Hourglass worm processing machine tool with on-line detection and correction processing functions

A technology of toroidal worms and processing machine tools, which is applied in the direction of metal processing machinery parts, worms, metal processing, etc., can solve the problems of low precision of toroidal worms, and achieve the effects of low processing accuracy, wide application value, and strong versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

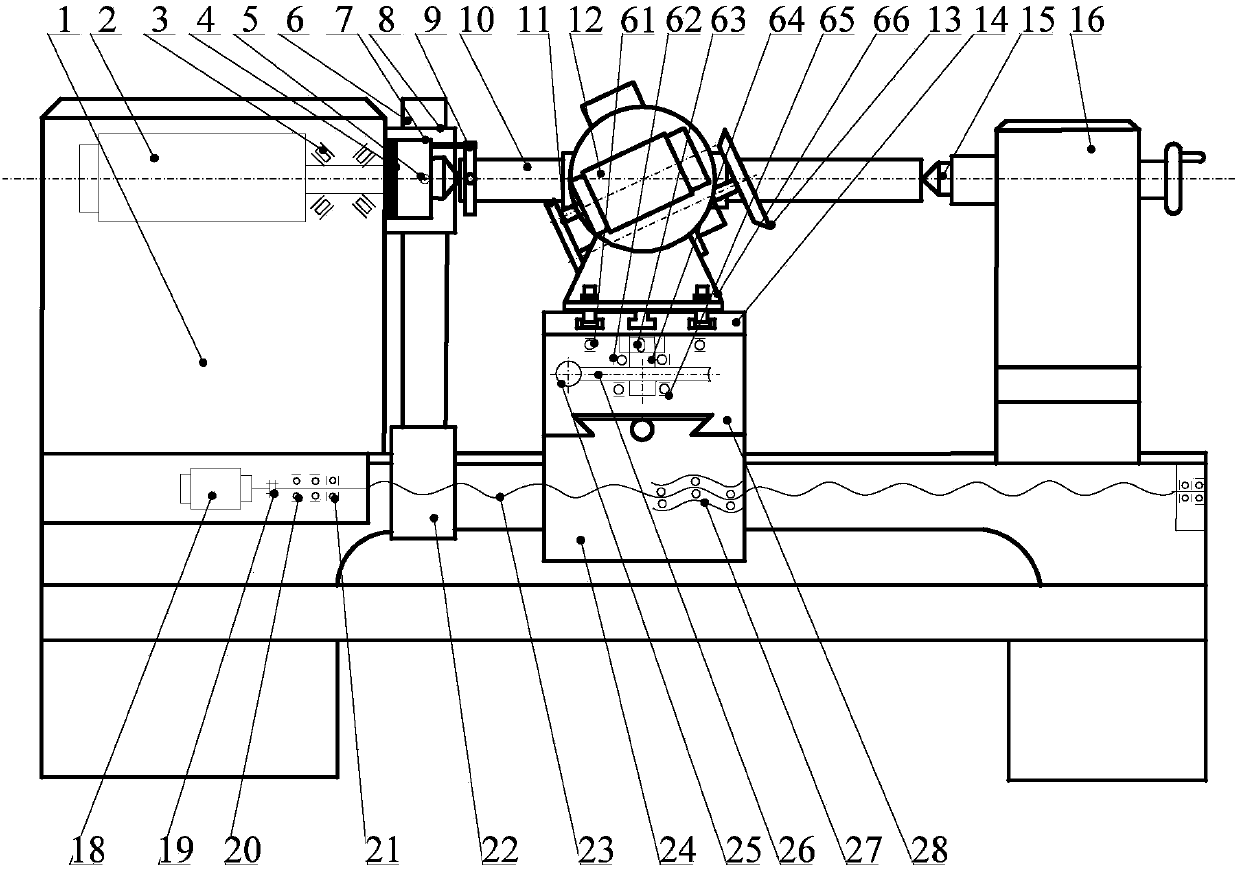

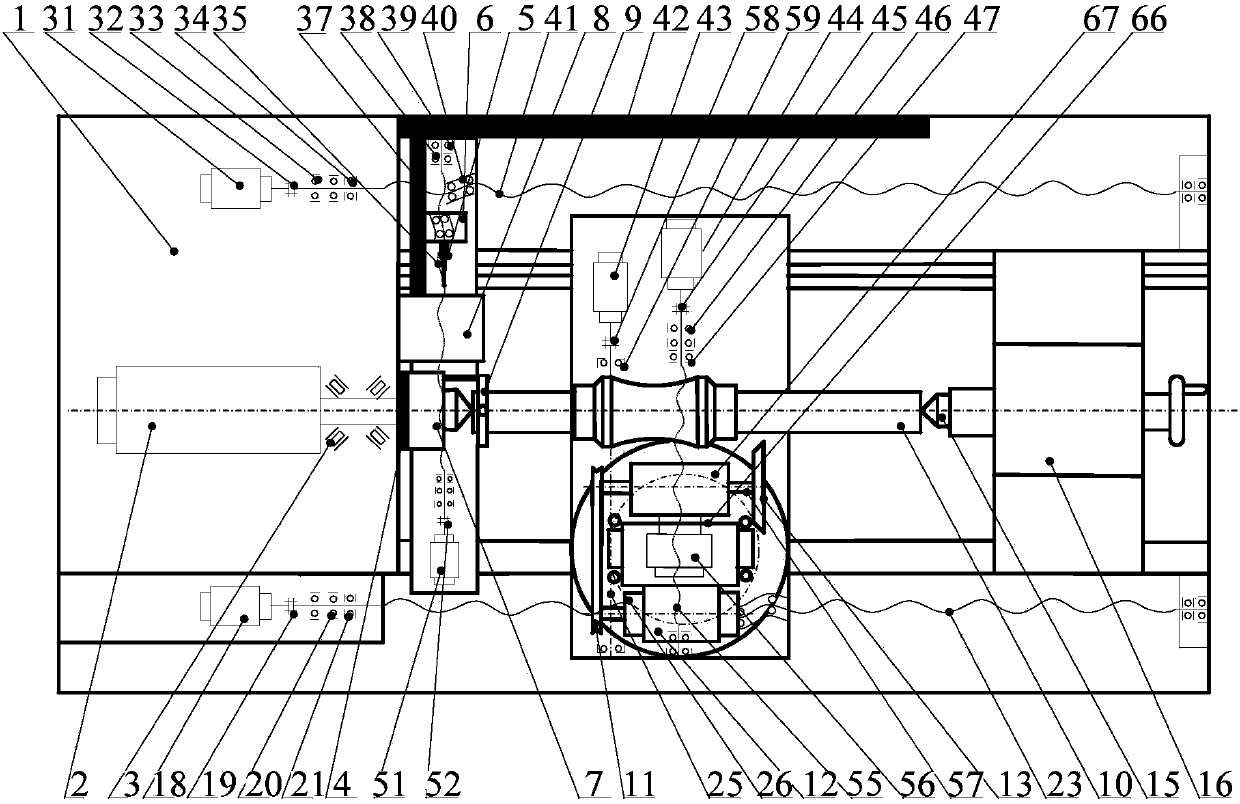

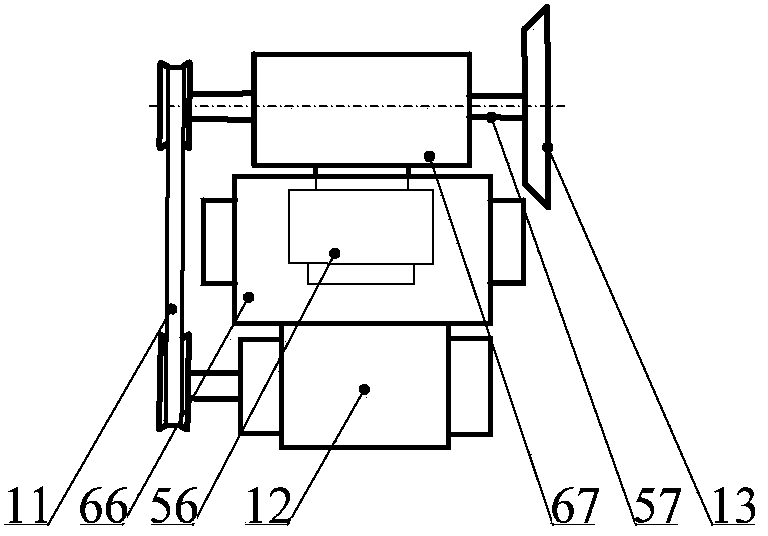

[0036] Such as Figures 1 to 6As shown, a toroidal worm processing machine tool with online detection and correction processing functions includes a bed 1, a spindle unit, a processing unit, a detection unit and a control unit, wherein the processing unit and the detection unit are respectively located on both sides of the spindle unit, Specifically, it is located on both sides of the toroidal worm 10 to be processed.

[0037] In this embodiment, the spindle unit includes a high-voltage winding spindle motor 2, a driving thimble 7, a heart clip 9, a toroidal worm 10 to be processed, a tailstock thimble 15, and a tailstock 16; wherein the high-voltage winding spindle motor 2 and the driving The thimble 7 is connected, and is positioned and fixed on the bed head box of the bed 1 through a pair of high-precision angular contact bearings 3; the toroidal worm 10 to be processed is supported by the driving thimble 7 and the tailstock thimble 15, and is passed through the heart clip ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com