Novel grinding and drilling integrated equipment

An integrated and new technology, applied in the field of mechanical processing, can solve the problems of insufficient precision of drilling machines, insufficient use of time and space, etc., and achieve the effects of saving processing time, improving work efficiency and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

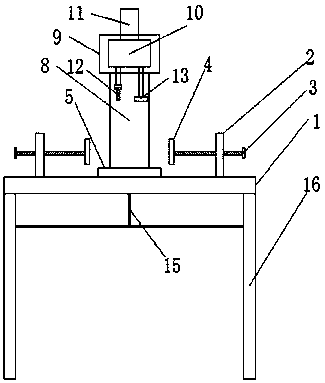

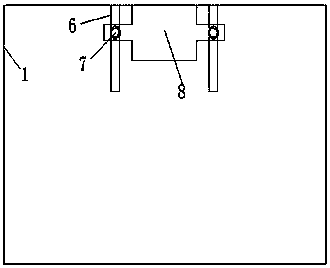

[0016] as attached Figure 1-3 Shown:

[0017] A new type of grinding and drilling integrated equipment, including a table top 1, a cylinder 11, a column 8, an electric drill 12, a grinding table 13, a connecting rod 14, a boss 5, a fixing table 9, and a fixing rod 15. It is characterized in that a limiting plate 2 is arranged on the top of the table 1, a stud 3 is arranged in the middle of the limiting plate 2, a limiting block 4 is arranged at the end of the stud 3, and the table 1 is provided with A boss 5, a chute 6 is arranged next to the boss 5, a screw 7 is arranged on the chute 6, the stud 7 is connected to a column 8, and a fixed platform 9 is provided on the column 8 , the fixed table 9 is connected to the crossbar 10, the crossbar 10 is provided with a cylinder 11, the cylinder 11 is connected to the electric drill 12 and the grinding table 13, and the described grinding table 13 and the electric drill 12 are connected to the horizontal The rods 10 are connected b...

Embodiment 2

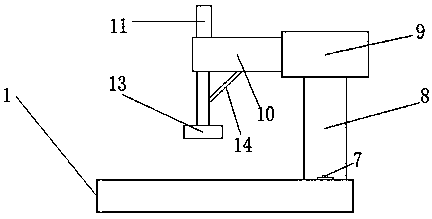

[0021] as attached Figure 4 Shown:

[0022] A new type of grinding and drilling integrated equipment, including a table top 1, a cylinder 11, a column 8, an electric drill 12, a grinding table 13, a connecting rod 14, a boss 5, a fixing table 9, and a fixing rod 15. It is characterized in that a limiting plate 2 is arranged on the top of the table 1, a stud 3 is arranged in the middle of the limiting plate 2, a limiting block 4 is arranged at the end of the stud 3, and the table 1 is provided with A boss 5, a chute 6 is arranged next to the boss 5, a screw 7 is arranged on the chute 6, the stud 7 is connected to a column 8, and a fixed platform 9 is provided on the column 8 , the fixed table 9 is connected to the crossbar 10, the crossbar 10 is provided with a cylinder 11, the cylinder 11 is connected to the electric drill 12 and the grinding table 13, and the described grinding table 13 and the electric drill 12 are connected to the horizontal Rod 10 links to each other by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com