Patents

Literature

43results about How to "Solve the problem of low machining accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

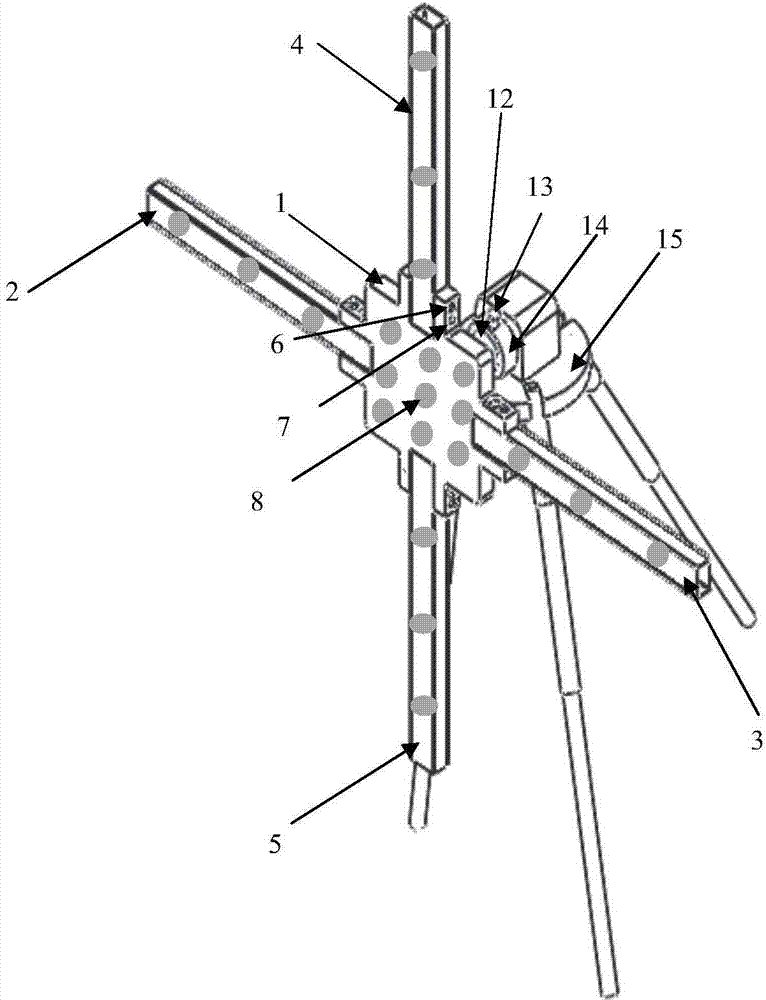

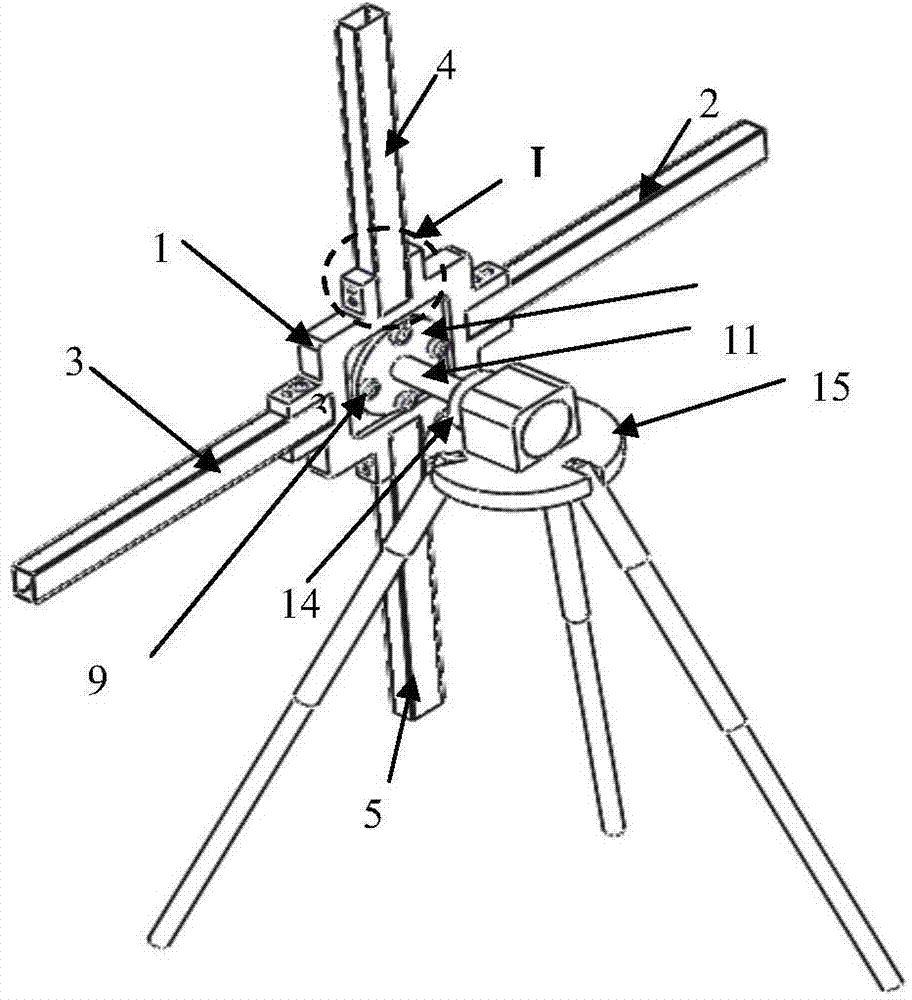

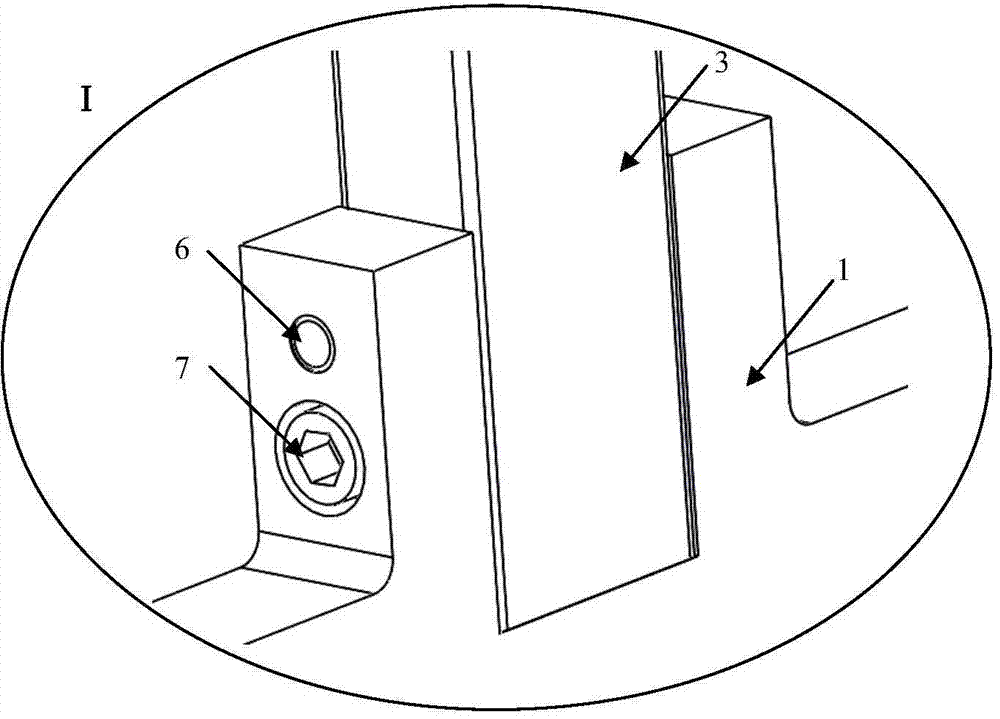

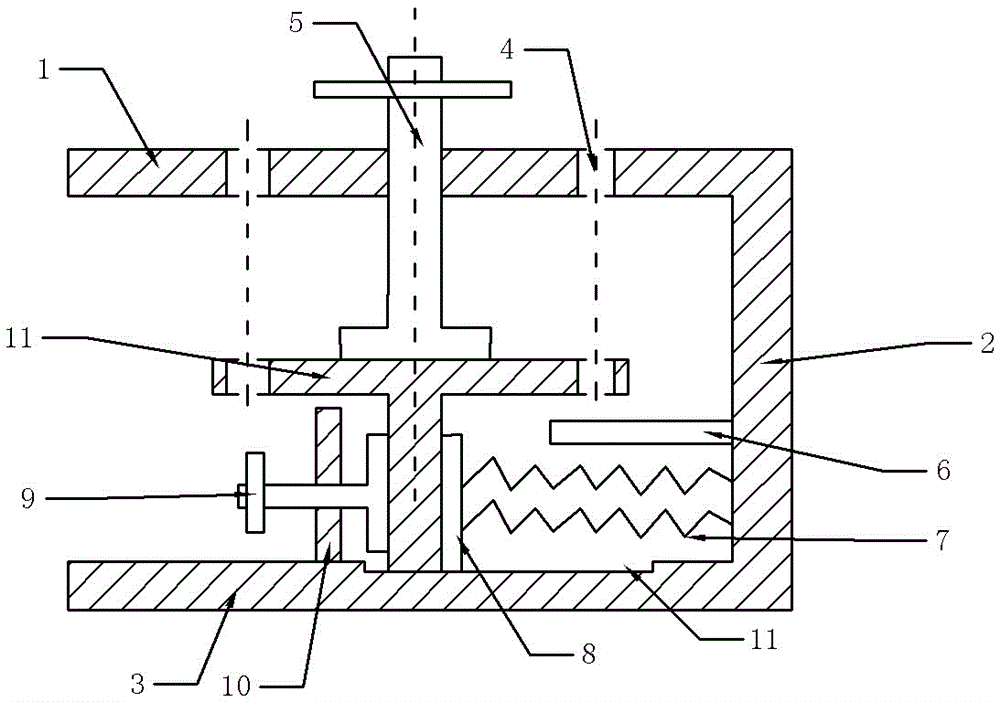

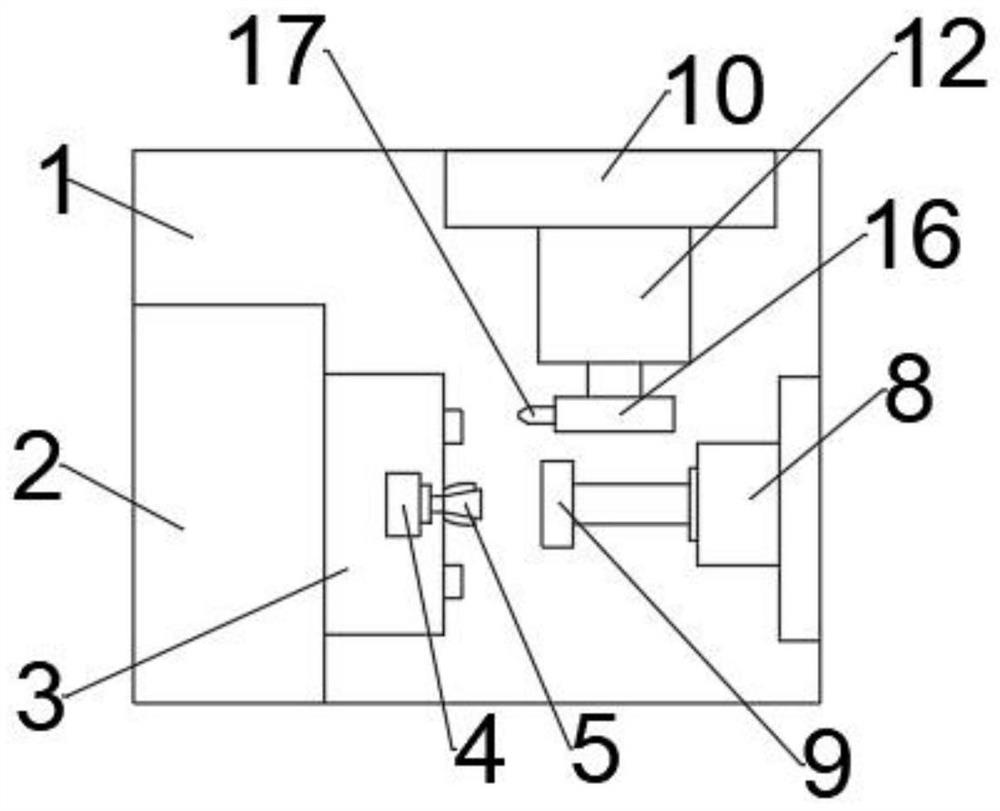

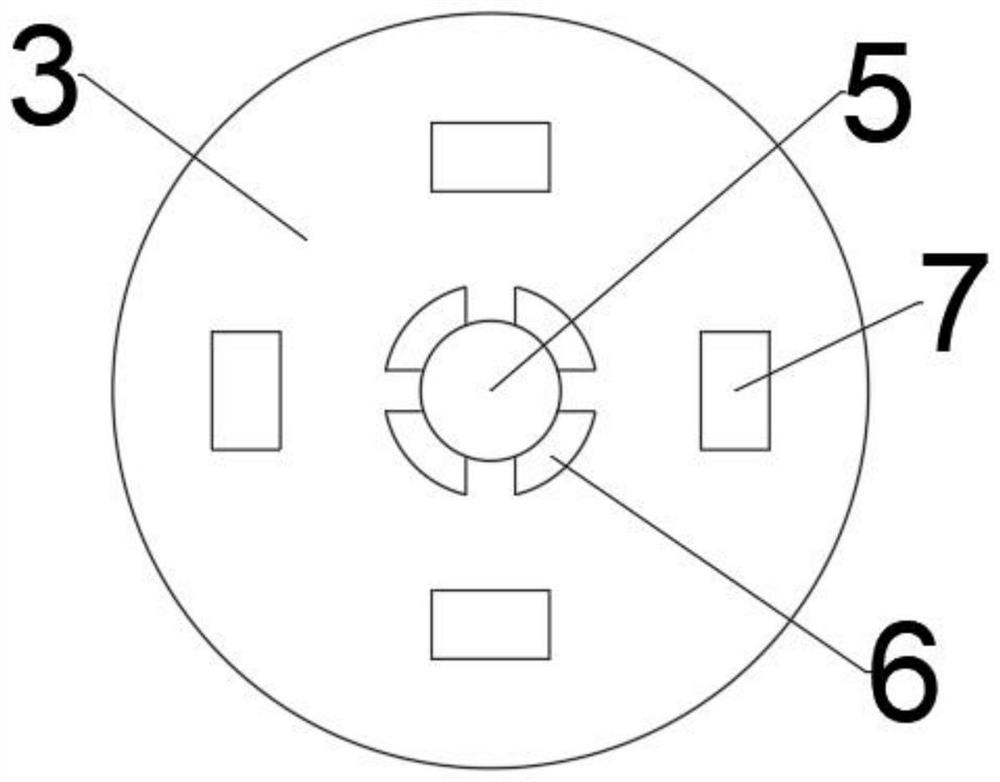

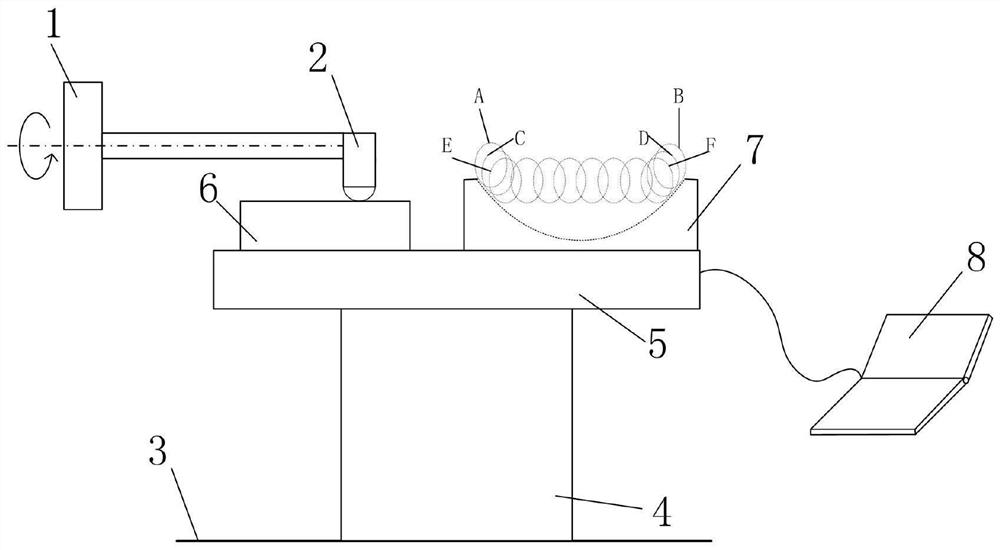

Flexible calibration device for calibrating wind tunnel vision measurement system

ActiveCN104776861ASolve the problem of low machining accuracySimple structureMeasurement devicesEngineeringMotion controller

