Melt-blown cloth nozzle structure capable of avoiding air passage blockage

A melt-blown cloth and nozzle technology, which is applied in the field of melt-blown cloth nozzle structures, can solve the problems of inability to stir raw materials, solidify raw materials, and filter fuses.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

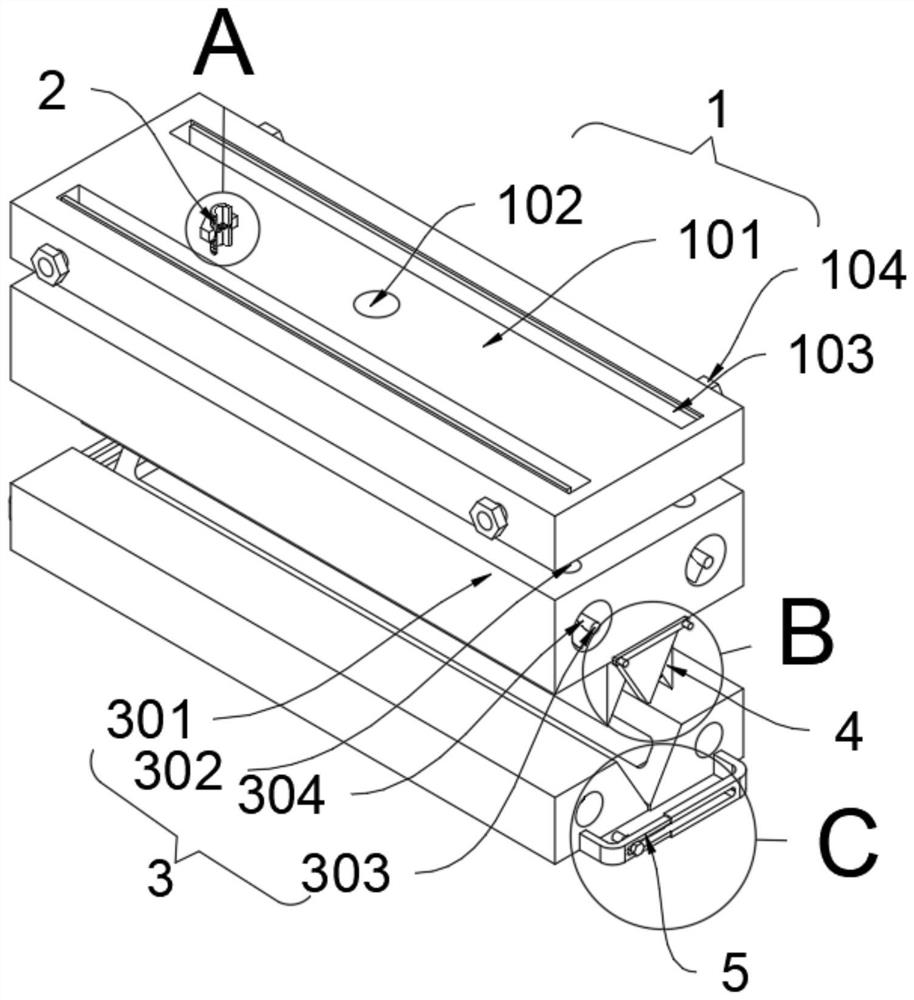

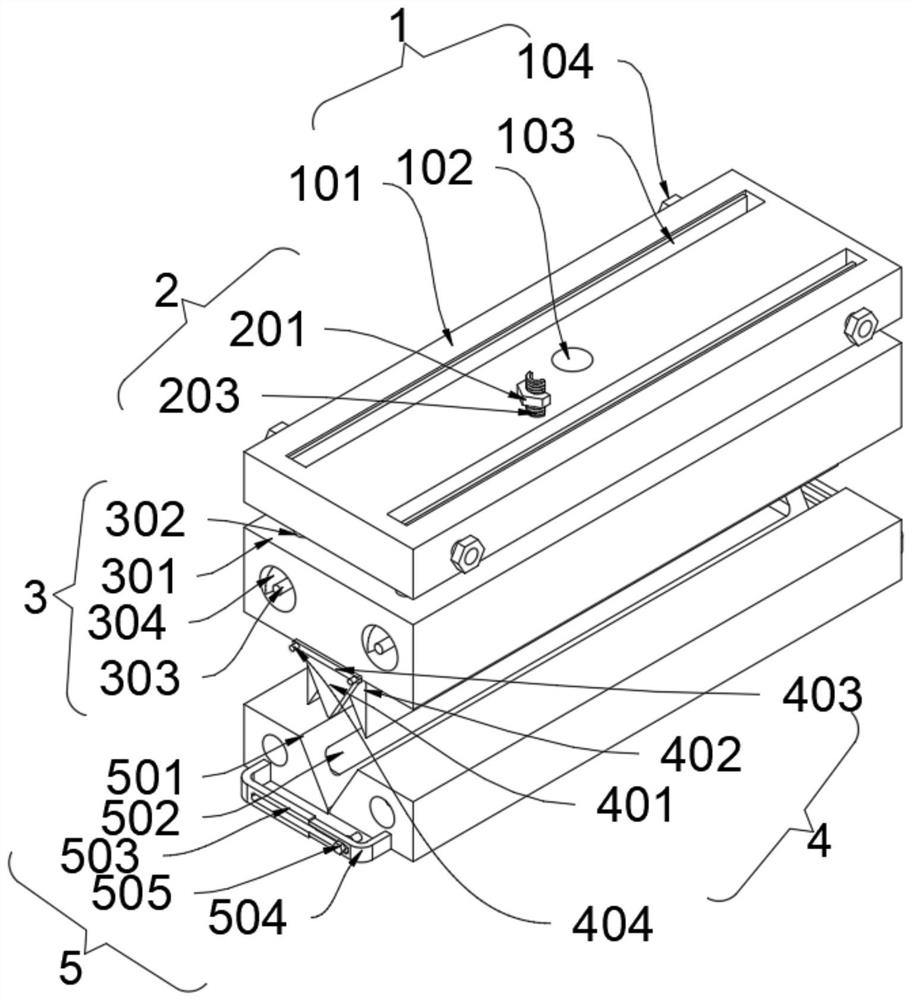

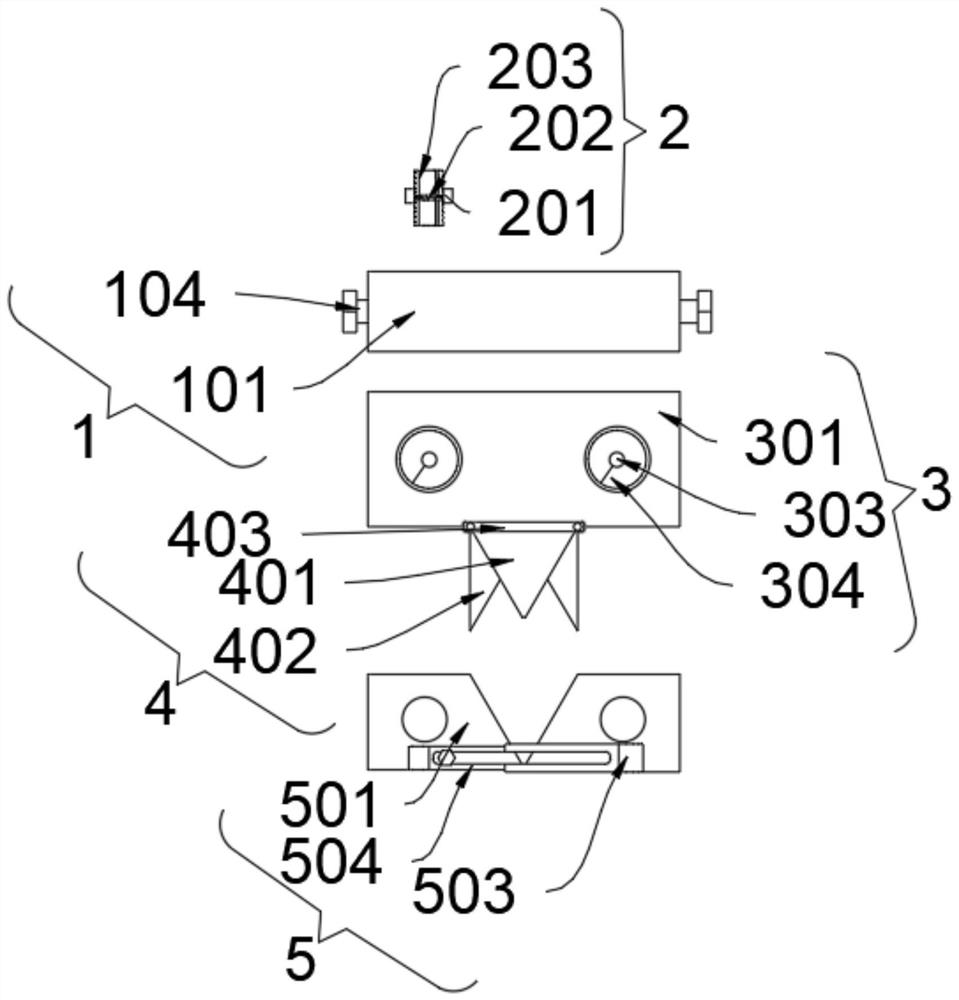

[0029] as attached figure 1 to attach Figure 6 Shown:

[0030] The present invention provides a melt-blown cloth nozzle structure that avoids airway blockage, including: a wire feeding mechanism 2 and a spinning mechanism 4, the wire feeding mechanism 2 is screwed to the top position of the feeding mechanism 1, and the feeding mechanism 1 The bottom end can also be condensed with an anti-blocking mechanism 3 through bolts, and communicates with the anti-blocking mechanism 3; The air guiding mechanism 5 is connected; the air guiding mechanism 5 also includes a secondary bracket 504 and a stopper 505, and there are two secondary brackets 504, and the two secondary brackets 504 are respectively fixedly connected to the guide block 501 located on the front side. The positions on the left and right ends are respectively plugged with two main brackets 503. There are two limit bolts 505, and the two limit bolts 505 are respectively screwed to the inner positions of the two main br...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com