Patents

Literature

42results about How to "Change production mode" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

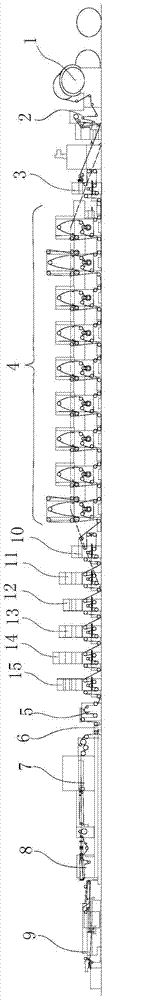

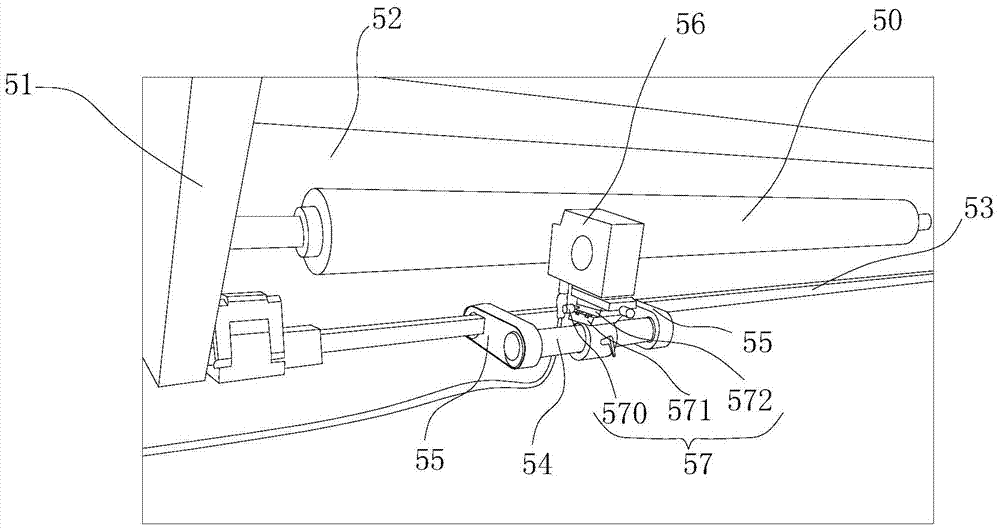

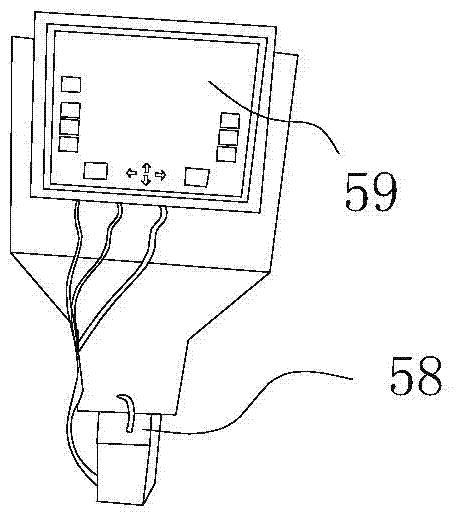

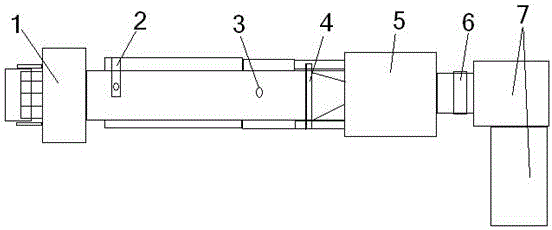

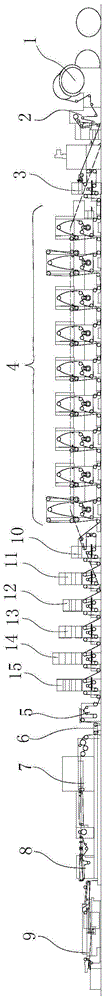

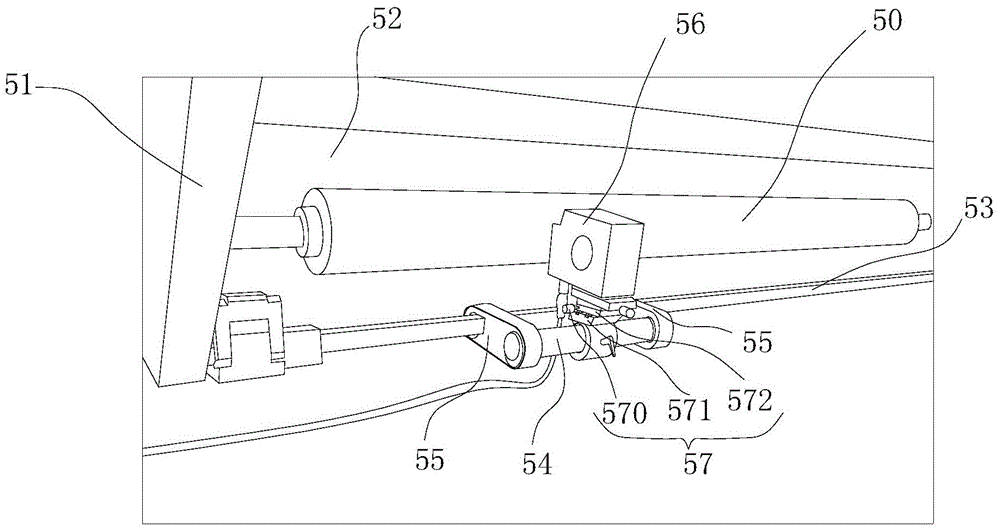

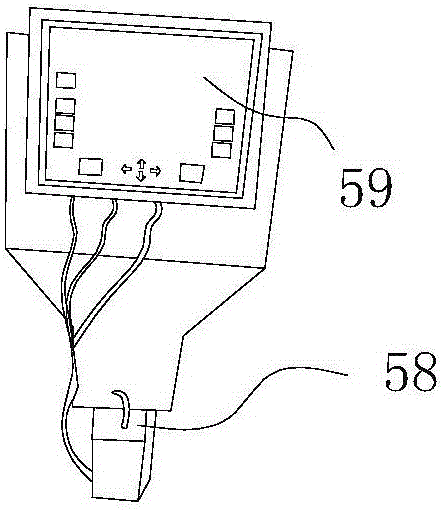

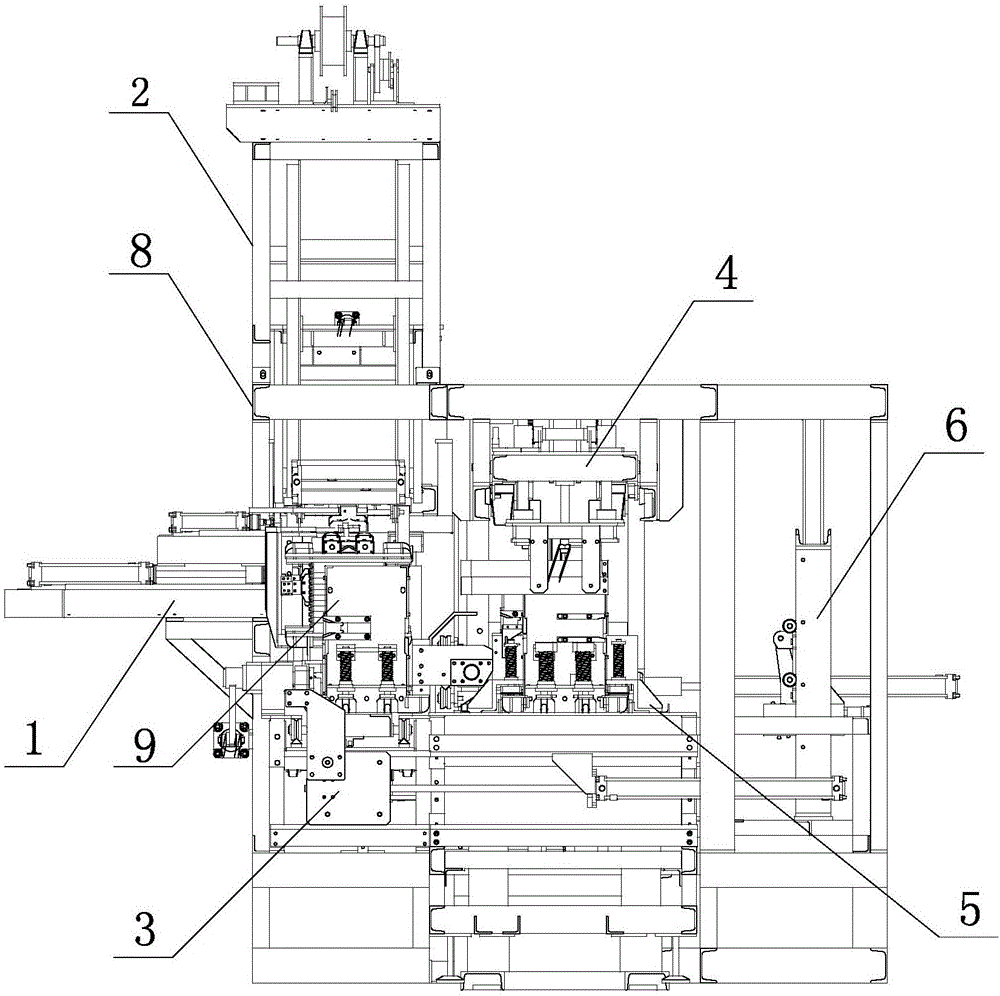

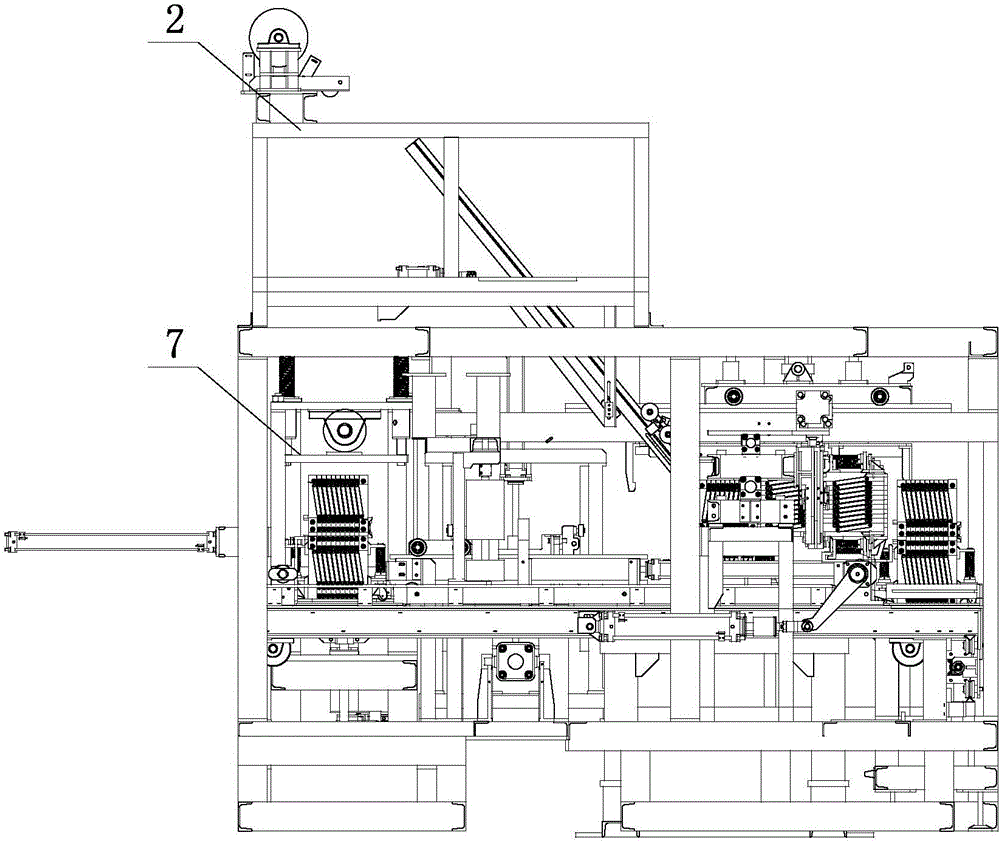

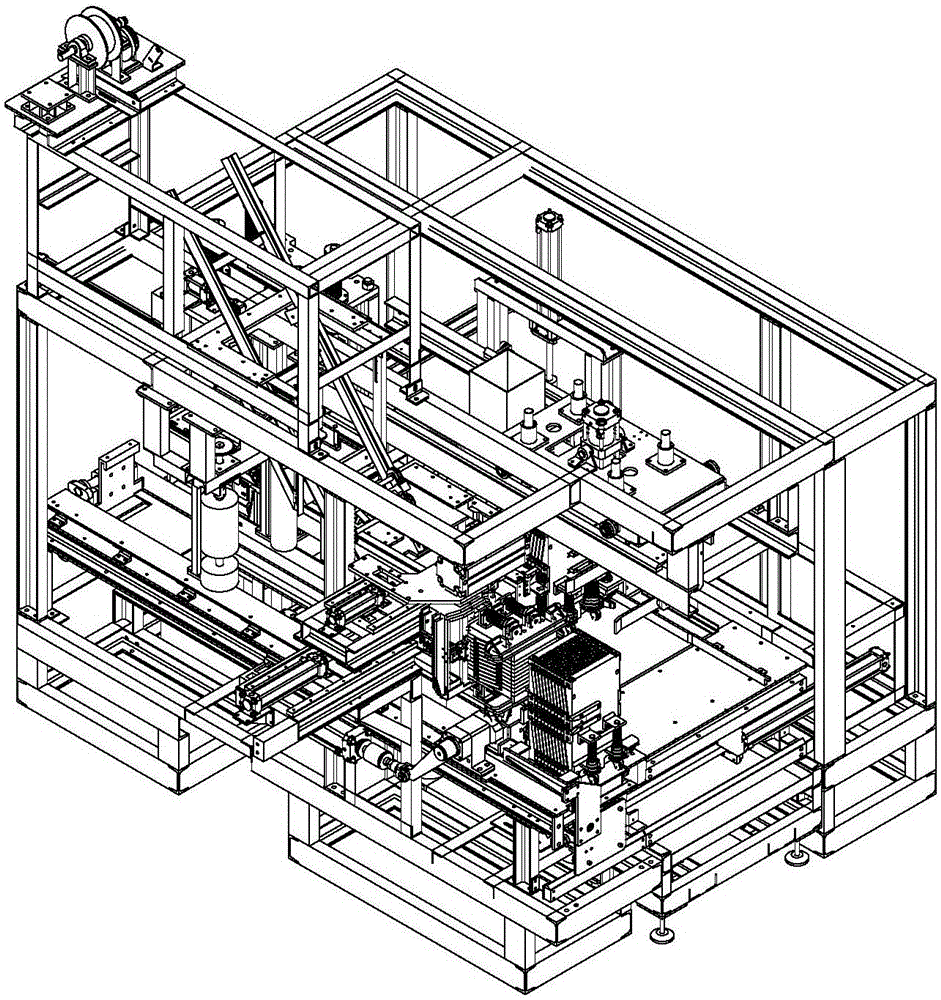

Multifunctional integrated intaglio printing press and machining process thereof

ActiveCN104708894AStable tensionSame line speedRotary intaglio printing pressHot stampingLaser holography

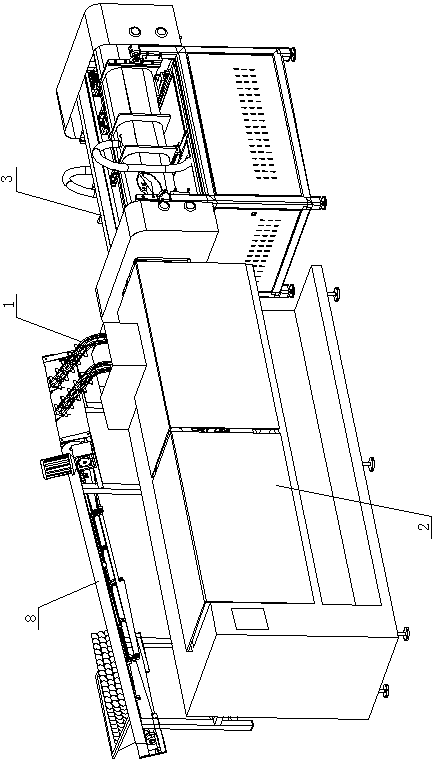

The invention provides a multifunctional integrated intaglio printing press which comprises an unreeling device, an introduction deviation rectifying device, a double-traction device, a printing unit, an edge cutting device, a belling device, a die cutting device, a soft pack cutting device and an automatic stacking paper collecting device. A first traction guide device, a gilding device, a holographic positioning ironing device, the belling device, an online detection device and a second traction guide device are sequentially arranged between the printing unit and the edge cutting device. The printing unit comprises at least nine gravure printing devices, and the multiple gravure printing devices are combined to form multi-color continuous gravure. The first traction guide device and the second traction guide device are provided with stepless speed regulating mechanisms to control the tension and the linear speed of paper passing the gilding device, the holographic positioning ironing device and the belling device at high accuracy, and accuracy control and position control over hot stamping, laser holography transfer printing and raised ironing of cigarette packs are achieved at the same time. The invention further provides a machining process of the multifunctional integrated intaglio printing press.

Owner:ZHUHAI S E Z CHENGCHENG PRINTING

Functional cigarette and its manufacturing method

A functional cigarette with health-care action is prepared from tobacco leaf, expanded tobacco stem shreds, expanded tobacco shreds, Chinese-medicinal sheets, Chinese-medicinal decoction, essence for cigarette, invertose, propanediol and alcohol through spraying the mixture of said decoction, essence, invertose, propanediol and alcohol onto tobacco material, storing the tobacco material at 40-65 deg.C for 3-24 hr, shredding and baking.