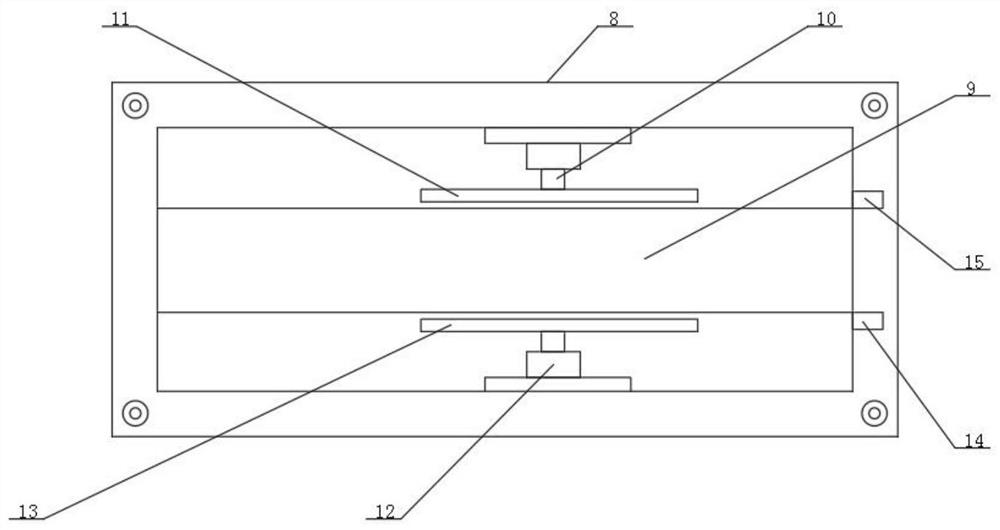

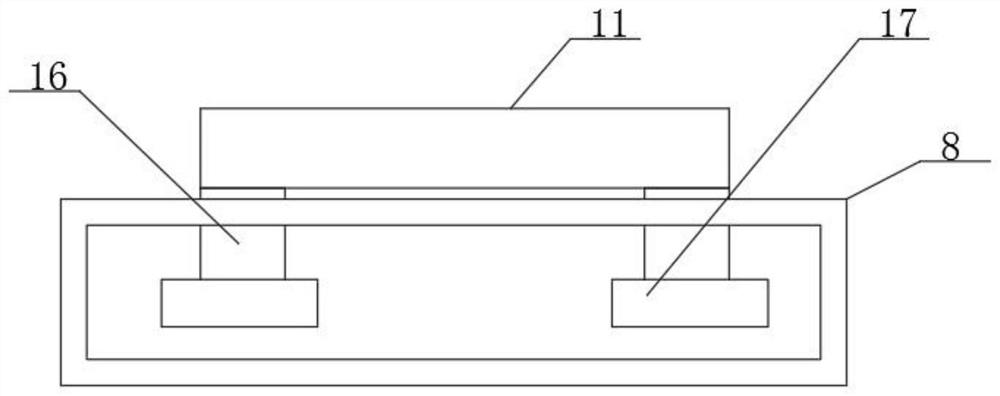

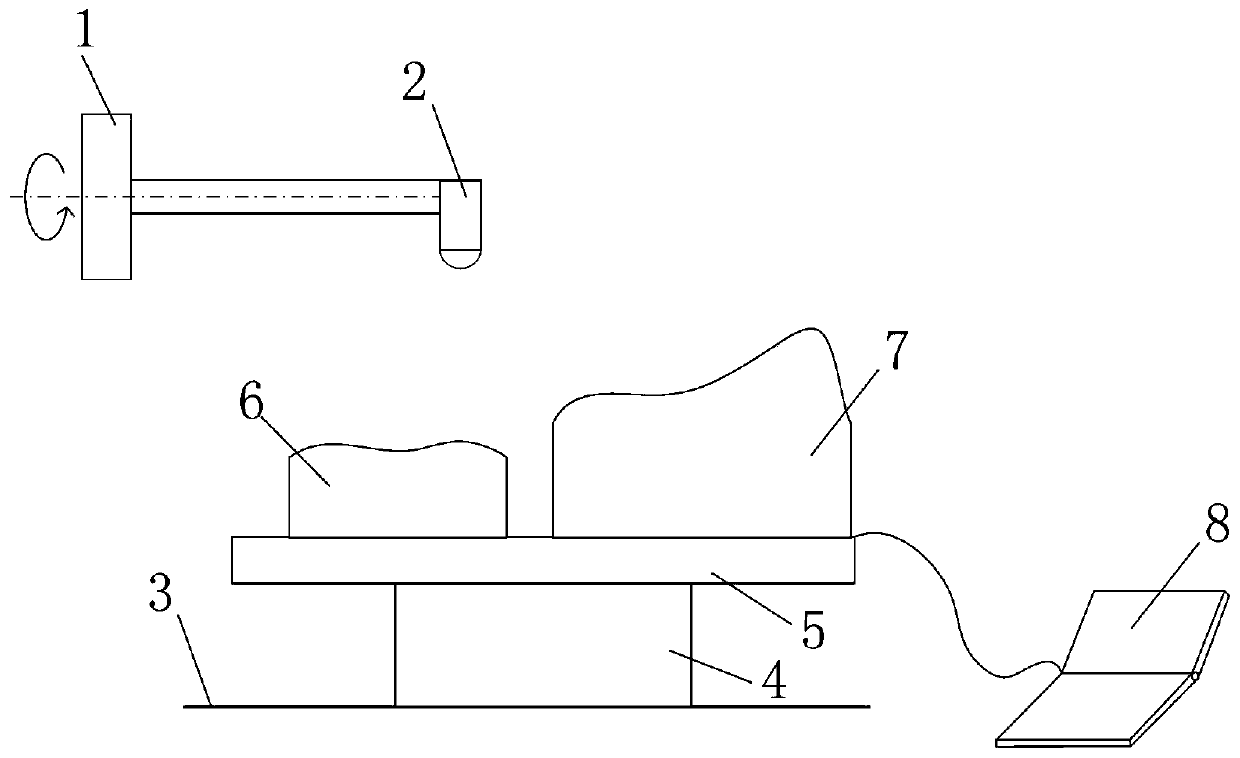

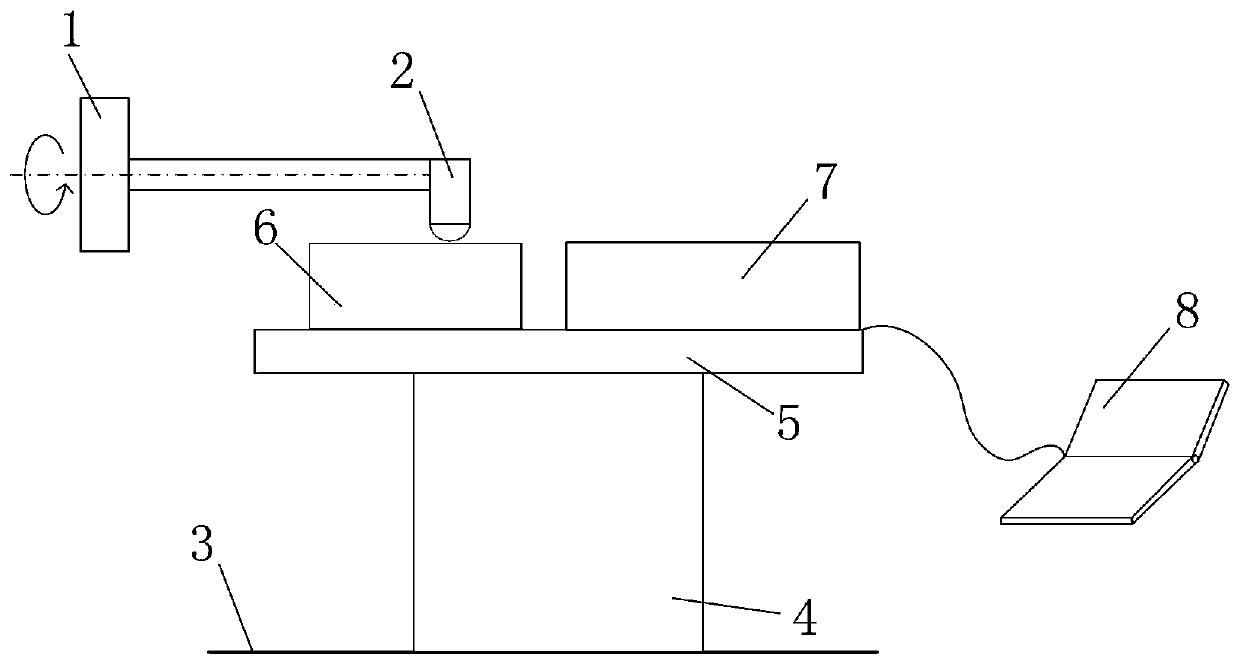

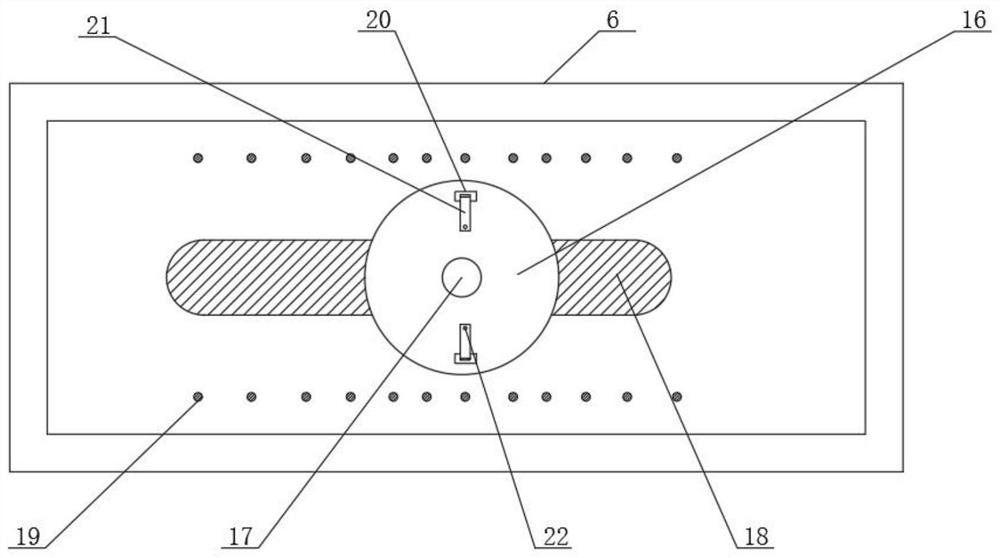

The invention discloses a flexible calibration device for calibrating a wind tunnel vision measurement system, belongs to the field of computer vision, and relates to a calibration device for calibrating a vision measurement system in a wind tunnel environment. The calibration device consists of a flexible target and a target position controller, wherein a groove is formed in each of four side surfaces of a calibration plate; two raised rectangular blocks are arranged on the side of each groove; the two rectangular blocks are arranged in a central symmetry manner relative to the side surface; and totally four calibration scales are arranged. In the target position controller, a circular flange plate is fixedly arranged on the calibration plate by virtue of four inside hexagonal bolts, namely a target motion controller and the flexible target are assembled and connected together. The flexible calibration device is low in cost, simple, convenient and easy to detach, and the problems that the large calibration plate is low in calibrating and machining precision, the adopted calibration cross rack is low in calibration and correction precision and the like are solved. During calibration, the target is arranged on a bracket, the target motion is controlled by adopting a ball bearing pair, and interference brought by handheld shake is reduced.

