Pipeline cleaning device used in lead nitrate production process

A production process and pipeline cleaning technology, applied in the direction of cleaning hollow objects, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of reduced purity of lead nitrate processing, inability to clean chemical pipelines, and easy residues of various compounds. Achieve the effect of improving efficiency and improving adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

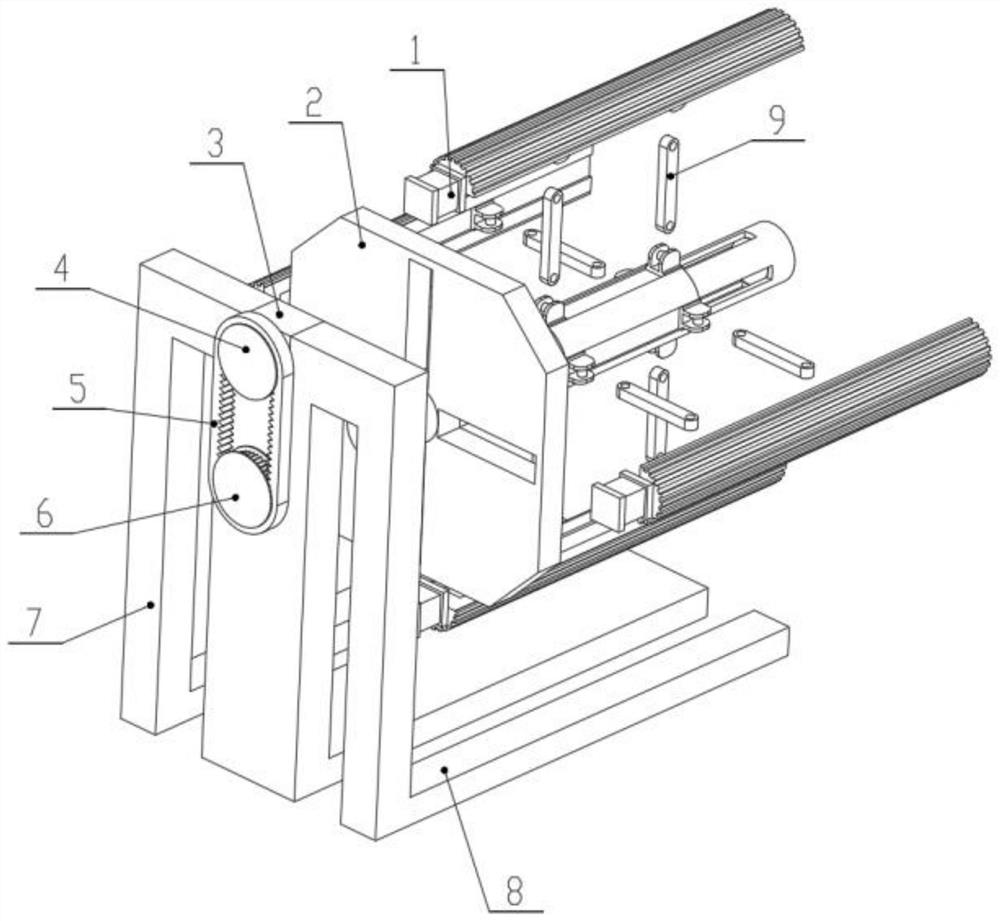

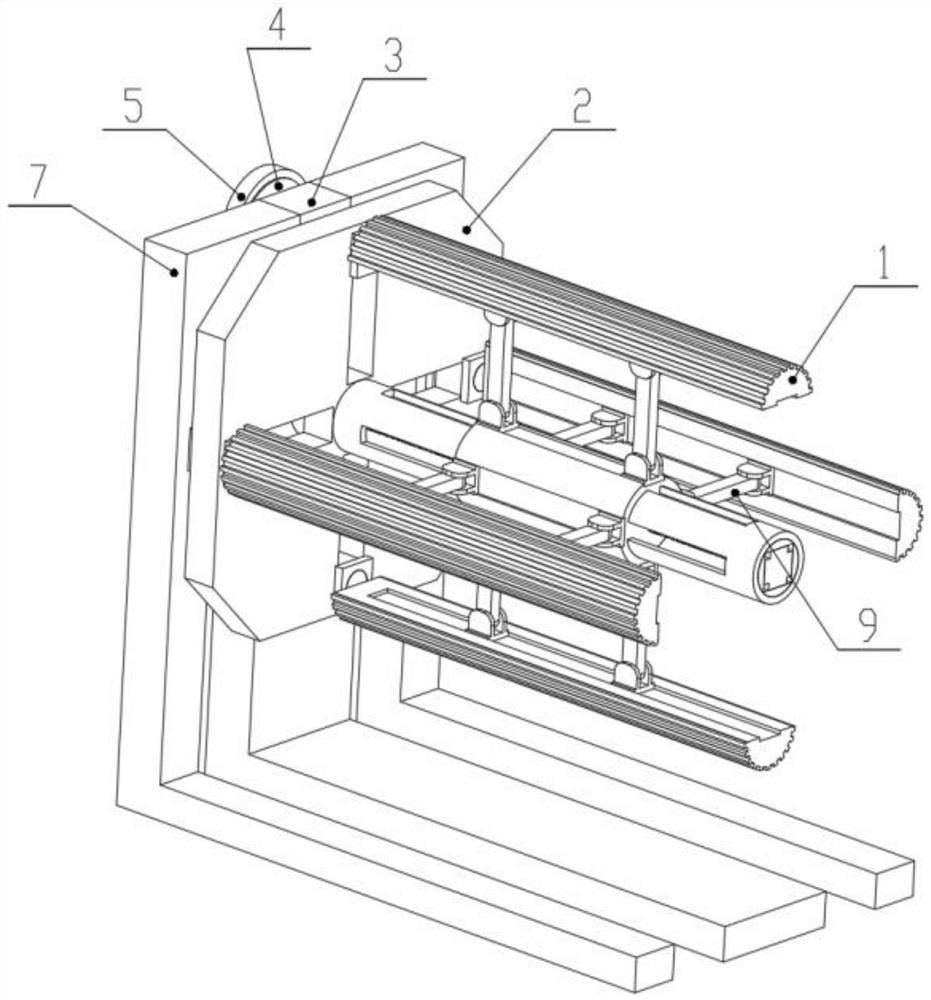

[0036] like Figure 1-2Shown, a kind of pipeline cleaning device for lead nitrate production process, the upper end face of the support base plate 8 is fixedly installed with the support card plate 7 for supporting near the end, and the upper end face of the support card plate 7 is located near the top. The driven toothed pulley 6 is rotated and clamped, the inner end face of the support card 7 is facing the driven toothed pulley 6 and the transmission device 2 is rotated and clamped, and the driven toothed pulley 6 and the transmission device 2 are connected. Fixed connection, the outer end surface of the support card 7 is fixedly connected with the servo motor 3 near the top, and the driving toothed pulley 4 is fixedly installed at the center of the rear end surface of the servo motor 3, and the driving toothed pulley 4 and the driven The toothed belt pulleys 6 are meshed and rotated through the toothed V-belt 5, and the outer end face of the transmission device 2 is evenly ...

Embodiment 2

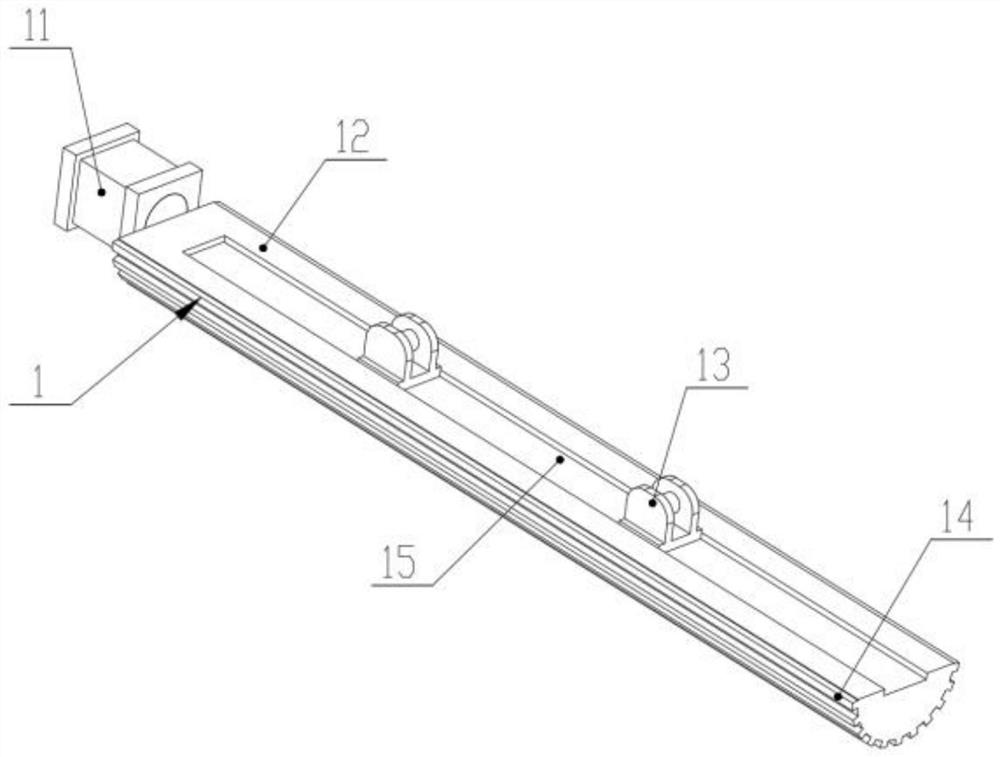

