Method for preparing specific conductive metal pattern on surface of polyimide film

A polyimide film, polyimide film technology, applied in conductive pattern formation, microlithography exposure equipment, photolithography process exposure devices, etc., can solve the problem of poor adhesion between metal wires and polymer substrates, spraying High cost of printing ink preparation, side etching of remaining metal lines, etc., to achieve the effect of improving the utilization rate of raw materials, solving the problem of low processing accuracy and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

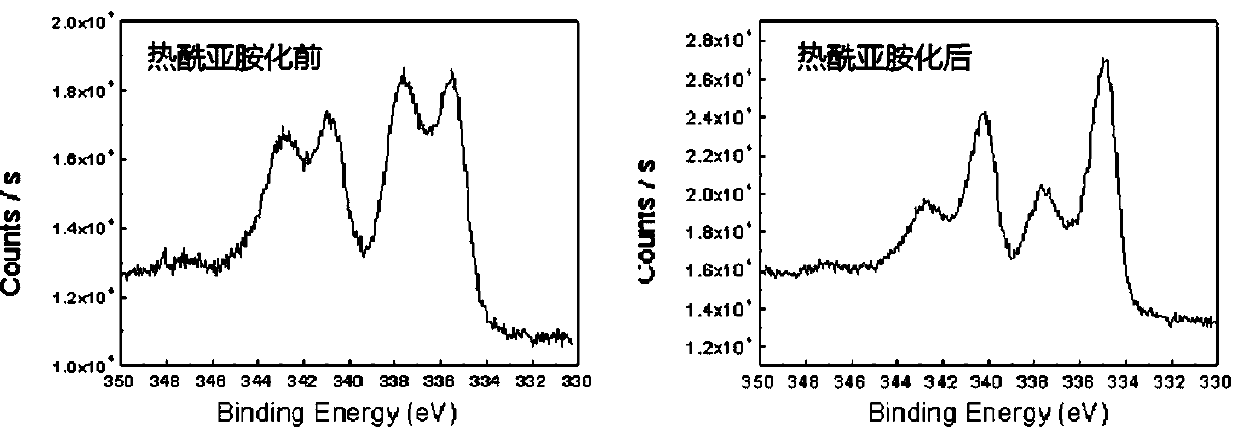

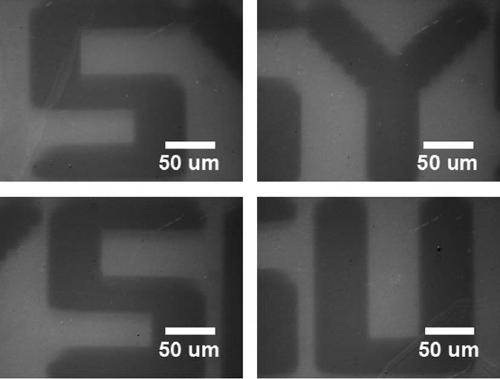

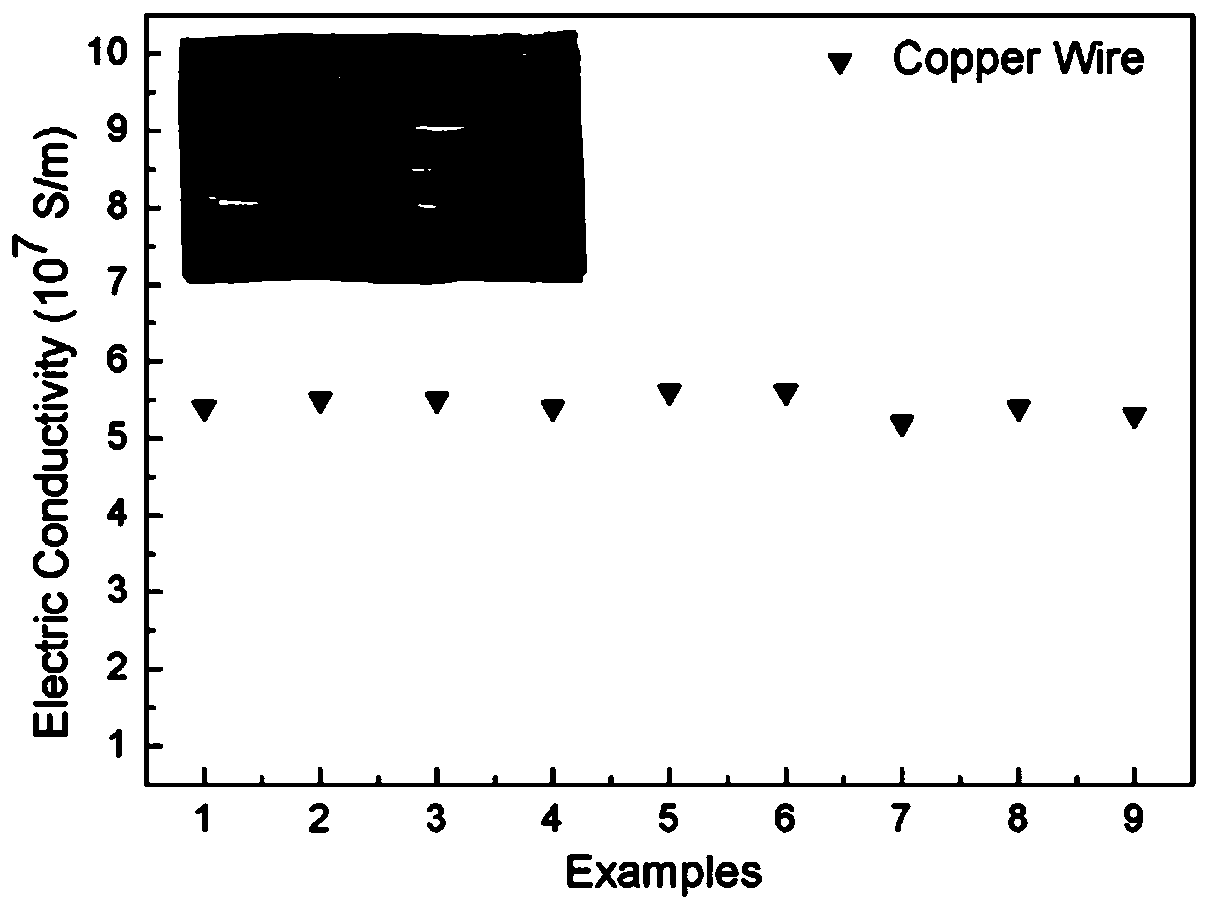

[0036] Example 1 A method of preparing a specific conductive metal pattern on the surface of a polyimide film

[0037] In the preparation of photosensitive polyamic acid film, the synthetic route of photosensitive polyamic acid solution is as follows:

[0038]

[0039] 1. Preparation of photosensitive polyamic acid film

[0040] The preparation method is carried out in the following order of steps:

[0041] S1. Under the protection of an inert gas (such as nitrogen), mix 18.4g of 4,4'-biphenylenediamine and 110.9g of biphenylenediamine containing a photosensitive structure into a device equipped with a mechanical stirring device, and then add Add 1556.1g of anhydrous N-methylpyrrolidone (NMP) to the equipment;

[0042] S2. After stirring and dissolving the diamine monomer at 20°C, add 43.6 g of pyromellitic anhydride to the reaction solution at one time;

[0043] S3, continue to stir and react for 24 hours to obtain a photosensitive polyamic acid solution;

[0044] S4. ...

Embodiment 2

[0061] Example 2 A method for preparing a specific conductive metal pattern on the surface of a polyimide film