Owner:DALIAN UNIV OF TECH

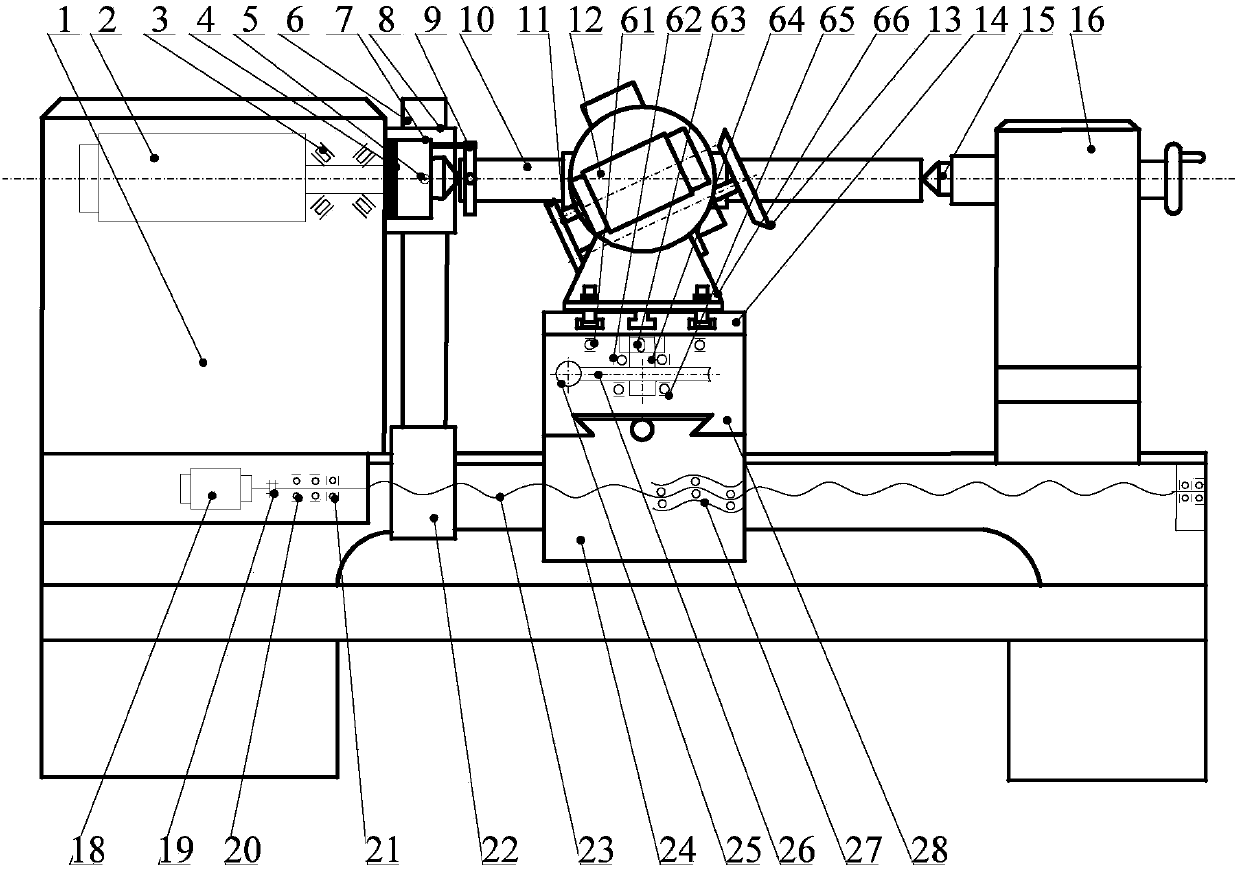

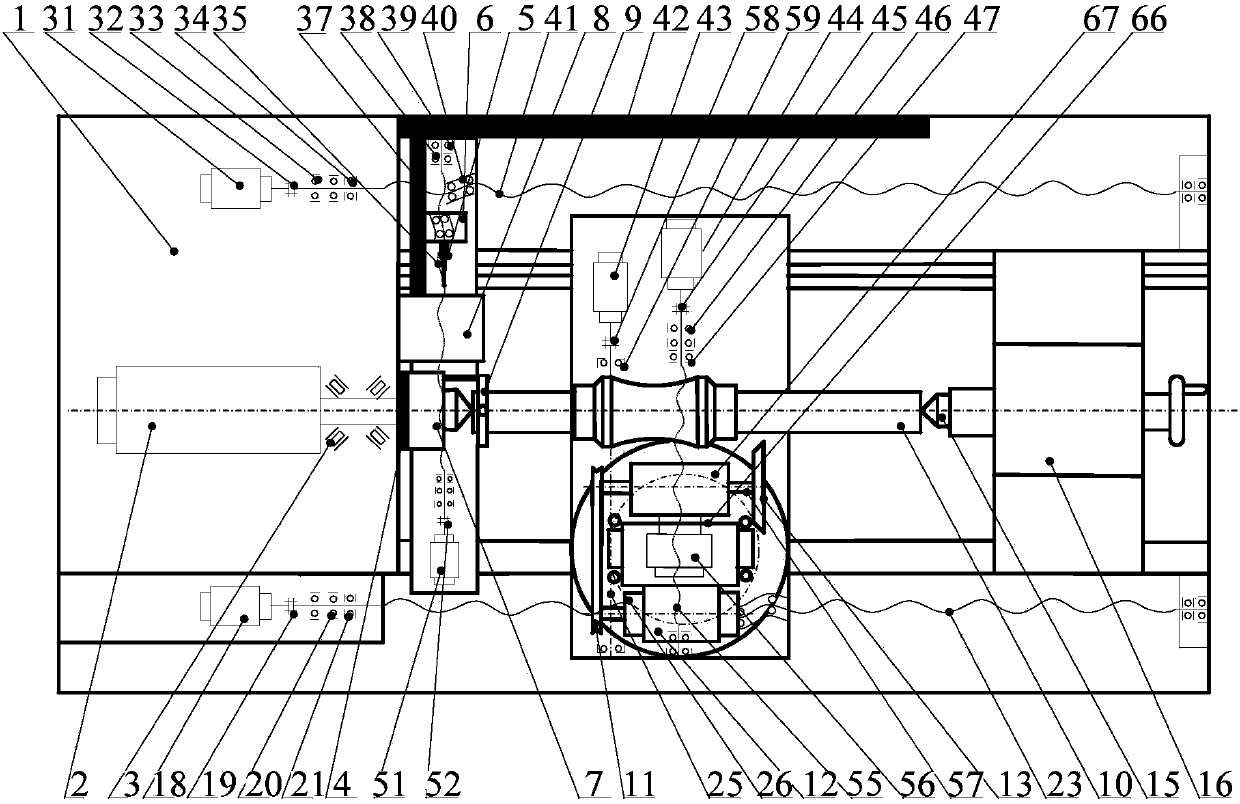

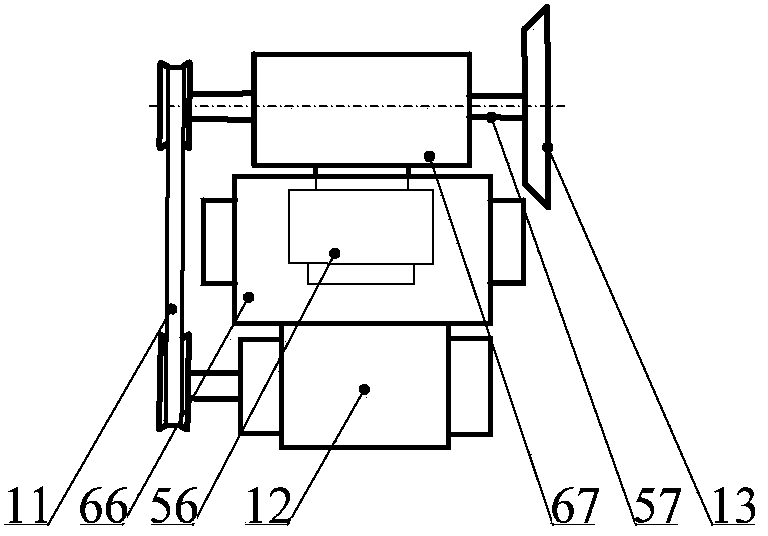

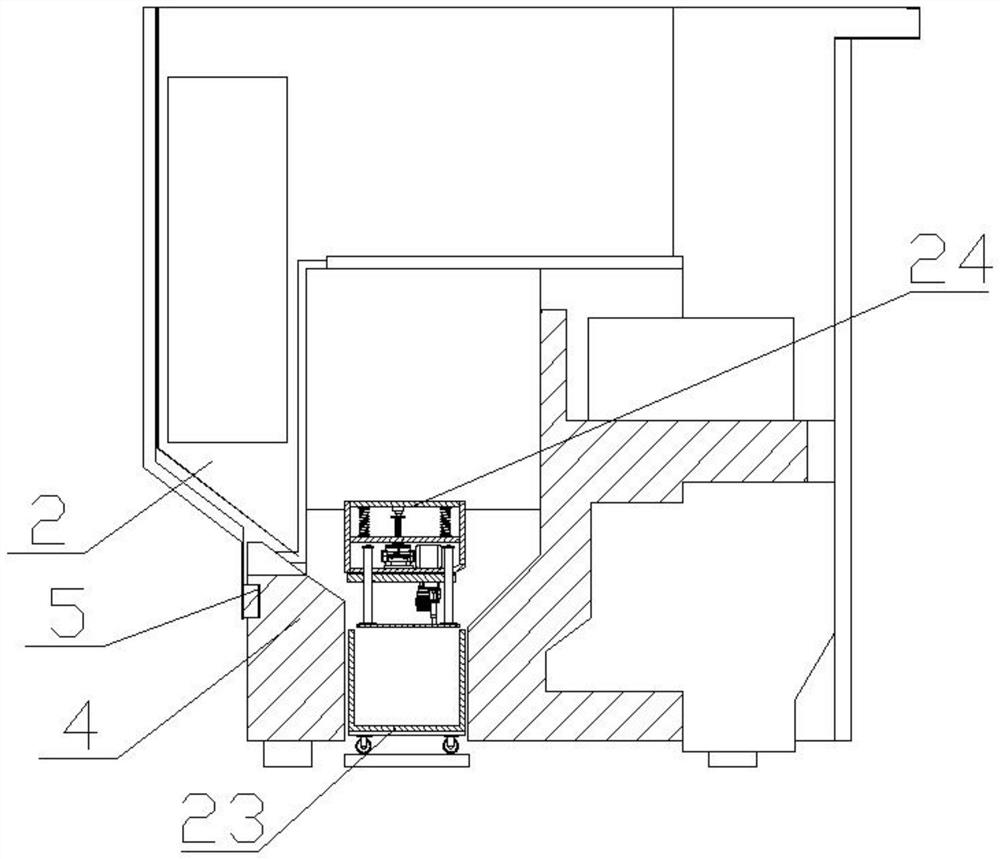

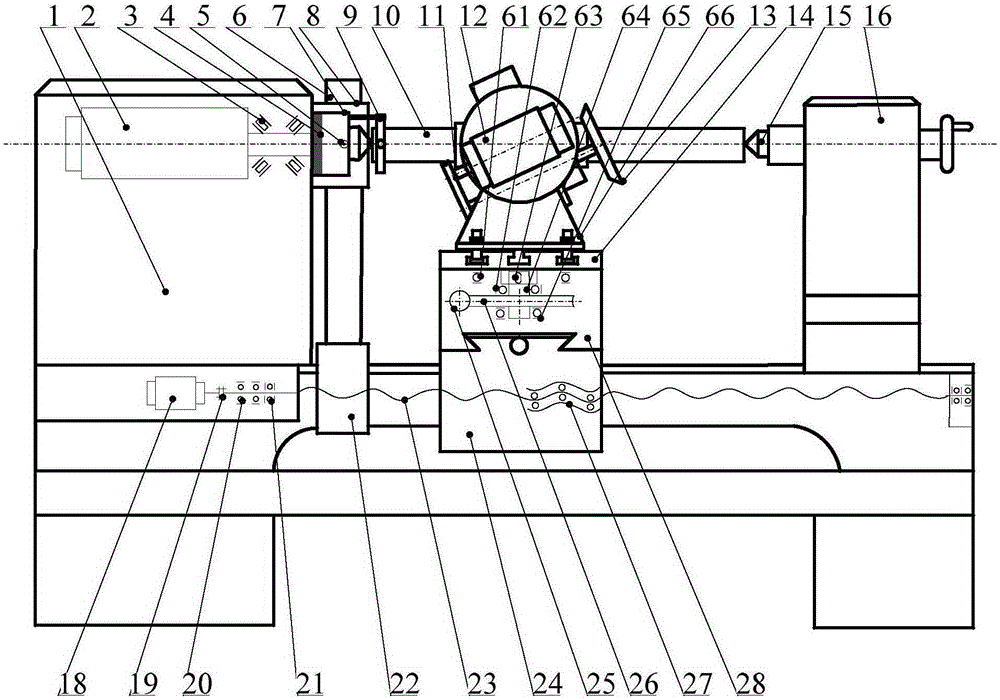

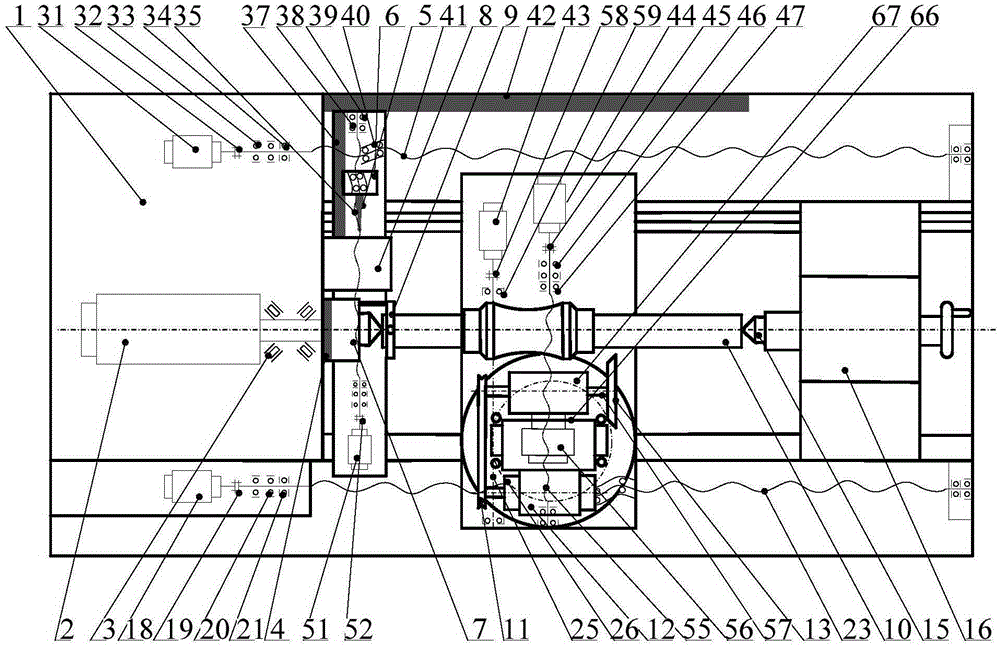

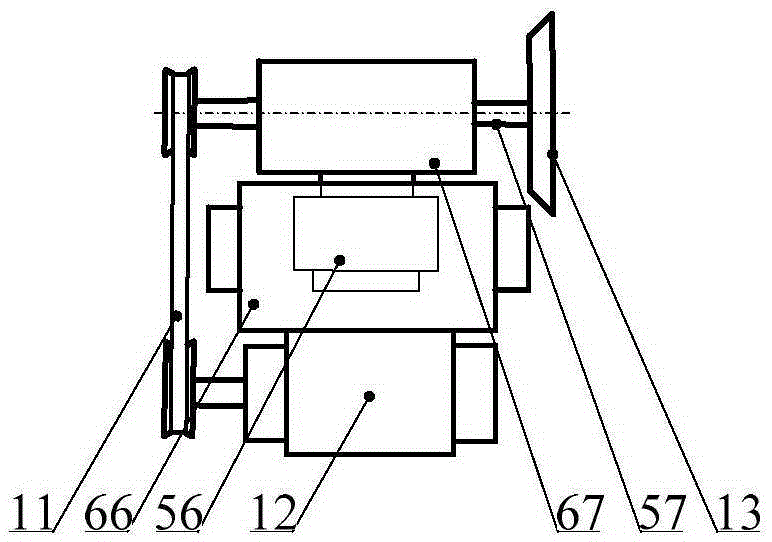

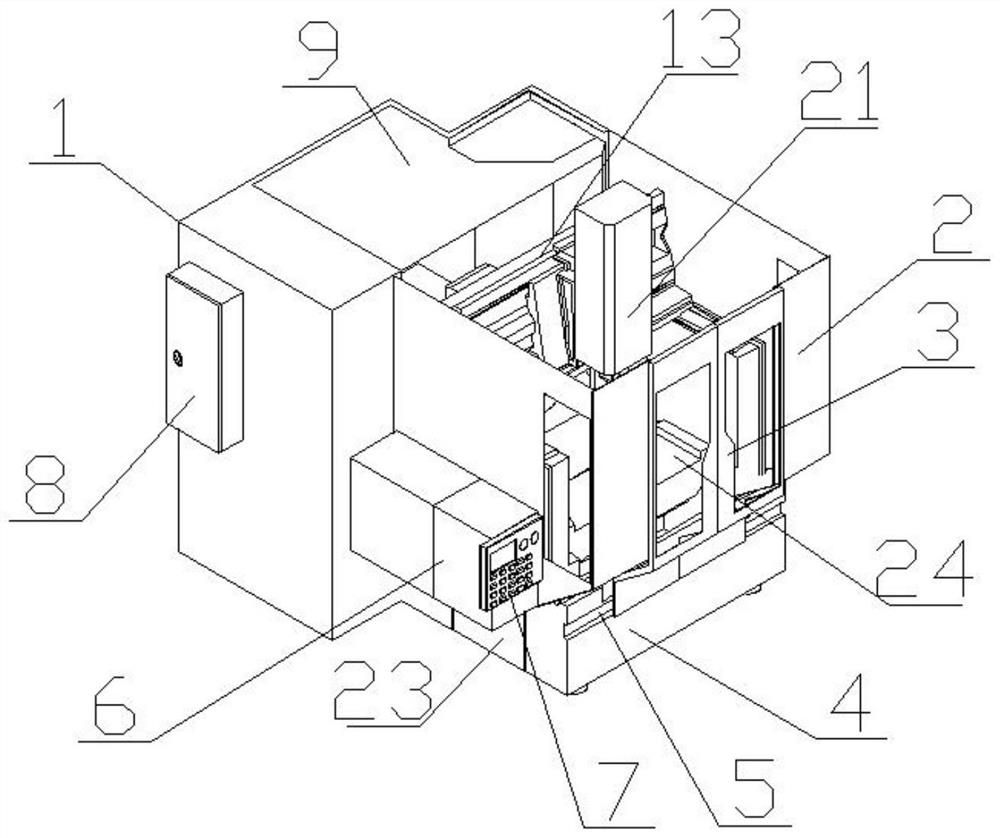

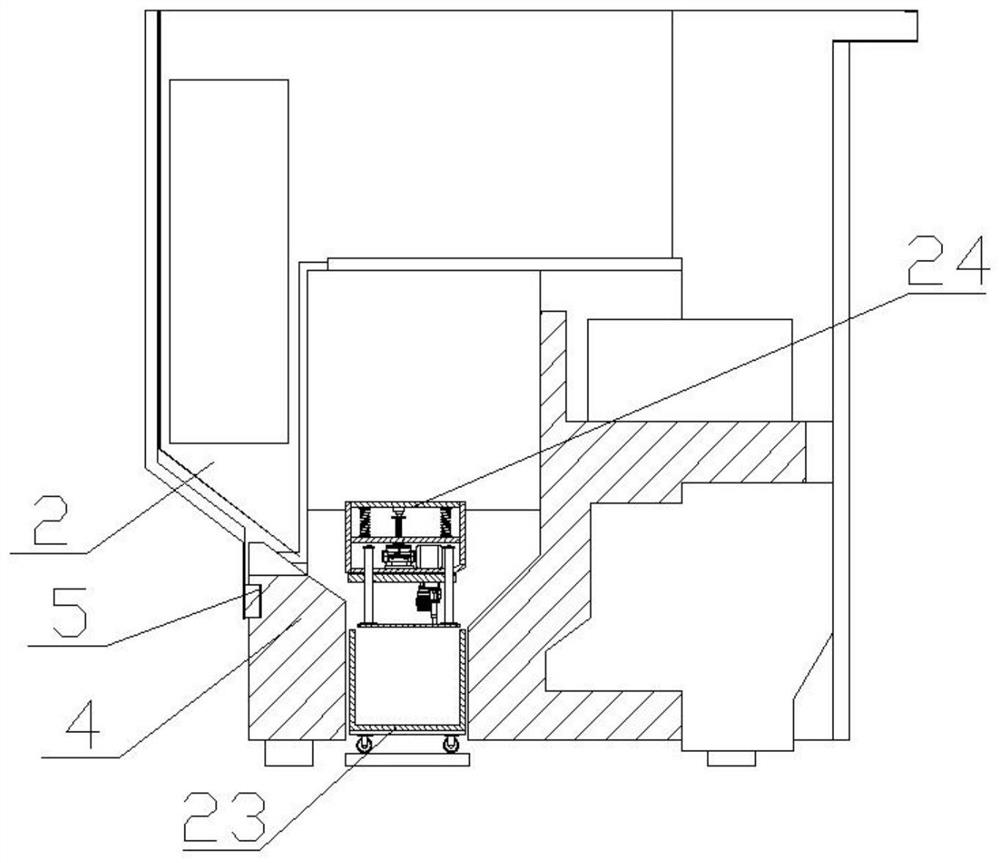

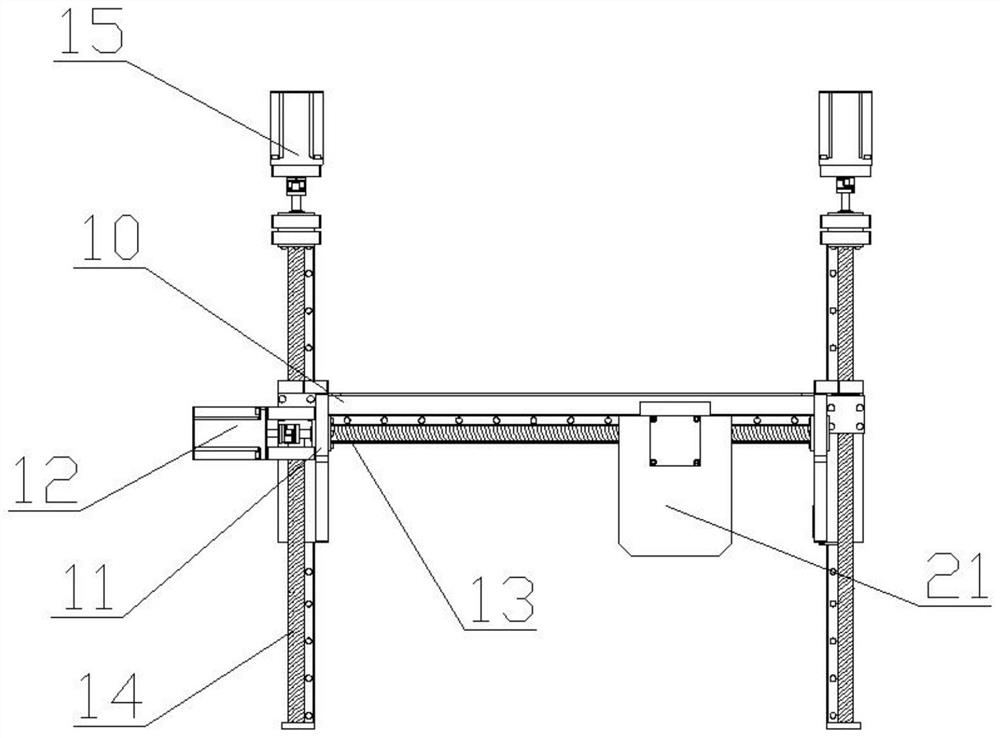

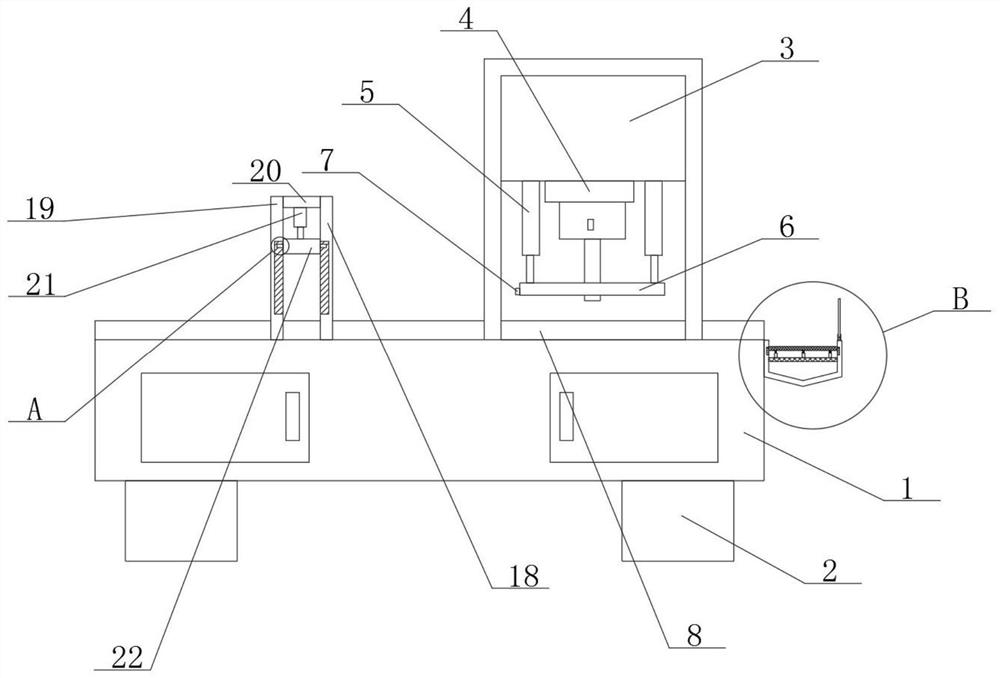

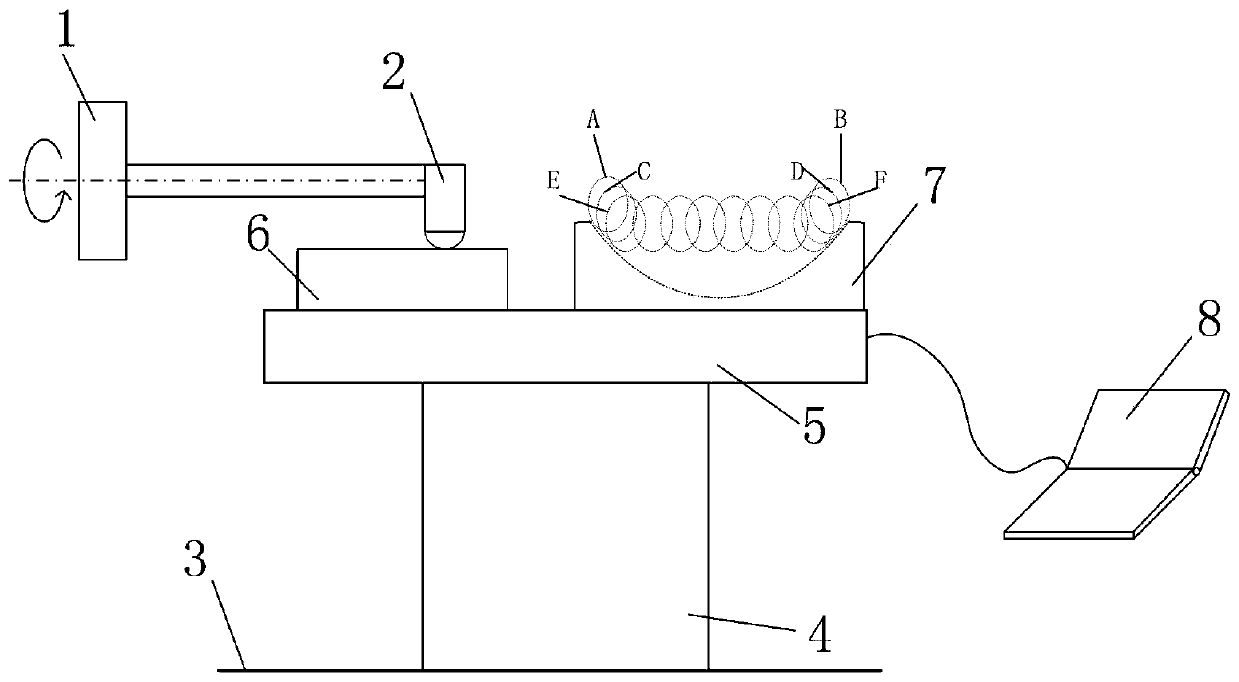

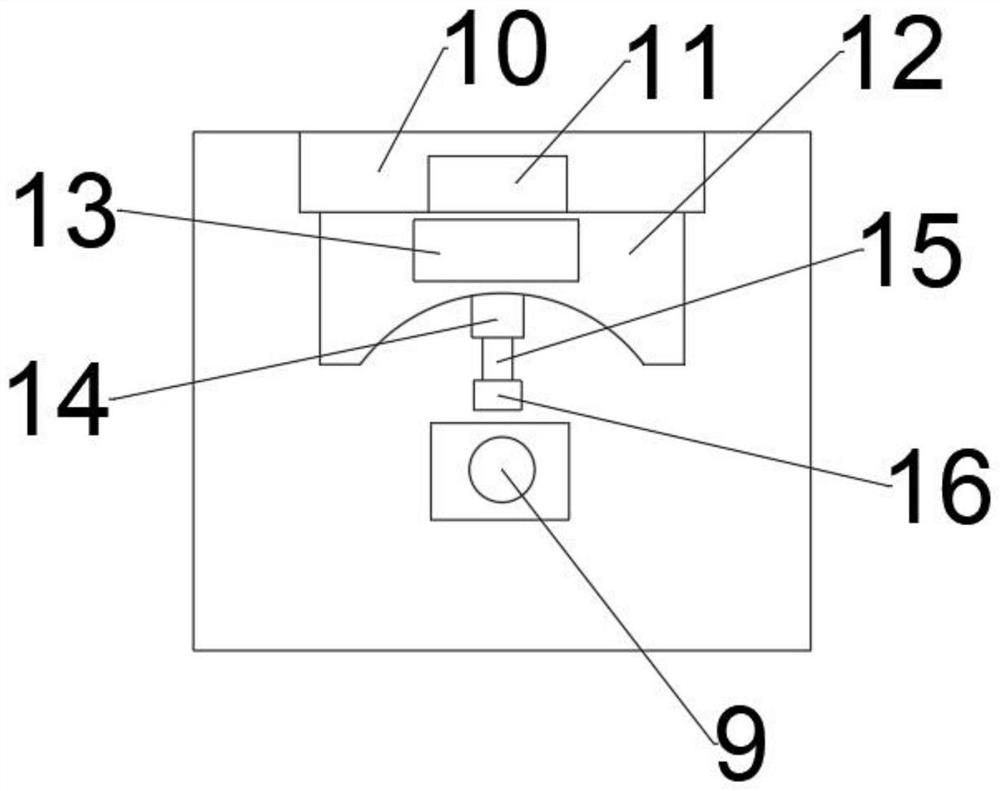

Hourglass worm processing machine tool with on-line detection and correction processing functions

ActiveCN104174938ASolve the problem of low machining accuracyImprove general performanceAutomatic control devicesMeasurement/indication equipmentsProcessing accuracyHourglass

The invention discloses a hourglass worm processing machine tool with on-line detection and correction processing functions. The hourglass worm processing machine tool comprises a machine tool body, wherein a spindle unit and a processing unit are arranged on the machine tool body; the spindle unit comprises a driving centre and a tailstock centre, which are used for ejecting and holding a hourglass worm to be processed; the processing unit is used for processing the tooth surface of the hourglass worm; the hourglass worm processing machine tool further comprises a detection unit and a control unit, so that on-line detection and correction processing are realized during the processing process of the tooth surface of the hourglass worm, and the problem of low processing precision of the tooth surface of the hourglass worm is solved basically.

Owner:XIHUA UNIV

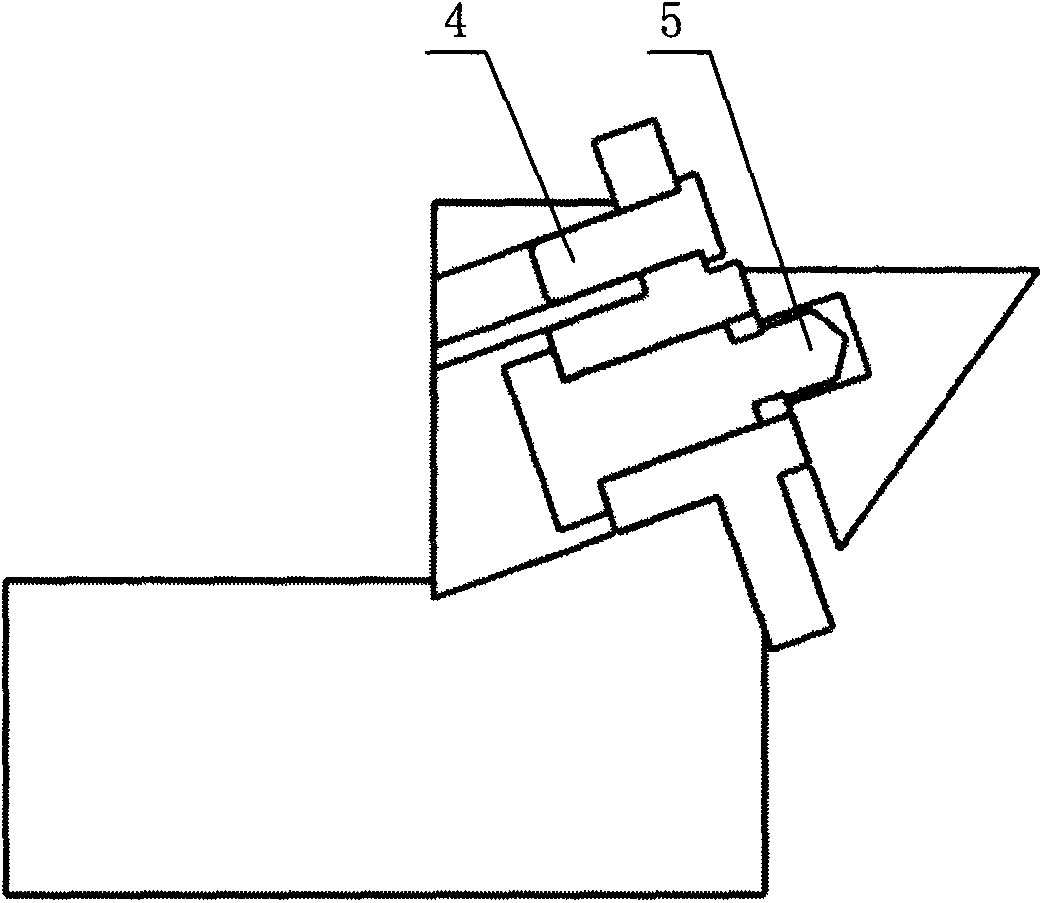

T-shaped workpiece machining fixture

InactiveCN105458969AImprove drilling accuracyNo loosenessWork holdersPositioning apparatusPunchingEngineering

The invention belongs to the field of workpiece machining and discloses a T-shaped workpiece machining fixture. The T-shaped workpiece machining fixture comprises a fixture body. The fixture body comprises a bottom plate, a top plate and a right side plate. The top plate is parallel to the bottom plate. The two ends of the right side plate are connected with the top plate and the bottom plate respectively. The top plate is provided with a first clamping shaft and a machining hole. The first clamping shaft is in threaded connection with the top plate. The first clamping shaft is perpendicular to the top plate. The right side plate is provided with springs. One ends of the springs are fixedly connected with the right side plate. The other ends of the springs are connected with a clamping block which is in sliding connection with the bottom plate. The bottom plate is provided with an auxiliary block which is a strip-shaped block and fixed to the bottom plate. The auxiliary block is perpendicular to the bottom plate and provided with a second clamping shaft which is perpendicular to the auxiliary block, and the second clamping shaft and the auxiliary block are in threaded connection. According to the T-shaped workpiece machining fixture, the punching precision of a T-shaped workpiece can be greatly improved, and the T-shaped workpiece machining fixture is worth using and popularization.

Owner:重庆天和玻璃有限公司

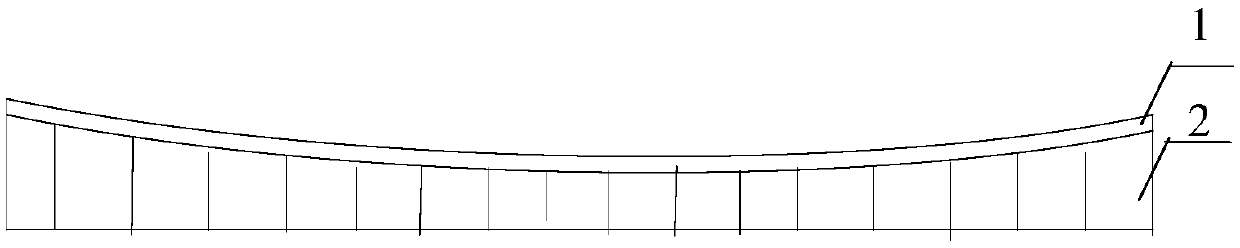

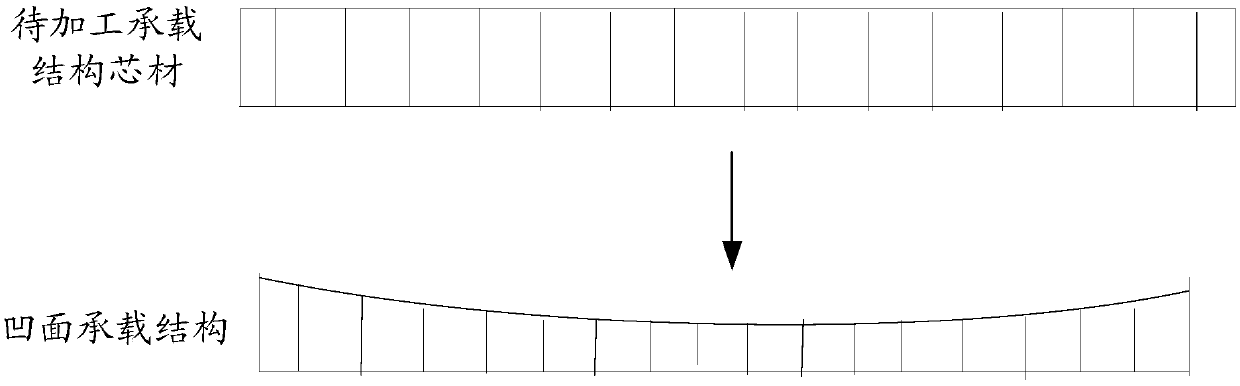

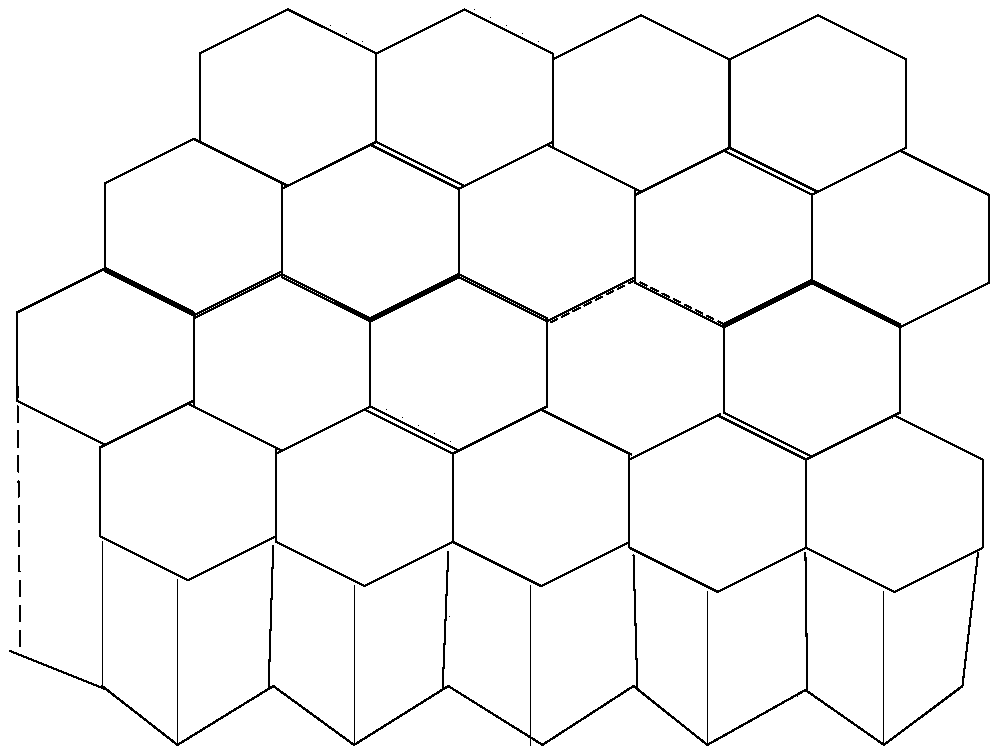

Curved-surface light focusing reflector, machining system, light focusing reflector set and preparation method thereof

PendingCN108680975AImprove spotlight effectSolve the problem of low machining accuracySolar heating energyMirrorsNumerical controlHeliostat

An embodiment of the invention discloses a curved-surface light focusing reflector, a curved-surface light focusing reflector machining system, a curved-surface light focusing reflector set and a preparation method thereof. A traditional mold is not depended in a process for preparing the curved-surface light focusing reflector. According to different light focusing distances of actual projects, acurved surface radian which makes the current curved-surface light focusing reflector reach a required optimal light focusing effect of a user is calculated. By means of cutting of a numerical control machining tool, a curved-surface radian bearing structure is obtained. Finally a reflecting layer with preset hardness uses the bearing structure as a similar mold for performing fixation and applying is fixedly adhered, thereby preparing the curved-surface light focusing reflector. The curved-surface light focusing reflector is obtained through splicing a plurality of sub-mirrors. The curved surface radian of each sub-mirror is obtained through performing distribution calculation on the integral curved-surface radian of the curved-surface light focusing reflector set according to the splicing position of each sub lens in the lens set. The curved-surface light focusing reflector can be applied in a tower type solar energy power generation heliostat, thereby effectively improving solar heat utilization efficiency and furthermore improving solar heat power generation efficiency.

Owner:许养新

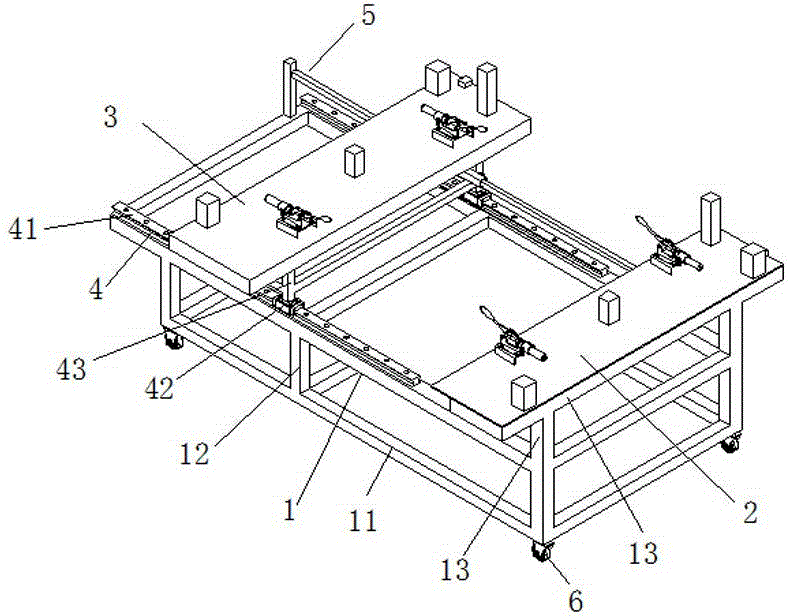

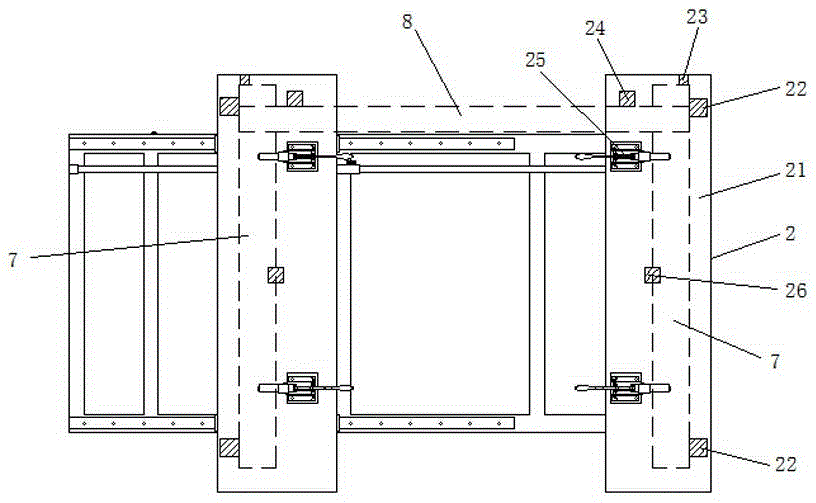

Machining and locating device for car platform bracket

ActiveCN104526237ASolve the problem of low machining accuracySimplify the difficulty of operationWelding/cutting auxillary devicesAuxillary welding devicesAutomobile platformEngineering

Provided is a machining and locating device for a car platform bracket. The bracket is defined by longitudinal beams and a cross beam which are machined with each other. The locating device comprises a support, one side of the support is fixedly connected with a right fixator, and the other side of the support is connected with a left fixator through a guide part. The structure of the left fixator and the structure of the right fixator are symmetrically arranged. The right fixator comprises a bearing plate which is provided with an X stopping block used for limiting the X-axis direction of the longitudinal beams and a Y stopping block used for limiting the Y-axis direction of the longitudinal beams. The X stopping blocks are higher than the longitudinal beams, and the higher parts of the X stopping blocks are used for limiting the X-axis direction of the cross beam. The bearing plates are further provided with Y-axis locating blocks used for limiting the Y-axis direction of the cross beam and pressing pliers used for fixing the longitudinal beams. The machining and locating device solves the problem that the machining precision is low due to the fact that the machining position needs to be manually measured originally, lowers the operation difficulty and improves the machining efficiency.