Owner:牟志鸿 +1

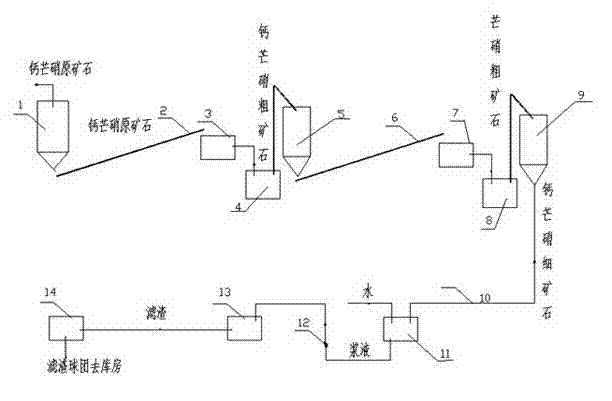

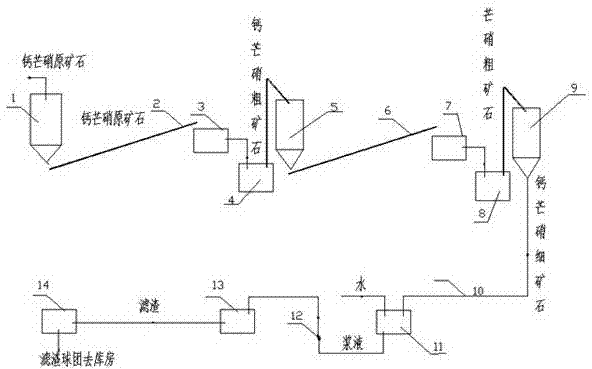

Method for purifying glauberite to prepare dihydrate gypsum

ActiveCN102963920AFull recoveryReduce mining costsCalcium/strontium/barium sulfatesCalcium Sulfate DihydrateMineralogy

The invention discloses a method for purifying glauberite to prepare dihydrate gypsum, which comprises the following steps of: 1) breaking glauberite by breaking equipment to obtain glauberite powder; 2) feeding the glauberite powder into a leaching stirring barrel and mixing with infiltration water; 3) feeding the mixture into mechanical filtering equipment capable of realizing quantitative washing to obtain filter residues of which the sodium sulfate content is lower than 2% and the water content is lower than 30%; and 4) making the filter residues into a pellet material by a pelletizer, wherein the material is a finished product of dihydrate gypsum. According to the invention, the infiltrated suspension is processed by a filter with a washing function, and the filtrate after filtration can be directly used as a raw material for producing anhydrous sodium sulfate since the concentration of sodium sulfate meets the requirements of the production technology of anhydrous sodium sulfate; the washing liquid containing sodium sulfate can be recovered as infiltration water; calcium sulphate dihydrate products reaching the national standard can be prepared by the method; and the method has strong operability and good market prospects, and the production cost is low.

Owner:SICHUAN TONGQING NANFENG

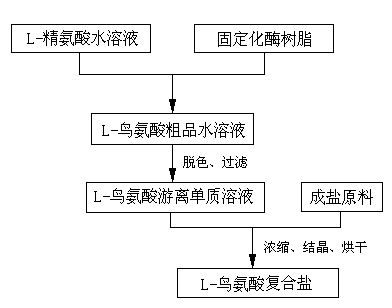

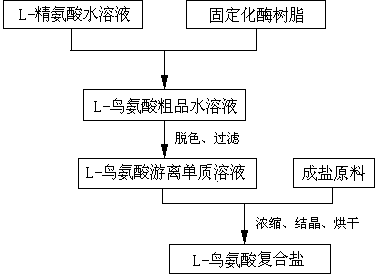

Method for continuously producing L-ornithine composite salt by enzyme immobilization

ActiveCN103014086AAchieve a fixed purposePromote regenerationOn/in organic carrierFermentationOrnithine synthesisMethod selection

The invention discloses a method for continuously producing an L-ornithine composite salt by enzyme immobilization. The method comprises the following steps of: selecting a macroporous adsorption resin with amidogen matrix, carrying out a special treatment by using a curing agent during a combined immobilization process of an enzyme and the resin, so that amidogens of inner surfaces and outer surfaces of holes of the macroporous adsorption resin are reacted to form a firm covalent structure during an adequate contact process of an arginine hydrolytic enzyme and the macroporous adsorption resin, and removing surface purities through simple eluting so as to reach an immobilization purpose. According to the method, the advantages that an enzymic method is high in production yield, good in quality and stable in quality are kept, the disadvantages that enzyme cannot be recycled during an enzymic method production process, so that the use cost is high and continuous production cannot be performed are solved; and meanwhile the L-ornithine composite salt can be synthesized in one step, and the method is high in yield, low in energy consumption, simple in process and stable in quality.

Owner:WUHAN SHENGJIA CHEM ENG

Full-automatic spiced egg dispensing and vacuum packing integrated machine

ActiveCN102530304ASave human effortImprove work efficiencyPackaging eggsPackaging under vacuum/special atmosphereContinuous productionMaterial resources

The invention discloses a full-automatic spiced egg dispensing and vacuum packing integrated machine, which comprises a full-automatic spiced egg dispensing machine, a full-automatic bag making machine and a full-automatic vacuum packing machine, wherein the discharge end of the full-automatic spiced egg dispensing machine corresponds to the bag making section of the full-automatic bag making machine, and the output end of the full-automatic bag making machine corresponds to the input end of the full-automatic vacuum packing machine. Through the integrated machine, continuous production of dispensing, bag feeding and vacuum packing steps of spiced eggs is realized, the production pattern of the conventional automatic equipment of manual operation or only independent steps is changed, a completely mechanical and automatic production line pattern is formed, the process requirement of a product for continuous production is realized, manpower, material resources and financial resources are greatly saved, the production and processing efficiency is improved, and the processing cost is reduced.

Owner:CHENGDU WENJIANG HAIKE INSTR FACTORY

Technical method for rapid asexual propagation and anti-enhancement of hybrid bollgard F1

The invention relates to a technical method for rapid asexual propagation and anti-enhancement of hybrid bollgard F1, which comprises the main steps of: firstly, identifying perennial cotton germplasm resources capable of naturally overwintering, and resisting fusarium wilt resistance and greensickness; adopting the perennial cotton germplasm resources as rootstock, scioning and grafting with the hybrid bollgard F1, and cultivating perennial root to obtain grafted plants; and secondly, carrying out large-scale propagation of hybrid bollgard F1 seedlings by using the method, and directly using the hybrid bollgard F1 seeldings for agricultural production. According to the technical method for rapid asexual propagation and anti-enhancement of the hybrid bollgard F1, field cotton hybrid seed production is free, the seed production process of the hybrid bollgard F1 is simplified, the seed purity of the hybrid bollgard F1 is improved, and the disease resistance of the hybrid bollgard F1 is enhanced. The method can be used for large-scale propagation of hybrid bollgard F1 seedlings with obviously improved anti-enhancement property, and is applied to agricultural production.

Owner:HUBEI PROVINCIAL SEED GRP CO LTD

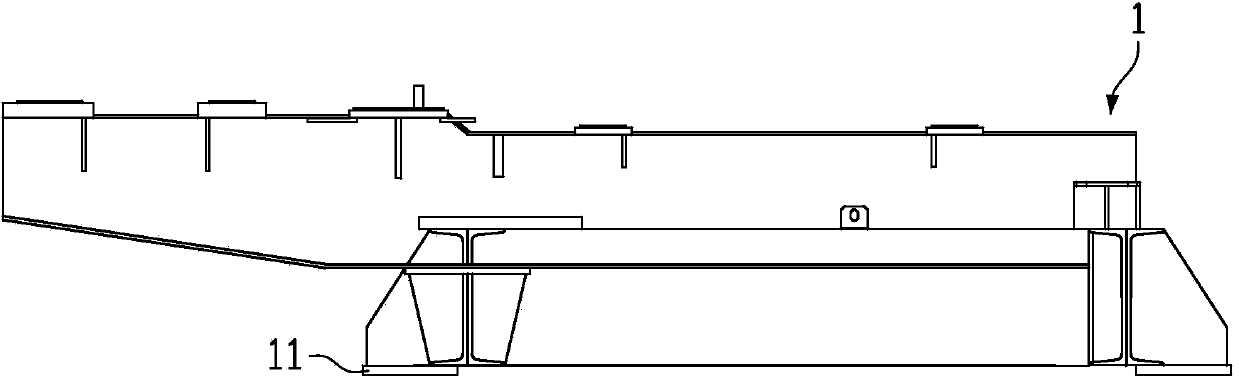

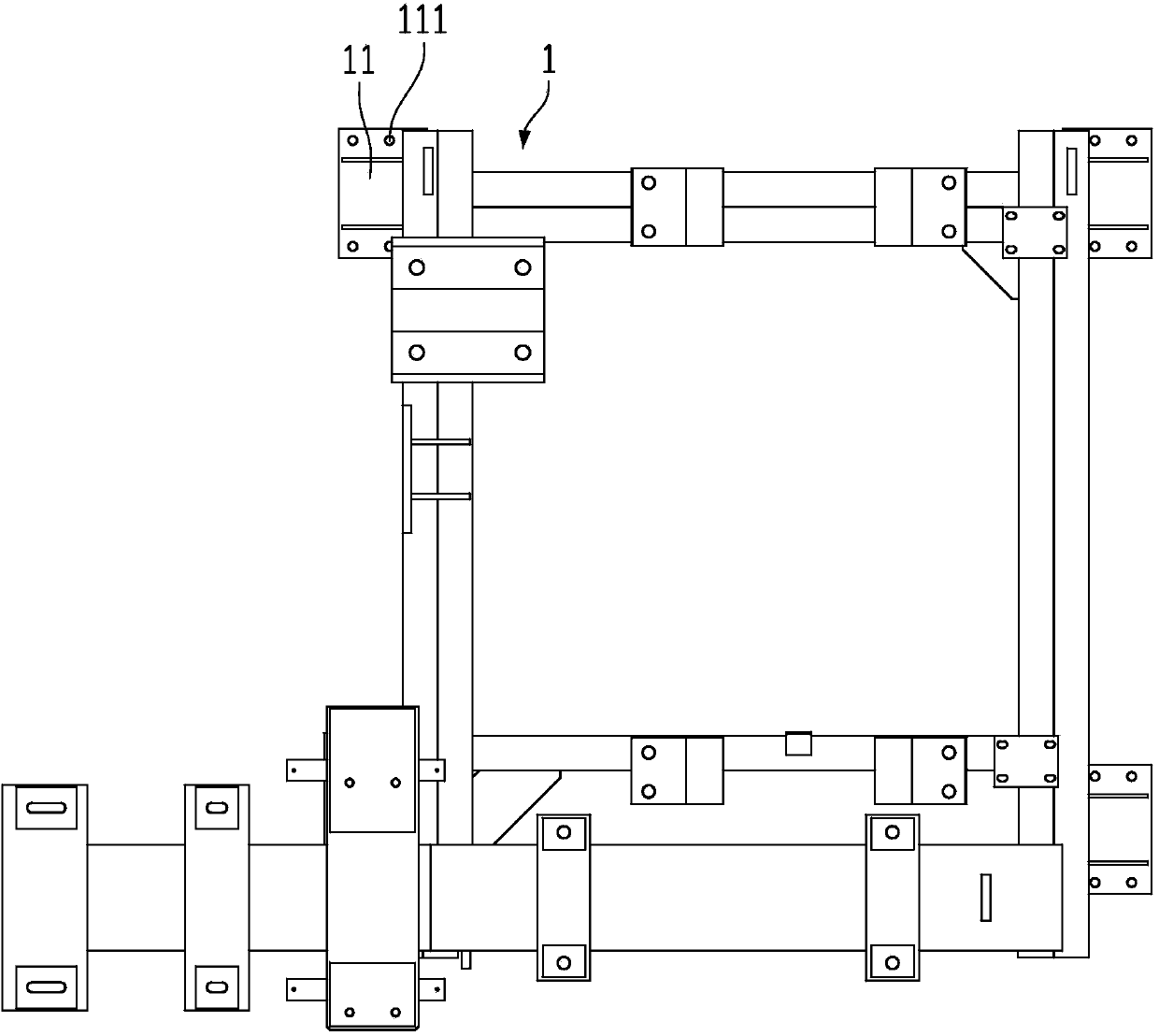

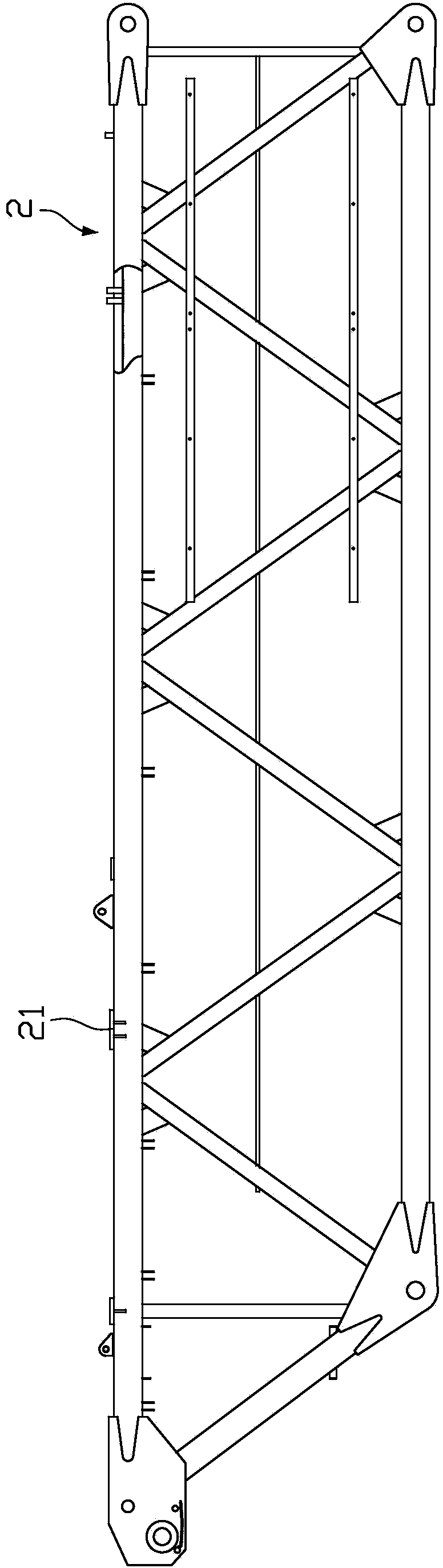

Assembly welding tool of installation bases and connecting method of lifting mechanism and balance arm

ActiveCN103722330AImprove versatilitySave the process of printing and matching solder codesWelding/cutting auxillary devicesAuxillary welding devicesEngineeringTower crane

An assembly welding tool of installation bases is used for welding the installation bases onto a balance arm of a tower crane in an assembled mode, and the installation bases welded in the assembled mode and a plurality of connection bases arranged on a lifting mechanism of the tower crane can be arranged together respectively and correspondingly. The assembly welding tool comprises a frame and a plurality of assembly welding plates arranged on the frame, the positions of the assembly welding plates correspond to the positions of the installation bases, needing to be welded in the assembled mode, on the balance arm, and each assembly welding plate is provided with at least one positioning hole. When the installation bases are welded to the balance arm in the assembled mode, the installation bases can be detachably arranged on the assembly welding plates respectively, and the assembly welding tool enables the installation bases to be positioned on the balance arm. When the positions of connecting holes are determined in the connection bases, the assembly welding tool is placed on the lifting mechanism, the assembly welding plates correspond to the connection bases respectively, and according to the position of the positioning hole in each assembly welding plate, the position of the connecting hole in the corresponding connection base is determined. The invention further provides a connecting method of the lifting mechanism and the balance arm.