[0038] like Figure 1-3 As shown, as the further optimization scheme of the above-mentioned embodiment: a kind of pipeline cleaning device used in the lead nitrate production process, the upper end face of the support bottom plate 8 is fixedly installed with the support card plate 7 for supporting near the end, and is located in the support plate 7. The upper end surface of the card plate 7 is rotated and clamped with the driven toothed pulley 6 near the top. The belt pulley 6 is fixedly connected with the transmission device 2, the outer end surface of the support card 7 is fixedly clamped with the servo motor 3 near the top, and the driving toothed belt pulley 4 is fixedly installed at the center of the rear end surface of the servo motor 3, The driving toothed pulley 4 and the driven toothed pulley 6 are meshed and rotated through the toothed V-belt 5, and the outer end face of the transmission device 2 is evenly and equally spaced. The cleaning device 1 is slidably and cl...

Embodiment 3

[0040] like Figure 1-4 As shown, as the further optimization scheme of the above-mentioned embodiment: a kind of pipeline cleaning device used in the lead nitrate production process, the upper end face of the support bottom plate 8 is fixedly installed with the support card plate 7 for supporting near the end, and is located in the support plate 7. The upper end surface of the card plate 7 is rotated and clamped with the driven toothed pulley 6 near the top. The belt pulley 6 is fixedly connected with the transmission device 2, the outer end surface of the support card 7 is fixedly clamped with the servo motor 3 near the top, and the driving toothed belt pulley 4 is fixedly installed at the center of the rear end surface of the servo motor 3, The driving toothed pulley 4 and the driven toothed pulley 6 are meshed and rotated through the toothed V-belt 5, and the outer end face of the transmission device 2 is evenly and equally spaced. The cleaning device 1 is slidably and cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com