polypropylene, melting index 20g / 10min (230℃, 2.16Kg)) 45g, polyphenylene ether (intrinsic viscosity 0.35dL / g 25℃ , chloroform is solvent) 15g, hydrogenated white oil (kinematic viscosity is 10mm 2 / s, 40℃) 120g, calcium carbonate (1250 mesh) 15g, [3-(methacryloyloxy)propyl]trimethoxysilane 0.3g, iron red 0.5g, zirconium phosphate supported silver 0.3g, silicon Ketone (60% silane content) 1.5g, antioxidant (mass ratio of antioxidant 1010 and antioxidant 168 10:1) 0.3g, organotin heat stabilizer 0.4g, light stabilizer (light stabilizer UV327 and Light stabilizer GW580 mass ratio 1:1) 0.4g, ethylene bis-stearic acid amide 0.2g;

[0090] S12, v...

Embodiment 2

[0096] like Image 6 Shown, S21, take by weighing the following weight raw materials: styrene-ethylene-butylene-styrene block copolymer (styrene content is 30%, number average molecular weight is 200000g / mol, hydrogenation amount is 93%, purchased from Sinopec Baling Petrochemical Co., Ltd. YH-503) 100g, polypropylene (random copolymer polypropylene, melting index 25g / 10min (230℃, 2.16Kg)) 35g, polyphenylene ether (intrinsic viscosity 0.4dL / g 25℃ , chloroform is solvent) 13g, hydrogenated white oil (kinematic viscosity is 20mm 2 / s, 40℃) 110g, calcium carbonate (1250 mesh) 17g, [3-(methacryloyloxy)propyl]trimethoxysilane 0.3g, iron red 0.5g, zirconium phosphate supported silver 0.3g, silicon Ketone (60% silane content) 1g, antioxidant (mass ratio of antioxidant 1010 to antioxidant 168 10:1) 0.3g, organotin heat stabilizer 0.4g, light stabilizer (light stabilizer UV327 and light stabilizer) Agent GW580 mass ratio 1:1) 0.3g and ethylene bis-stearic acid amide 0.2g;

[0097] S...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt finger | aaaaa | aaaaa |

| Intrinsic viscosity | aaaaa | aaaaa |

| Melt finger | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com