Owner:布劳恩机电(嘉兴)有限公司

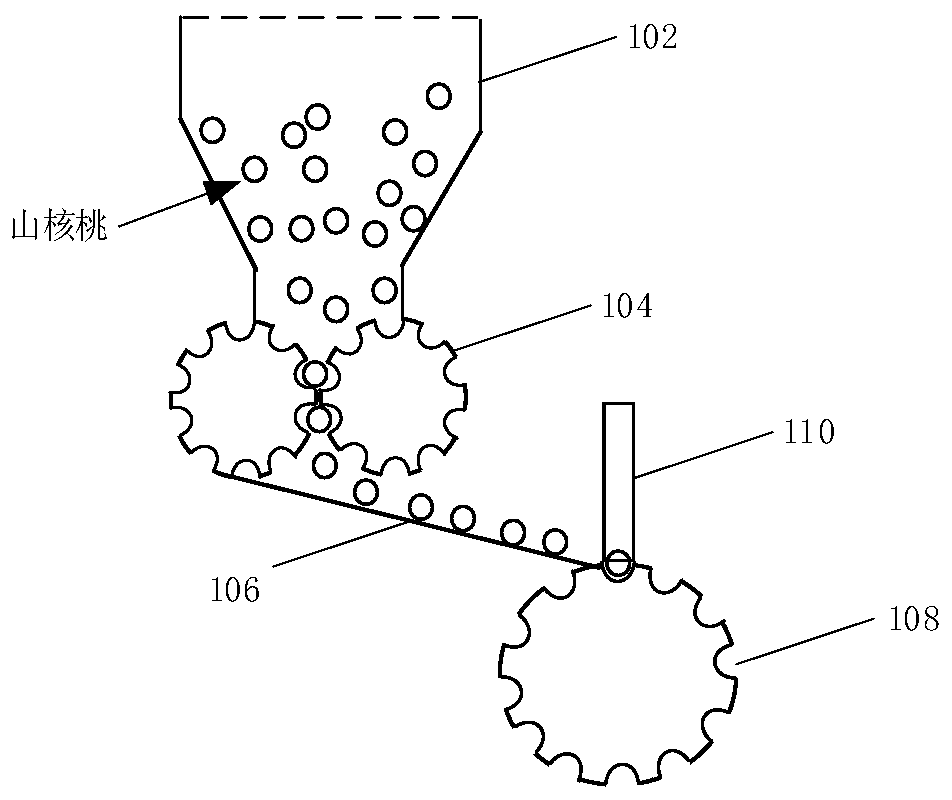

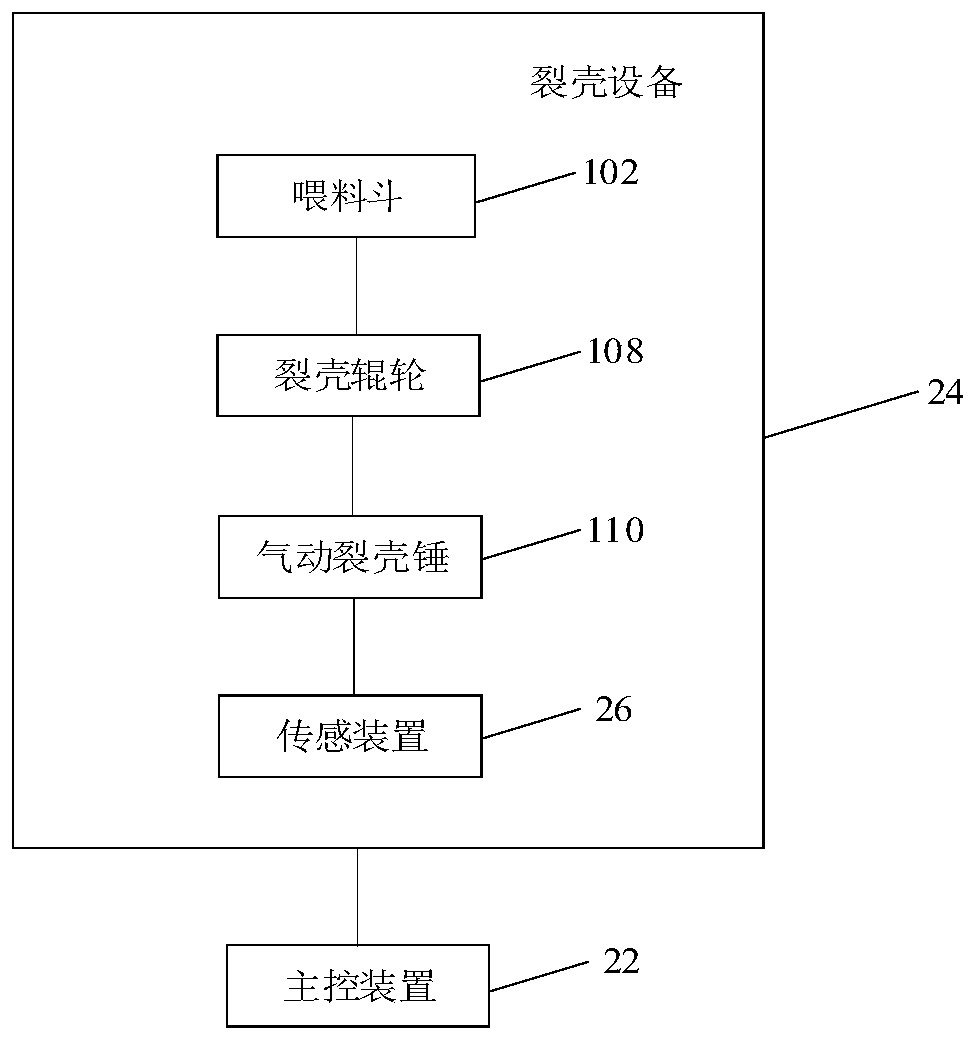

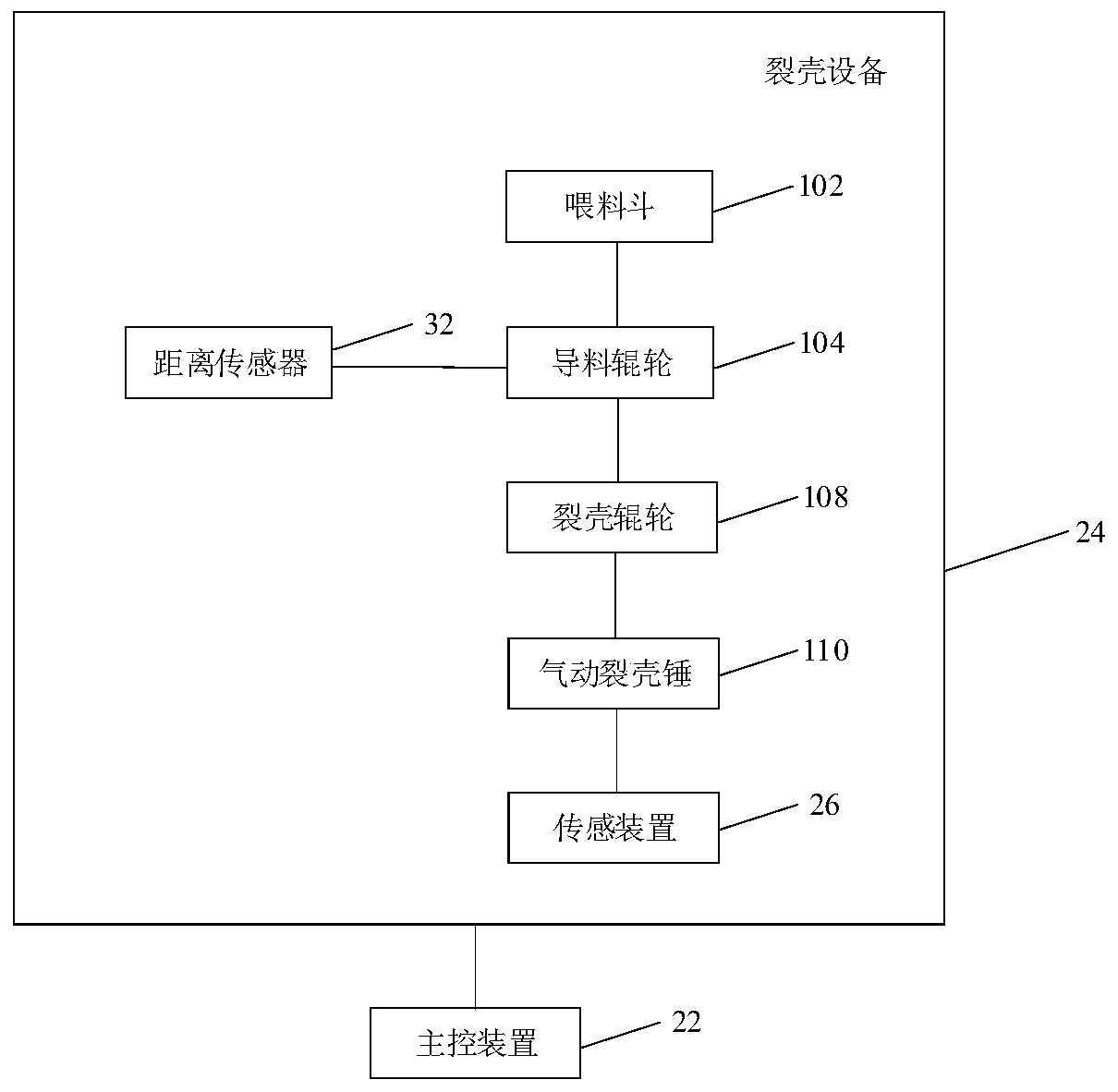

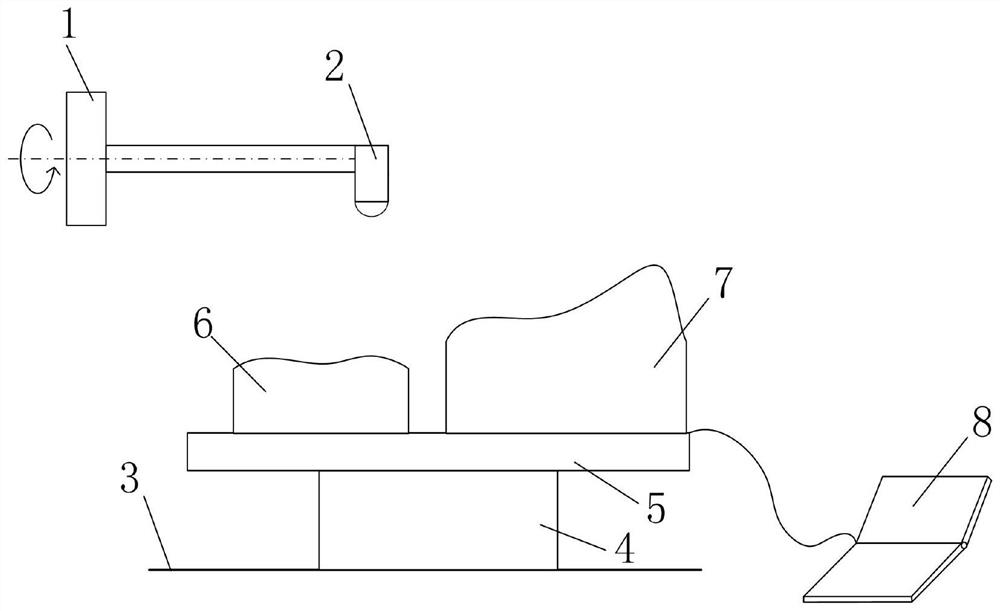

Processing method and processing system for cracking carya cathayensis fruit shells

ActiveCN111418854ASolve the problem of low machining accuracyHuskingProgramme control in sequence/logic controllersCarya cathayensisReciprocating motion

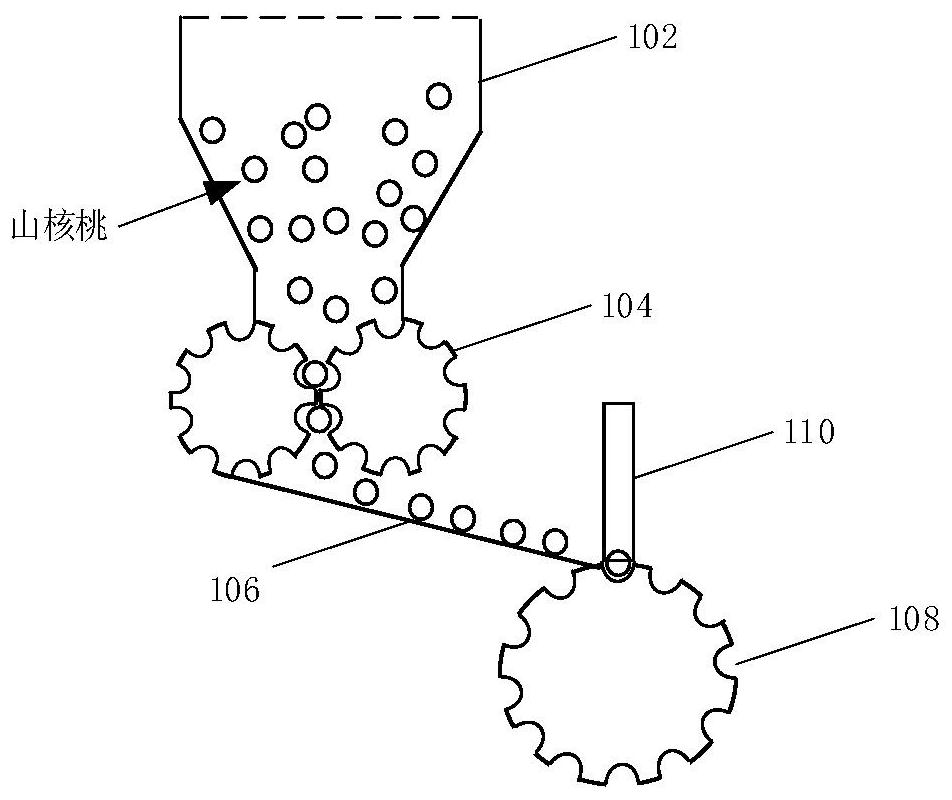

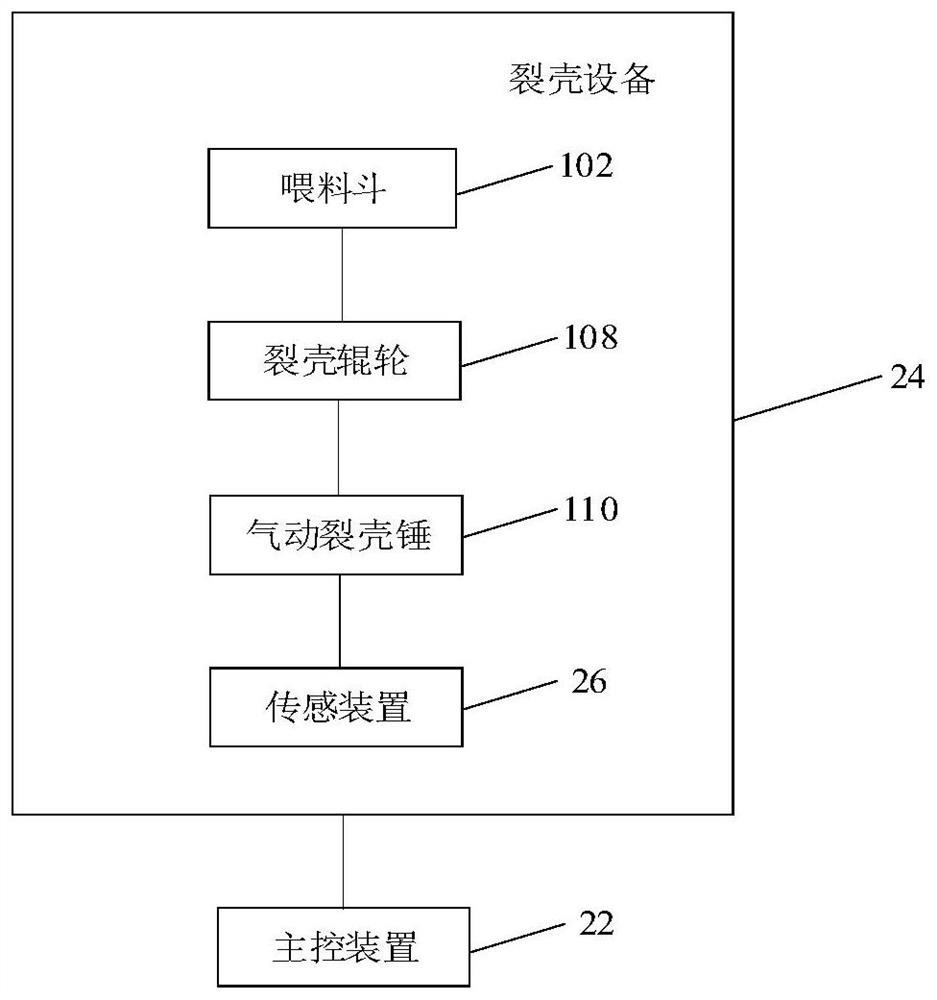

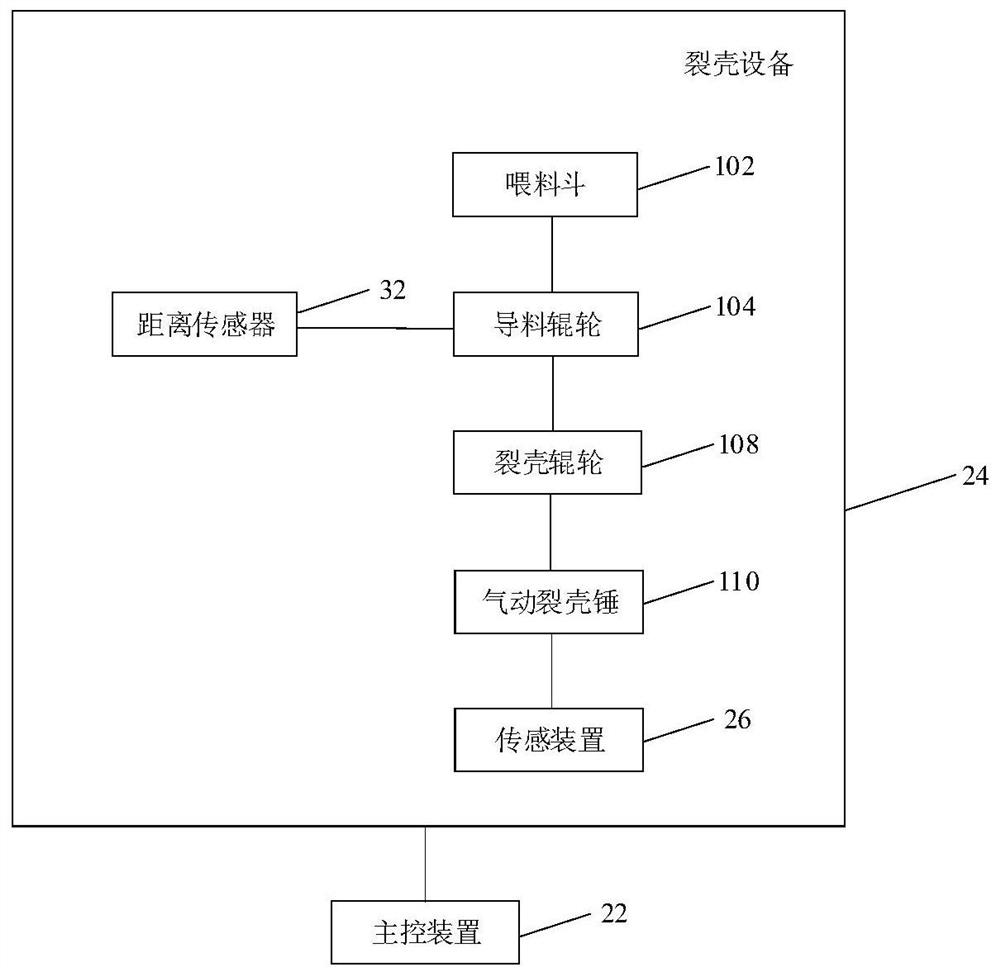

The invention discloses a processing method and processing system for cracking carya cathayensis fruit shells. The system includes a shell cracking device and a main control device; the shell crackingdevice includes a feeding hopper, a shell cracking rolling wheel, a sensing device and a pneumatic shell cracking hammer; the main control device conveys the carya cathayensis fruits fed into the feeding hopper to the shell cracking roll wheel and controls the vertical reciprocating motion of the pneumatic shell cracking hammer to crack the shells of the carya cathayensis fruits; the main controldevice is connected with the pneumatic shell cracking hammer to acquire the deformation amount of the carya cathayensis fruits detected by the sensing device; and the sensing device is arranged on the pneumatic shell cracking hammer, and the sensing device is connected with the main control device. The main control device determines that the pneumatic shell cracking hammer completes the processing of the shell cracking of the carya cathayensis fruits when the deformation amount is greater than or equal to a preset compression amount, and controls the pneumatic shell cracking hammer to reset to an initial state, so that the problem of low processing accuracy in the processing process of the shell cracking of the carya cathayensis fruits is solved.

Owner:杭州姚生记食品有限公司

Machining method applicable to step shaft

InactiveCN106826143AIncrease stiffnessSolve the problem of low machining accuracyShaftsMachiningHeat treated

The invention discloses a processing method suitable for stepped shafts, which comprises the following steps: A: select a 45 steel forging, process the 45 steel forging into a bar, and heat-treat the bar; B: heat-treat the bar Clamp the clamped bar, correct the clamped bar, and ensure that the bar is clamped; C: Then rough turn the left and right end faces of the bar, turn the left end face into a cylinder, and ensure that the right end face remains There is a length of 1mm, and then drill a center hole on the right end face; D: Hold the center hole, and turn three sections of outer circles with different sizes from the left end to the right end face; Turning; E: Then, the three outer circles after finishing turning in step D are polished; the present invention solves the problems of too low rigidity of the existing stepped shaft and low machining accuracy.

