Manufacturing method and system device of aluminum foil port sealed air bag

A production method and a technology of an operating device, which are applied in the packaging and production of aluminum foil airbag sealing bags, and in the field of production system devices, can solve the problems of low production efficiency and difficulty in ensuring the quality of production, and achieve stable and reliable quality, save manual operation costs, and reduce random link effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

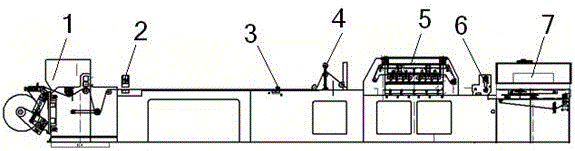

[0032] The accompanying drawing shows an embodiment of the present invention, and it can be seen from the accompanying drawings that the present invention relates to a mechanized production device for aluminum foil end-sealed bags, including a feeding device 1, punching 2, installing silica gel 3, and automatically shaping and folding 4 , middle sealing 5, cutting 6, end sealing 7 and other 7 working devices, feeding device 1, punching 2, installing silica gel 3, automatic shaping and folding 4, middle sealing 5, cutting 6, end sealing 7 and so on 7 The process operation devices are connected in series through an assembly line to realize the automatic operation of 7 processes including feeding device 1, punching 2, installing silica gel 3, automatic shaping and folding 4, middle sealing 5, cutting 6, and end sealing 7.

[0033] The above-mentioned 7 process operating devices including feeding device 1, punching 2, installing silica gel 3, automatic shaping and folding 4, middle...

Embodiment 2

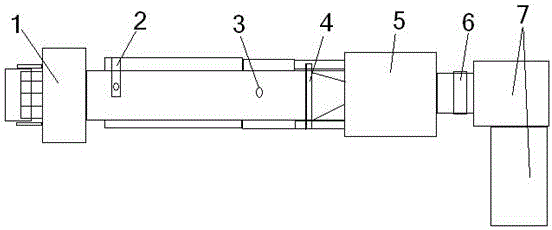

[0043] The basic principle of the second embodiment is the same as that of the first embodiment, except that the arrangement structure of the mechanized production device of the aluminum foil port-sealed bag is different. There are 7 operating devices for shaping and folding, center sealing, cutting and end sealing, and the 7 operating devices for feeding, installing silica gel, punching, automatic shaping and folding, center sealing, end sealing and cutting are connected in series through one assembly line It realizes the automatic operation of 7 processes of feeding, installing silica gel, punching, automatic shaping and folding, middle sealing, end sealing and cutting. The above-mentioned seven process operation devices of feeding device, installing silica gel, punching, automatic shaping and folding, middle sealing, end sealing, and cutting are connected in series through one assembly line according to the principle of feeding, installing silica gel, punching, and automatic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com