Owner:ZOOMLION HEAVY IND CO LTD

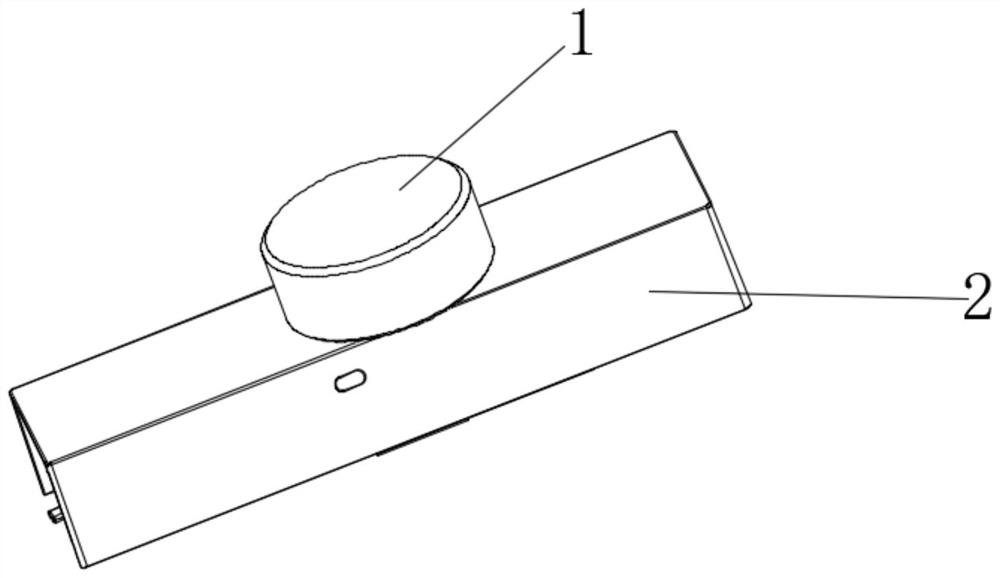

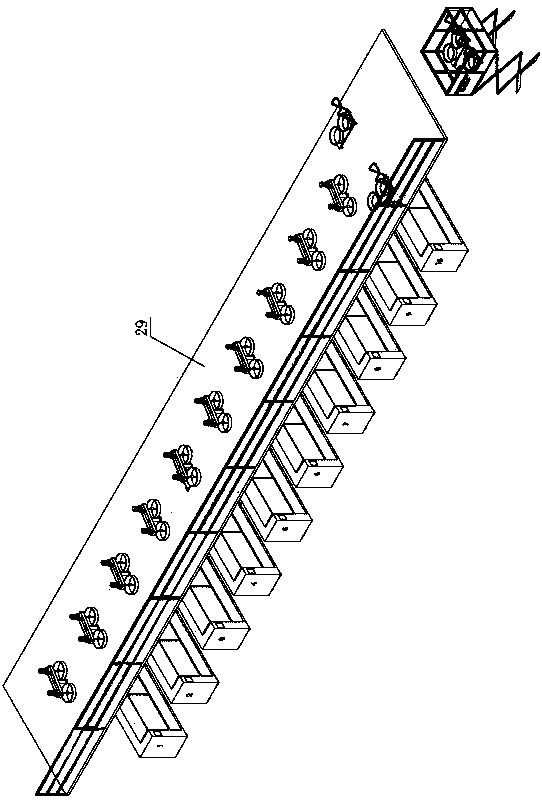

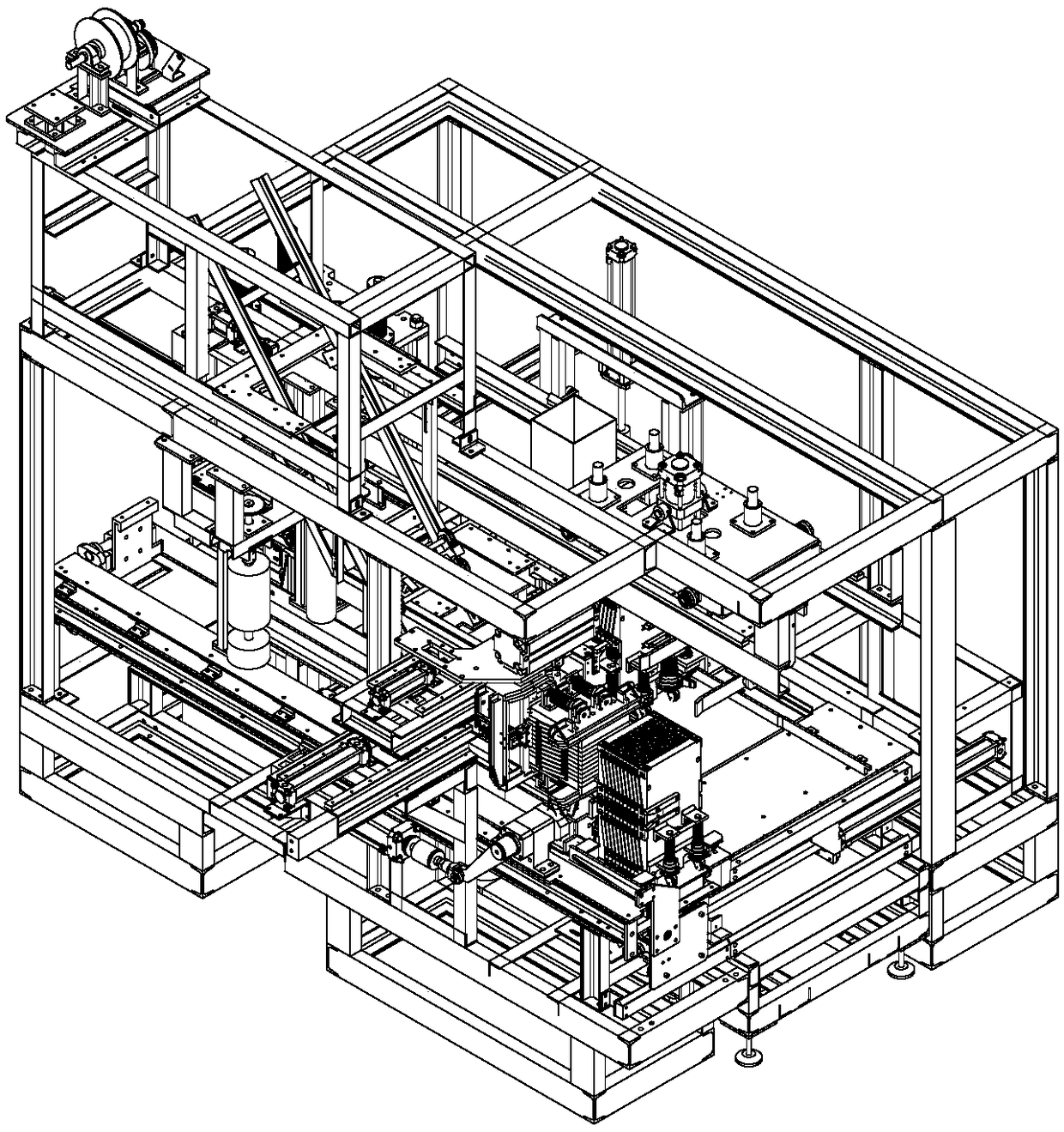

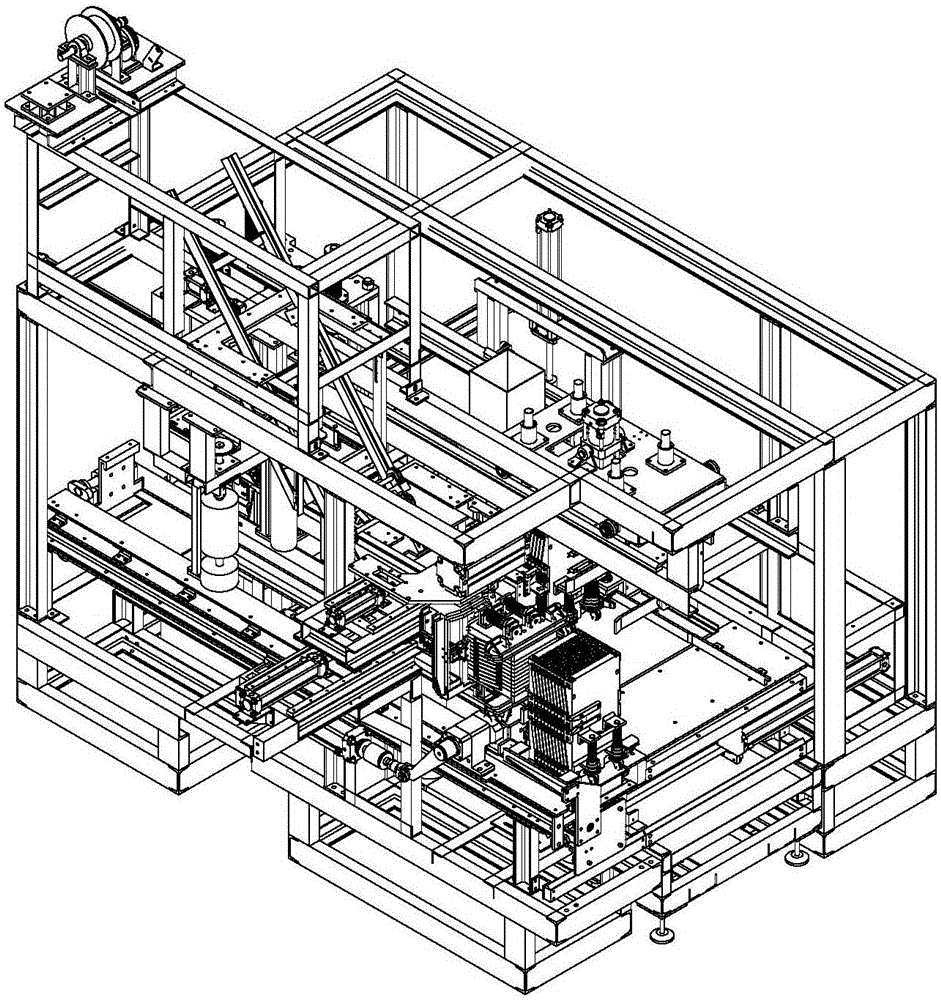

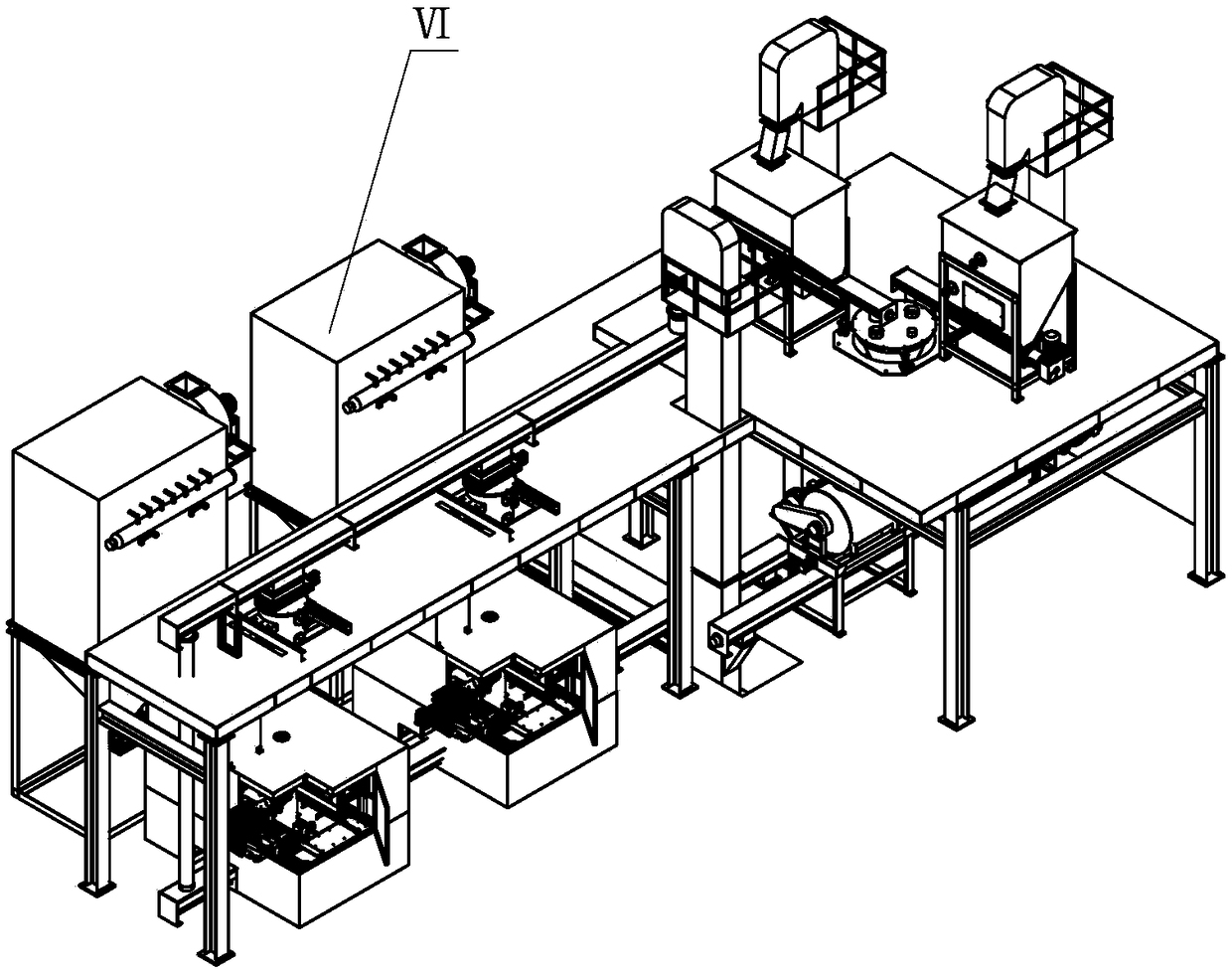

Manufacturing method and system device of aluminum foil port sealed air bag

PendingCN106696346AImprove production efficiencyPracticalPaper-makingBox making operationsPunchingAssembly line

Disclosed is a mechanical manufacturing method and device of an aluminum foil port sealed bag. According to the manufacturing processes of the aluminum foil port sealed bag, part of the processes which have large difficulty and low efficiency in manual production are arranged, and by means of an assembly line mode, automatic processing and manufacturing are achieved. The automatic processing and manufacturing comprises at least seven processes of feeding, punching, silica gel mounting, automatic shaping and edge-folding, middle sealing, cutting-off and end sealing. Feeding, punching, silica gel mounting, automatic shaping and edge-folding, middle sealing, cutting-off and end sealing are connected in series through the assembly line mode, so that assembly line automated operation of the aluminum foil port sealed bag is achieved. By adopting the automatic assembly line mode, the aluminum foil port sealed bag is manufactured, so that the production efficiency and quality are improved greatly.

Owner:株洲市完全科技有限公司

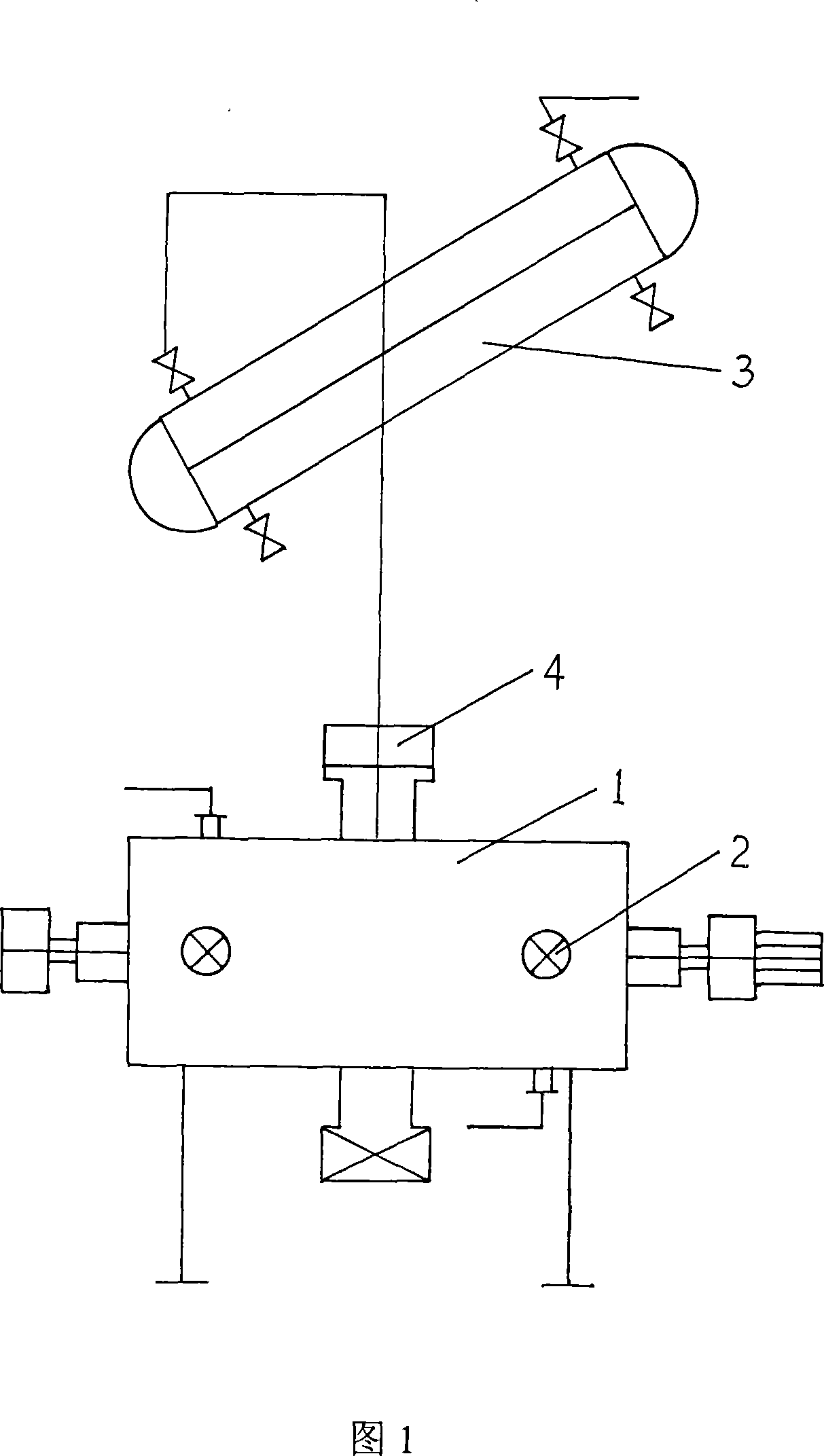

Method for producing boron-amine compound and its special apparatus

A process for preparing boron amide compounds includes such steps as proportionally mixing dimethylamine with solvent, cooling to -20 deg.C,stirring while filling BCl3 at -20-80 deg.C, stirring for 0.5 hr, and vacuum distilling to obtain high-purity product. Its dedicated apparatus is also disclosed.