Owner:CHENGDU HENGTONG ZHAOYE PRECISION MACHINERY

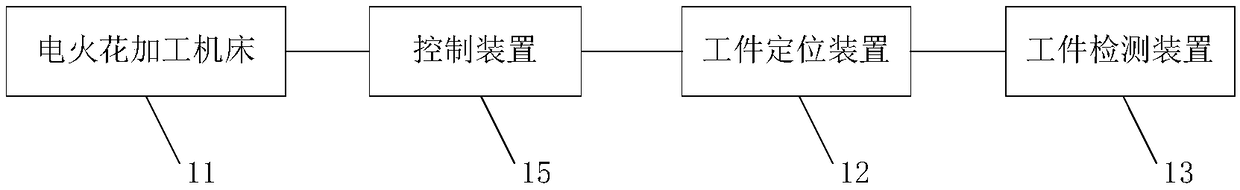

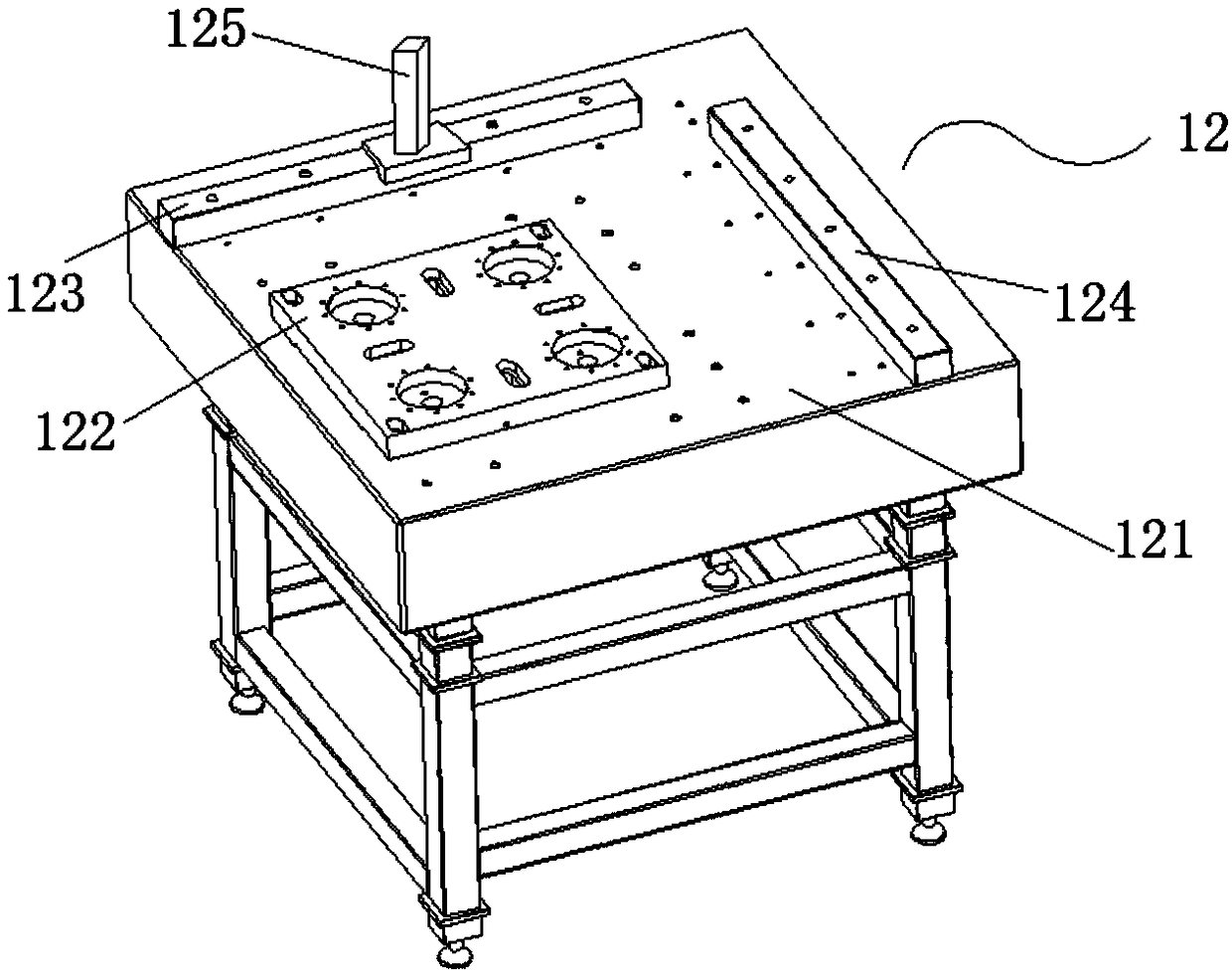

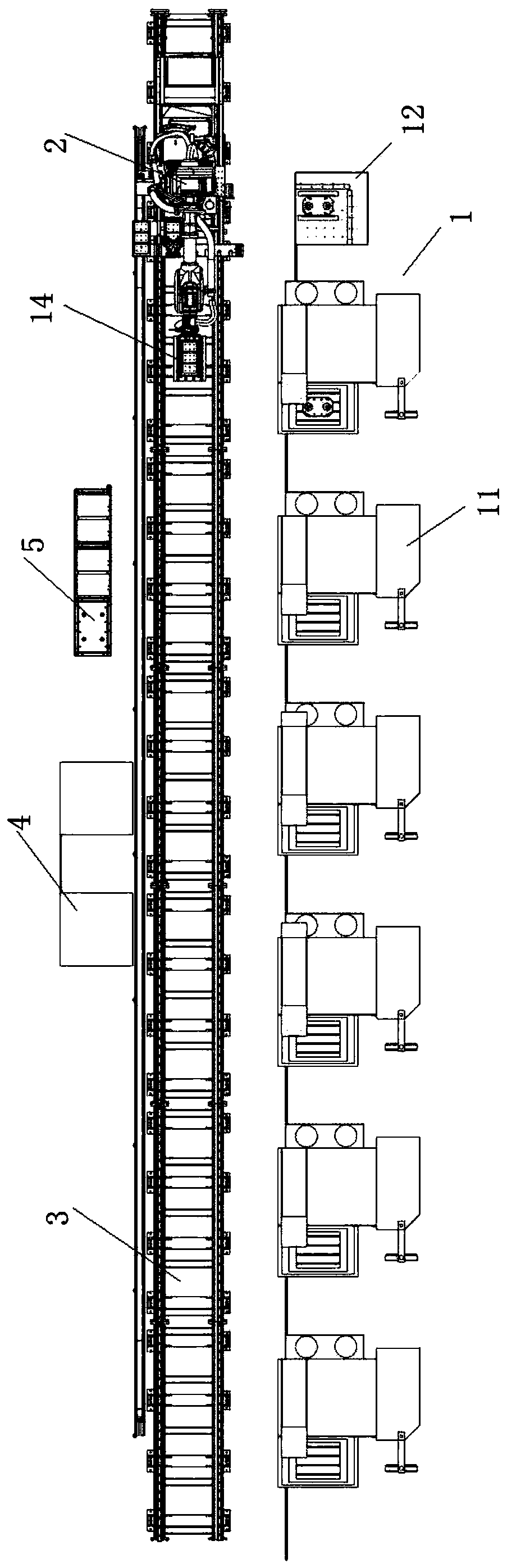

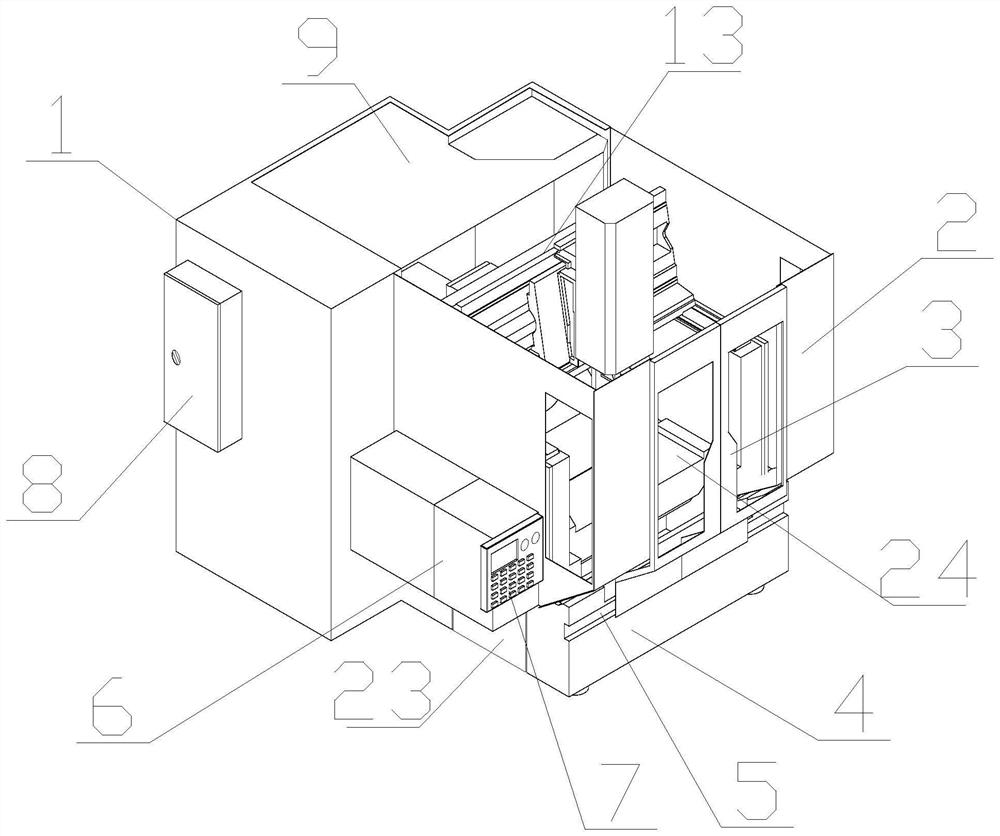

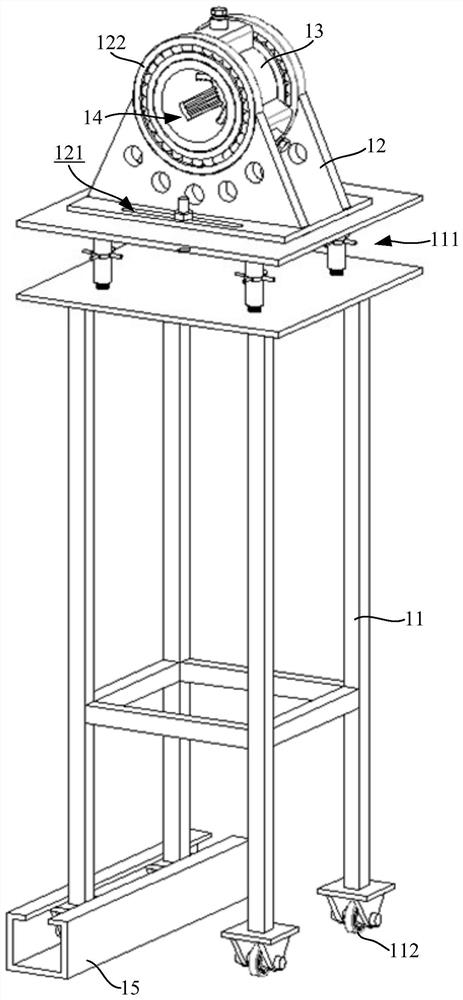

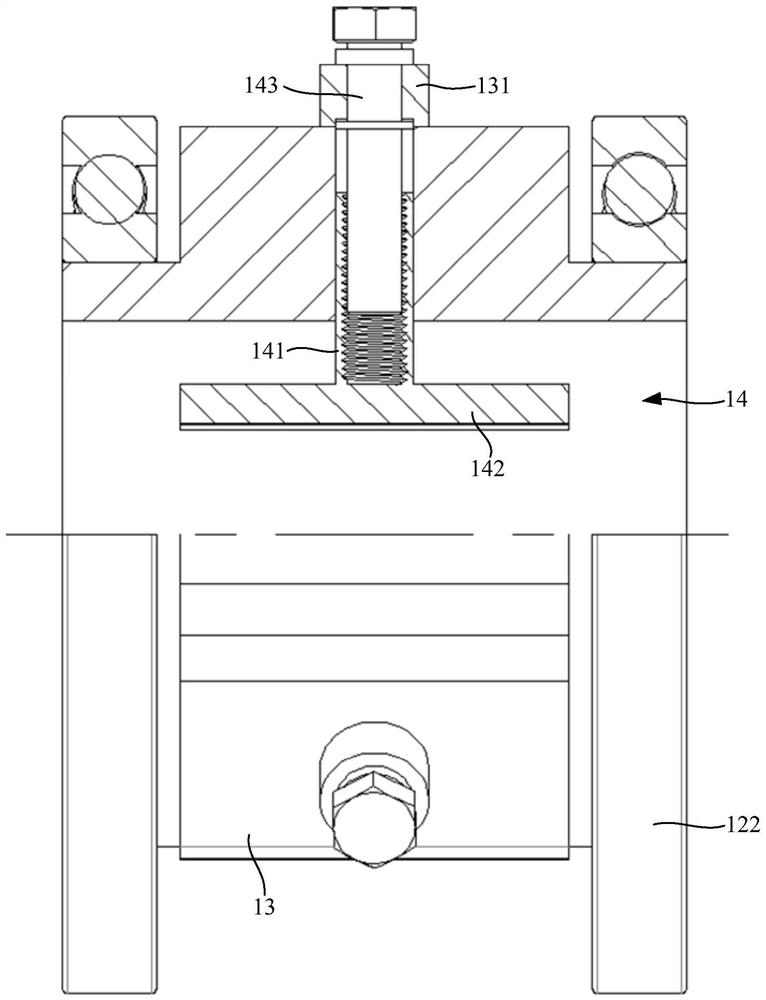

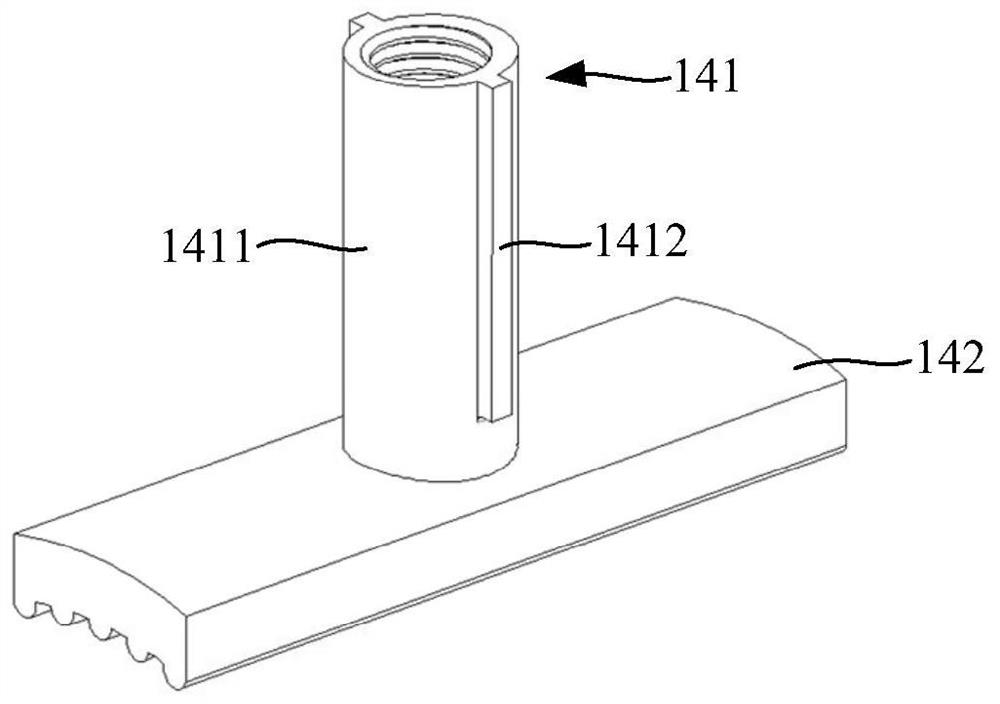

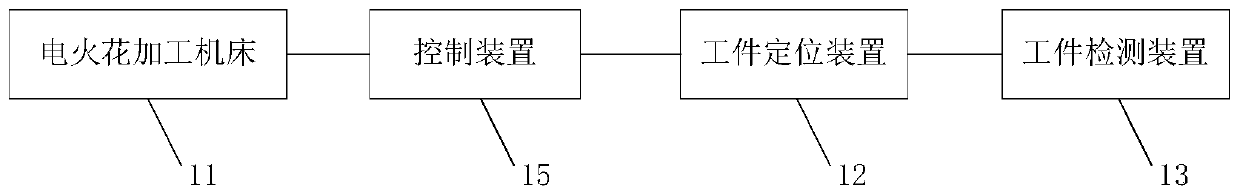

Electrosparking device, system and method

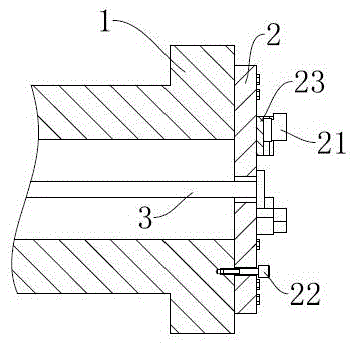

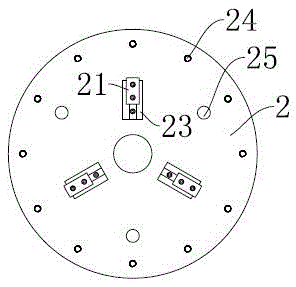

ActiveCN109108404ARealize automated productionReduce labor costsElectrical-based auxillary apparatusEngineeringMachining process

The invention provides an electrosparking device, system and method. The electrosparking device comprises an electrosparking machine tool, a workpiece locating device and a workpiece detector. The electrosparking machine tool is provided with a tray fixing mechanism which is located below a machining electrode and used for fixing a tray bearing a workpiece. The workpiece locating device and the electrosparking machine tool are separated. The workpiece locating device is used for locating the workpiece on the tray. The workpiece detector is used for detecting position information of the workpiece relative to the tray. A control device is arranged on the electrosparking machine tool, can obtain the position information and controls the machining electrode to machine the workpiece according to the position information and the machining programme of the workpiece. Through implementation of the electrosparking device, system and method, the problems that in the workpiece machining process of an existing electrosparking device, a meter is directly pulled for a workpiece on an electrosparking machine tool to look for the machining datum point, and machining precision is low are solved.

Owner:GREE ELECTRIC APPLIANCES INC +1

An anti-collision knife CNC machine tool

ActiveCN112475397BSolve the problem of low machining accuracyAvoid damageMilling machinesMaintainance and safety accessoriesNumerical controlMilling cutter

Owner:温岭市华中数控机床有限公司

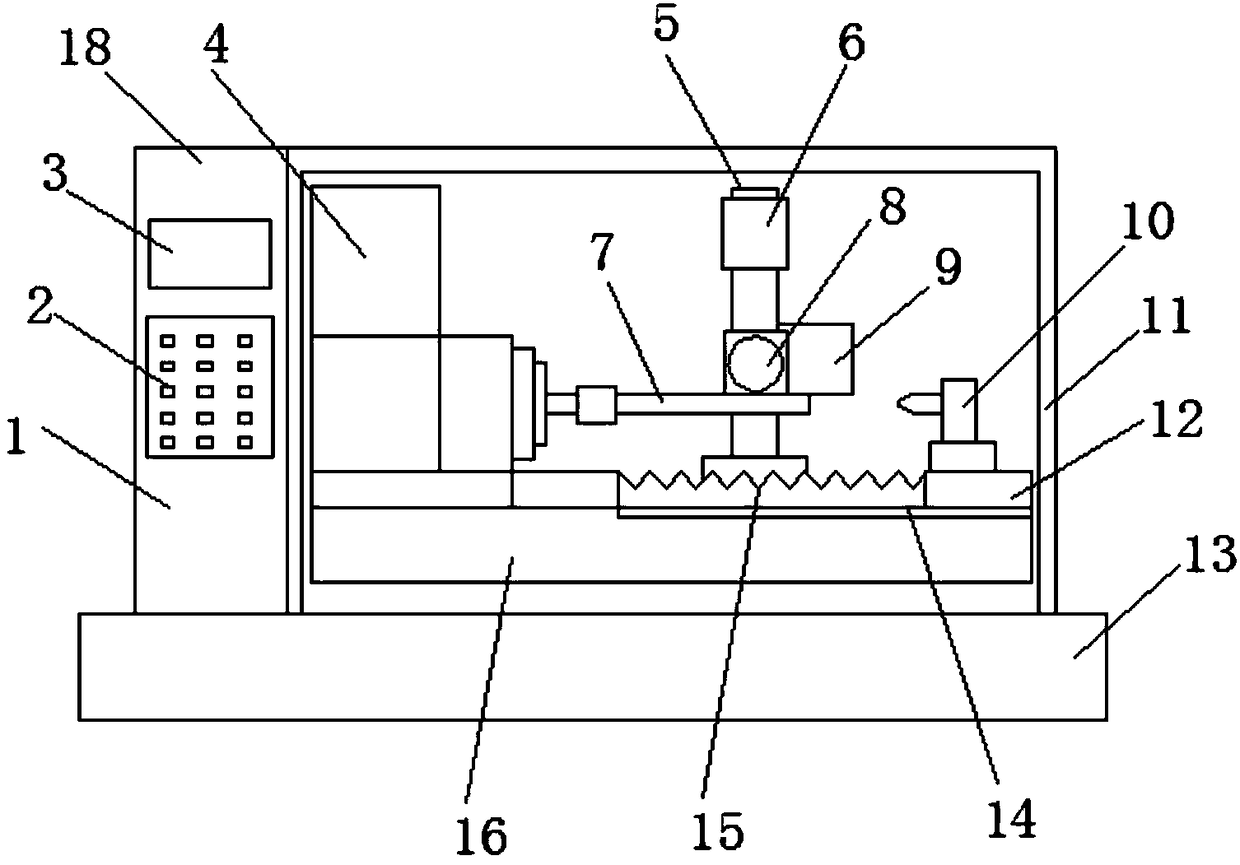

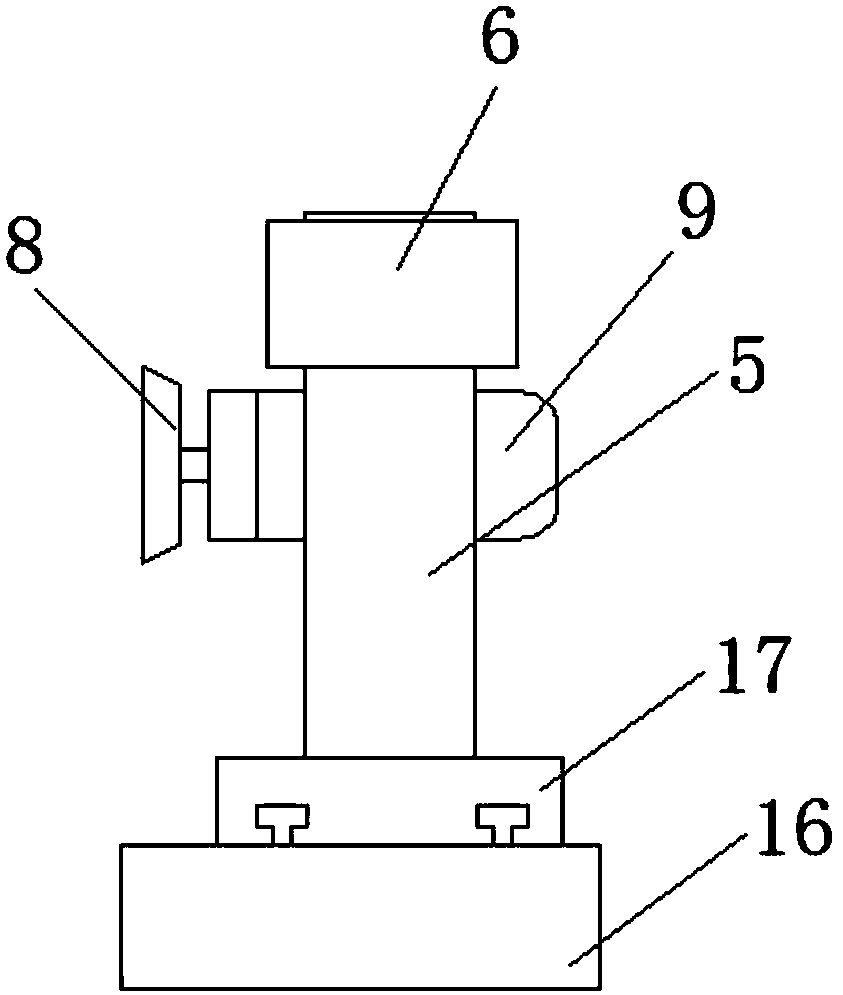

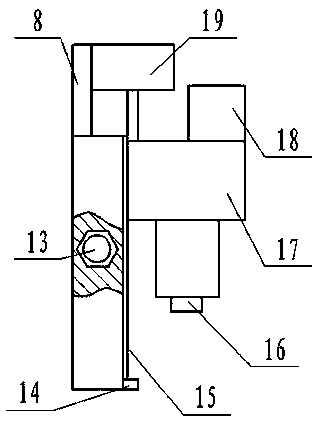

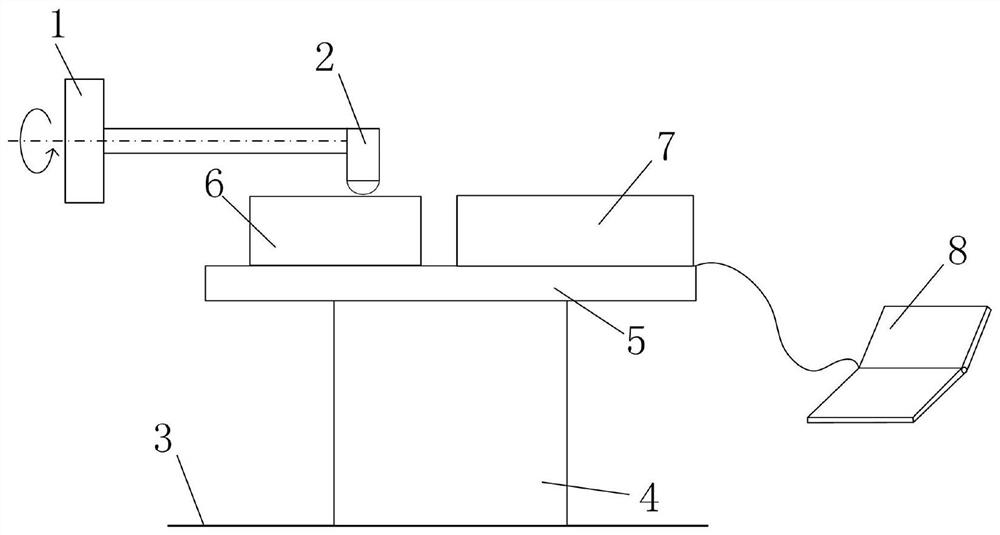

High-precision hob rake angle grinder

InactiveCN108067950AImprove processing qualityEasy to useGrinding carriagesRevolution surface grinding machinesLiquid-crystal displayEngineering

The invention discloses a high-precision hob rake angle grinder. The high-precision hob rake angle grinder includes a main body, and a base and a lathe body which are arranged on the main body; the lathe body is provided with a control mechanism, a hob cutter grinding mechanism, a first sliding pair, a second sliding pair and a workbench surface, and the control mechanism is electrically connectedwith the hob cutter grinding mechanism, the first sliding pair and the second sliding pair; the control mechanism includes a control box disposed at one end of the lathe body, a liquid crystal display screen disposed on the control box, and an operation panel disposed below the liquid crystal display screen; the hob cutter grinding mechanism includes an index head disposed inside the lathe body,a mandrel connected with the index head, the base, and a stand column disposed on the base; and a grinding motor is disposed on the stand column, and a grinding wheel is disposed on the grinding motor. According to the high-precision hob rake angle grinder, the feed in the vertical direction of the grinding wheel is carried out by a lifting cylinder, so that the problem that existing rake angle grinders are low in machining precision is effectively solved, and the advantages of simple structure, convenient use, and good use effect are achieved.

