T-shaped workpiece machining fixture

A fixture and workpiece technology, which is applied in the field of T-shaped workpiece processing fixtures, can solve the problems of T-shaped workpiece looseness, inadvertent movement of feet, and low processing accuracy, so as to prolong the service life, prevent springs from contacting high-temperature debris, and improve drilling accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in further detail below by means of specific embodiments:

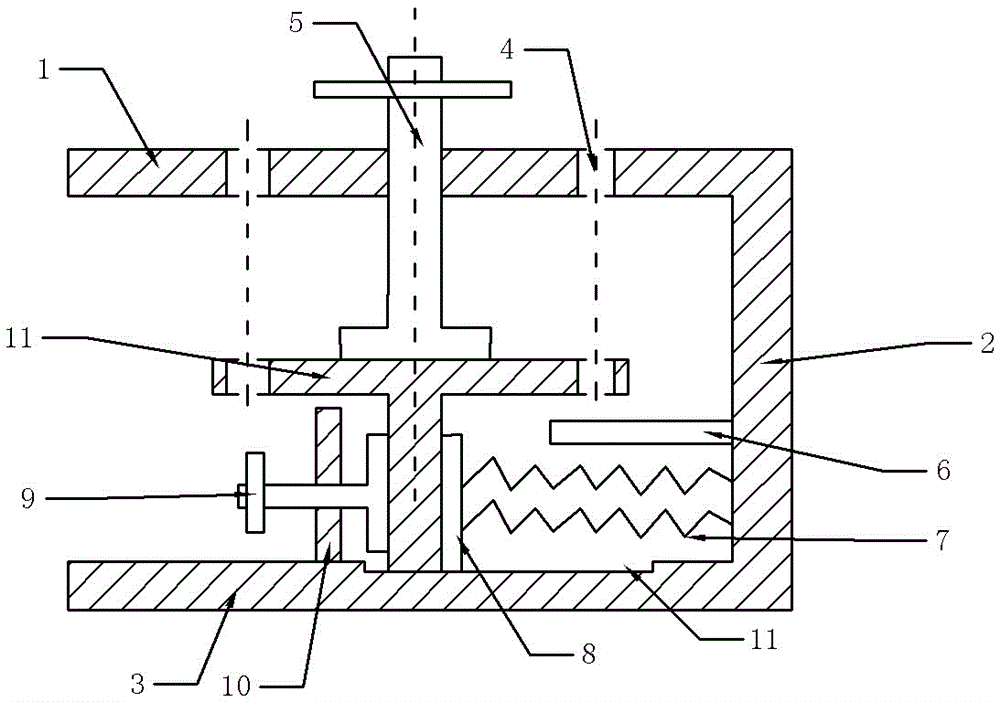

[0014] The reference signs in the drawings of the description include: top plate 1, right side plate 2, bottom plate 3, machining hole 4, first clamping shaft 5, protection block 6, spring 7, clamping block 8, second clamping shaft 9 , Auxiliary block 10, chute 11.

[0015] Such as figure 1 As shown, the clamp body provides processing space for the workpiece. The clamp body is composed of the bottom plate 3, the top plate 1 and the right side plate 2. The top plate 1 is parallel to the bottom plate 3, which is beneficial to locate the position where the workpiece needs to be drilled through the processing hole 4. The right side Both ends of the plate 2 are vertically connected to the top plate 1 and the bottom plate 3 respectively. The top plate 1 is provided with a first clamping shaft 5 and a processing hole 4. The first clamping shaft 5 cooperates with the bottom plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com