Automatic ball machining device and ball machining method

An automatic processing and spherical technology, applied in metal processing equipment, grinding/polishing safety devices, manufacturing tools, etc., can solve the problems of unsuitable for small-sized spherical workpiece processing, unsuitable for large-scale processing, and low degree of automation. , to achieve the effect of simple structure, saving manpower and material resources, and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] A device for automatically processing spheres and a method for processing spheres according to the present invention will be further described below in conjunction with the accompanying drawings in the embodiments of the present invention.

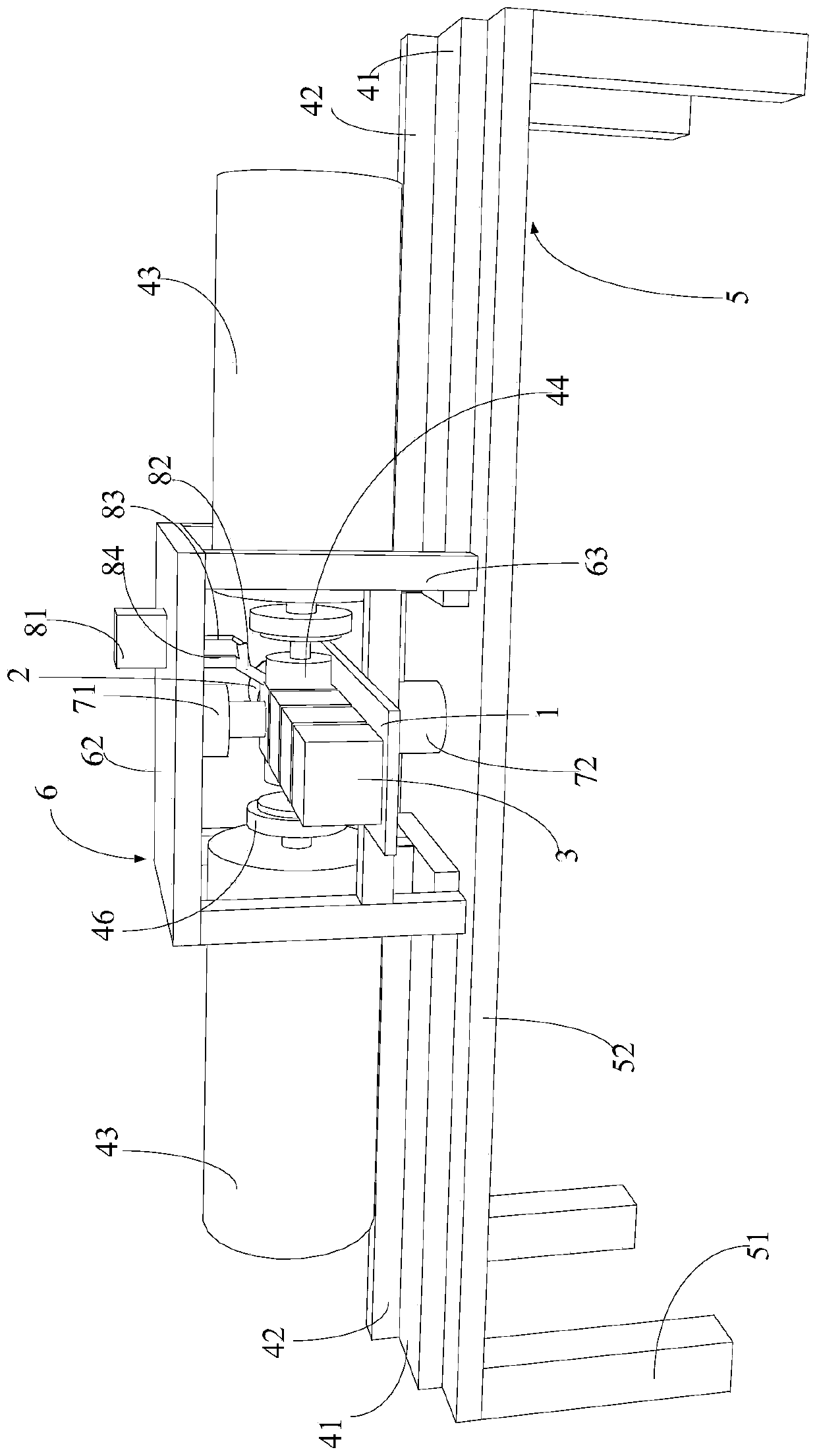

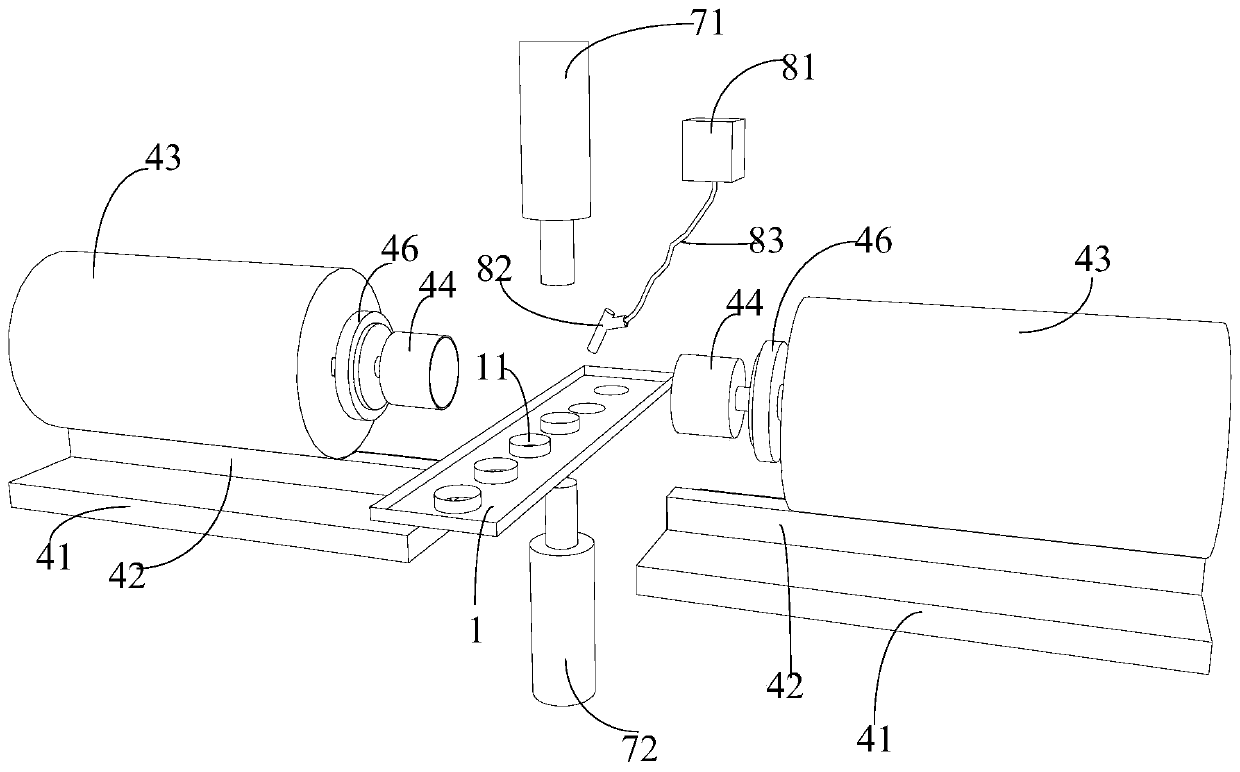

[0033] Such as Figure 2 ~ Figure 6 A device for automatically processing balls 2 is shown, which is characterized in that it includes a conveyor belt 1 for transferring blanks 3 for processing balls 2, two moving mechanisms, two rotating shaft motors 43, two nesting devices 44, and a A water spraying device for station water spraying; two moving mechanisms are erected on both sides in the width direction of the conveyor belt 1, and the two moving mechanisms include two bottom plates 41 and guide rails 42 respectively arranged on the two bottom plates 41 and relatively slid on the The electric slider of the two described guide rails 42, the two described guide rails 42 are located on the same line; the two rotating shaft motors 43 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com