Curved-surface light focusing reflector, machining system, light focusing reflector set and preparation method thereof

A reflector group and reflector technology, which is applied in solar heating systems, lighting and heating equipment, optics, etc., can solve the problems that are not conducive to improving the efficiency of solar thermal power generation, low precision of curved reflectors, and reduced focusing effect, and achieve Eliminate serious divergence losses, reduce input costs, and improve power generation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

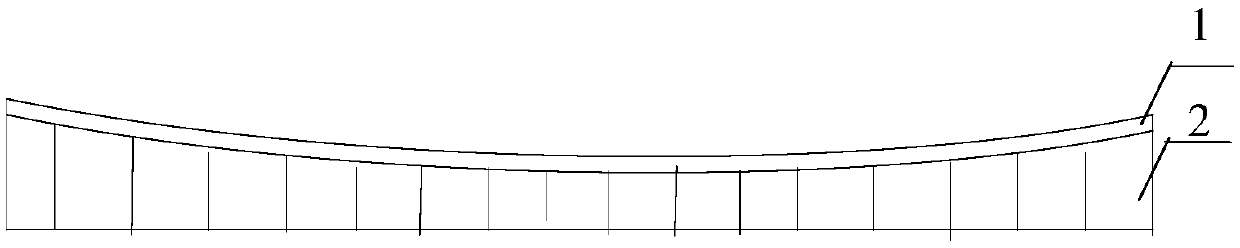

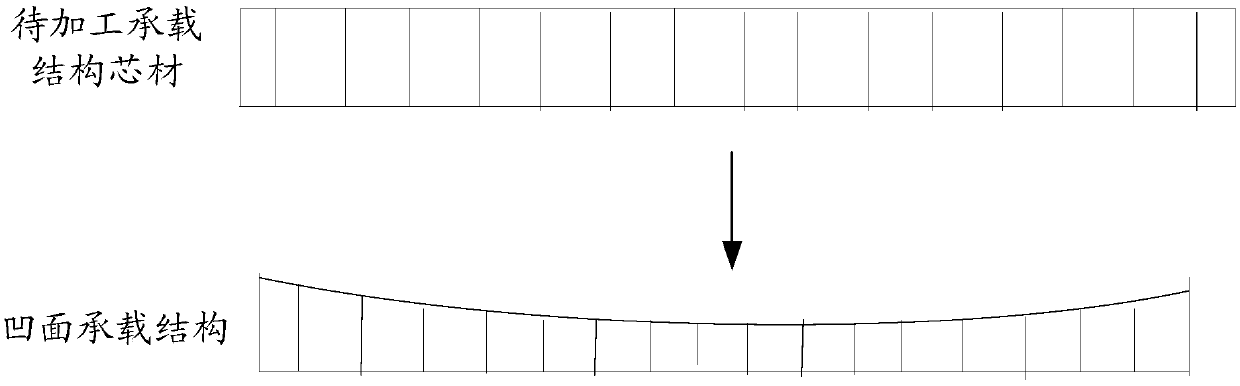

[0057] The preparation process of the concave bearing structure 2 can be:

[0058] The material for preparing the concave load-bearing structure 2 is the core material of the load-bearing structure to be processed. After calculating the radian of the target surface, according to the radian of the target surface and the structural parameters of the core material of the load-bearing structure to be processed (the length, width and height of the core material of the load-bearing structure to be processed etc.) to calculate the cutting processing data, the cutting processing data is used to control the numerical control machine tool to cut the load-bearing structure into the data with the radian of the target surface. The position, cutting depth and other data. The cutting processing data can be input into the CNC machining machine tool, and the CNC processing machine tool (such as planer, grinder) will process the core material of the load-bearing structure to be processed into a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com