Owner:DALIAN NETCHEM CHIRAL TECH

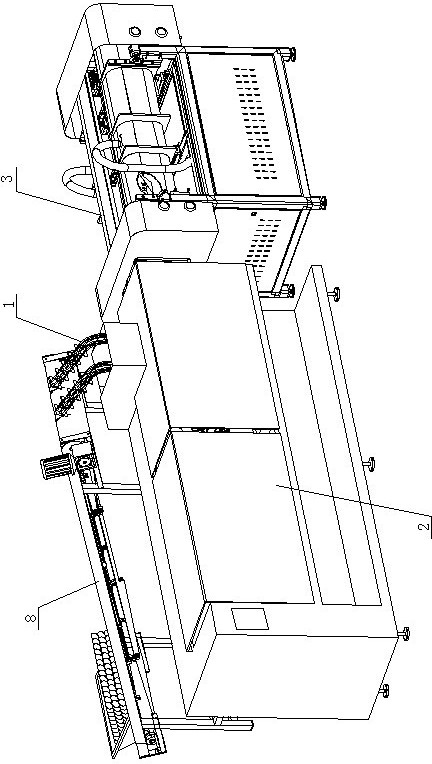

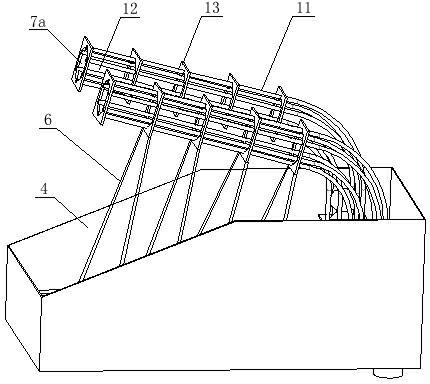

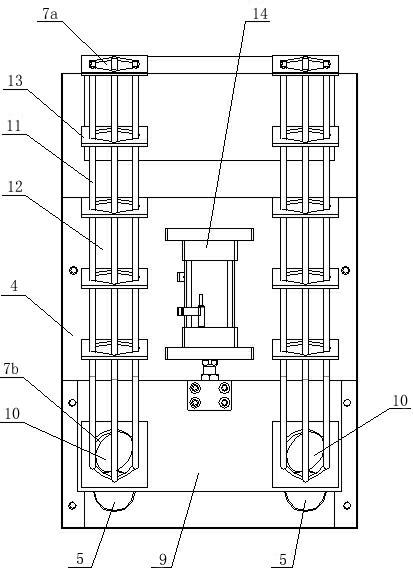

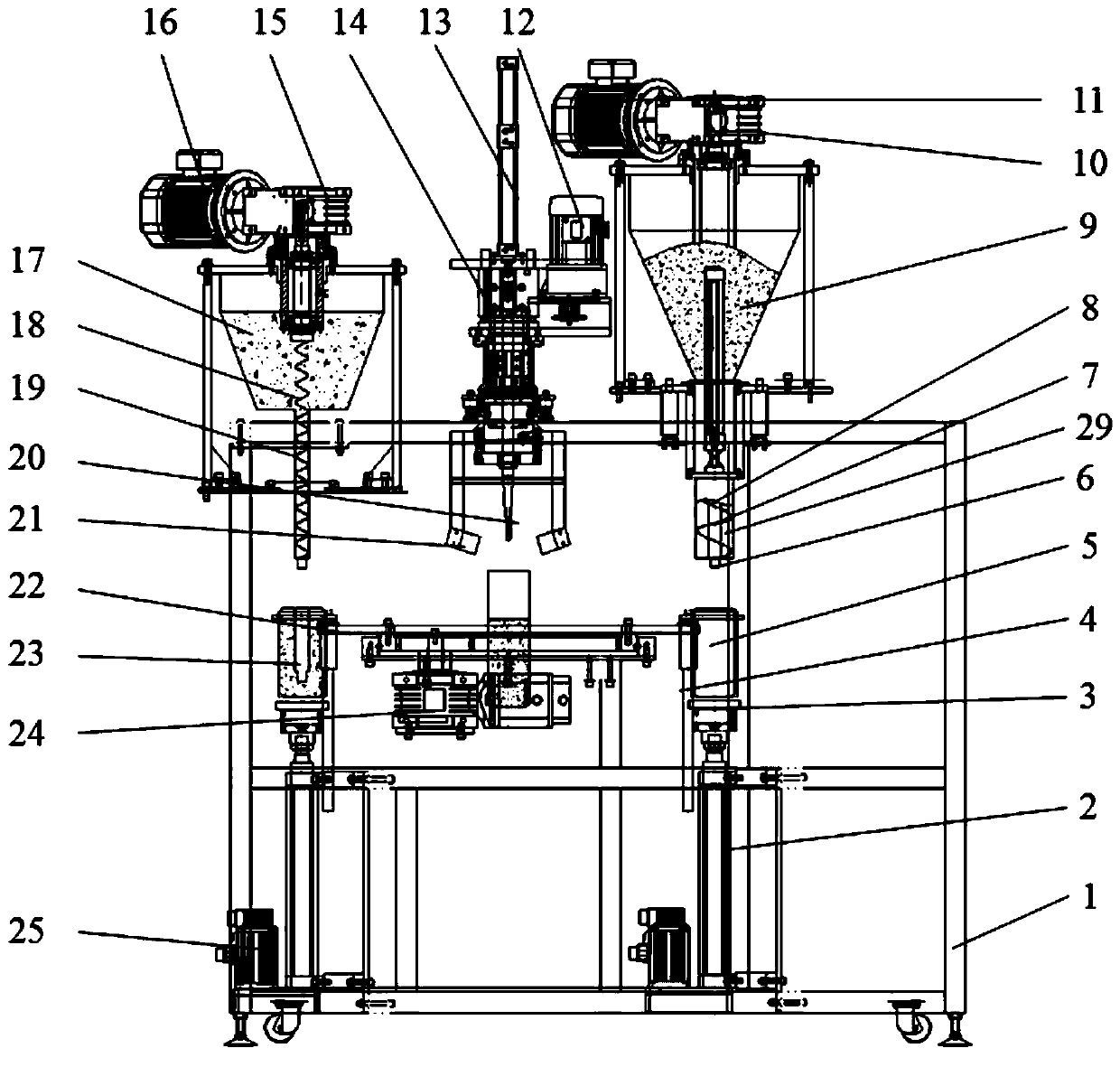

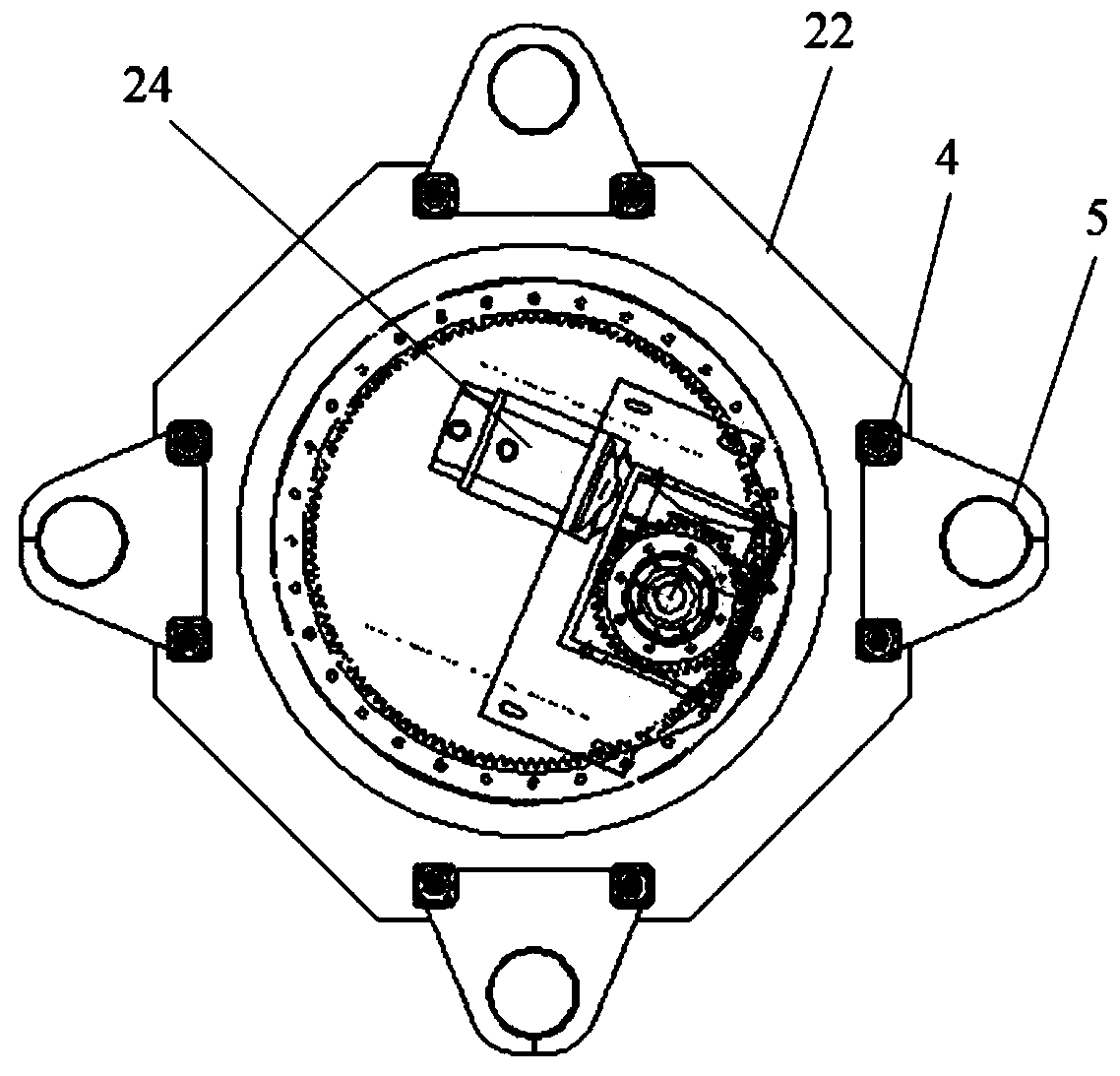

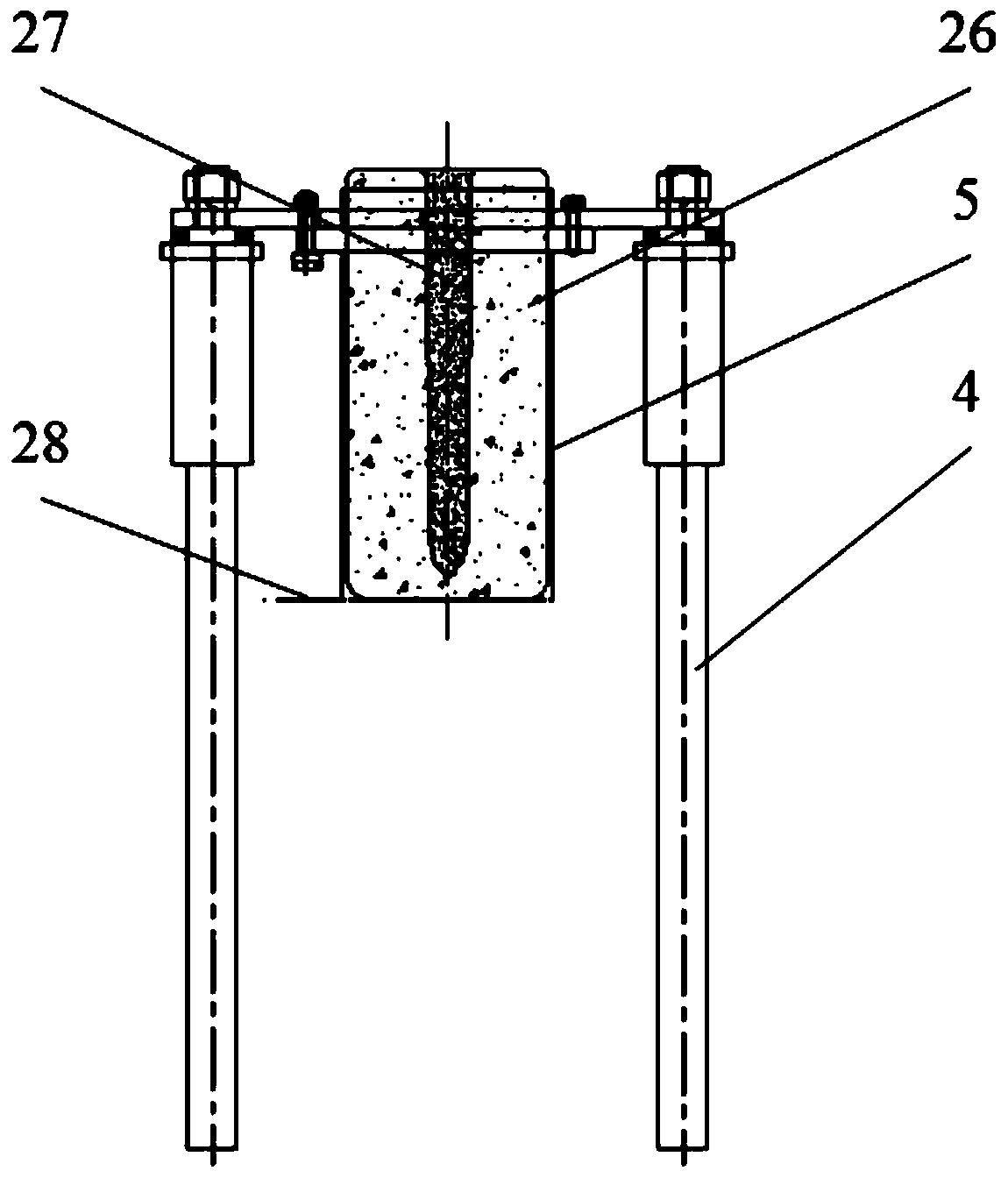

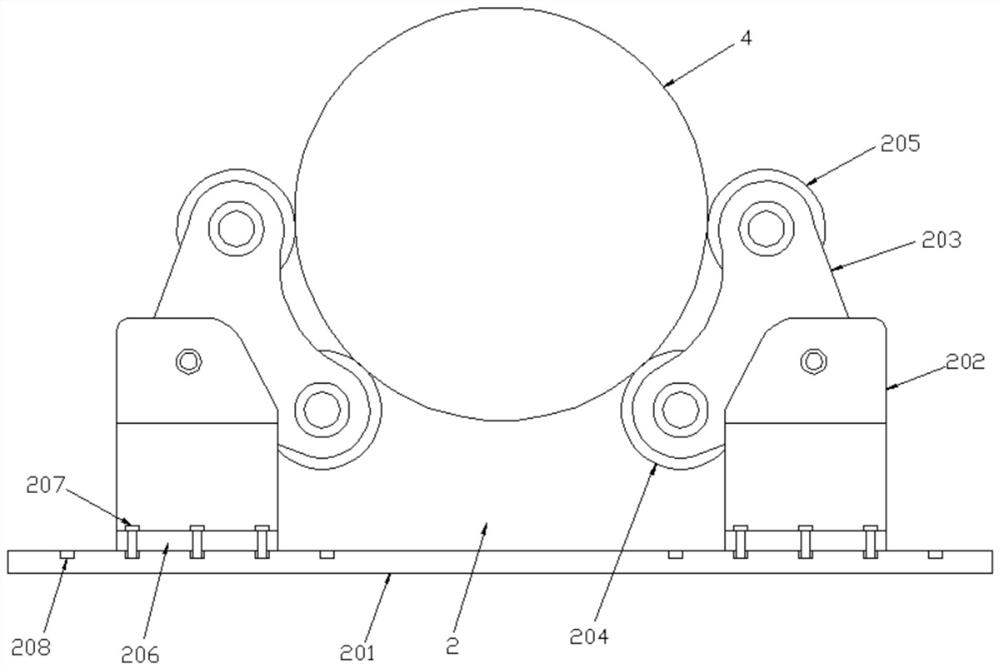

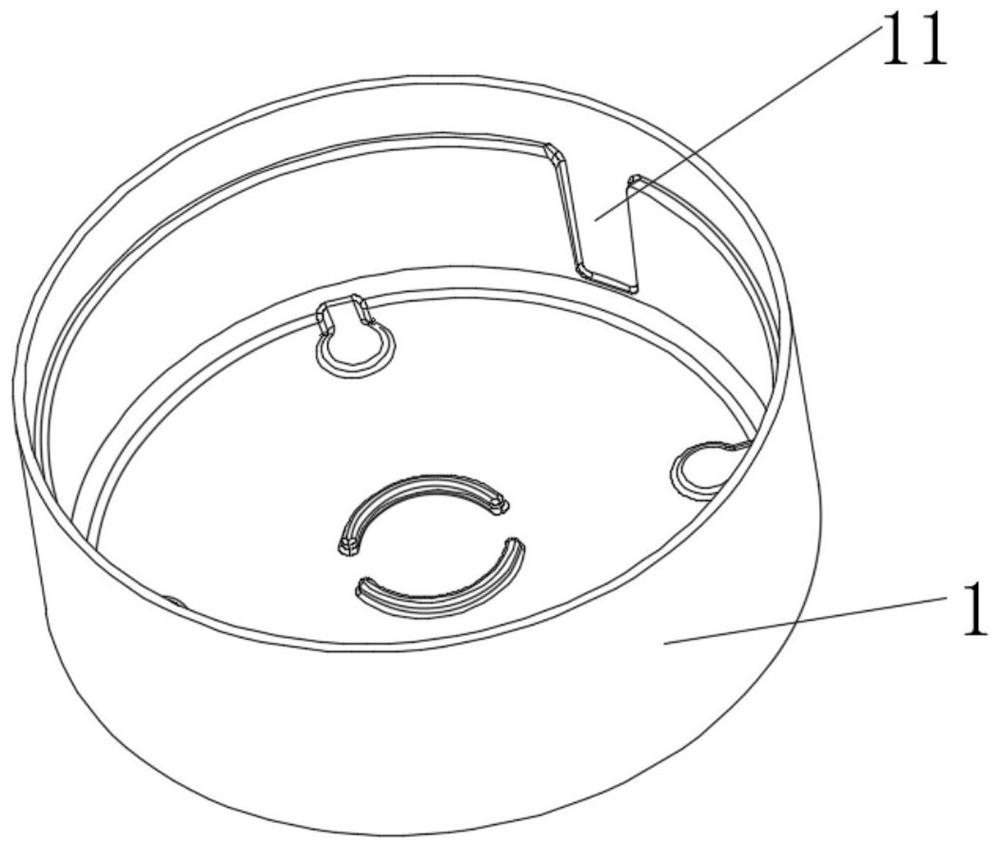

Oyster mushroom fermentation material feeding and inoculating integrated synchronous equipment and operation method

