Machining method for eccentric crescent cylindrical mirror

A processing method and technology of cylindrical mirrors, applied in metal processing equipment, manufacturing tools, optical surface grinders, etc., can solve the problems of low processing precision of eccentric meniscus cylindrical mirrors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in combination with specific embodiments.

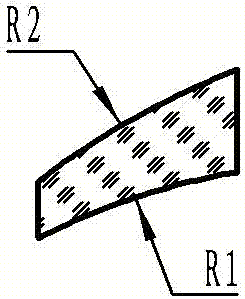

[0015] The profile of the eccentric meniscus mirror to be processed in this embodiment is as follows figure 1 , 2 as shown,

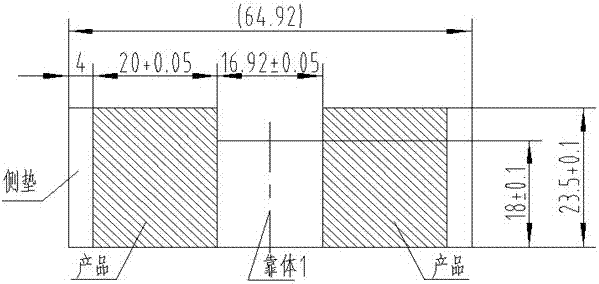

[0016] The processing method of the eccentric meniscus cylindrical mirror of this embodiment includes the following steps: 1) Processing the product into a cuboid of a specified size by milling and grinding the blank, and processing the side pads and low Pad and backing body; 2) Heat to melt the wax, stick two pieces of products on both sides of the backing body 1, and then stick a side pad on the other side of the product, wait for the wax to cool down, and complete the first loading, such as image 3 ;3) Use the milling wheel to mill the concave surface of the product, then use a cast iron disc with silicon carbide sand to finely grind the concave surface, and then use asphalt polishing powder to polish the concave surface. During the processing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com