Immersed tunnel concrete pouring system and method

An immersed tube tunnel and concrete technology, which is applied in the field of concrete pouring, can solve the problems of long pouring tubes and the inability to meet the pouring requirements of self-compacting steel shell concrete immersed tubes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

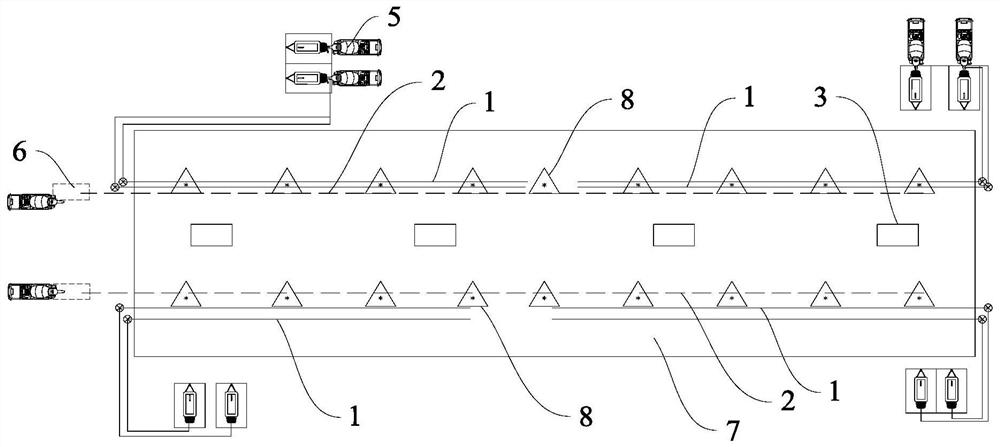

[0039] Such as figure 1 As shown, a concrete pouring system for an immersed tube tunnel includes a pouring pipe 1 , a return pipe 2 , a pouring machine 3 and an elbow 4 .

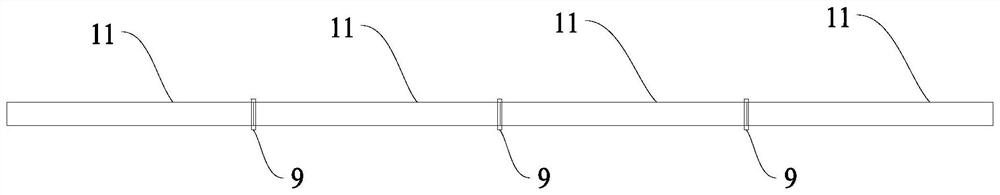

[0040] A plurality of pouring pipes 1 are symmetrically arranged in the prefabricated site 7, and each said pouring pipe 1 is arranged from the end of the prefabricated site to the center, such as figure 2 As shown, each pouring pipe 1 includes a plurality of pouring pipe segments 11, the length of the pouring pipe segments 11 is 2m-5m, and the interface between two adjacent pouring pipe segments 11 is through a pump pipe joint 9 detachable connections. The pouring pipe 1 is a high-pressure steel pipe, and a hose can be used locally.

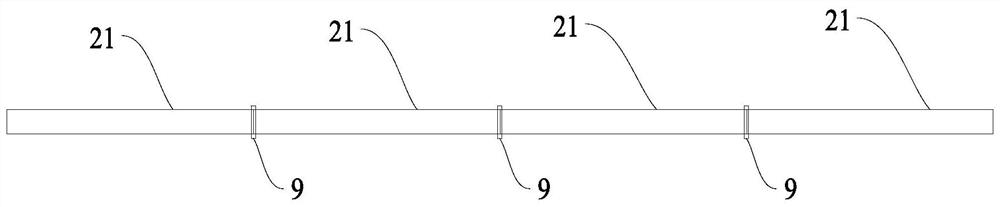

[0041] A plurality of return pipes 2 are symmetrically arranged in the prefabricated site 7, and each said return pipe 2 is arranged from one end of the prefabricated site to the other end, as image 3 As shown, each of the return pipes 2 includes a plurality of return pi...

Embodiment 2

[0046] Such as Figure 1-Figure 5 Shown, a kind of immersed tube tunnel concrete pouring method comprises the following steps:

[0047] Step 1: arranging the concrete pouring system of the immersed tube tunnel as described in embodiment 1 in the prefabricated site;

[0048] Step 2: move the pouring machine 3 to the position 8 to be poured, and connect the feed inlet 31 to the interface of the nearest pouring pipe segment 11 through the elbow 4;

[0049] Step 3: Self-compacting concrete enters the pouring pipe 1 from the drag pump 5, enters the pouring machine 3 through the feed port 31, and pours concrete;

[0050] Step 4: After the concrete pouring is completed, the connection between the feed inlet 31 and the elbow 4 is removed;

[0051] Step 5: Connect the elbow 4 to the interface of the nearest return pipe segment 21 to form a cleaning channel, such as Figure 4 shown;

[0052] Step 6: Insert a sponge ball into the cleaning channel, pump water or air into the cleaning ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com