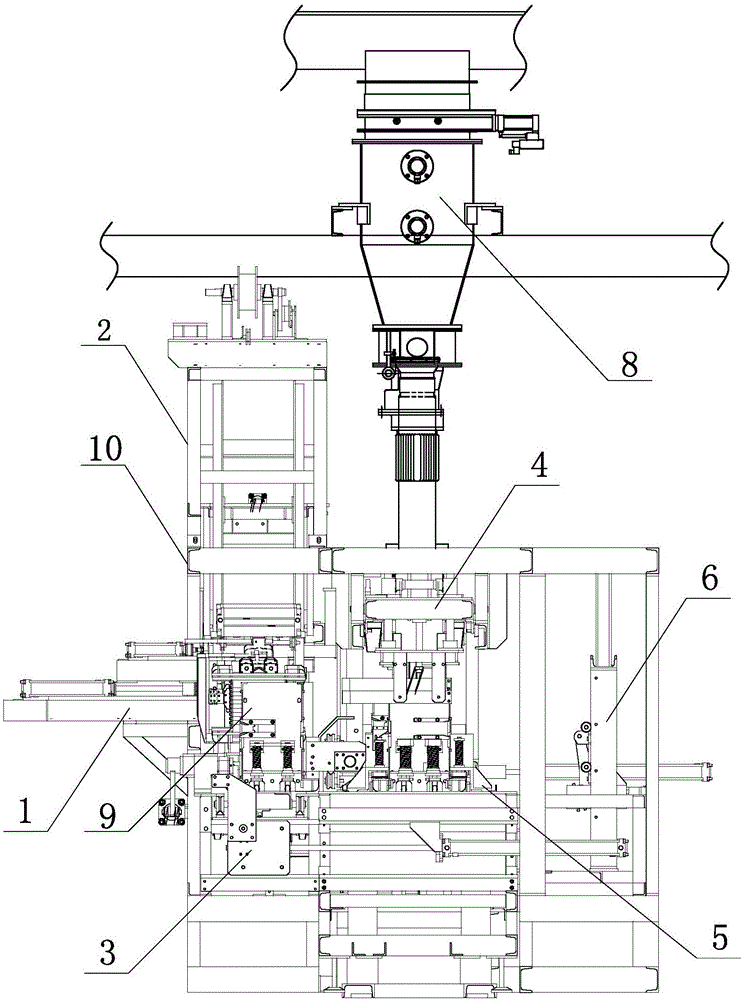

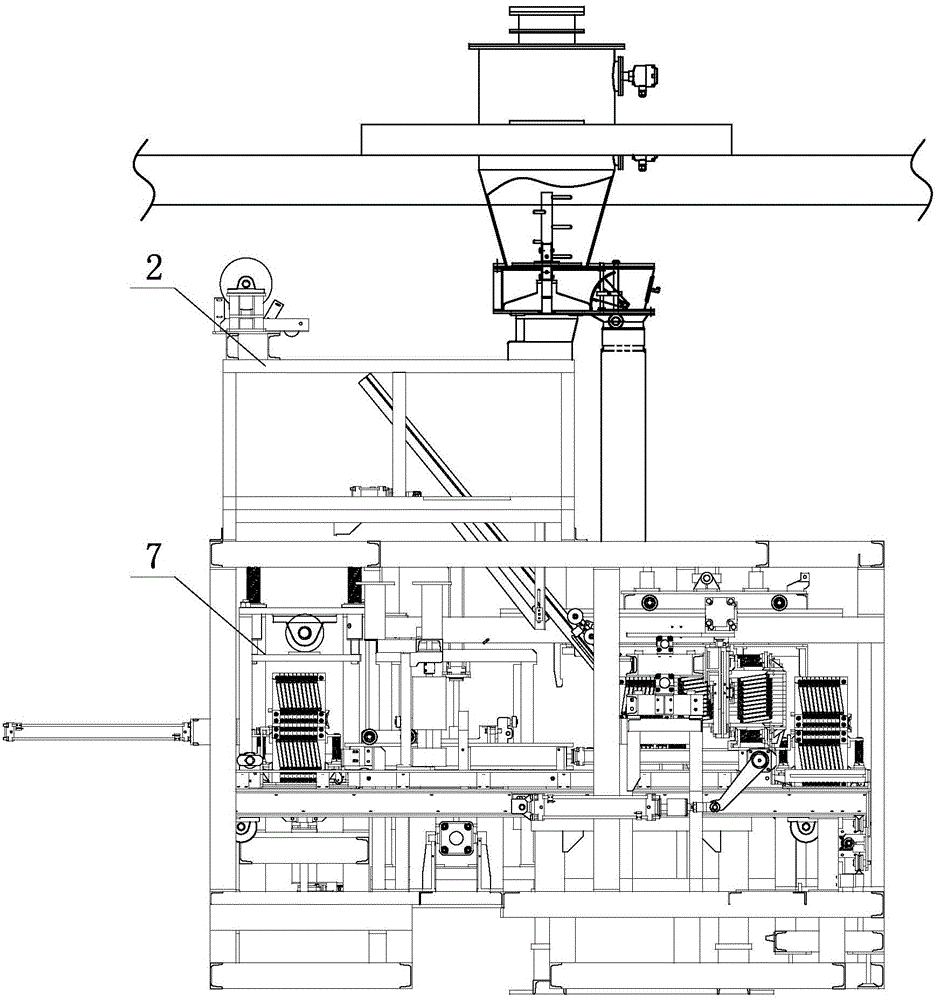

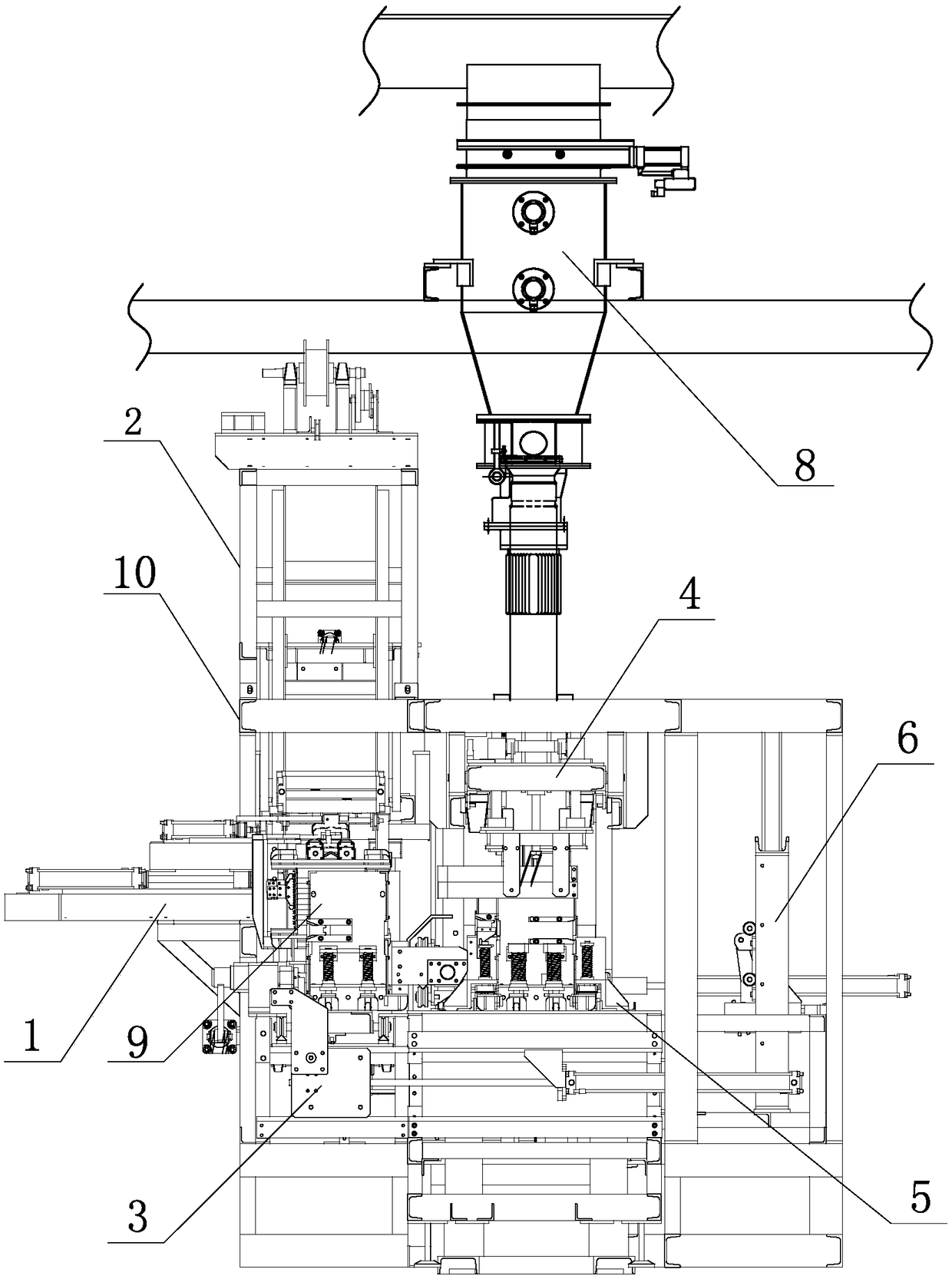

PendingCN111357569AChange production modeReasonable structural designCultivating equipmentsMushroom cultivationGear wheelAgricultural engineering

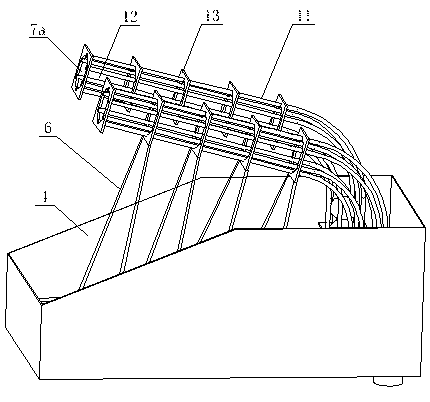

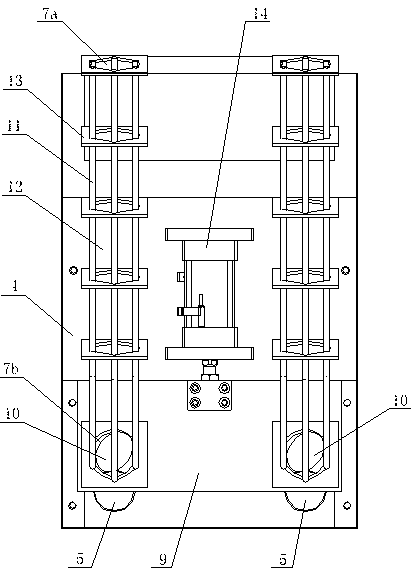

The invention relates to oyster mushroom fermentation material feeding and inoculating integrated synchronous equipment. The oyster mushroom fermentation material loading and inoculating integrated synchronous equipment comprises a control cabinet,a machine frame, a rotary disk device, a feeding device, an opening sealing device, an inoculating device and an out-of-bag device, wherein the rotary disk device, the feeding device, the opening sealing device, the inoculating device and the out-of-bag device are mounted on the machine frame; the rotary disk device comprises a rotary disk motor anda hollow rotary disk; the rotary disk motor is mounted on the machine frame, a driving pinion gear is connected to an output shaft of the rotary disk motor through a coupling, a driven bull gear is fixedly mounted on the inner circular ring of the hollow rotary disk, and the driving pinion gear is meshed with the driven bull gear; and four service positions are distributed on the excircle of the hollow rotary dish along the circumferential direction; a cylinder holding device is mounted at each service position, and the four service positions on the hollow rotary disk are in one-to-one correspondence to the feeding device, the opening sealing device, the inoculating device and the out-of-bag device.

Owner:NANJING AGRI MECHANIZATION INST MIN OF AGRI

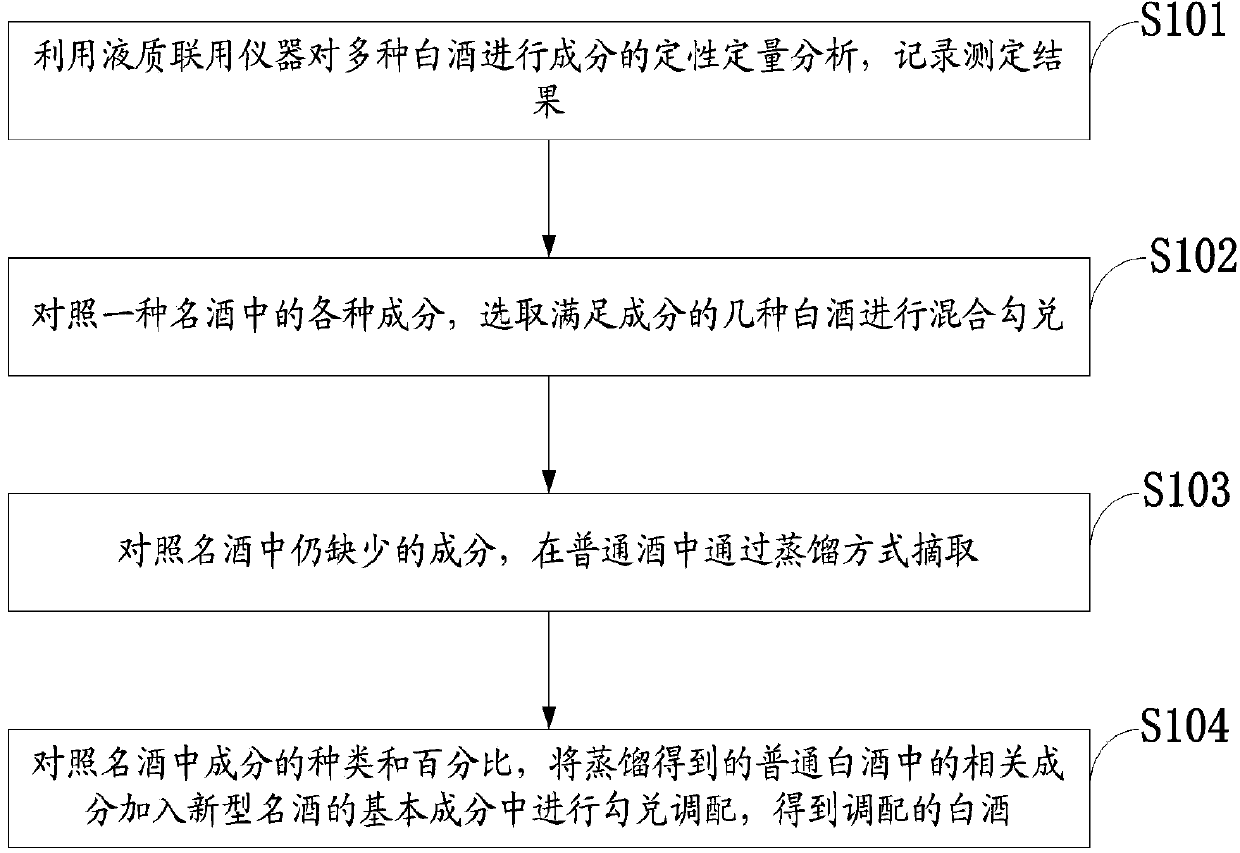

Method for blending high-grade white spirit based on modern analysis technology

InactiveCN103627599AImprove the brewing processChange production modeAlcoholic beverage preparationDistillationBrewing

The invention discloses a method for blending high-grade white spirit based on a modern analysis technology. The method comprises the following steps: qualitatively and quantitatively analyzing components of various types of white spirit and blended white spirit by using a liquid chromatograph / mass spectrometer and recording a determined result; comparing with various components in vintage wine and selecting a plurality of types of white spirit meeting the components to be mixed and blended; comparing with components lacked in the vintage wine, so as to obtain in the common white spirit in a distillation manner; and comparing with the varieties and the percents of the components in the white spirit, adding relative components in the common white spirit obtained by distillation into basic components of novel vintage wine to be mixed and blended to obtain blended white spirit. According to the method disclosed by the invention, the components of the white spirit are judged by using a modern analysis technology and variables are arranged to obtain the percents of the components in the white spirit; the components are mixed and blended according to the percents and a brewing process of the white spirit is improved; an existing production mode is changed and the production cost is reduced; the method is simple and convenient to operate.

Owner:CENT SOUTH UNIV

Waterborne salt spray-resistant epoxy primer

InactiveCN110283516AEmission reductionChange production modeAnti-corrosive paintsEpoxy resin coatingsEpoxyEmulsion

The invention discloses waterborne salt spray-resistant epoxy primer. The primer is prepared from a component A and a component B, wherein the component A comprises 15 to 55 parts of an epoxy emulsion with low molecular weight, 20 to 55 parts of an epoxy emulsion with high molecular weight, 20 to 60 parts of water, 0 to 1 part of a leveling agent, 0 to 2 parts of a drier, and 0 to 5 parts of polyurethane; the component B comprises 25 to 70 parts of a curing agent, 10 to 50 parts of zinc powder, 0 to 1 part of graphene, 5 to 30 parts of water, 0 to 2 parts of a dispersant, 0 to 2 parts of organic bentonite, and 0 to 3 parts of an antifoaming agent. The primer has the following beneficial effects: 1, the salt spray resistance of the epoxy primer prepared by adopting a natural drying technology can reach 1500 hours; 2, the production mode of existing traditional paint is changed, the water is used as a diluent, the discharge of pollution sources is reduced and the safety of production and transportation is improved; 3, water resistance is increased by 20% while the salt spray resistance is increased.

Owner:山东海思蓝高分子材料有限公司

Functional cigarette and its manufacturing method

A functional cigarette with health-care action is prepared from tobacco leaf, expanded tobacco stem shreds, expanded tobacco shreds, Chinese-medicinal sheets, Chinese-medicinal decoction, essence for cigarette, invertose, propanediol and alcohol through spraying the mixture of said decoction, essence, invertose, propanediol and alcohol onto tobacco material, storing the tobacco material at 40-65 deg.C for 3-24 hr, shredding and baking.

