High-speed clamping, transporting and locating system for workpieces

A positioning system, high-speed technology, used in positioning devices, metal processing machinery parts, clamping and other directions, can solve the problems of slow workpiece processing, cumbersome operation process, waste of time, etc., to improve production efficiency, reduce scrap rate, save The effect of user time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

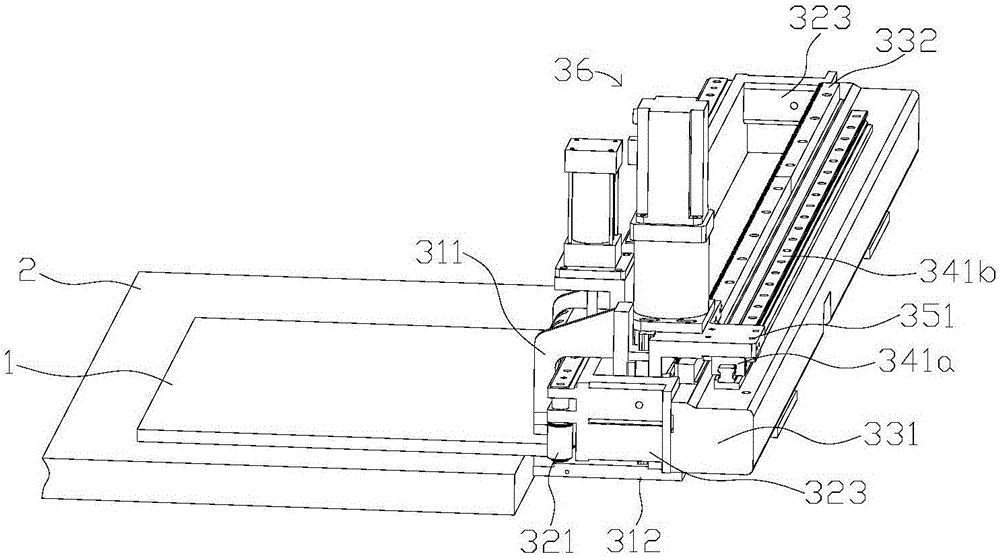

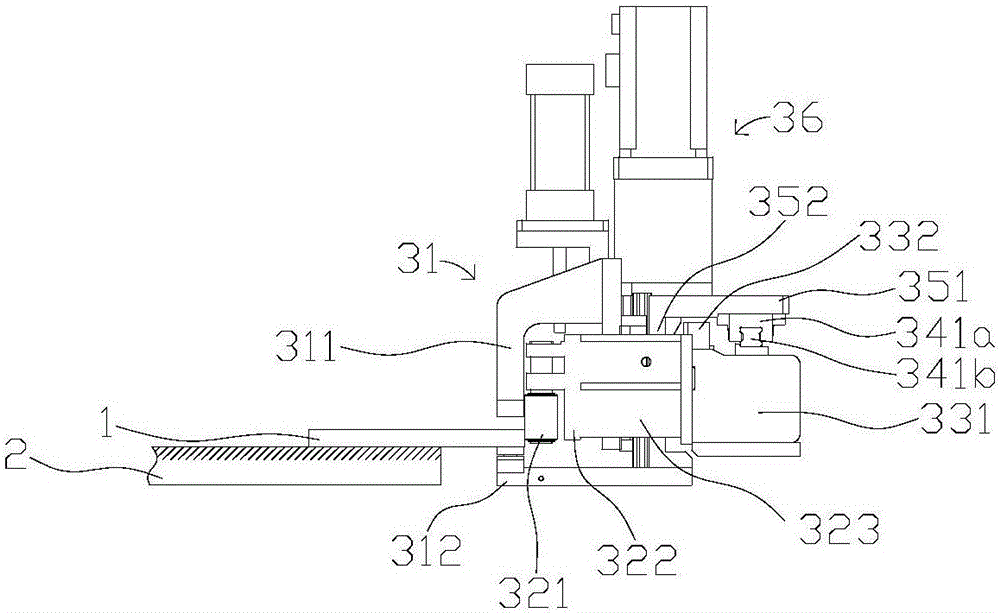

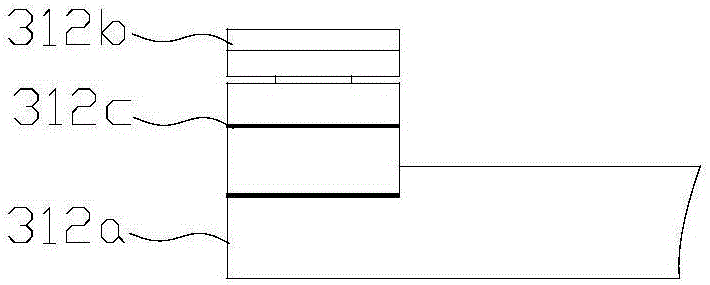

[0018] see Figure 1 to Figure 3 , a high-speed workpiece clamping, transportation and positioning system, the system includes a mounting bracket 331, a guide structure and a clamping structure 31 for clamping the workpiece 1, and the clamping structure 31, the guide structure and the mounting bracket 331 are arranged on the work surface 2 side parts, the clamping structure 31 includes an upper clamping arm 311 and a lower clamping arm 312, the upper clamping arm 311 is movably connected with the guide structure, the lower clamping arm 312 is fixedly connected with the guide structure, and the lower clamping arm 312 is upper A floating chuck that can move up and down relative to the lower clamping arm 312 is provided, and the guiding structure is movably connected with the mounting bracket 331 through two slide rails.

[0019] The beneficial effect of the present invention is to provide a high-speed workpiece clamping, transportation and positioning system, by utilizing the cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com