Gear inner ring interference fit tool clamp

A technology of interference fit and tooling fixtures, which is applied in gear tooth manufacturing devices, manufacturing tools, belts/chains/gears, etc., can solve the problems of low gear machining accuracy and non-common central axis, etc., and achieve simple structure and high reliability , a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below by means of specific embodiments:

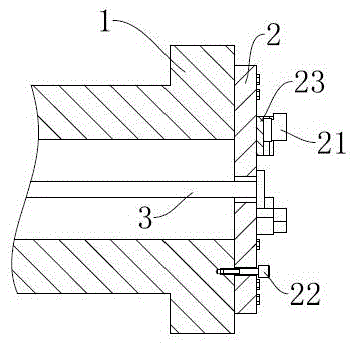

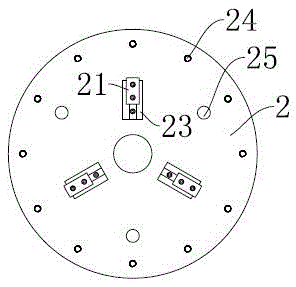

[0017] The reference signs in the accompanying drawings of the specification include: the rotating shaft seat 1 , the chuck 2 , the jaw 21 , the pin 22 , the T-shaped slot 23 , the connection hole 24 , the pin hole 25 , and the piston rod 3 .

[0018] The embodiment is basically as attached figure 2 As shown: there are twelve connecting holes 24 evenly distributed on the outermost circle of the outer circumference of the chuck 2, and three T-shaped chute 23 are evenly distributed on the chuck 2 with the center of the chuck 2 as the center, and the T-shaped chute 23 is fixed on the chuck 2 through the inner hexagonal bolt, and a T-shaped slider matching the T-shaped groove 23 is arranged in the T-shaped groove 23, and on the T-shaped slider, the T-shaped slider passes through two inner hexagons. The fixed clamping jaws 21 are connected by bolts, pin holes 25 are provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com