Owner:牟志鸿 +1

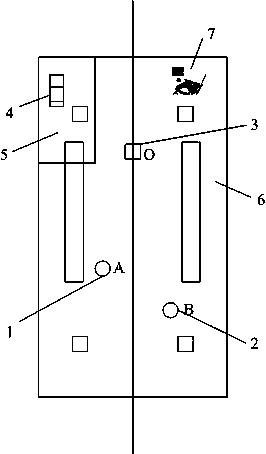

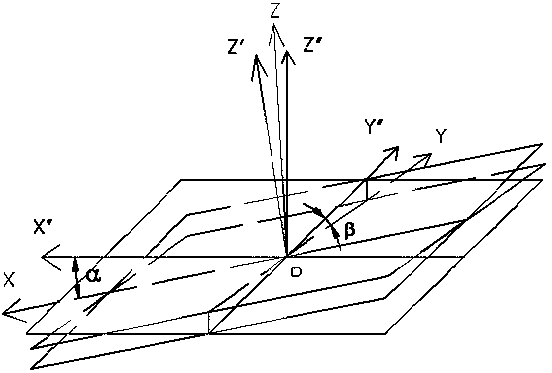

A method for real-time high-precision positioning of drill pipes in open-pit mine drilling rigs

ActiveCN105320831BChange production modeSolve the accuracy problemData processing applicationsSpecial data processing applicationsThree-dimensional spaceTransformation algorithm

The invention discloses a method for achieving real-time high-precision location of a strip mine driller drilling rod, and relates to the field of electronics technology and high-precision GPS location application. The real-time high-precision location of the drilling rod when a strip mine driller works is achieved by utilizing two high-precision GPS devices and an electronic compass apparatus, which are mounted on the driller, combining with a vehicular terminal, initializing apparatuses and then operating a three-dimensional space coordinate transformation algorithm and a two-dimensional space coordinate transformation algorithm. The method for achieving the achieving real-time high-precision location of the strip mine driller drilling rod changes the traditional manual by-experience hole alignment production mode, and solves the problems that the precision cannot be ensured and the service lives of apparatuses are short by the existing method. The hole drilling precision of the driller is largely improved, and the blasting effect and the automation level of mining are improved.

Owner:DANDONG DONGFANG MEASUREMENT&CONTROL TECHCO

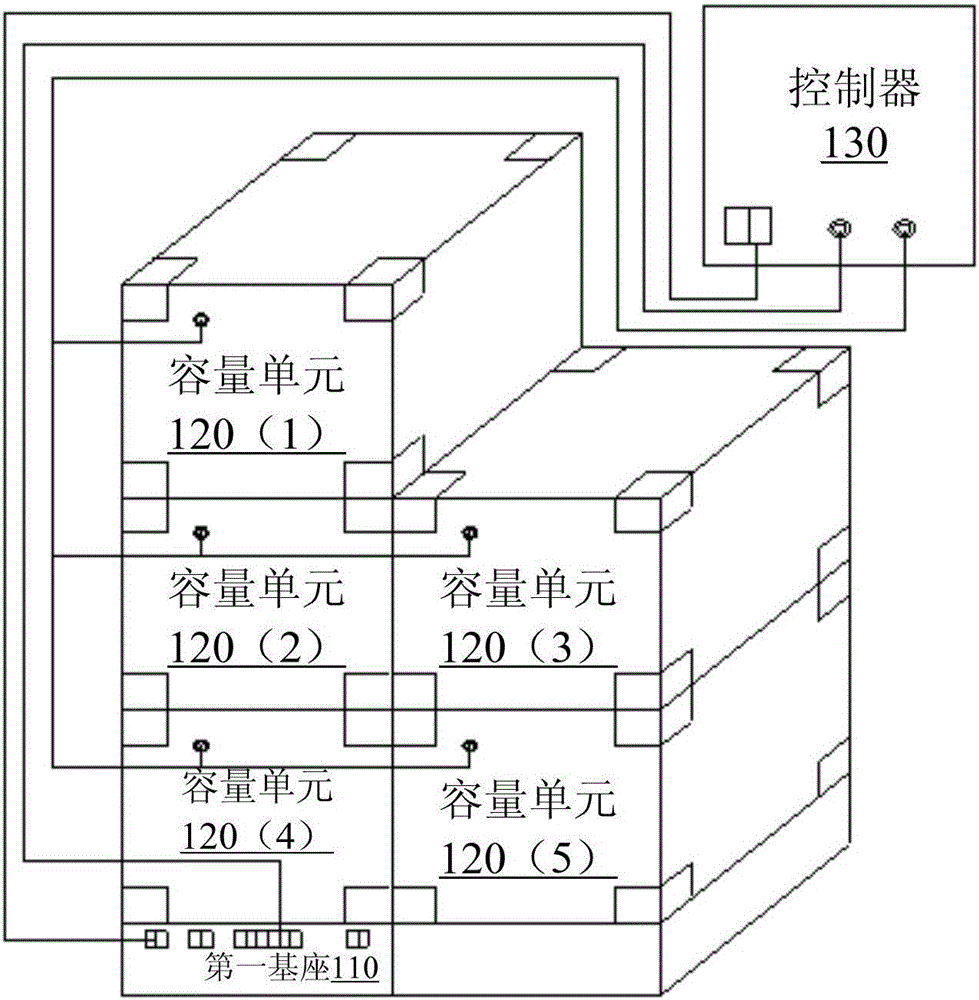

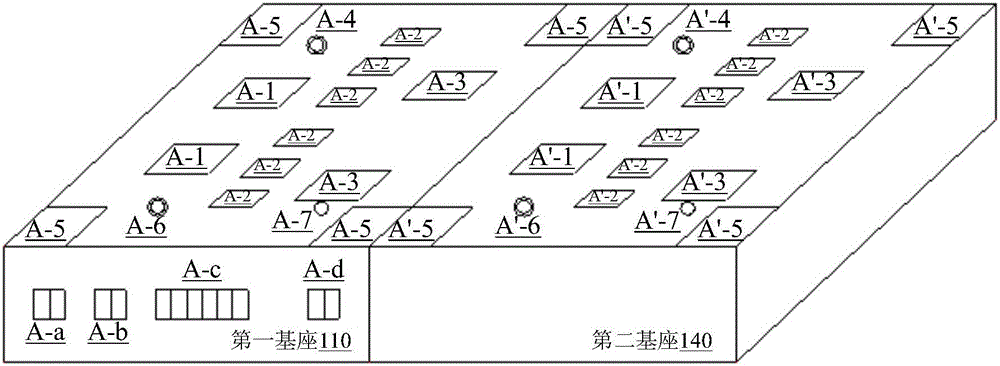

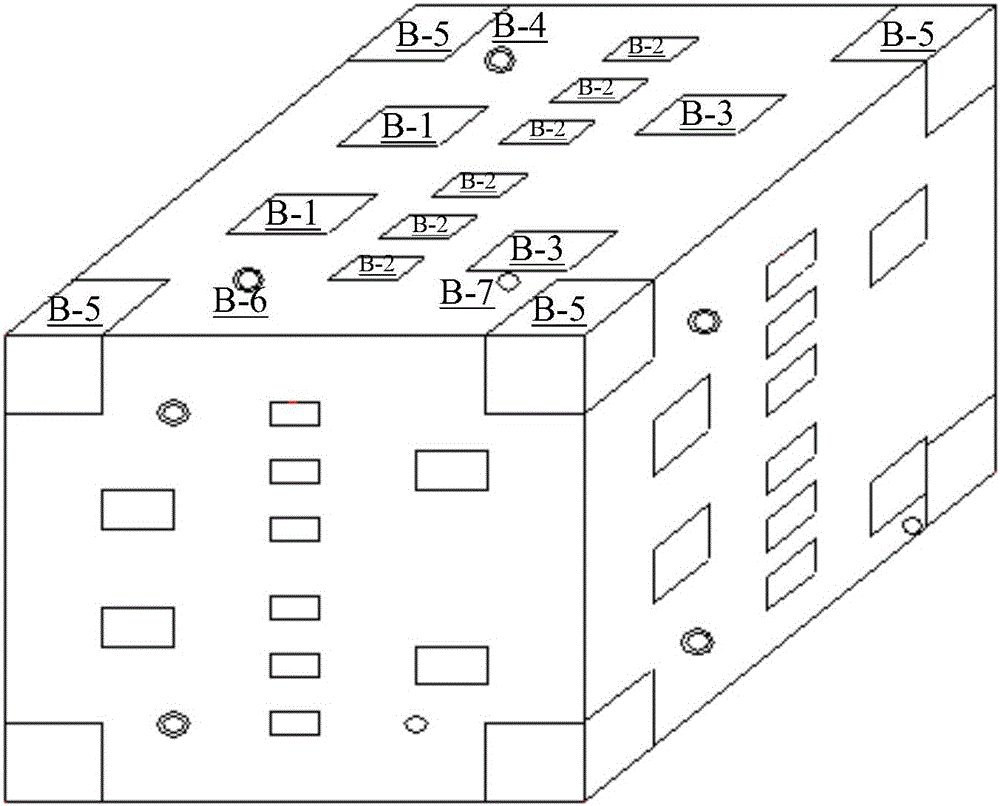

Active power filter

ActiveCN105006826AMeet capacity needsEasy maintenanceActive power filteringAc network to reduce harmonics/ripplesEngineeringActive power filter

The present invention relates to an active power filter comprising a first base, a plurality of capacity units, and a controller. Wherein, each two capacity units can be connected with contact through the connection pieces of the two capacity units, and one capacity unit in the multiple capacity units is connected to the base with contact through the connection piece of the capacity unit and the connection piece of the base. According to the active power filter of the embodiment of the present invention, the requirement of an active power filter capacity by the field can be conveniently satisfied, and the filter can be rapidly replaced in the field and can be conveniently repaired in the condition that the filter is failed.

Owner:SHANGHAI ELECON INTELLIGENT TECH CO LTD

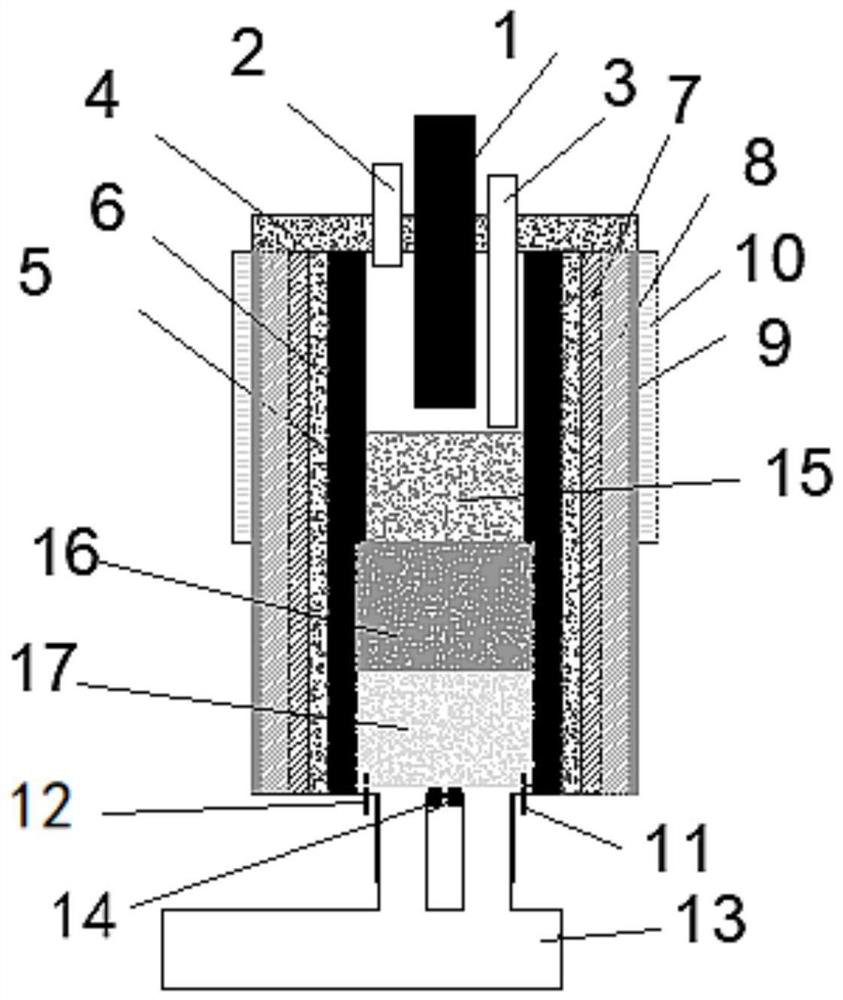

High-temperature furnace capable of continuously producing artificial graphite

PendingCN111847442AChange production modeReduce the temperatureCarbon compoundsChemical industryGraphite electrodeFluidized bed

The invention discloses a high-temperature furnace capable of continuously producing artificial graphite. The furnace comprises a furnace lining, a working layer of the furnace lining is sequentiallyprovided with a water-cooled jacket, a low-temperature light heat preservation layer, a medium-temperature layer and a high-temperature layer from outside to inside, the upper portion of the furnace lining is provided with a furnace cover matched with the furnace lining, the furnace cover is provided with a smoke outlet, a graphite electrode positive electrode and a furnace top discharging hole, and the inner wall of the high-temperature layer is provided with a graphite electrode negative electrode; characteristics of a high-temperature fluidized bed are used for reference; the production mode of the traditional graphitization furnace is changed; a masonry or pouring process of a multi-layer structure is adopted; the water-cooled jacket is adopted by the outer layer, so that the operationenvironment is improved; inert gas can be introduced through a first distribution valve and a second distribution valve installed at the bottom of the graphite electrode negative electrode, the temperature of the discharged material is reduced, meanwhile, the temperature of the inert gas entering the furnace is increased, it is guaranteed that energy consumption is not greatly increased, the discharged material is cooled again through a heat energy recovery device, and the requirement for the proper temperature is met.

Owner:江苏润美新材料有限公司

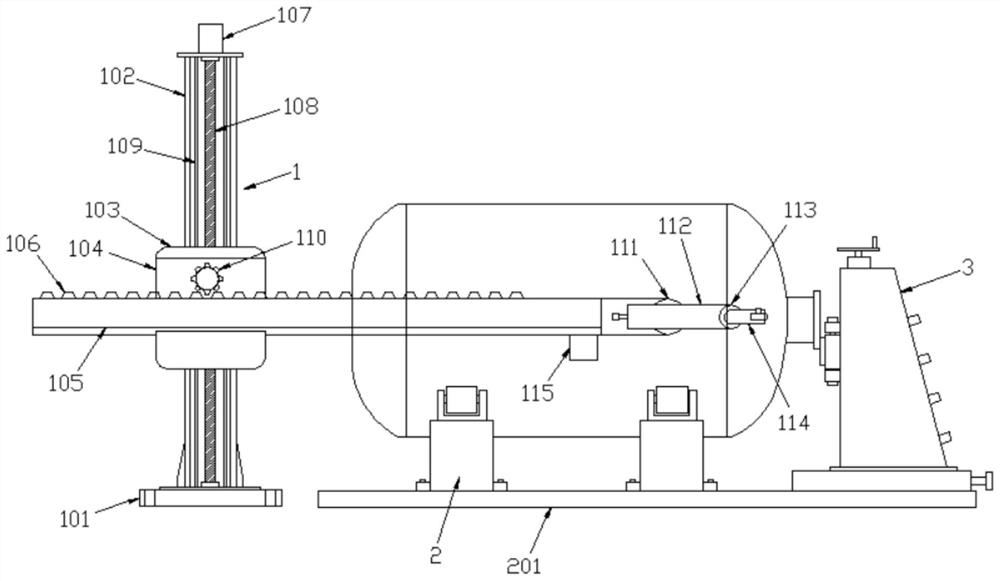

Automatic powder spraying device of glass lining equipment

PendingCN114832961AAdjustable positionSpray evenlyLiquid spraying plantsNumerical controlDrive wheel

The invention belongs to the technical field of glass-lined tank production, and particularly discloses an automatic powder spraying device of glass-lined equipment, which comprises a powder spraying support mechanism, a tank body support mechanism and a tank body anti-channeling mechanism, the powder spraying supporting mechanism comprises a first base, the top end of the first base is fixedly connected with a vertical rod, and the vertical rod is slidably sleeved with a lifting block; a first sliding groove is formed in the front side of the lifting block, a large arm telescopic shaft is arranged in the first sliding groove, the bottom end of the large arm telescopic shaft is slidably connected with the inner bottom wall of the first sliding groove, a rack is arranged at the top of the large arm telescopic shaft, and the tank body supporting mechanism is used for supporting a tank body and comprises a second base. Four moving seats are arranged on the top of the second base in a rectangular array mode, a surrounding frame is installed on the moving seats, numerical control driving wheels are installed at the bottom of the surrounding frame, and guide wheels are installed at the top of the surrounding frame; the spraying device is good in spraying effect and capable of spraying can bodies of different sizes, and the production cost is reduced.

