Fracturing flow-back fluid pretreatment device facilitating grating cleaning

A technology for fracturing flowback fluid and pretreatment device, which is applied in the fields of filtration and separation, fixed filter element filters, chemical instruments and methods, etc., and can solve the problems of the internal quality of fracturing flowback fluid and the generation of a large number of impurities in the grid. , to achieve the effect of reducing work intensity and reducing time occupied

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

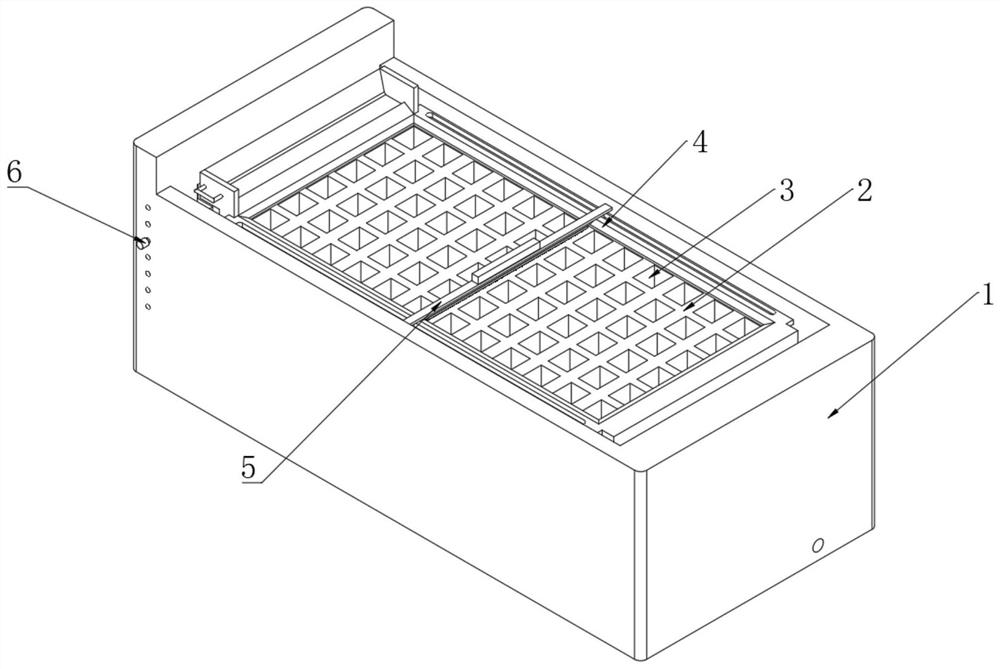

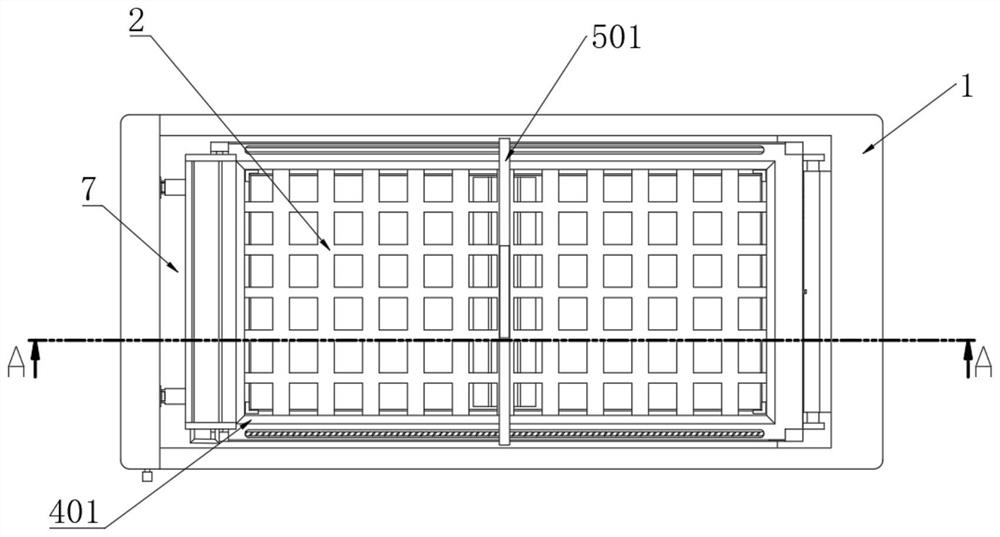

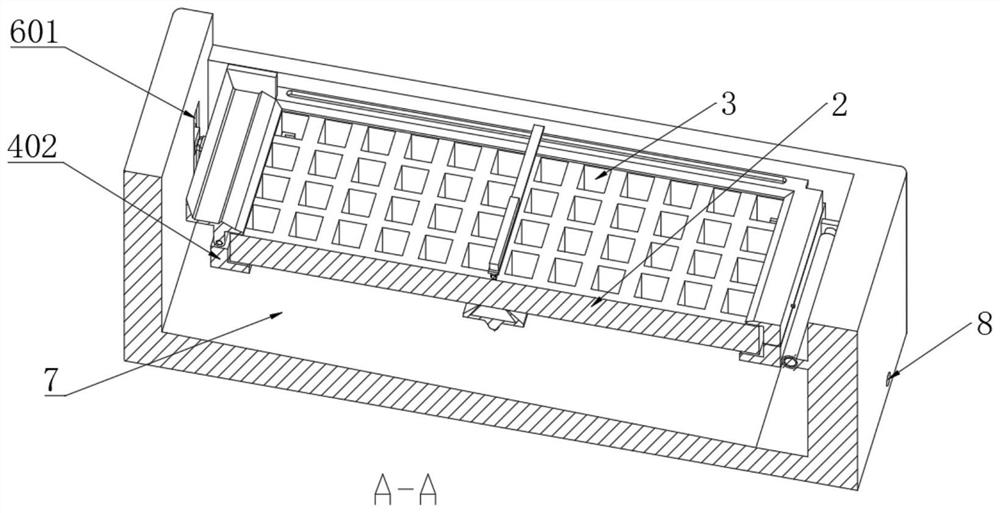

[0042] Such as Figures 1 to 16 As shown in the figure, a pretreatment device for fracturing flowback fluid that is convenient for grid cleaning includes a transfer box 1, a filter storage tank 7 is provided inside the transfer box 1, and a transfer through hole is opened on one side of the filter storage tank 7 8. An adjustment assembly 6 is installed on one side of the inner wall of the filter storage tank 7, and a positioning and rotating sleeve rod 9 is installed on the other side of the inner wall of the filter storage tank 7. A placement assembly 4 is installed between the positioning and rotation sleeve rod 9 and the adjustment assembly 6, and the placement assembly 4. A grid body 2 is placed inside, and cleaning components 5 are installed on both sides of the placement component 4 located on the outer periphery of the grid body 2;

[0043] The placement component 4 includes a matching bracket 401 and a base bracket 402. Both the matching bracket 401 and the middle part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com