Patents

Literature

97results about How to "Realize automated manufacturing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Inductor manufacturing method

InactiveCN104200981ASimple production processRealize automated manufacturingInductances/transformers/magnets manufactureInductance with magnetic coreInductorInductance

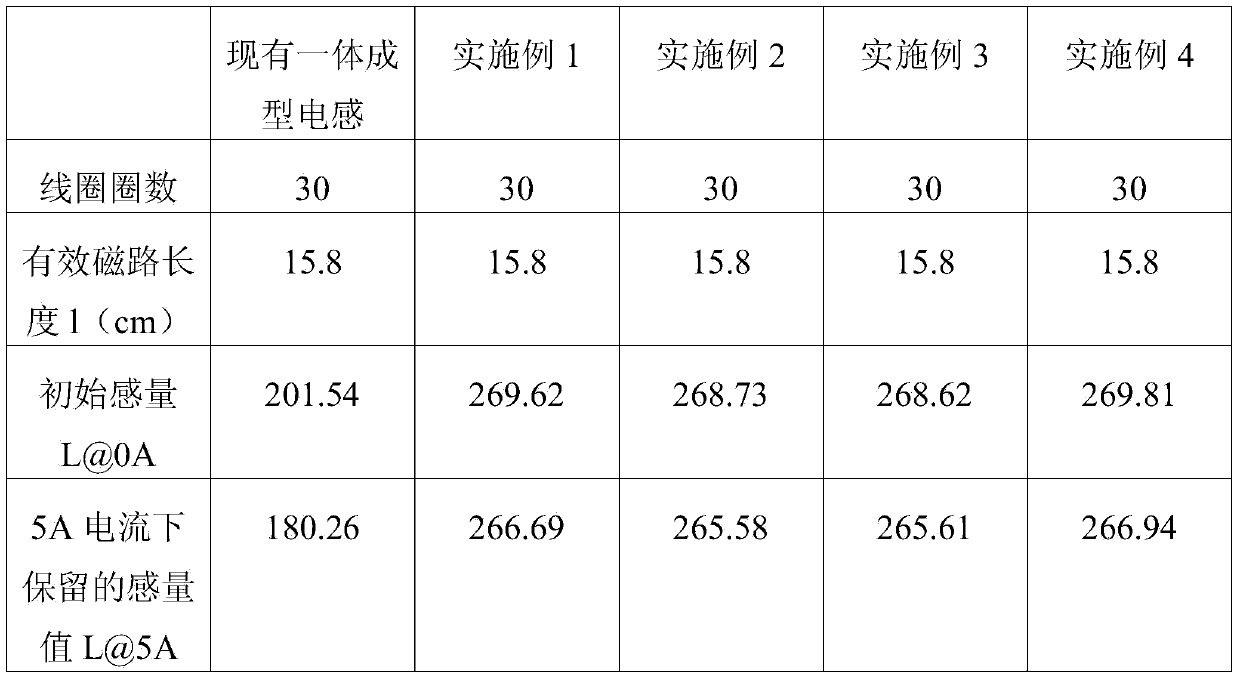

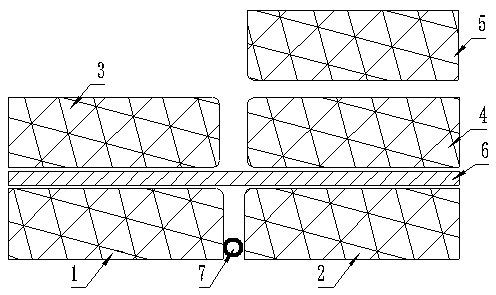

The invention provides an inductor manufacturing method. The method includes the following steps that first, an enameled wire coil is wound; second, first ferromagnetic powder is pressed into a magnetic core; third, the magnetic core is installed in a hollow cavity of the coil; fourth, the coil is installed in an injection mold; fifth, second ferromagnetic powder and high-temperature resin are evenly stirred and mixed power can be obtained; sixth, the mixed powder is injected into the injection mold and formed so that an outer magnet can be obtained, and it is guaranteed that the density of the outer magnet is smaller than that of the magnetic core; seventh, cooling and demolding are performed so that an inductor can be obtained. The inductor manufactured according to the scheme has the advantages that the inductor is good in thermal conductivity and long in service life; the density of the magnetic core is different from that of the outer magnet, a totally-sealed magnetic shielding structure is achieved as a whole, and the EMI effect of the inductor is better compared with that of an existing integrally formed inductor; the problem that a coil is damaged by mechanical stress in the original integrally formed inductor is solved, and in other words, the insulating capacity of the original coil is not weakened.