Owner:临沂市海鑫化工设备有限公司

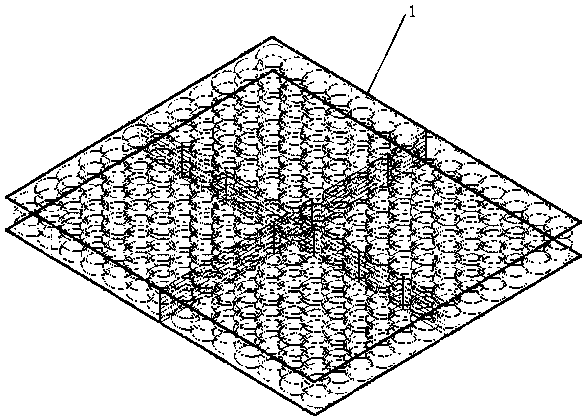

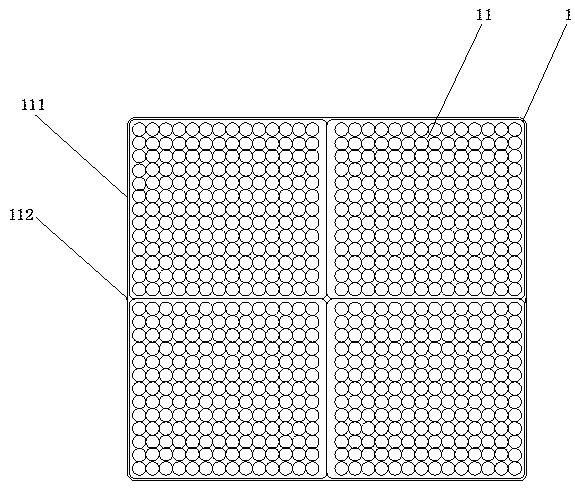

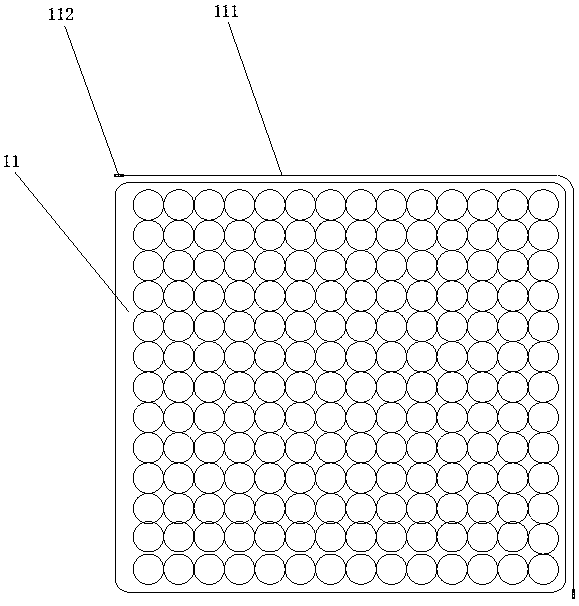

Assembly type spring mattress

PendingCN109363423ASimple structural designReasonable structural designStuffed mattressesSpring mattressesMechanical engineeringEngineering

The invention relates to an assembly type spring mattress, wherein the assembly type spring mattress comprises a spring package assembly; the spring package assembly is formed by detachably assemblingtwo or more single spring packages with the same structure, and each single spring package is a rectangular spring package structure assembled from a plurality of spare springs. The integrated mattress is changed to assembly of multiple separated blocks, the structure design is simple and reasonable, the dismounting and the assembly are convenient, the transportation is convenient, the comfortability in use is good, and the quality is high.

Owner:宝鸡华保家具有限责任公司

Method for continuously producing L-ornithine composite salt by enzyme immobilization

ActiveCN103014086BHigh product yieldImprove qualityOn/in organic carrierFermentationOrnithine synthesisL-Ornithine

Owner:WUHAN SHENGJIA CHEM ENG

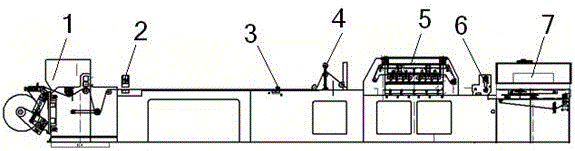

Multifunctional integrated gravure printing machine and its processing technology

ActiveCN104708894BStable tensionSame line speedRotary intaglio printing pressHot stampingLaser holography

The invention provides a multifunctional integrated intaglio printing press which comprises an unreeling device, an introduction deviation rectifying device, a double-traction device, a printing unit, an edge cutting device, a belling device, a die cutting device, a soft pack cutting device and an automatic stacking paper collecting device. A first traction guide device, a gilding device, a holographic positioning ironing device, the belling device, an online detection device and a second traction guide device are sequentially arranged between the printing unit and the edge cutting device. The printing unit comprises at least nine gravure printing devices, and the multiple gravure printing devices are combined to form multi-color continuous gravure. The first traction guide device and the second traction guide device are provided with stepless speed regulating mechanisms to control the tension and the linear speed of paper passing the gilding device, the holographic positioning ironing device and the belling device at high accuracy, and accuracy control and position control over hot stamping, laser holography transfer printing and raised ironing of cigarette packs are achieved at the same time. The invention further provides a machining process of the multifunctional integrated intaglio printing press.

Owner:ZHUHAI S E Z CHENGCHENG PRINTING

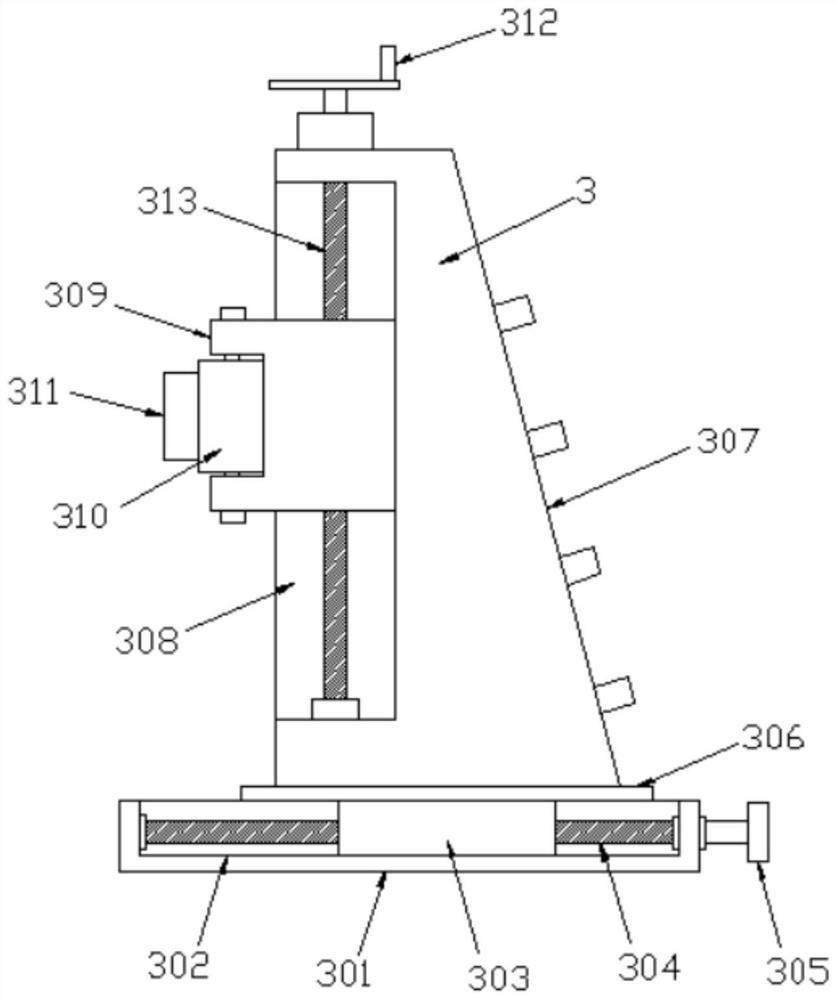

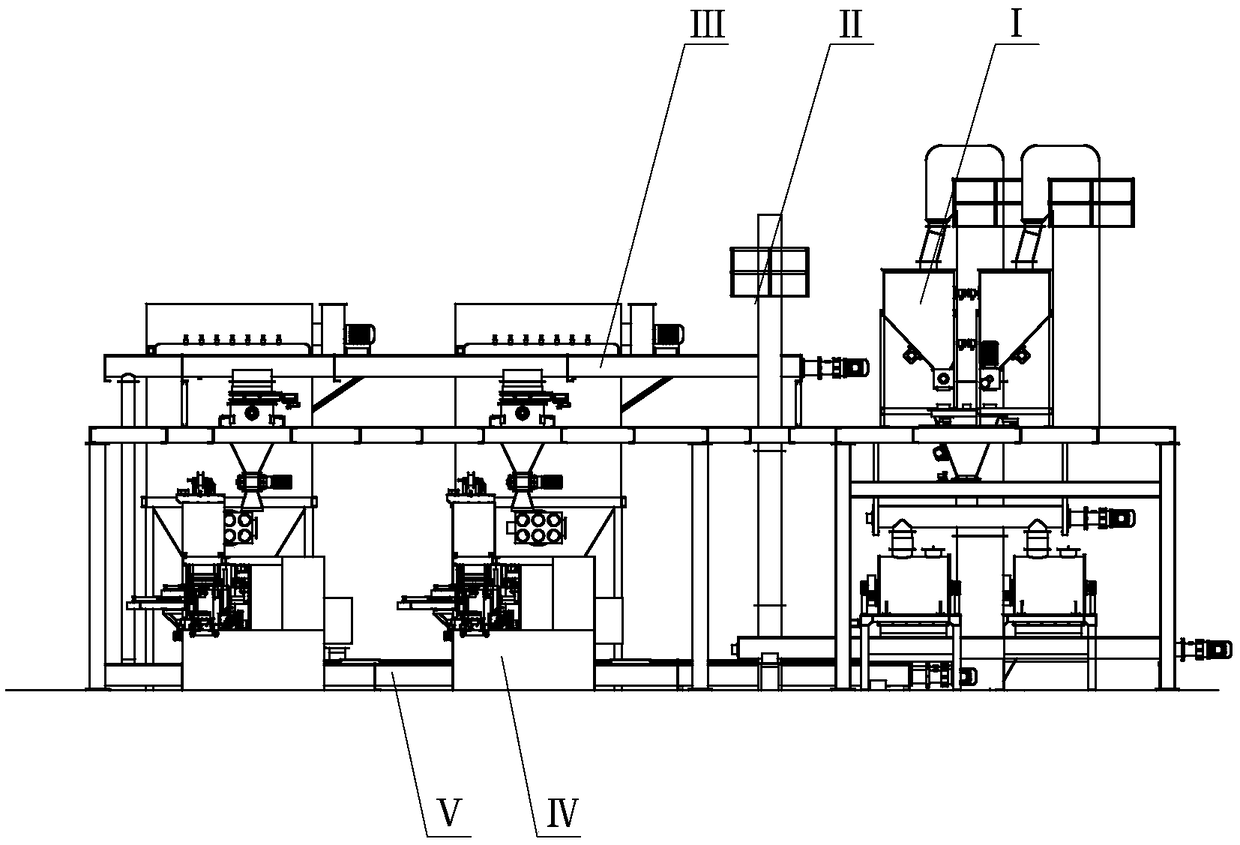

Full-automatic bottom sealing type closed power filling system and process

ActiveCN106207081AAvoid harmChange production modeFilling tube/pocket electrodesLead-acid accumulator electrodesEngineeringMechanical engineering

The invention relates to a full-automatic bottom sealing type closed power filling system and a process, and belongs to the technical field of tubular lead-acid storage battery production. The system comprises a complete machine frame; a tool locking apparatus, a tool unlocking apparatus, a moving rack apparatus, a tool transfer apparatus, a vibration platform apparatus, a turnover powder brushing apparatus and an automatic bottom sealing apparatus are arranged on the complete machine frame; and the powder filling process is carried out by utilizing the full-automatic bottom sealing type closed power filling system. According to the system and the process, a previous bottom sealing mode is adopted; and automatic bottom sealing is realized in a device after the power filling is finished, so that the harm of lead powder on a human body in the bottom sealing process is avoided and an original production mode is thoroughly changed.

Owner:ZIBO XINXU POWER SUPPLY TECH

Production process and equipment of intelligent door lock

ActiveCN114473484AMeet supply needsImprove work efficiencyAssembly machinesIndustrial engineeringFully automated

The invention discloses a production process of an intelligent door lock, which comprises the following specific steps: mounting an internal driving mechanism, mounting a bottom plate assembly, pasting an ESD (Electro-Static Discharge) gasket, mounting a button ring, mounting a pin column, applying lubricating oil and mounting a button, so that the assembly work of the intelligent door lock is completed, and the whole set of assembly process is completed through full-automatic intelligent door lock assembly equipment. According to the pin column mounting device, the working efficiency is greatly improved, the supply requirement of the market is met, a traditional manual assembly production mode is changed, the automation degree is high, the size of the needed pin column can be tested through the depth testing mechanism, then the needed pin column is blanked and finally mounted through the pin column selecting and mounting mechanism, the automation degree is high, and the production efficiency is improved. The button assembling device is simple in structure and high in yield, the technical problem that the traditional defective product rate is high due to assembling errors is solved, the rotary positioning device can adjust the button to be assembled to the needed accurate position, and therefore the clamping requirement of follow-up assembling is met.

Owner:ZHEJIANG LIANDA SCI & TECH

Full-automatic spiced egg dispensing and vacuum packing integrated machine

ActiveCN102530304BChange production modeRealize continuous productionPackaging eggsPackaging under vacuum/special atmosphereProduction linePulp and paper industry

The invention discloses a full-automatic spiced egg dispensing and vacuum packing integrated machine, which comprises a full-automatic spiced egg dispensing machine, a full-automatic bag making machine and a full-automatic vacuum packing machine, wherein the discharge end of the full-automatic spiced egg dispensing machine corresponds to the bag making section of the full-automatic bag making machine, and the output end of the full-automatic bag making machine corresponds to the input end of the full-automatic vacuum packing machine. Through the integrated machine, continuous production of dispensing, bag feeding and vacuum packing steps of spiced eggs is realized, the production pattern of the conventional automatic equipment of manual operation or only independent steps is changed, a completely mechanical and automatic production line pattern is formed, the process requirement of a product for continuous production is realized, manpower, material resources and financial resources are greatly saved, the production and processing efficiency is improved, and the processing cost is reduced.