[0062] In the preparation of photosensitive polyamic acid film, the synthetic route of photosensitive polyamic acid solution is as follows:

[0063]

[0064] 1. Preparation of photosensitive polyamic acid film

[0065] The preparation method is carried out in the following order of steps:

[0066] S1. Under the protection of an inert gas (such as nitrogen), mix 20.0g of 4,4'-biphenyl ether diamine and 59.1g of biphenyl ether diamine containing a photosensitive structure into the equipment equipped with a mechanical stirring device, Then add 1108.8g of anhydrous N,N-dimethylformamide (DMF) to the equipment;

[0067] S2. After stirring and dissolving the diamine monomer at 18°C, add 44.1 g of 3,3',4,4'-biphenyldianhydride to the reaction solution at one time;

[0068] S3, continue stirring and reacting for 20 hours to obtain a photosensitive polyamic acid soluti...

Embodiment 3

[0084] Example 3 A method for preparing a specific conductive metal pattern on the surface of a polyimide film

[0085] In the preparation of photosensitive polyamic acid film, the synthetic route of photosensitive polyamic acid solution is as follows:

[0086]

[0087] 1. Preparation of photosensitive polyamic acid film

[0088] The preparation method is carried out in the following order of steps:

[0089] S1. Under the protection of an inert gas (such as nitrogen), mix 10.8g of p-phenylenediamine and 62.7g of p-phenylenediamine containing a photosensitive structure into the equipment equipped with a mechanical stirring device, and then add 1220.4g to the equipment Anhydrous N,N-dimethylformamide (DMF);

[0090] S2. After stirring and dissolving the diamine monomer at 25°C, add 62.1 g of 4,4'-oxydiphthalic anhydride to the reaction solution at one time;

[0091] S3, continue stirring and reacting for 23 hours to obtain a photosensitive polyamic acid solution;

[0092]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com