Owner:TIANJIN BAOLITONGDA TOOL CO LTD

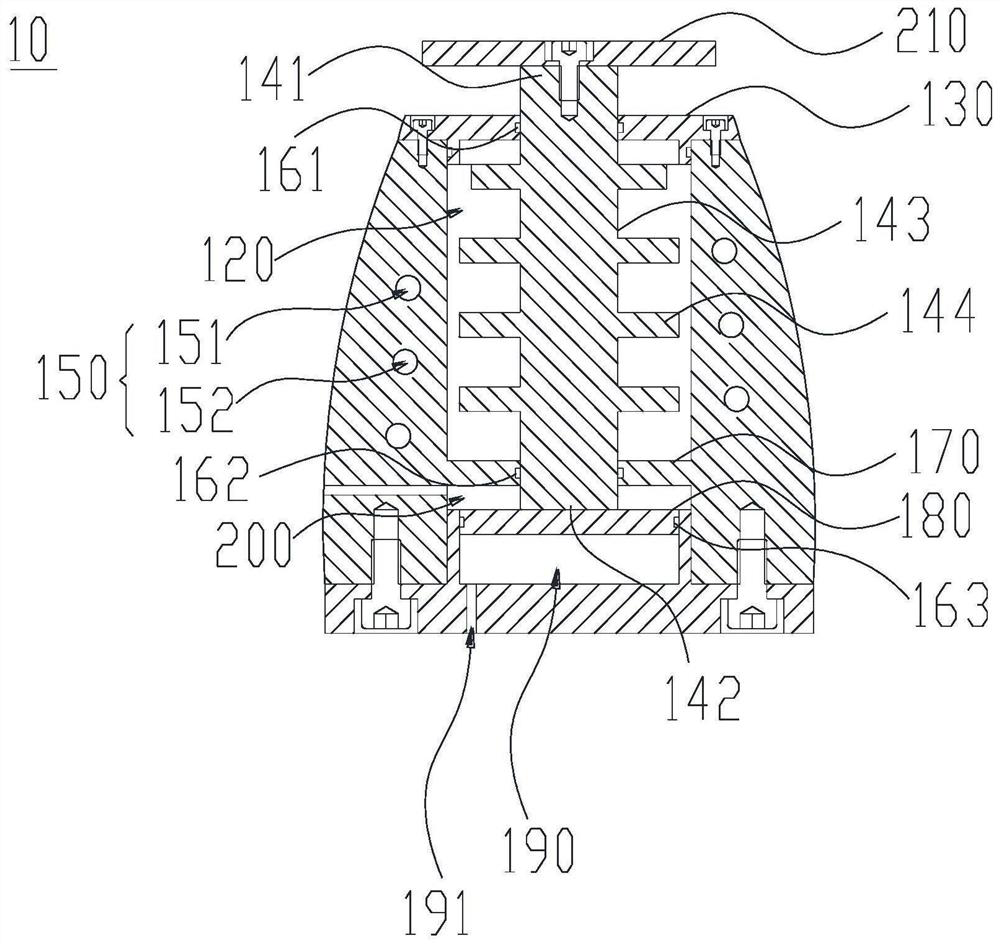

Gear inner ring interference fit tool clamp

InactiveCN105458417ASimple structureEasy to installGear-cutting machinesGear teethInterference fitPush and pull

The invention discloses a gear inner ring interference fit tool clamp. The clamp comprises a rotating shaft seat, a chuck and a pull rod. The chuck and the rotating shaft seat are coaxially and rotatably connected, and three clamping jaws are evenly distributed on the circumference of the chuck; the outer circumferential faces of the clamping jaws are in interference fit with the inner ring of a machined gear, and the pull rod pushes and pulls the center of the chuck to move in the axial direction of the centre of the chuck; and positioning blocks are arranged on the sides of the clamping jaws of the chuck. According to the gear inner ring interference fit tool clamp, the problems that in the prior art, a gear penetrates a mandrel, so that the gear inner ring and the mandrel do not share the central axis, and the gear machining precision is low are solved.

Owner:CHONGQING SHUNHUAI MACHINERY MFG CO LTD

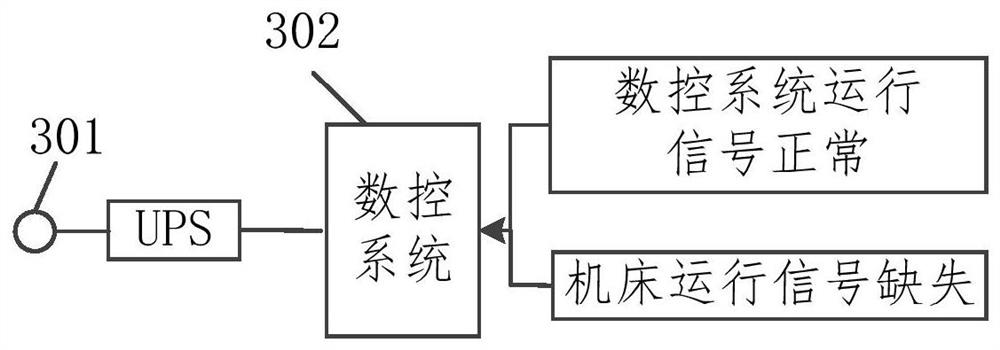

Machine tool machining method, device and equipment and storage medium

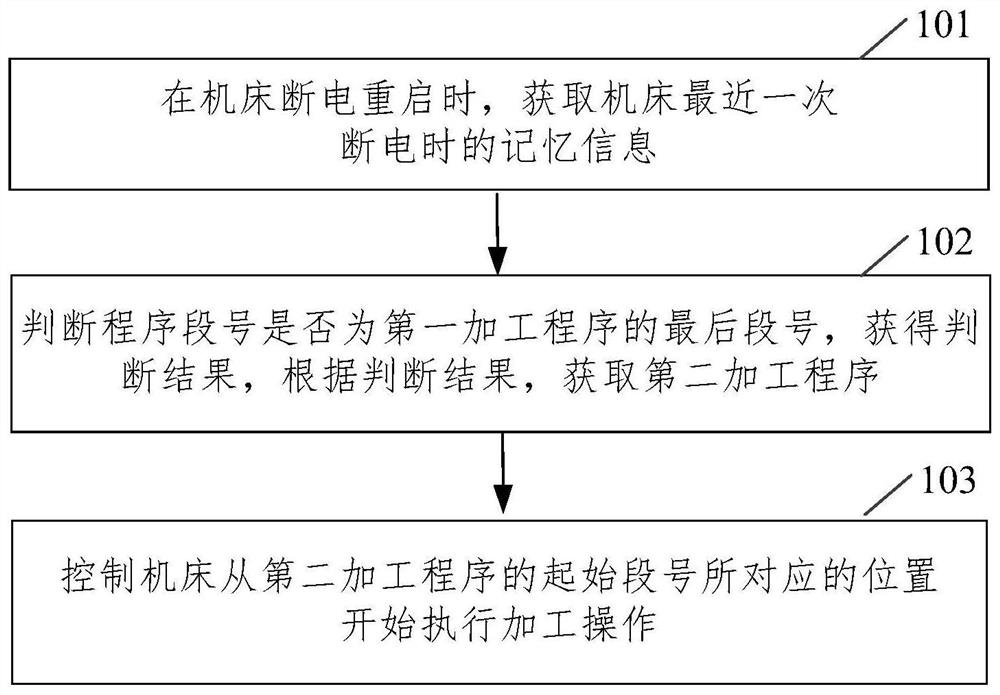

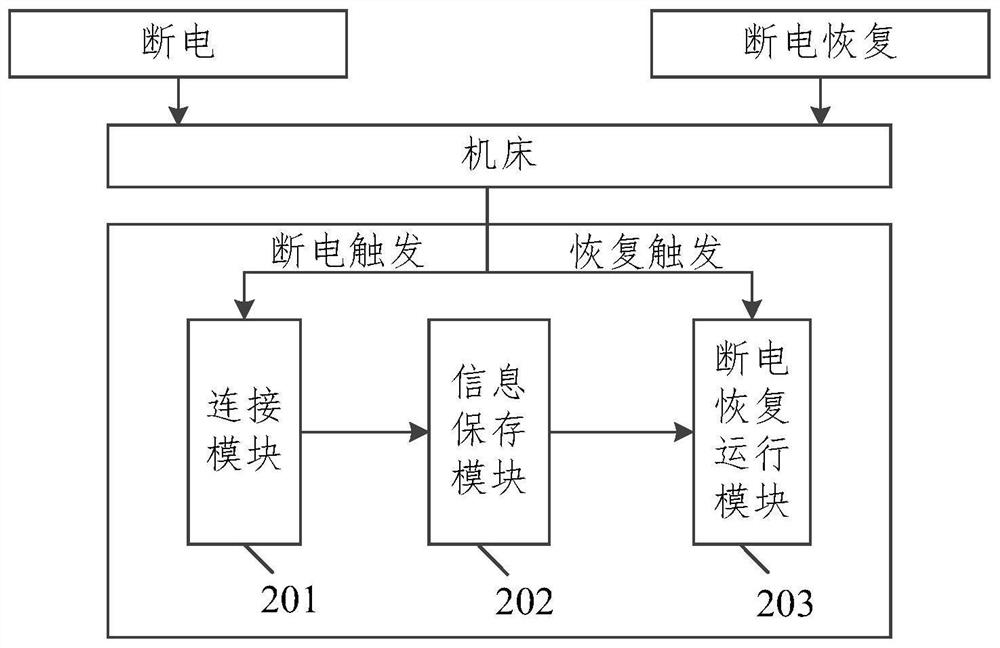

ActiveCN112034784AImprove accuracyImprove reliabilityAutomatic control devicesFeeding apparatusProgram segmentMachine tool

The invention relates to a machine tool machining method, a device and equipment and a storage medium, and the method comprises the steps: obtaining the memory information of a machine tool during thelatest power failure when the machine tool is powered off and restarted; determining whether the program segment number is the last segment number of the first machining program or not, obtaining a judgment result, and obtaining a second machining program according to the judgment result; and controlling the machine tool to execute machining operation from the position corresponding to the starting section number of the second machining program. The method is used for solving the problems of machine tool damage and low part machining precision due to the fact that the machine tool directly continues machining according to the memory information after being powered off and restored.

Owner:GREE ELECTRIC APPLIANCES INC

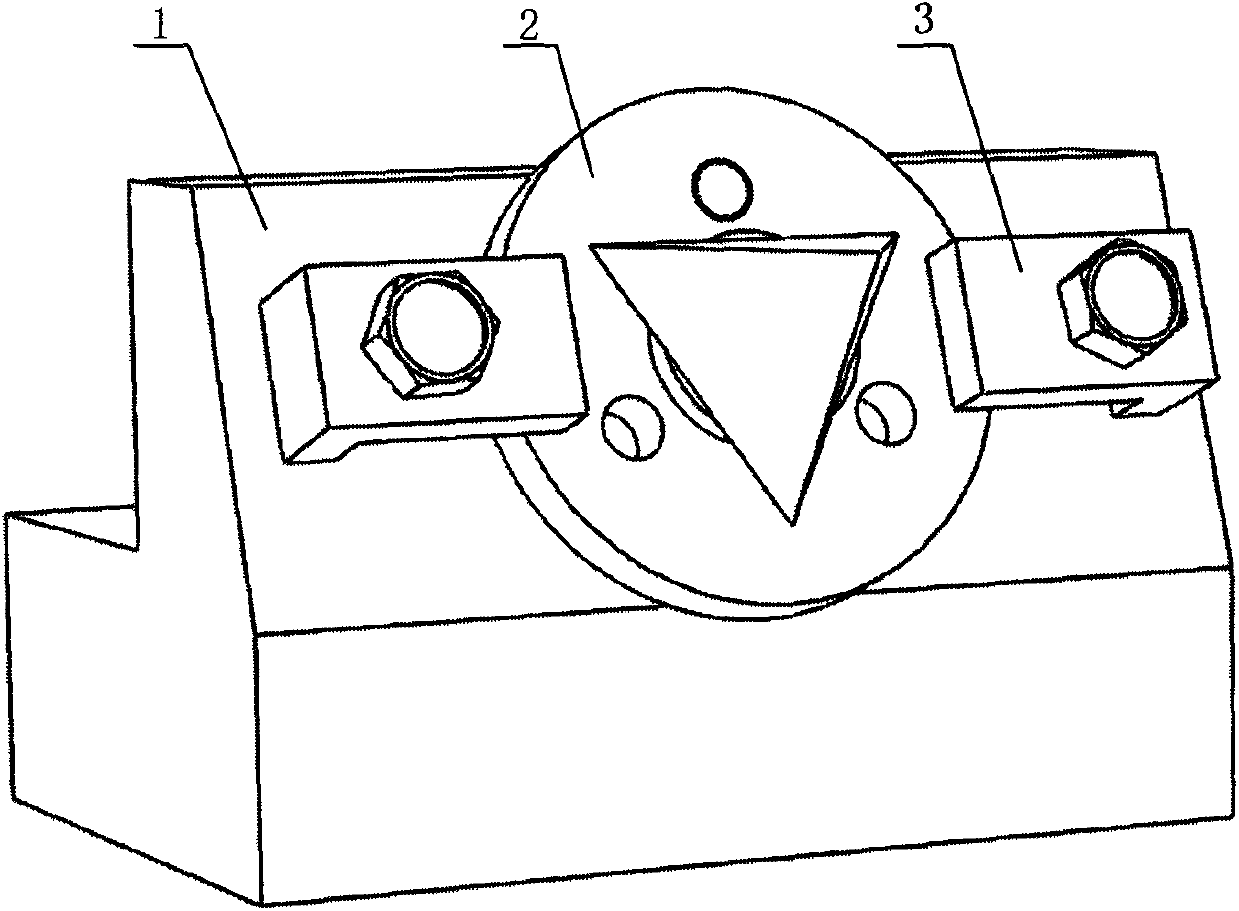

Special clamp for machining triangular pyramid

InactiveCN103358154ASolve clamping difficultiesSolve the problem of low machining accuracyPrecision positioning equipmentPositioning apparatusMachine toolPyramid

The invention relates to a special clamp for machining a triangular pyramid. The special clamp comprises a base, a positioning index plate, a clamping block, a positioning pin and bolts, wherein the base is fixedly arranged on a machine tool work bench; the positioning index plate is connected with a workpiece blank through the bolts; the positioning index plate is attached to a positioning surface on the base; a stepped shaft on the positioning index plate is arranged in a positioning index plate mounting hole in the base; and the rotational degree of freedom of the positioning index plate is limited through the positioning pin inserted in a positioning hole in the base and a positioning hole in the positioning index plate; the clamping block is connected with the base through the bolts; and the axial degree of freedom of the positioning index plate is limited by the clamping block pressing the positioning index plate so that the whole workpiece is fixed. The special clamp is reasonable in structure and convenient to disassemble, thus effectively solving the problems that the triangular pyramid is difficult to clamp, low in machining accuracy and the like when being machined.

Owner:TIANJIN RUICHI SHIPPING MACHINERY

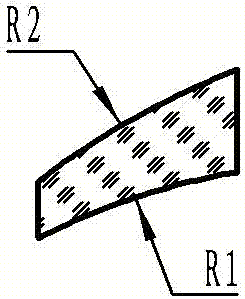

Machining method for eccentric crescent cylindrical mirror

InactiveCN107378652ASolve the problem of low machining accuracyOptical surface grinding machinesWaxConvex side

The invention discloses a machining method for an eccentric crescent cylindrical mirror. The method comprises the steps that blank and cushion material taking is conducted, and a blank and cushion materials are bonded through wax; concave face milling grinding, fine grinding and polishing are conducted; the blank and the cushion materials are heated to be separated, and the blank and new cushion materials are bonded again through wax; convex face milling grinding, fine grinding and polishing are conducted; and heating is conducted, a product is taken out, and the eccentric crescent cylindrical mirror can be obtained. According to the machining method, through strict control over the cushion material size and the center thickness and eccentric volume of the cylinder face obtained after fine grinding, and accordingly the high-precision eccentric crescent cylindrical mirror can be machined. Through the manner that the cushion materials are bonded and fed to discs to be machined, the machining difficulty and detection difficulty are effectively lowered, and the machining efficiency and the product qualification rate are improved; and the beneficial effects that the technology is simple, and operation is convenient are achieved.

Owner:FUJIAN CASTECH CRYSTALS

Toroidal worm processing machine tool with on-line detection and correction processing functions

ActiveCN104174938BSolve the problem of low machining accuracyImprove general performanceAutomatic control devicesMeasurement/indication equipmentsEngineeringMachining process

The invention discloses a hourglass worm processing machine tool with on-line detection and correction processing functions. The hourglass worm processing machine tool comprises a machine tool body, wherein a spindle unit and a processing unit are arranged on the machine tool body; the spindle unit comprises a driving centre and a tailstock centre, which are used for ejecting and holding a hourglass worm to be processed; the processing unit is used for processing the tooth surface of the hourglass worm; the hourglass worm processing machine tool further comprises a detection unit and a control unit, so that on-line detection and correction processing are realized during the processing process of the tooth surface of the hourglass worm, and the problem of low processing precision of the tooth surface of the hourglass worm is solved basically.

Owner:XIHUA UNIV

Anti-cutter-collision numerical control machine tool

ActiveCN112475397ASolve the problem of low machining accuracyAvoid damageMilling machinesMaintainance and safety accessoriesNumerical controlMilling cutter

The invention discloses an anti-cutter-collision numerical control machine tool. The machine tool comprises a machine tool body, an x-axis motor, an x-axis lead screw, a y-axis lead screw, a y-axis motor, a z-axis sliding rail, a z-axis lead screw, a fixing frame, a fourth motor, a shell, a clamp, a collecting cart and an anti-cutter-collision device. In the debugging feeding process of a clamp built-in milling cutter, the milling cutter accidentally collides with a supporting plate, under the effect of spring force, the supporting plate slides downwards to provide buffer for the clamp built-in milling cutter, the phenomenon that the clamp built-in milling cutter is in direct collision, and the clamp built-in milling cutter is broken and damaged is avoided, after numerical control programdebugging is completed, a fifth motor is started to rotate forwards to enable a fourth lead screw to move upwards, and a connecting block at the top end is attached to the bottom end face of a limiting block to fix a top end supporting plate, in the deep hole machining process of a workpiece, due to the fact that the workpiece sinks under the action of the spring force, buffering of the spring forthe workpiece causes workpiece precision errors, the supporting plate is fixed through the device, and the workpiece machining errors are prevented from being affected by the action of the spring force in the machining process.