Owner:CHENGDU WENJIANG HAIKE INSTR FACTORY

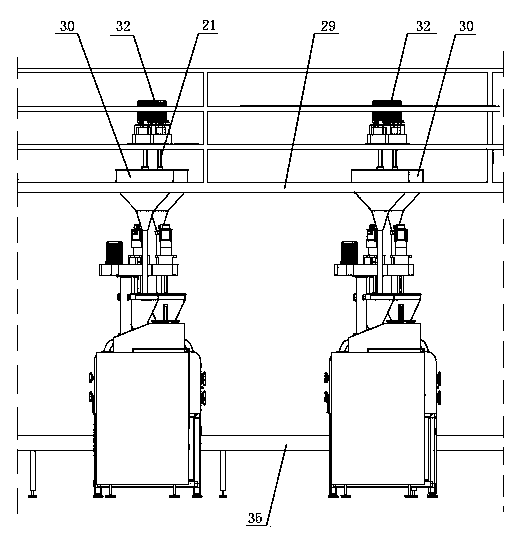

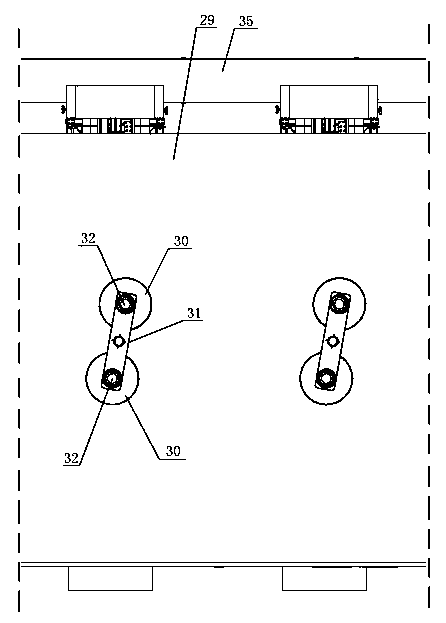

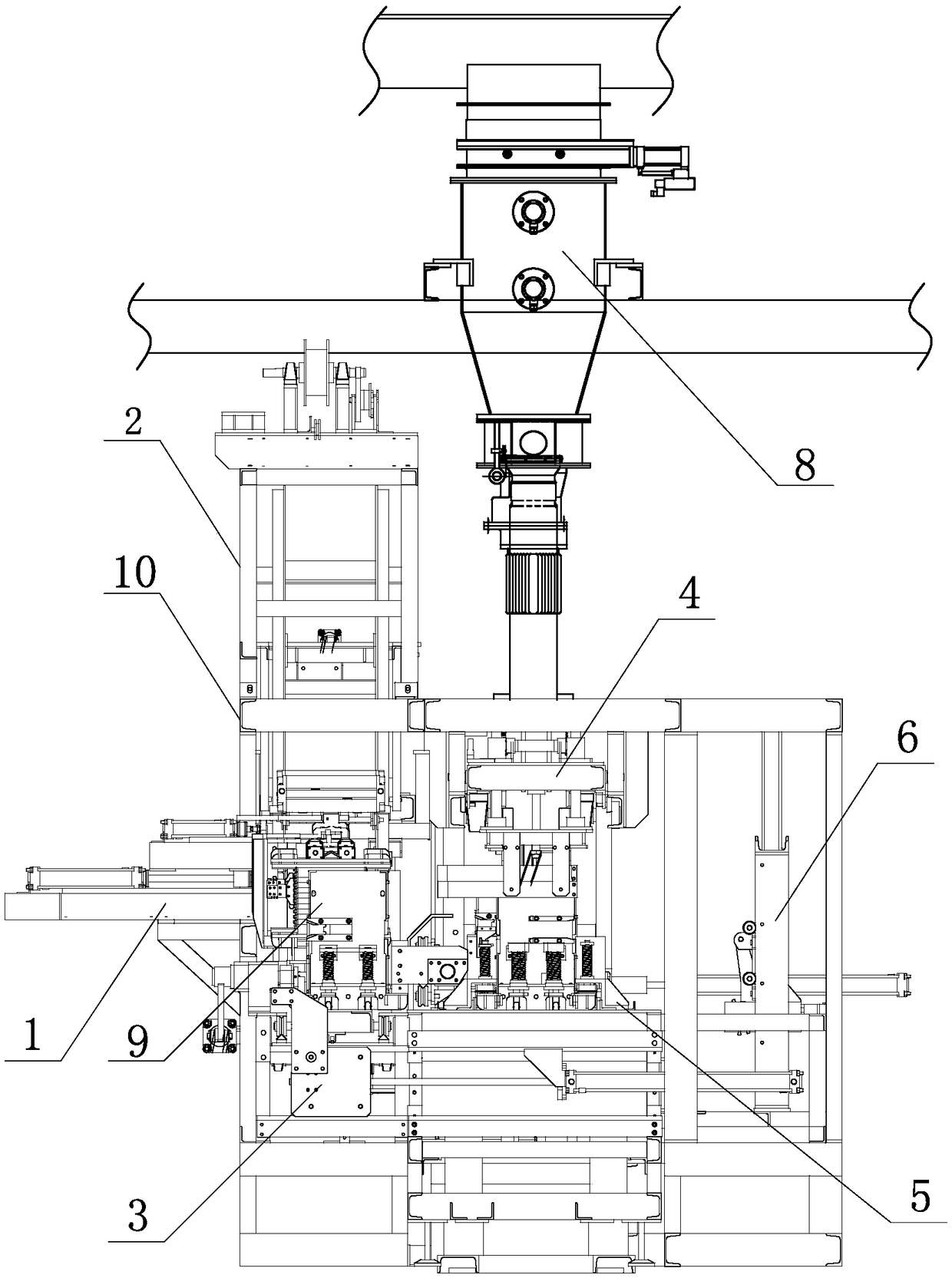

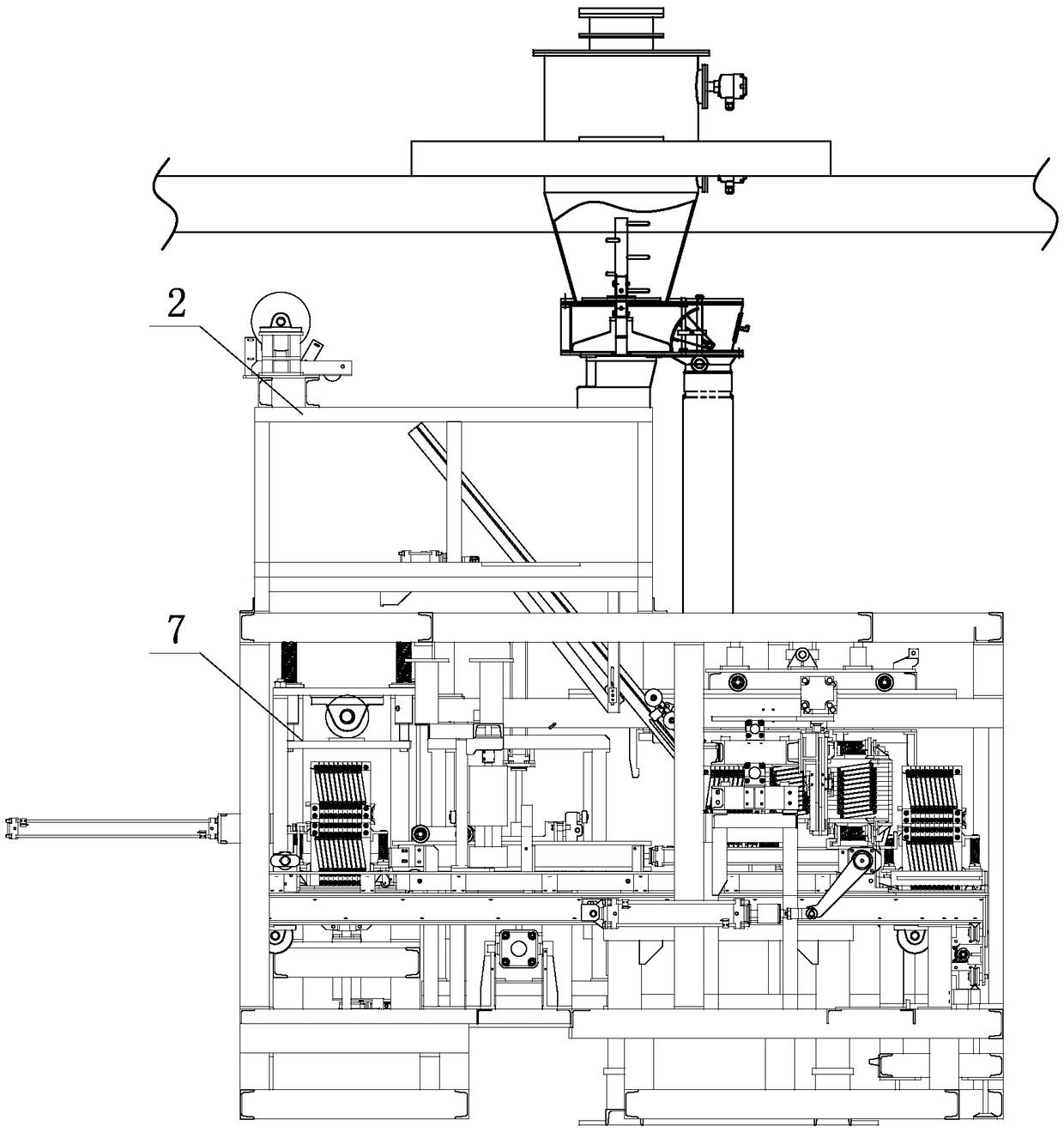

Full-automatic double-end metering, filling and vacuumizing production line

ActiveCN102700730BRealize continuous productionChange manual operationSolid materialProduction lineMaterial resources

The invention discloses a full-automatic double-end metering, filling and vacuumizing production line which comprises a plurality of full-automatic double-end metering, filling and vacuumizing integrated machines, wherein supporting floorslabs are arranged above the full-automatic double-end metering, filling and vacuumizing integrated machines, the supporting floorslabs are provided with feed hoppers corresponding to feed positions of the full-automatic double-end metering, filling and vacuumizing integrated machines and feeding mechanism corresponding to the feed hoppers. The invention realizes continuous production of filling, packaging, and vacuumizing materials, changes the production mode of current manual operation or an automated device with only independent steps, forms the fully mechanical and automated production line mode, realizes the technical requirements of continuous production of products, saves the labor, material resources and financial resources greatly and has high work efficiency.

Owner:CHENGDU WENJIANG HAIKE INSTR FACTORY

Lead-acid battery automatic back cover powder filling system

ActiveCN106207084BAvoid harmChange production modeLead-acid accumulator electrodesImpregnation manufacturingEngineeringBrush device

The invention relates to a fully-automatic bottom sealing and powder filling system for lead-acid storage batteries, and belongs to the technical field of production of tubular lead-acid storage batteries. The system comprises a complete appliance rack, and a tool locking device, a tool starting device, a movable frame table device, a tool transfer device, a vibration platform device, a turnover powder brushing device, an automatic bottom sealing device and a quantitative powder discharge device are arranged on the complete appliance rack. The system adopts a mode of sealing a bottom in advance, the bottom is automatically sealed in equipment after the powder is filled, the damage of lead powder to a human body is completely eradiated in the process of sealing the bottom, the original production mode is completely changed, a mode of reverse operation of two eccentric vibration motors is adopted, a frequency converter is used to change the amplitude, the noise is reduced, the service life is guaranteed, and meanwhile, the use and the maintenance are facilitated.

Owner:ZIBO XINXU POWER SUPPLY TECH

Fully-automatic bottom sealing and powder filling system for lead-acid storage batteries

ActiveCN106207084AEliminate harm to the human bodyReduce noiseLead-acid accumulator electrodesImpregnation manufacturingBrush deviceFrequency changer

The invention relates to a fully-automatic bottom sealing and powder filling system for lead-acid storage batteries, and belongs to the technical field of production of tubular lead-acid storage batteries. The system comprises a complete appliance rack, and a tool locking device, a tool starting device, a movable frame table device, a tool transfer device, a vibration platform device, a turnover powder brushing device, an automatic bottom sealing device and a quantitative powder discharge device are arranged on the complete appliance rack. The system adopts a mode of sealing a bottom in advance, the bottom is automatically sealed in equipment after the powder is filled, the damage of lead powder to a human body is completely eradiated in the process of sealing the bottom, the original production mode is completely changed, a mode of reverse operation of two eccentric vibration motors is adopted, a frequency converter is used to change the amplitude, the noise is reduced, the service life is guaranteed, and meanwhile, the use and the maintenance are facilitated.

Owner:ZIBO XINXU POWER SUPPLY TECH

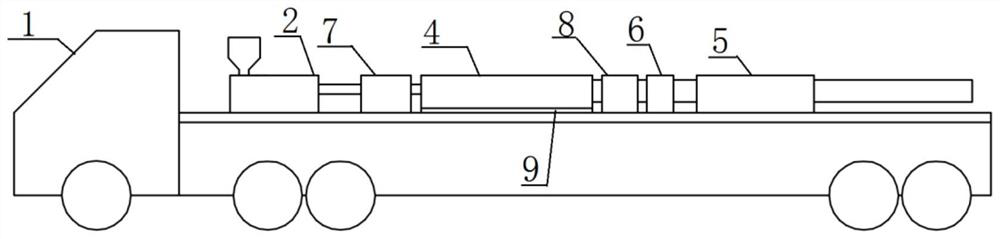

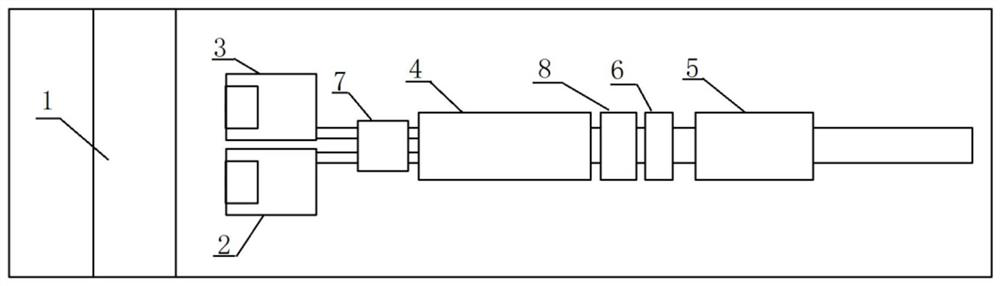

Method for manufacturing HDPE double-wall corrugated pipe on vehicle-mounted movable pipeline production line and vehicle-mounted movable pipeline production line

PendingCN112757673ARealize production process requirementsChange production modeTubular articlesProduction lineMolding machine

The invention relates to a method for manufacturing an HDPE double-wall corrugated pipe on a vehicle-mounted movable pipeline production line and the vehicle-mounted movable pipeline production line, and aims at the method. The method specifically comprises the following steps of S1, mounting an inner wall extruder (2) and an outer wall extruder mold on a moving vehicle (1); and S2, feeding, starting the inner wall extruder to extrude an inner wall pipe, starting the outer wall extruder to extrude an outer wall pipe, performing vacuum adsorption molding on the inner wall pipe and the outer wall pipe by a molding machine (4), extruding corrugations by modules of the molding machine (4), feeding the pipes by a discharging frame (5), and cutting the pipes by a cutting machine (6). The vehicle-mounted movable pipeline production line comprises the moving vehicle, the inner wall extruder, the outer wall extruder, the molding machine, the discharging frame and the cutting machine. Plastic pipelines can be temporarily manufactured near a construction site, the transportation cost can be saved, and the transportation quantity can be increased.

Owner:HUNAN SPACE KANDAK PLASTIC

Method for purifying glauberite to prepare dihydrate gypsum

ActiveCN102963920BFull recoveryReduce mining costsCalcium/strontium/barium sulfatesPhysical chemistryCalcium Sulfate Dihydrate

The invention discloses a method for purifying glauberite ore to prepare dihydrate gypsum, which comprises the following steps: 1) crushing glauberite ore by crushing equipment to obtain glauberite ore powder; 2) making glauberite ore powder Send it into the leaching mixing tank and mix it with the immersion water; 3) Send the mixture into a mechanical filtration device capable of quantitative washing to obtain a filter residue with a sodium sulfate content of less than 2% and a water content of less than 30%. ;4) The filter residue is made into a spherical material through a ball forming mechanism. This material is the finished dihydrate gypsum. In this application, the leached suspension is passed through a filter with washing function. According to the requirements of the sodium sulfate production process, it can be directly used as the raw material for the production of anhydrous sodium sulfate. Because the washing liquid contains sodium sulfate, it can be recycled as immersion water. Through this method, calcium sulfate dihydrate products that meet the national standards can be produced, and the operability Strong, low production cost, good market prospect.

Owner:SICHUAN TONGQING NANFENG

Fully automatic back cover powder filling system and process

ActiveCN106207083BPrecise control of proportioning and weighingAvoid harmLead-acid accumulator electrodesImpregnation manufacturingLow voltageEngineering

The invention relates to a powder filling system and process with a fully automatic bottom-sealing function, and belongs to the production technical field of a tubular lead-acid storage battery. The powder filling system comprises a weighing and powder-mixing apparatus, a mixed powder lifter, a quantitative powder-unloading spiral component, a plurality of fully-automatic powder filling machines, and a plurality of low-voltage pulse dust removers, wherein the weighing and powder-mixing apparatus is connected with the mixed powder lifter; the mixed powder lifter is connected with the fully-automatic powder filling machines through the quantitative powder-unloading spiral component; the fully-automatic powder filling machines are correspondingly connected with the low-voltage pulse dust removers; and the fully-automatic powder filling machines and the low-voltage pulse dust removers are all connected with the quantitative powder-unloading spiral component, and the powder filling process is performed through the powder filling system. The system and the process are reasonable in design; the matching ratio and the weighing of the raw materials can be accurately controlled; the full mixing of the powder can be realized automatically; direct contact between a human body and lead dust is avoided; a pre-bottom-sealing way is adopted, automatic bottom sealing in the equipment is realized automatically after the powder filling is completed, so that harm to the human body from lead powder is completely eradicated; therefore, an original production mode is completely changed; and in addition, the powder filling system is convenient to use and maintain.

Owner:ZIBO XINXU POWER SUPPLY TECH

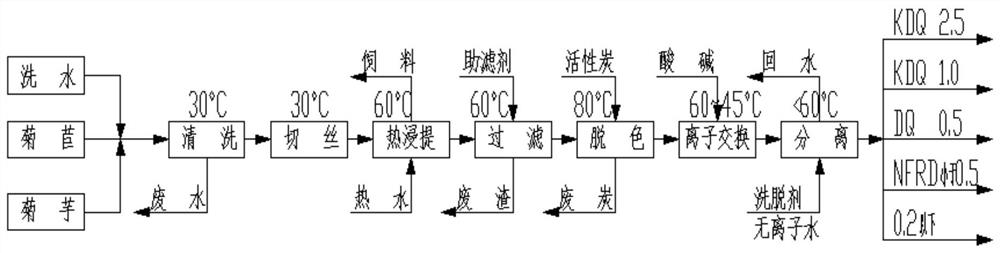

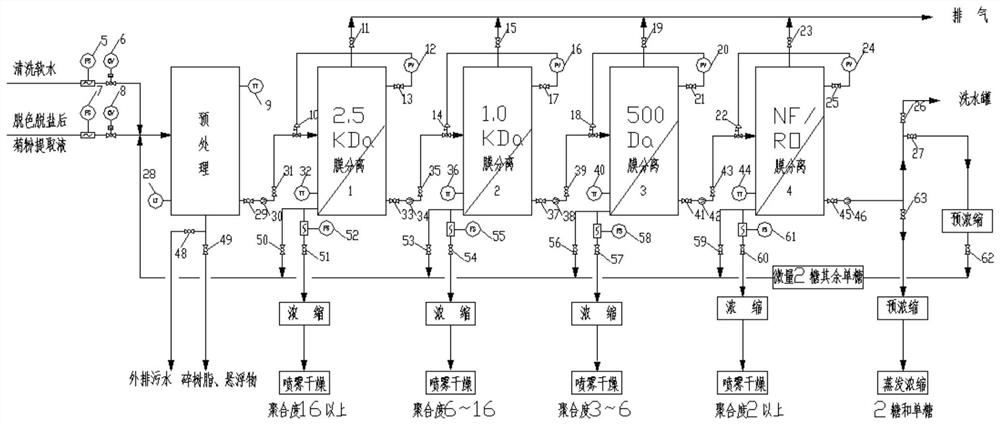

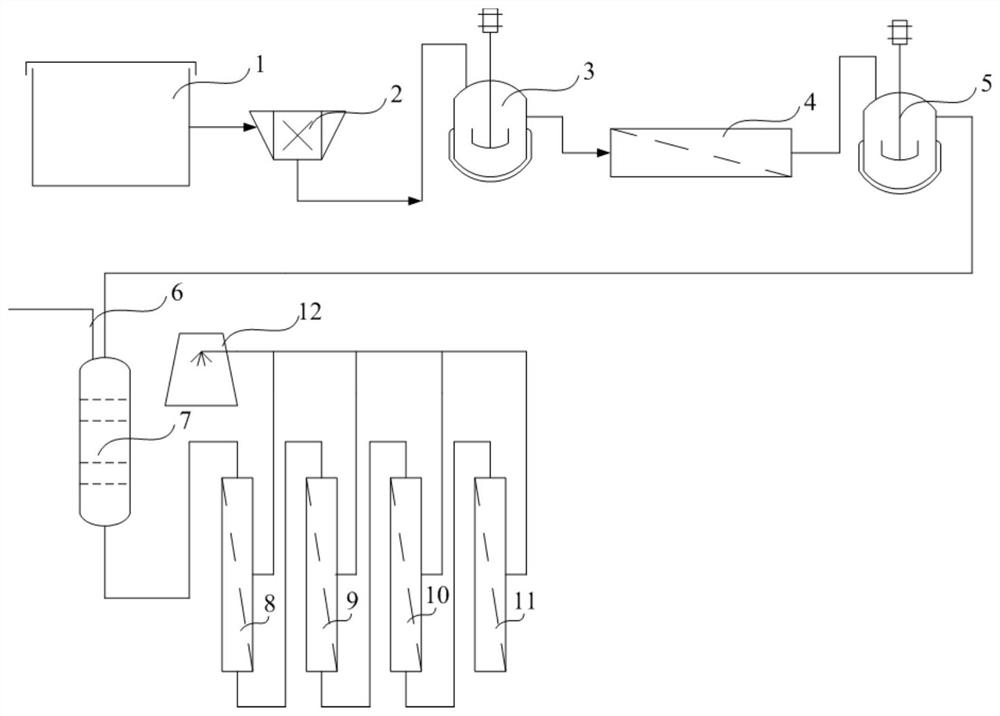

Molecular-level production process and device of inulin

The invention relates to a molecular-level production process and device of inulin, and belongs to the technical field of natural plant extraction. The invention provides a molecular-grade inulin production technology, which utilizes a molecular weight grading and separating device, i.e., inulin is divided into four different grades of products with the molecular weight of more than 2500, more than 1000, more than 500 and less than 500 and more than 200 according to the molecular weight.

Owner:吉林省石油化工设计研究院

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com