Oil tank liquid level maintaining device for numerical control machine tool

A holding device, CNC machine tool technology, applied in liquid level control, control/adjustment system, non-electric variable control and other directions, can solve the problems of detection failure, influence on accuracy, influence on normal operation of the machine, etc., and achieve adjustable liquid level maintenance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

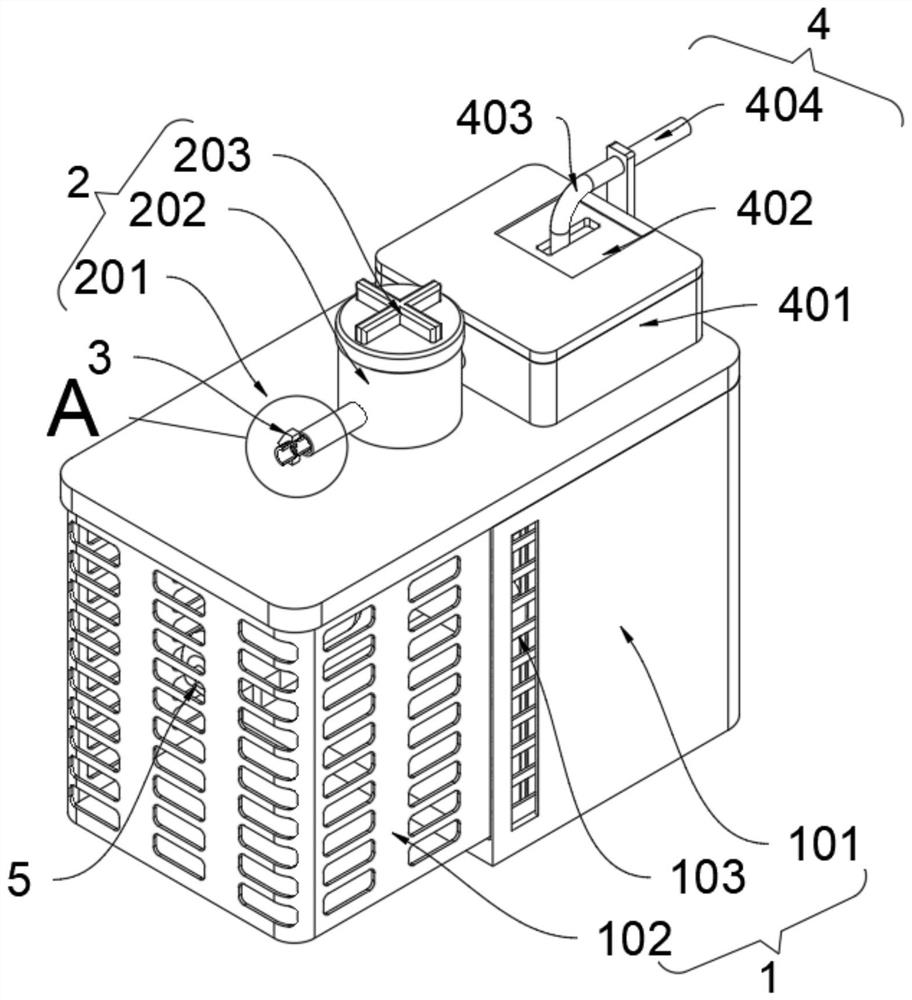

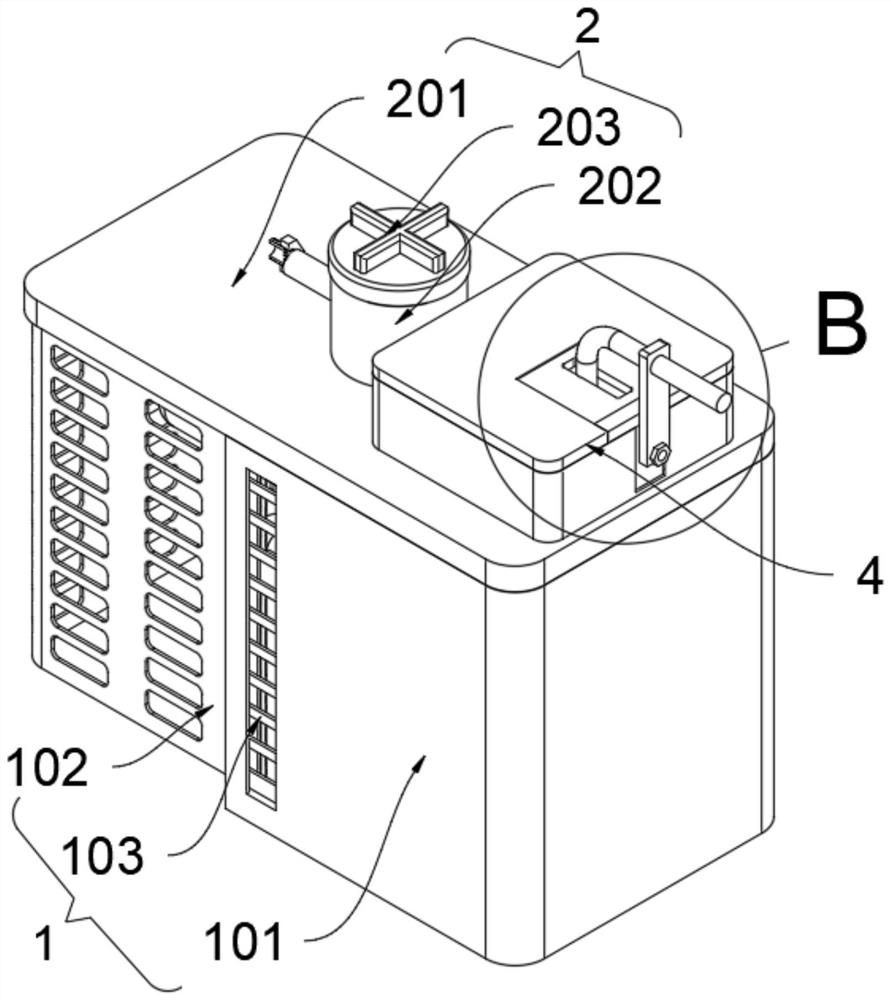

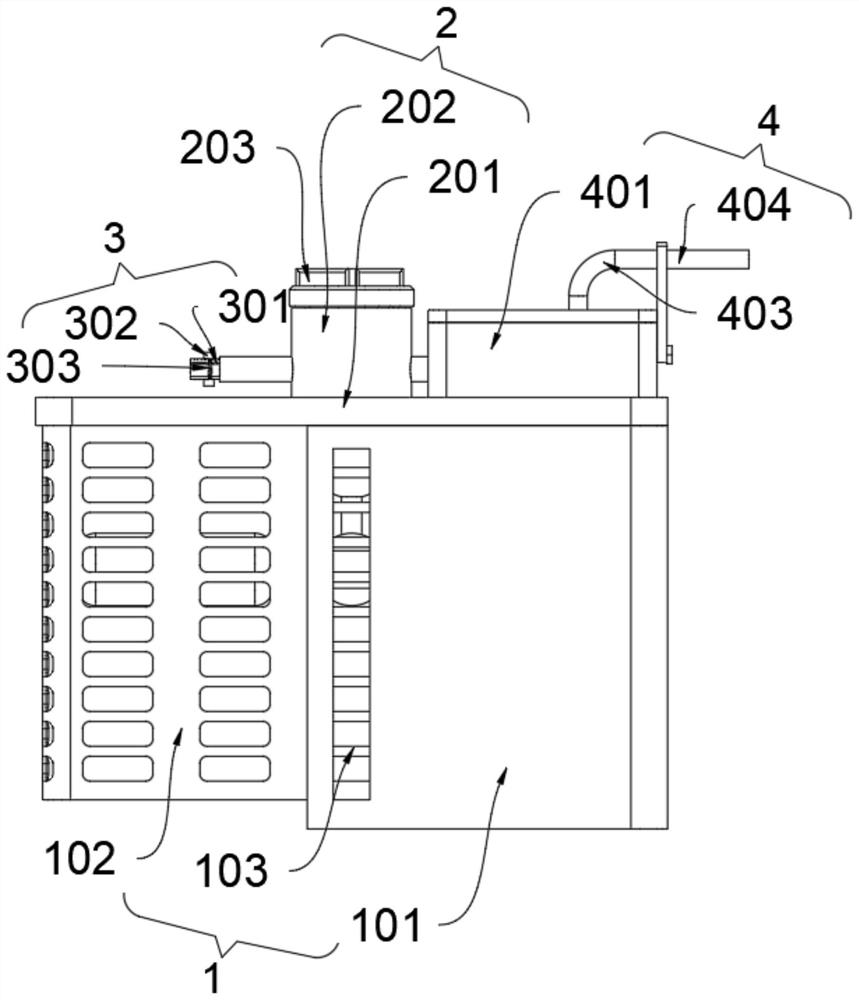

[0029] as attached figure 1 To attach Figure 6 Shown:

[0030] The invention provides an oil tank liquid level maintaining device for a numerical control machine tool, comprising: a sealing mechanism 2, a backflow anti-blocking mechanism 3 and a liquid level maintaining mechanism 5, the sealing mechanism 2 is clamped at the top position of the bearing mechanism 1; the backflow The anti-blocking mechanism 3 is screwed to the left side of the sealing mechanism 2, and the right side of the sealing mechanism 2 is also equipped with a liquid supply holding mechanism 4; the liquid level holding mechanism 5 is slidably connected to the inner side of the carrying mechanism 1; the liquid level holding mechanism 5 also includes a strut 504 and a flow control ball 505, the support 504 is fixedly connected to the position of the top end of the intersection of the four columns 502, and the top end of the support 504 is fixedly connected with a flow control ball 505, and the diameter of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com