Owner:温岭市华中数控机床有限公司

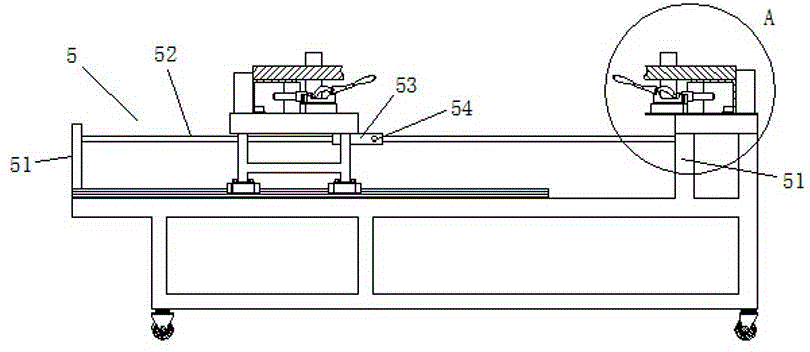

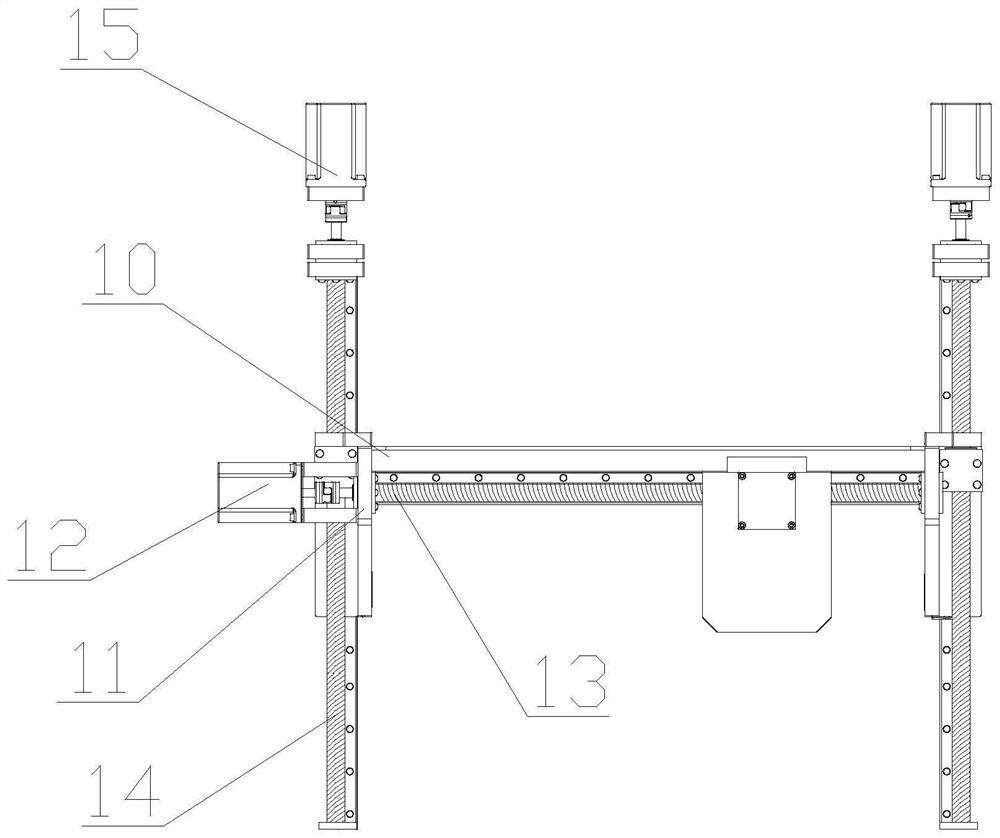

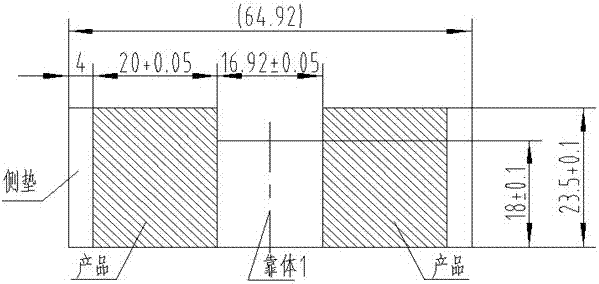

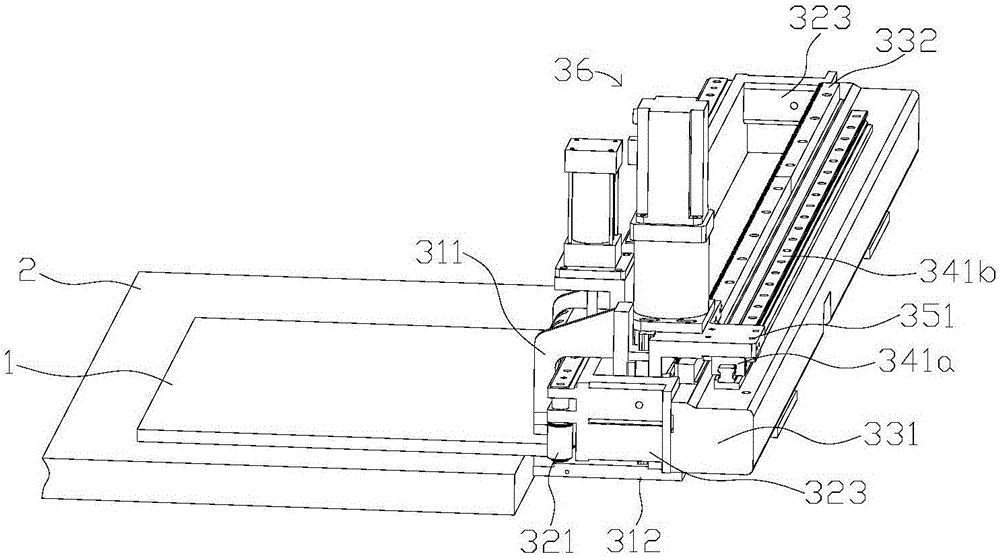

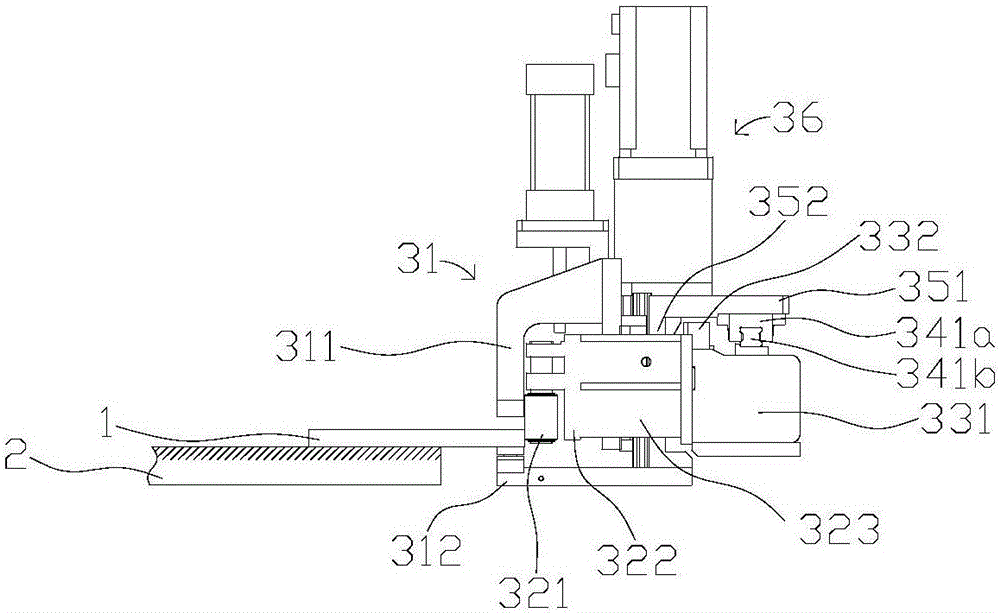

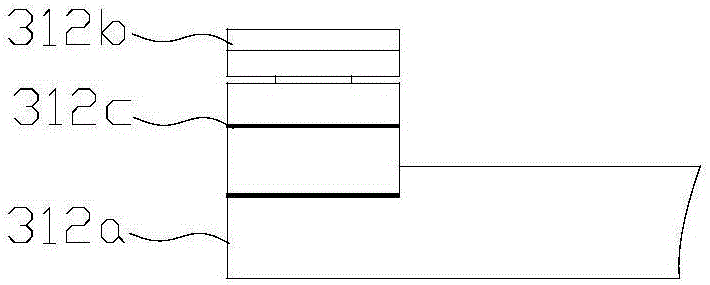

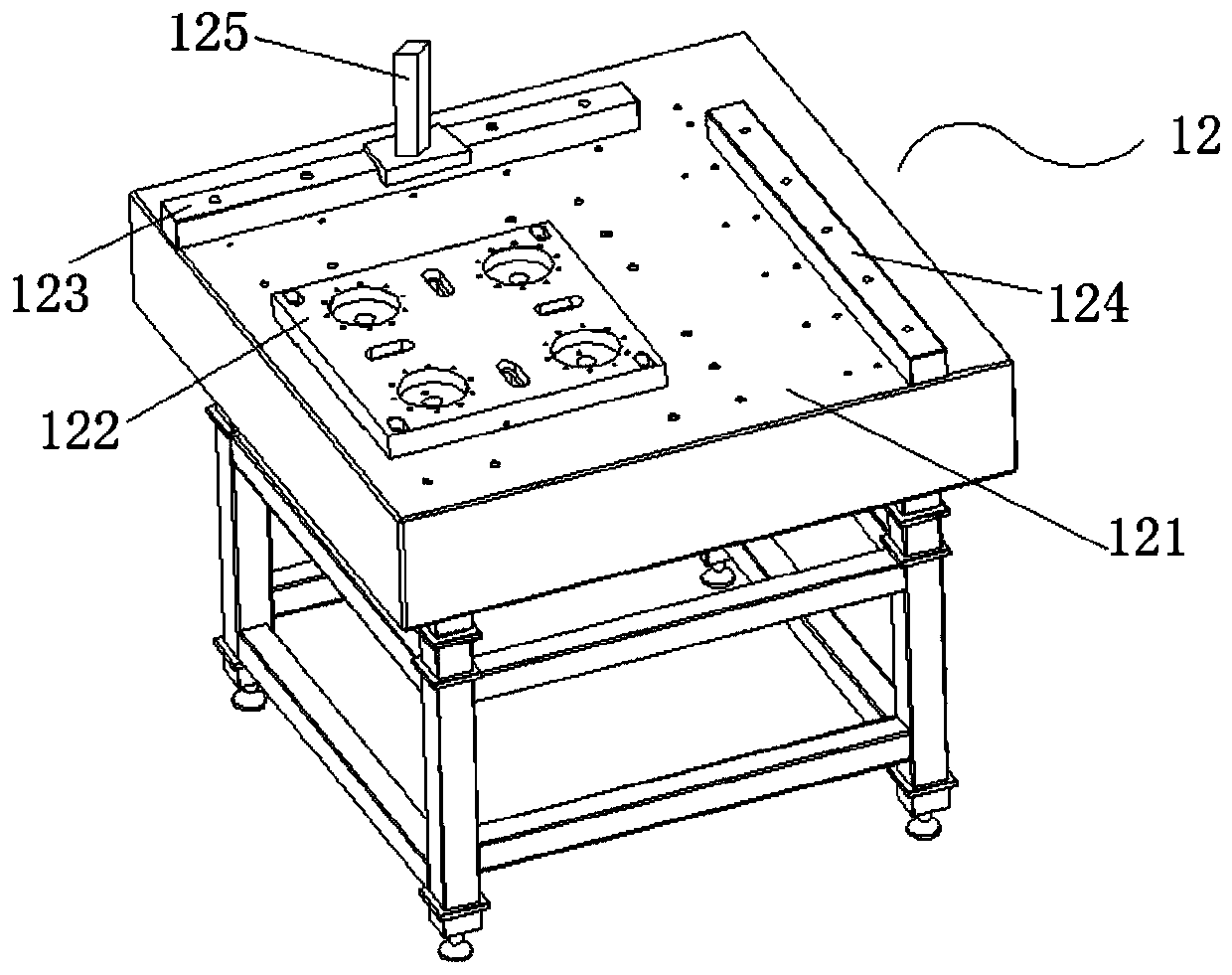

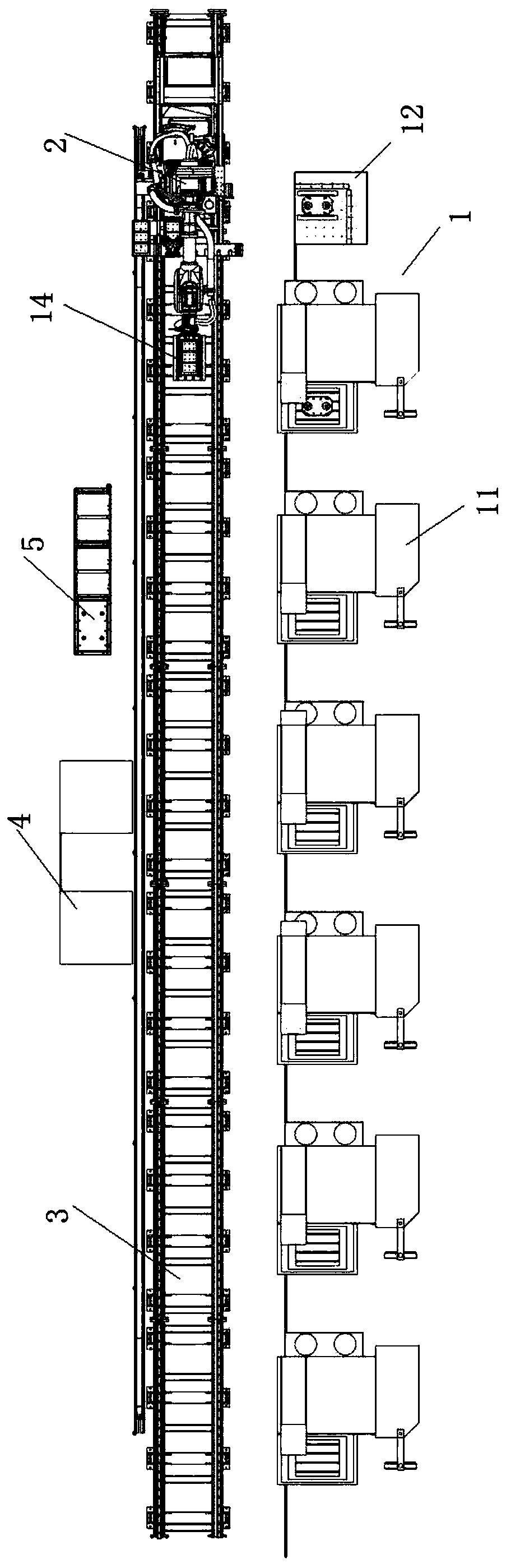

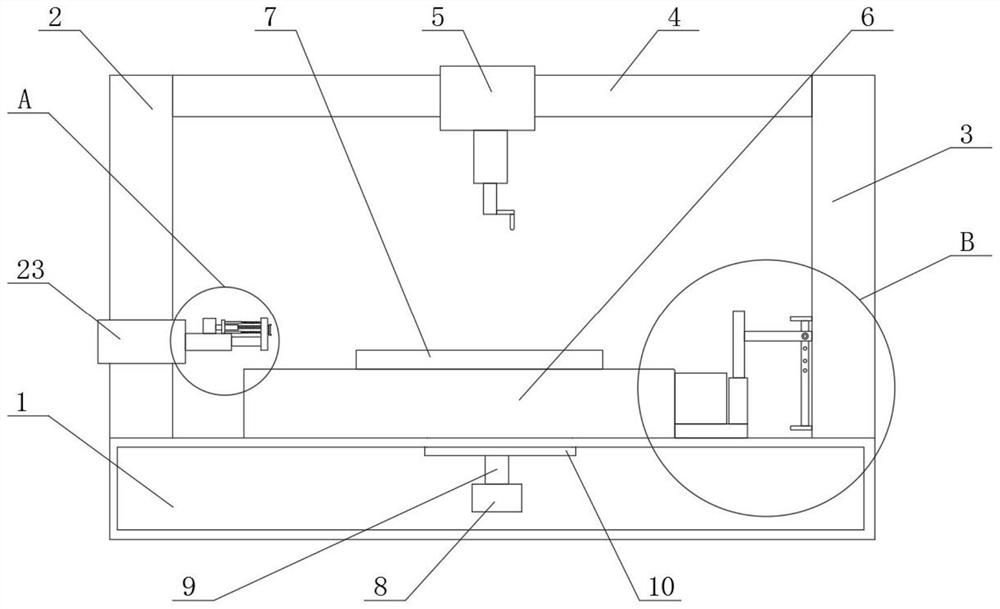

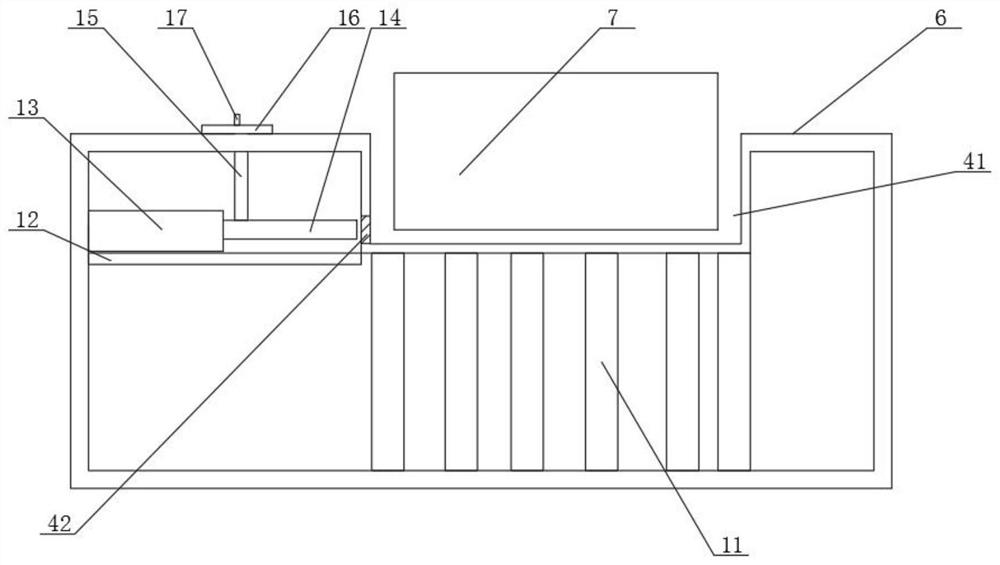

High-speed clamping, transporting and locating system for workpieces

InactiveCN106624904ASolve the problem of low machining accuracyShorten the timeWork clamping meansMetal working apparatusEngineeringRejection rate

The invention discloses a high-speed clamping, transporting and locating system for workpieces. The system includes a clamping structure, a guide structure and a mounting bracket, wherein the clamping structure comprises an upper clamping arm and a lower clamping arm, the upper clamping arm of the clamping structure is movably connected with the guide structure, the lower clamping arm of the clamping structure is fixedly connected with the guide structure that is movably connected with the mounting bracket, a floating clamp is arranged on the lower clamping arm, and the guide structure is movably connected with the mounting bracket through two sliding rails. According to the high-speed clamping, transporting and locating system for workpieces, by the adoption of the clamping structure provided with the floating clamp and the coordination of the guide structure that is movably connected with the mounting bracket through two sliding rails, the high-speed clamping, transporting and locating system for workpieces clamps and precisely moves a workpiece on a work surface, and the workpiece are firmly arranged on a preset position of the work surface. The system solves the problem of low processing accuracy resulting form inaccurate locating and shaking of the workpiece during processing, and reduces the rejection rate of products and improves the efficiency of furniture manufacture.

Owner:GUANGDONG SANDAR CNC MACHINERY CO LTD

Conveying device for hinge conveying

InactiveCN111689185AAvoid Accuracy CompromiseSolve the problem of low machining accuracySievingConveyorsStructural engineeringWorkbench

The invention discloses a conveying device for hinge conveying. The conveying device comprises a workbench, supporting legs are fixedly connected with the bottom of the workbench, a mounting frame isfixedly connected with the top of the workbench, a machining device is fixedly connected with the top end of the interior of the mounting frame, first hydraulic rods are arranged on the outer side ofthe machining device, the number of the first hydraulic rods is two, and the tops of the two first hydraulic rods are fixedly connected with the top end of the interior of the mounting frame; and thebottoms of the two first hydraulic rods are fixedly connected with a fixing plate, and one side of the fixing plate is fixedly connected with a first laser line marker. Through the designed second laser line marker and the designed third laser line marker, after a hinge on the top of a conveying belt deviates, a second hydraulic rod, a first deviation rectifying plate, a third hydraulic rod and asecond deviation rectifying plate are controlled to rectify deviation of the hinge, so that the precision of the hinge is prevented from being influenced, and the problem that an existing device is low in machining precision is solved.

Owner:浙江金昂五金制品有限公司

Machining method of aspherical cylindrical mirror

ActiveCN111452227ASolve the problem of increased processing costsSolve the problem of low precision in servo millingWorking accessoriesStone-like material working toolsEngineeringMachine tool

The invention discloses a machining method of an aspherical cylindrical mirror. The machining method of the aspherical cylindrical mirror comprises the steps that the feed in the direction of a Y axisis realized by installing a coarse adjusting displacement platform and a fine adjusting displacement platform from bottom to top on a machine tool table; first, machining is carried out by adjustingthe fine adjusting displacement platform, when the range M of the fine adjusting displacement platform is reached, the fine adjusting displacement platform is lowered and the coarse adjusting displacement platform is raised, after precision correction, a tool tip is coincident with a datum of a measurement block, the high-precision feed in the direction of the Y axis is realized by constantly adjusting the fine adjusting displacement platform, and the machining of the aspheric surface cylindrical mirror is completed by repeating the steps. By combining the fine adjusting displacement platformwith the coarse adjusting displacement platform, the form of high-precision feed in the direction of the Y axis is realized, and the machining of the aspherical cylindrical mirror with low cost, highprecision and large depth ratio is realized on a two-axis ultra-precision machine tool.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

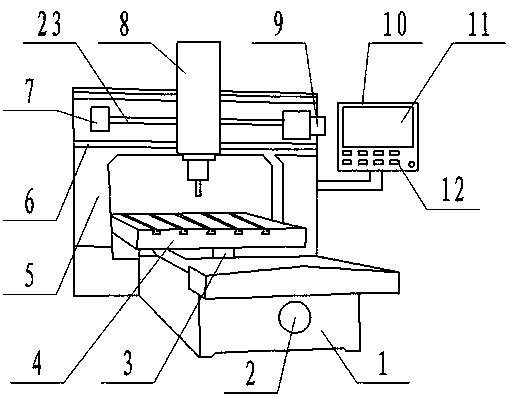

Computer controlled high-precision drilling device

InactiveCN108772577AHigh degree of automationSolve the problem of low machining accuracyBoring/drilling machinesNumerical controlEngineering

The invention discloses a computer controlled high-precision drilling device which comprises a machine tool body, a longitudinal feed motor, a supporting seat and a workbench. The longitudinal feed motor is arranged at one end of the machine tool body. The supporting seat is arranged on the machine tool body. The workbench is arranged on the supporting seat. An upper rack is arranged on the outerside of the machine tool body and provided with horizontal guide rails. A lead screw is arranged between the horizontal guide rails. A bearing pedestal is arranged at one end of the lead screw, and atransverse feed motor is arranged at the other end of the lead screw. A power plate is arranged on the lead screw. A nut seat is arranged between the lead screw and the power plate. A lifting air cylinder is arranged at the upper end of the power plate. The computer controlled high-precision drilling device has the advantages that a computer control case is arranged, control over the equipment work process is achieved through numerical control programming, the automation degree is high, the drilling machining precision is high, size control is precise, and the device is suitable for machininghigh-precision parts.

Owner:杨静

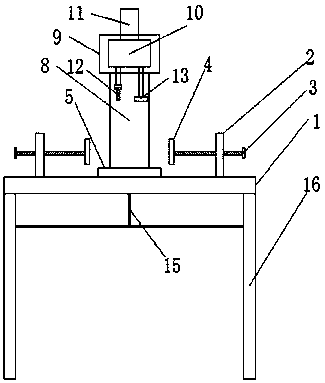

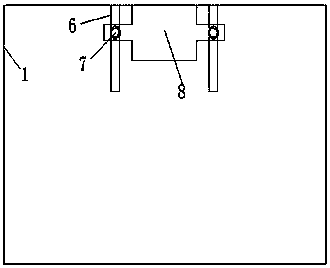

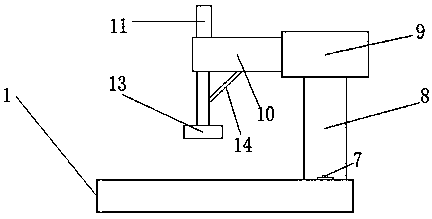

Novel grinding and drilling integrated equipment

InactiveCN108927662ASolve the problem of low machining accuracyImprove ergonomicsOther manufacturing equipments/toolsMachining timeDrill

The invention discloses novel grinding and drilling integrated equipment comprising a tabletop, a cylinder, a column, an electric drill, a grinding table, connecting rods, a boss, a fixed table and fixed rods. The integrated equipment is characterized in that the upper surface of the tabletop is provided with stop plates of which the middle parts are provided with studs, and the tail end of each stud is provided with a stop block; the tabletop is provided with the boss, and sliding chutes are formed beside the boss, and provided with screw rods connected to the column; the column is provided with the fixed table connected to a cross rod, and the cross rod is provided with the cylinder connected to the electric drill and the grinding table; and the grinding table and the electric drill areconnected to the cross rod through the connecting rods, and brackets are arranged under the tabletop, and connected by the five fixed rods. The integrated equipment has the beneficial effects that theproblem of low machining accuracy of workpieces is solved, and the working efficiency is improved; and the machining time is saved, and the production cost is reduced.

