A kind of processing method of aspherical cylindrical mirror

A processing method and cylindrical mirror technology, which are applied in the direction of stone processing tools, stone processing equipment, manufacturing tools, etc., can solve the problems of insufficient precision, low processing precision, inability to complete high-precision aspheric cylindrical mirrors, etc. Precise, guaranteed high-precision results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

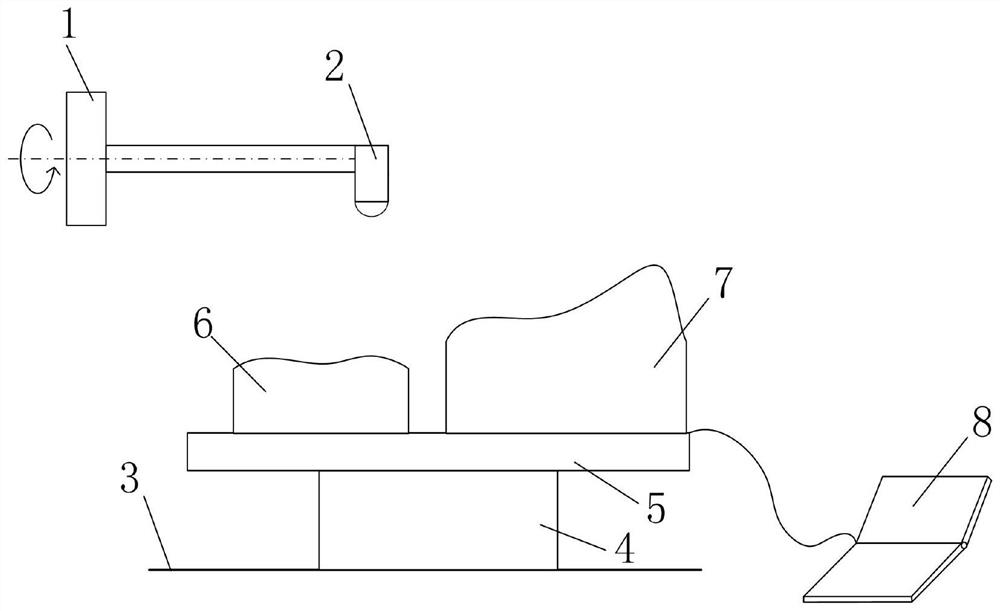

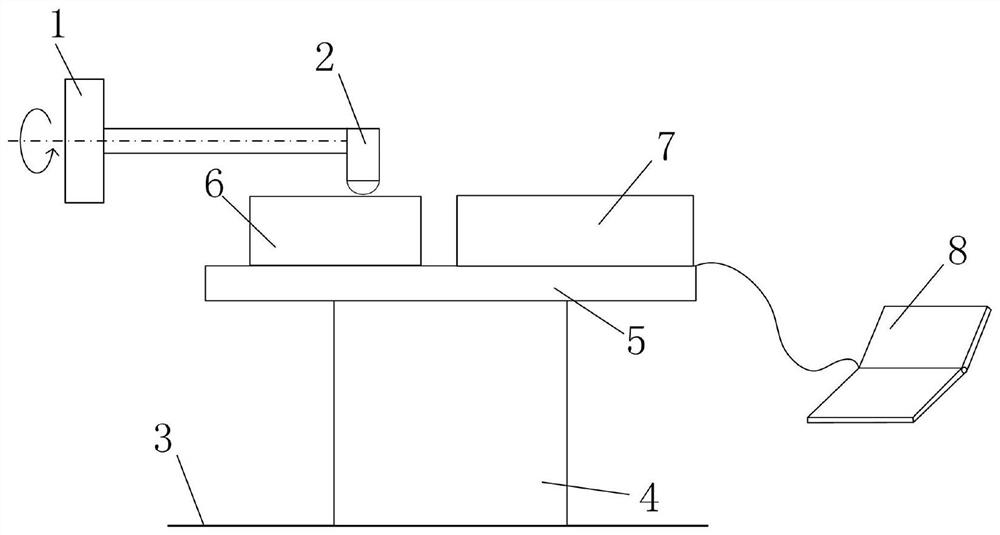

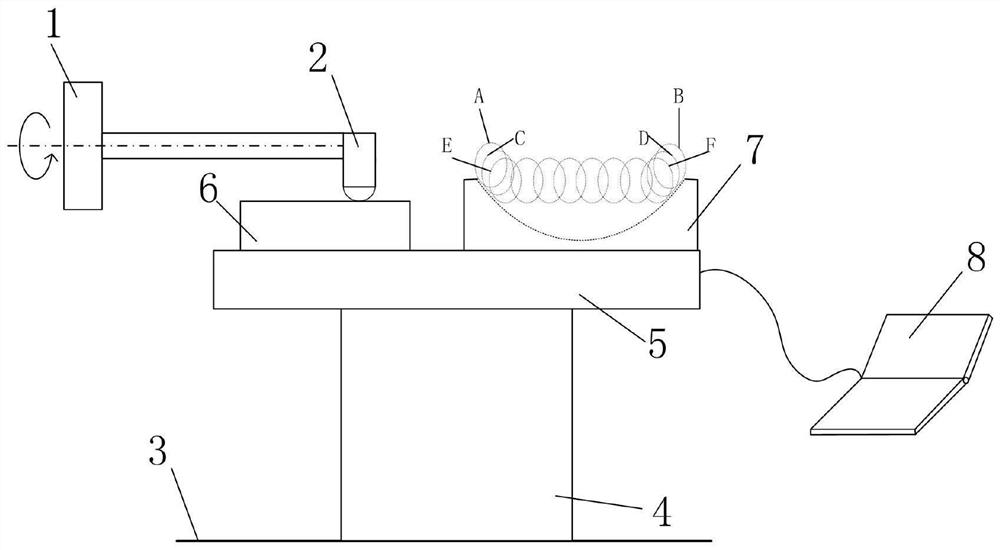

[0033] Such as Figure 1-Figure 5 As shown, the present embodiment provides a processing method of an aspheric cylindrical mirror, and the equipment used is a two-axis ultra-precision machine tool. The two-axis ultra-precision machine tool has two ultra-precision linear axes X-axis and Z-axis. Cutter 2 is installed on the machine tool spindle 1 of lathe, and the preferred cutter head of cutter 2 is the diamond cutter of circular arc in the present embodiment; Specifically comprises the following steps:

[0034] Step S01, such as figure 1 As shown, a rough adjustment displacement platform 4 and a fine adjustment displacement platform 5 are placed on the machine tool table 3, and the fine adjustment displacement platform 5 is placed on the coarse adjustment displacement platform 4. By making the lower surface of the coarse adjustment displacement platform 4 close to the upper surface of the machine tool table 3, and the lower surface of the fine adjustment displacement platform...

Embodiment 2

[0041] Such as Figure 6 As shown, on the basis of the first embodiment, step S06 is further included, and step S01 to step S05 are repeated in the Z direction, so as to obtain the processing of the aspheric cylindrical mirror array.

[0042] Through the above method, not only the processing of the aspheric cylindrical mirror array with large depth-to-diameter ratio and processing depth greater than the Y-axis range is realized, but also the consistency of the array is high, so that a high-precision aspheric cylindrical mirror array can be obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com