Method for purifying glauberite to prepare dihydrate gypsum

A technology of dihydrate gypsum and glauberite, which is applied in the direction of calcium/strontium/barium sulfate, etc., can solve the problems of low recovery rate of sodium sulfate, high safety risk, and large land occupation, so as to achieve good market prospects and reduce dependence , the effect of low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

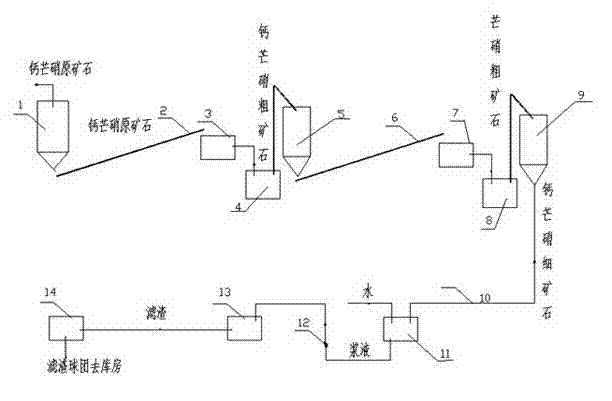

Image

Examples

Embodiment 1

[0031] A method for preparing dihydrate gypsum by purifying glauberite ore, comprising the steps of:

[0032] 1) The glauberite ore is crushed by crushing equipment to obtain glauberite ore powder; the particle size of the obtained glauberite ore powder is less than 8mm. Mineral powder below 8mm can fully dissolve sodium sulfate in water.

[0033] 2) Put the glauberite ore powder into the leaching mixing tank and mix it with the leaching water containing 20g / L of sodium sulfate in the leaching mixing tank. The mass ratio of the leaching water in the leaching mixing tank to the glauberite ore powder is 0.8:1. Sodium glauberite powder and sodium sulfate aqueous solution were leached for 1 hour. Because the mineral powder of this mass ratio and the immersion water of this concentration are under the action of the agitator, and the sodium sulfate in the glauberite ore can be fully dissolved in the water for 1 hour. The purpose of this step is to ensure that the solution concent...

Embodiment 2

[0042] A method for preparing dihydrate gypsum by purifying glauberite ore, comprising the steps of:

[0043] 1) The glauberite ore is crushed by crushing equipment to obtain glauberite ore powder; the particle size of the obtained glauberite ore powder is less than 8mm. Mineral powder below 8mm can fully dissolve sodium sulfate in water.

[0044] 2) Put the glauberite ore powder into the leaching and mixing tank, and mix it with the sodium sulfate aqueous solution containing 100g / L sodium sulfate in the leaching and mixing tank, and the quality of the leaching water in the leaching and mixing tank and the glauberite ore powder The ratio is 1.8:1. Glauberite powder and sodium sulfate aqueous solution were leached for 5 hours. Because the mineral powder of this mass ratio and the leaching water of this concentration are under the action of the stirrer, it takes 5 hours to ensure that the sodium sulfate in the glauberite ore is fully dissolved in the water. The purpose of thi...

Embodiment 3

[0053] A method for preparing dihydrate gypsum by purifying glauberite ore, comprising the steps of:

[0054] 1) The glauberite ore is crushed by crushing equipment to obtain glauberite ore powder; the particle size of the obtained glauberite ore powder is less than 8mm. Mineral powder below 8mm can fully dissolve sodium sulfate in water.

[0055] 2) Put the glauberite ore powder into the leaching and mixing tank, and mix it with the sodium sulfate aqueous solution containing 80g / L sodium sulfate in the leaching and mixing tank, and the quality of the leaching water in the leaching and mixing tank and the glauberite ore powder The ratio is 1.0:1. Sodium glauberite powder and sodium sulfate aqueous solution were leached for 2 hours. Because the mineral powder of this mass ratio and the immersion water of this concentration are under the action of the agitator, it takes 2 hours to ensure that the sodium sulfate in the glauberite ore is fully dissolved in the water. The purpos...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com