Owner:彭波

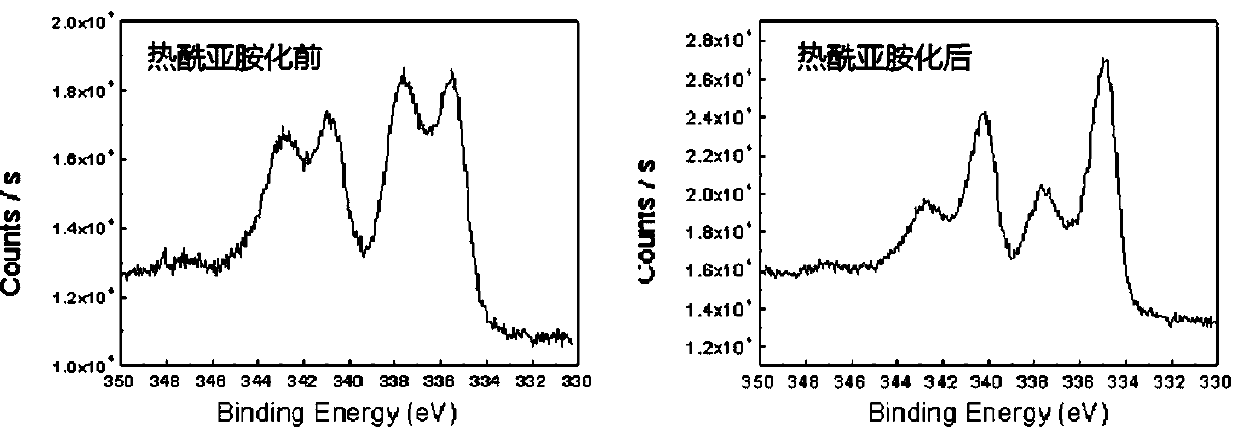

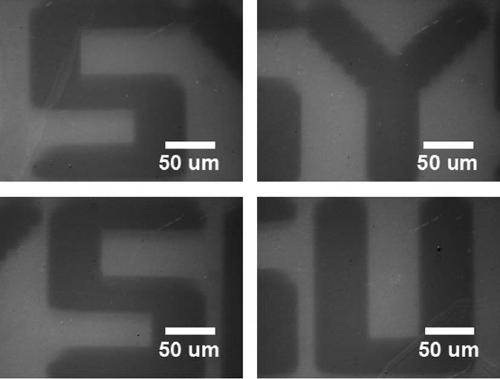

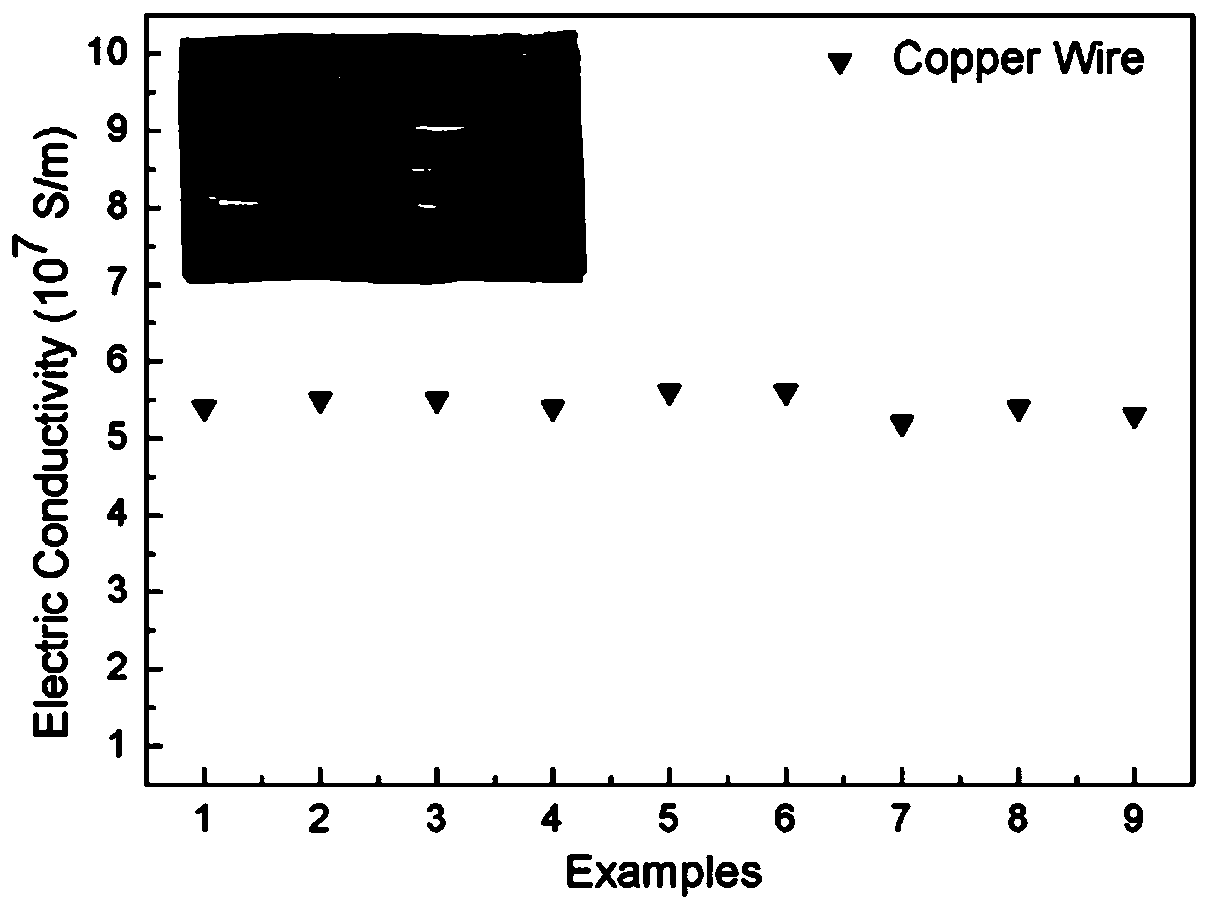

Method for preparing specific conductive metal pattern on surface of polyimide film

InactiveCN111423613AEfficient depositionShorten the timePhotomechanical exposure apparatusConductive pattern formationImidePolymer science

The invention discloses a method for preparing a specific conductive metal pattern on the surface of a polyimide film, which sequentially comprises the following steps of: (1) performing exposure treatment on a photosensitive polyamide acid film, and immersing the photosensitive polyamide acid film into an organic solution containing a chemical plating catalyst to perform exposure region development, (2) carrying out imidization reaction on the developed photosensitive polyamide acid film to prepare a polyimide film material, and (3) carrying out chemical plating treatment on the polyimide film to prepare the polyimide film material containing the specific conductive metal pattern on the surface. According to the preparation method provided by the invention, the catalyst required by chemical plating can be efficiently deposited on the surface of the photosensitive polyamide acid thin film, synchronous thermal activation is achieved along with the thermal imidization process of the photosensitive polyamide acid thin film, and the imidized thin film can be directly subjected to subsequent metal plating patterning by adopting a chemical plating method. The method is used for continuous and efficient industrial production of polyimide electronic circuit materials.

Owner:SUN YAT SEN UNIV

Adjustable curved wheel machining tool

PendingCN114453601AEasy to fixAvoid jitterTurning toolsFeeding apparatusMachine partsElectric machine

The invention discloses an adjustable curved wheel machining tool which comprises a rack, a rotating motor is arranged in the rack, a rotating disc is arranged on one side of the rotating motor, a first electric push rod is arranged in the rotating disc, a telescopic rod is arranged on the first electric push rod, and a clamping block is arranged on one side of the telescopic rod. A rotating disc is arranged on the upper end of the rack, a supporting block is arranged on the surface of the rotating disc, a second electric push rod is arranged on the side, away from the rotating motor, of the rotating disc, a pressing block is arranged on the second electric push rod, a sliding frame is arranged at the upper end of the rack, a gear motor is arranged in the sliding frame, and a concave sliding frame is arranged below the sliding frame. And a gear motor is arranged in the concave sliding frame. According to the adjustable curved wheel machining tool, the telescopic rod and the clamping block are arranged to fix a to-be-machined part, then the pressing block is matched for assistance, the effect of better fixing the to-be-machined part can be achieved, and shaking of the to-be-machined part in the machining process is avoided.

Owner:盐城市鑫海机械有限公司

A kind of processing method of aspherical cylindrical mirror

ActiveCN111452227BSolve the problem of increased processing costsSolve the problem of low precision in servo millingWorking accessoriesStone-like material working toolsEngineeringMachine tool

The invention discloses a processing method of an aspherical cylindrical mirror. The feed in the direction of the Y axis is realized through a rough adjustment displacement platform and a fine adjustment displacement platform installed sequentially on a machine tool workbench from bottom to top; firstly, by adjusting the fine adjustment When the displacement platform reaches the range M of the fine adjustment displacement platform, the fine adjustment displacement platform is lowered and the coarse adjustment displacement platform is raised, and the precision calibration is performed so that the tool tip coincides with the reference plane of the measuring block, and then the fine adjustment is continuously adjusted. Adjust the displacement platform to realize high-precision feeding in the Y-axis direction, and complete the processing of the aspheric cylindrical mirror by continuously repeating the above steps. The present invention realizes the form of high-precision feeding in the Y-axis direction by combining the fine-adjustment displacement platform and the coarse-adjustment displacement platform, and realizes low-cost, high-precision, and large depth-to-diameter ratio non-feeding on a two-axis ultra-precision machine tool. Processing of spherical cylindrical mirror.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Auxiliary positioning device of rod piece and using method thereof

InactiveCN112372331AAvoid jitterReduce the impactWork clamping meansPositioning apparatusEngineeringMachining

The invention relates to an auxiliary positioning device of a rod piece. The auxiliary positioning device comprises a height-adjustable frame body, a fixing seat, a ring piece and a clamping piece, and the frame body is arranged on the ground; the fixing seat is mounted at the top of the frame body and can move back and forth in the direction perpendicular to the rod piece; the ring piece is installed on the fixing seat and can rotate around the axis direction, the exposed part of the rod piece is sleeved with the ring piece, and the center of the ring piece coincides with the center of the rod piece by adjusting the height of the frame body; and the clamping piece is installed on the ring piece and used for clamping the rod piece, the rod piece is clamped through the clamping piece so asto fix and support the exposed part of the rod piece, and the rod piece can drive the ring piece and the clamping piece to rotate together when rotating. According to the auxiliary positioning device,the problem that the rod piece machining precision is low is effectively solved, the auxiliary positioning device and the rod piece rotate synchronously, the rod piece can be prevented from shaking,the influence on the rod piece machining precision can be reduced, the rod piece cannot be damaged, and the machining quality can be guaranteed.

Owner:CHINA CONSTR EIGHT ENG DIV CORP LTD

An electrical discharge machining device, system and method

ActiveCN109108404BImprove machining accuracySolve the problem of low machining accuracyElectrical-based auxillary apparatusMachining processMachine tool

The invention provides an electrosparking device, system and method. The electrosparking device comprises an electrosparking machine tool, a workpiece locating device and a workpiece detector. The electrosparking machine tool is provided with a tray fixing mechanism which is located below a machining electrode and used for fixing a tray bearing a workpiece. The workpiece locating device and the electrosparking machine tool are separated. The workpiece locating device is used for locating the workpiece on the tray. The workpiece detector is used for detecting position information of the workpiece relative to the tray. A control device is arranged on the electrosparking machine tool, can obtain the position information and controls the machining electrode to machine the workpiece according to the position information and the machining programme of the workpiece. Through implementation of the electrosparking device, system and method, the problems that in the workpiece machining process of an existing electrosparking device, a meter is directly pulled for a workpiece on an electrosparking machine tool to look for the machining datum point, and machining precision is low are solved.

Owner:GREE ELECTRIC APPLIANCES INC +1

A long-lived leaf surface treatment device

ActiveCN111673580BEasy to limitStructural solutionGrinding carriagesGrinding machinesAir pumpLocal flap

Owner:浙江剑锋机械有限公司

Processing method and processing system of cracked hickory nut shell

ActiveCN111418854BSolve the problem of low machining accuracyHuskingProgramme control in sequence/logic controllersReciprocating motionControl engineering

The invention discloses a processing method and system for cracking pecan shells. The system includes cracking equipment and a main control device; wherein, the cracking equipment includes: a feeding hopper, cracking rollers, a sensing device and a pneumatic cracking device. shell hammer; the main control device transmits the hickory nuts fed into the feeding hopper to the cracking rollers, and controls the vertical reciprocating movement of the pneumatic cracking hammer to crack the hickory nuts; wherein, the main control device and the pneumatic The cracking hammer is connected; the deformation amount of the hickory nut detected by the sensing device is obtained; wherein, the sensing device is arranged on the pneumatic cracking hammer, and the sensing device is connected with the main control device; the main control device is in the When the deformation amount is greater than or equal to the preset compression amount, it is determined that the pneumatic cracking hammer has completed the hickory cracking process, and the pneumatic cracking hammer is controlled to reset to the initial state, thereby solving the problem of processing the hickory cracking shell. The problem of low machining accuracy in the process.

Owner:杭州姚生记食品有限公司

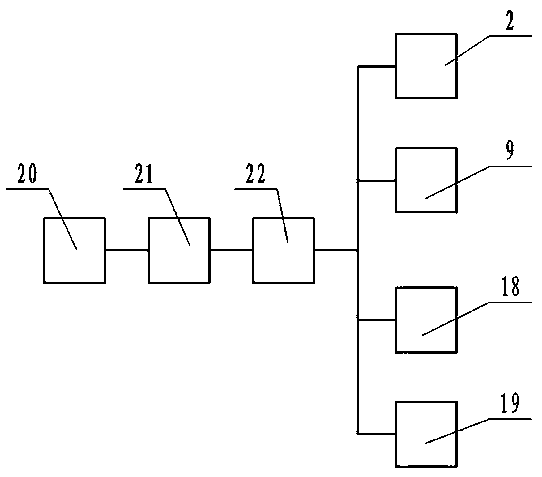

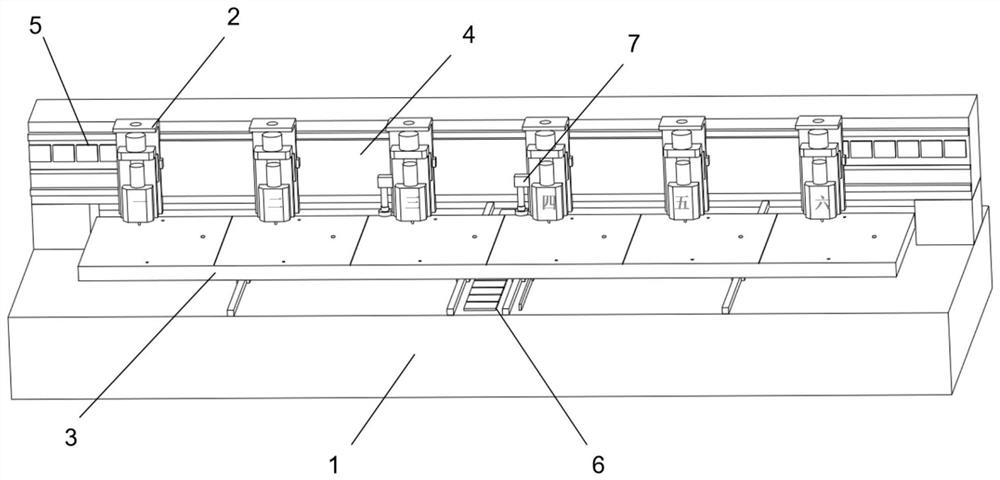

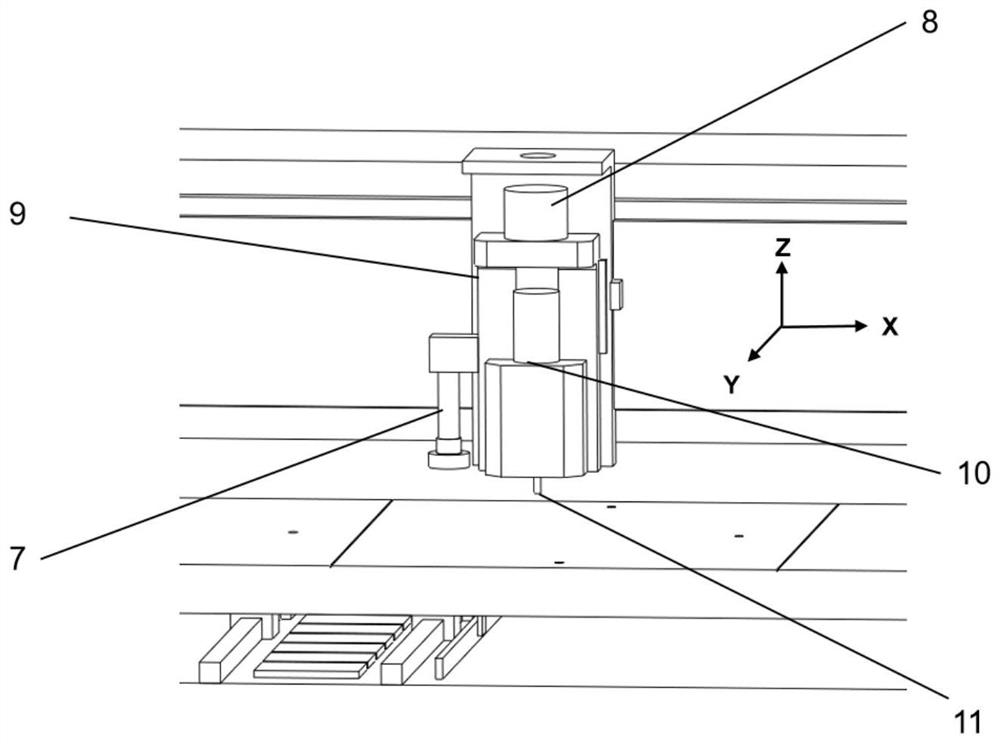

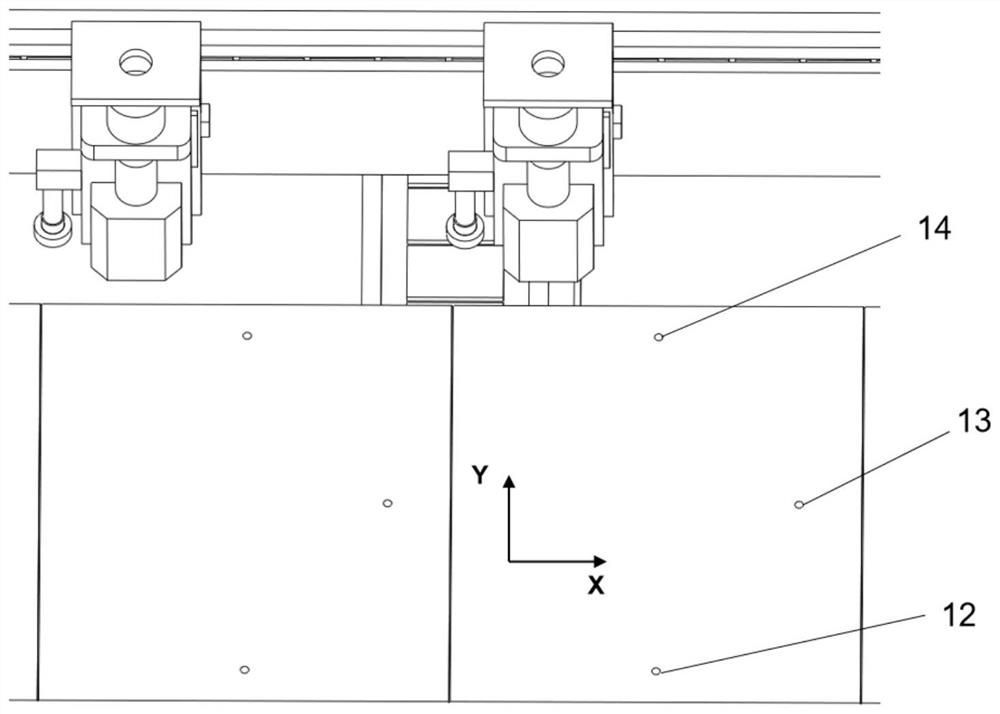

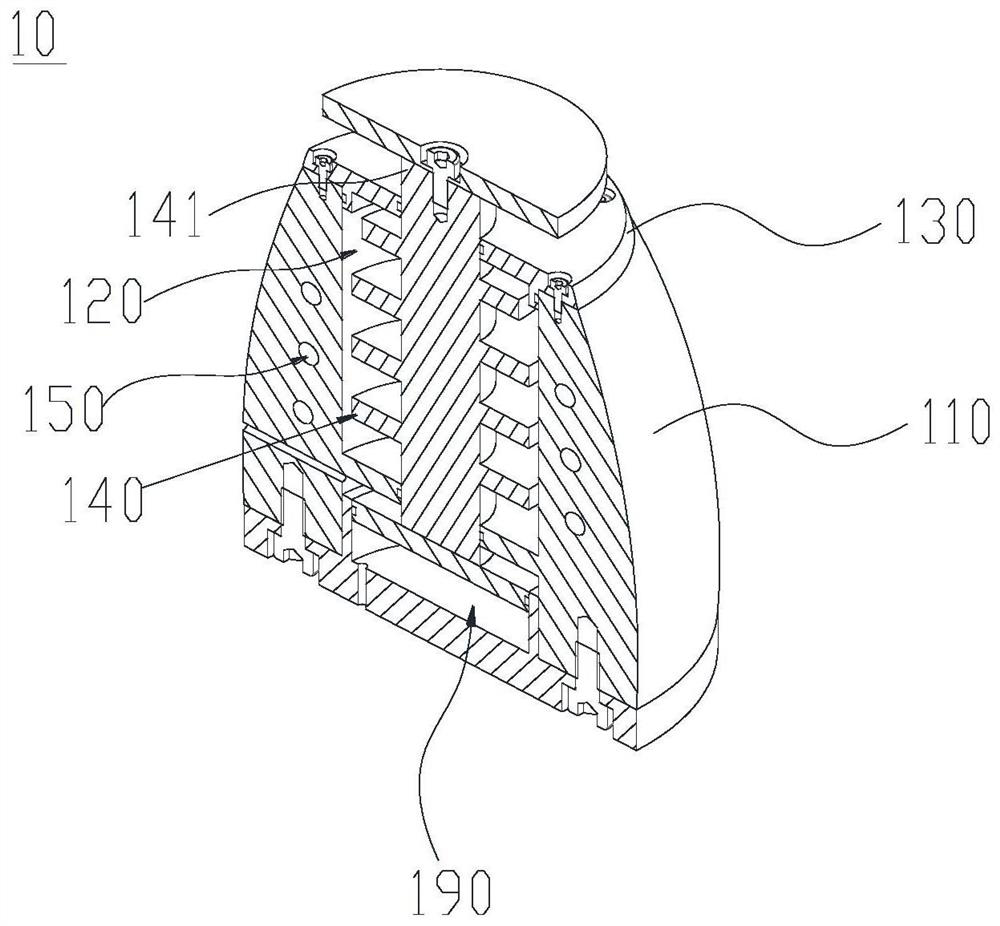

Multi-axis machining system and its machining method, device, and computer-readable storage medium

ActiveCN112731866BImprove the problem of low machining accuracySolve the problem of low machining accuracyProgramme controlComputer controlMachining systemCoordinate difference

The invention discloses a multi-axis processing system, a processing method, a device, and a computer-readable storage medium, wherein the multi-axis processing system includes a plurality of processing axes, and each processing axis corresponds to a processing area, and the method includes the following steps: obtaining The actual coordinates of at least two positioning points on the board to be processed in at least one processing area, so as to obtain the actual coordinates of multiple positioning points; obtain the coordinate difference between the actual coordinates and theoretical coordinates of each positioning point in the multiple positioning points Values to obtain multiple processing compensation values; obtain the average value of multiple processing compensation values as the processing compensation values of multiple processing axes; perform compensation processing on the plate to be processed according to the processing compensation values of multiple processing axes. This method can not only improve the problem of low processing accuracy caused by the large difference between the expansion and contraction coefficient and the actual value, but also solve the problem of low processing accuracy caused by large installation errors, and improve the processing accuracy and quality.

Owner:SUZHOU VEGA TECH CO LTD

Vibration reduction device and machine tool

ActiveCN113027987AImprove vibration damping effectSolve the problem of low machining accuracySpringsNon-rotating vibration suppressionMagnetorheological fluidEngineering

The invention provides a vibration reduction device and a machine tool. The vibration reduction device comprises: a shell, wherein a first sealing cavity is formed in the shell, the interior of the first sealing cavity is used for containing magnetorheological fluid, and one end of the shell is connected with a first connecting plate; a moving part, wherein at least part of the moving part is arranged in the first sealing cavity, the first end of the moving part penetrates out of the first connecting plate, the first end of the moving part and the first connecting plate are arranged in a sealed mode, and a wire hole is formed in the shell and surrounds the first sealing cavity, so that a magnetic field is formed in the first sealing cavity by electrifying a wire in the wire hole, wherein the moving part is movably arranged in the preset direction relative to the shell. The magnetorheological fluid can be converted into a semi-solid from a freely flowing liquid under the action of an external magnetic field, and when the moving part is stressed to move, damping force generated by the magnetorheological fluid can partially counteract impact force caused by vibration, so that the vibration reduction effect of the machine tool is improved, and the problem that in the prior art, the machining precision of the machine tool is low is solved.

Owner:ZHUHAI GREE INTELLIGENT EQUIP CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com