Owner:POCO HLDG CO LTD

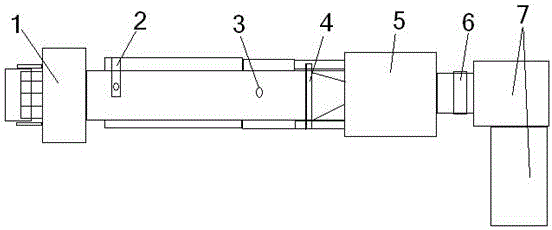

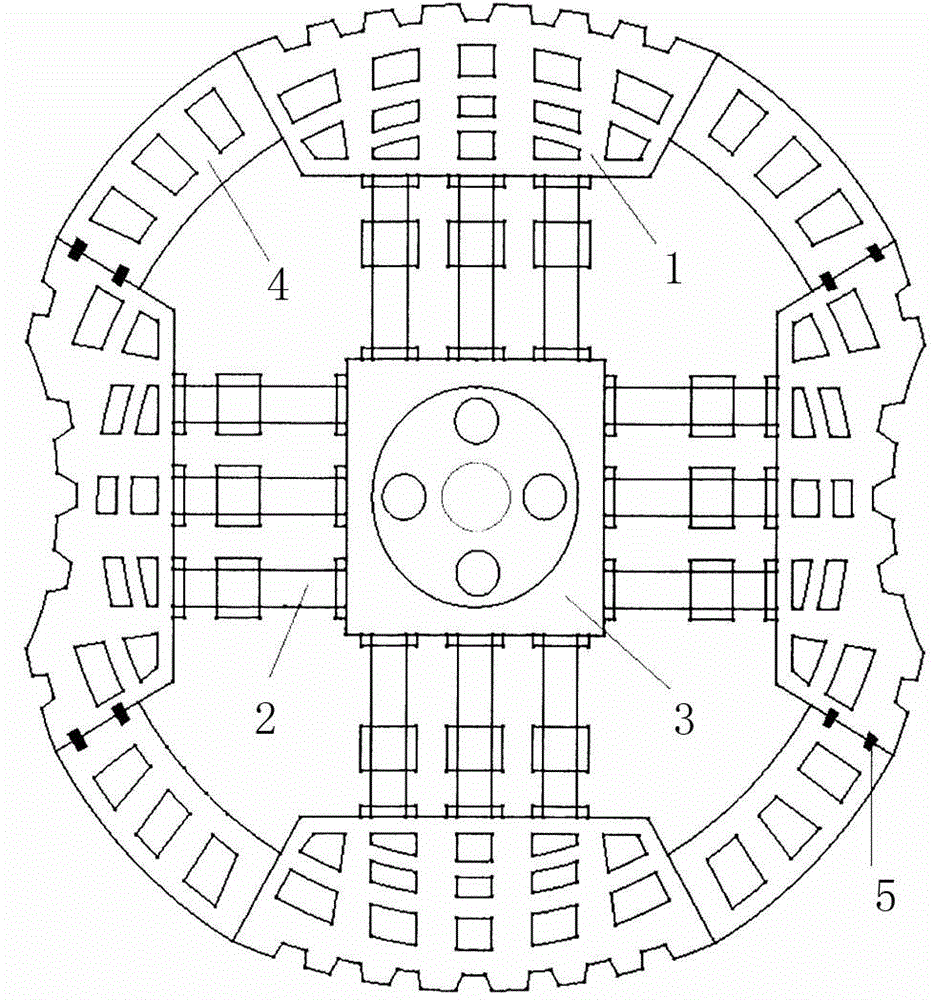

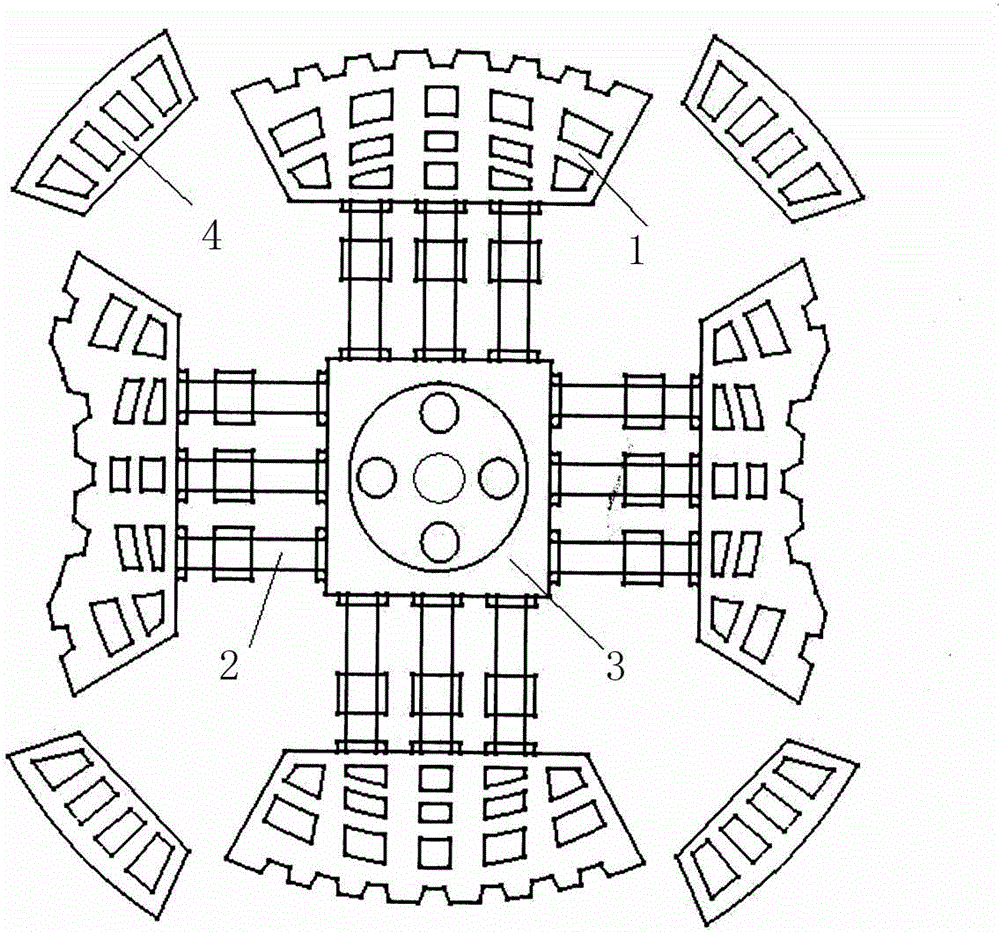

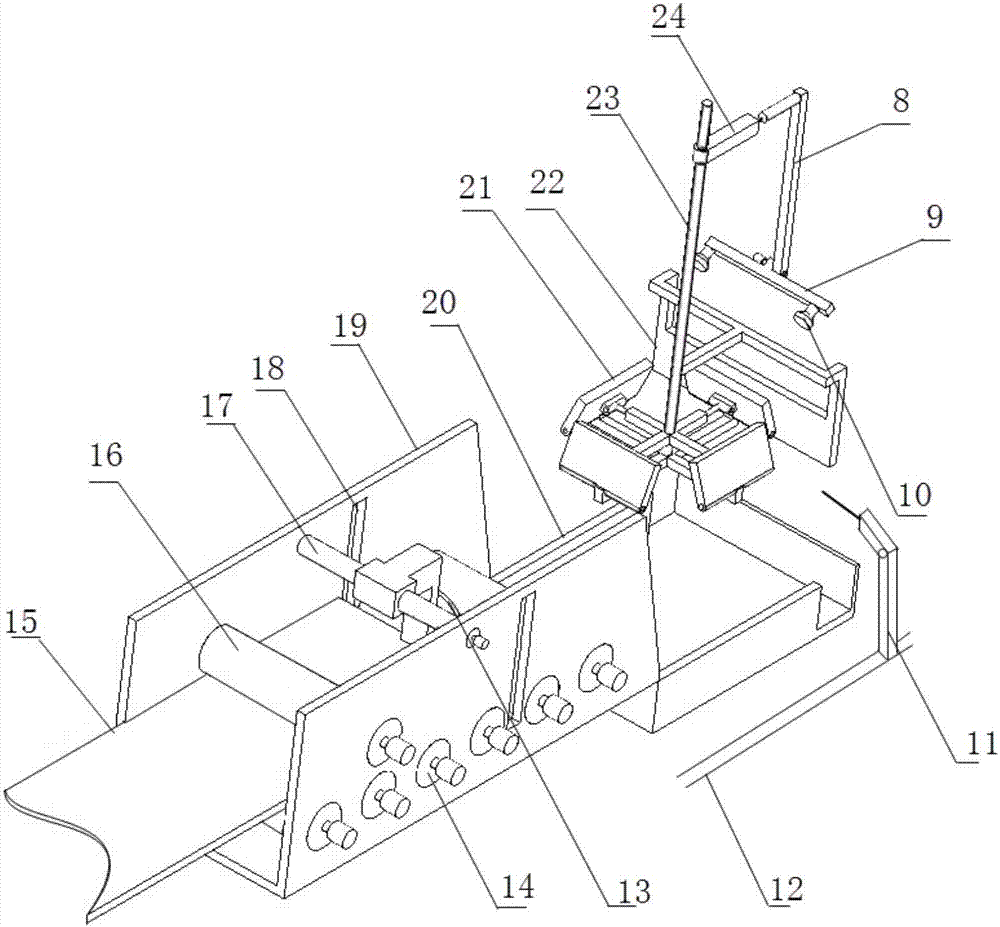

Integrated automatic punching and flanging machine for valve pipes

InactiveCN104646488AImprove product qualityReasonable designMetal-working feeding devicesStripping-off devicesPunchingMechanical equipment

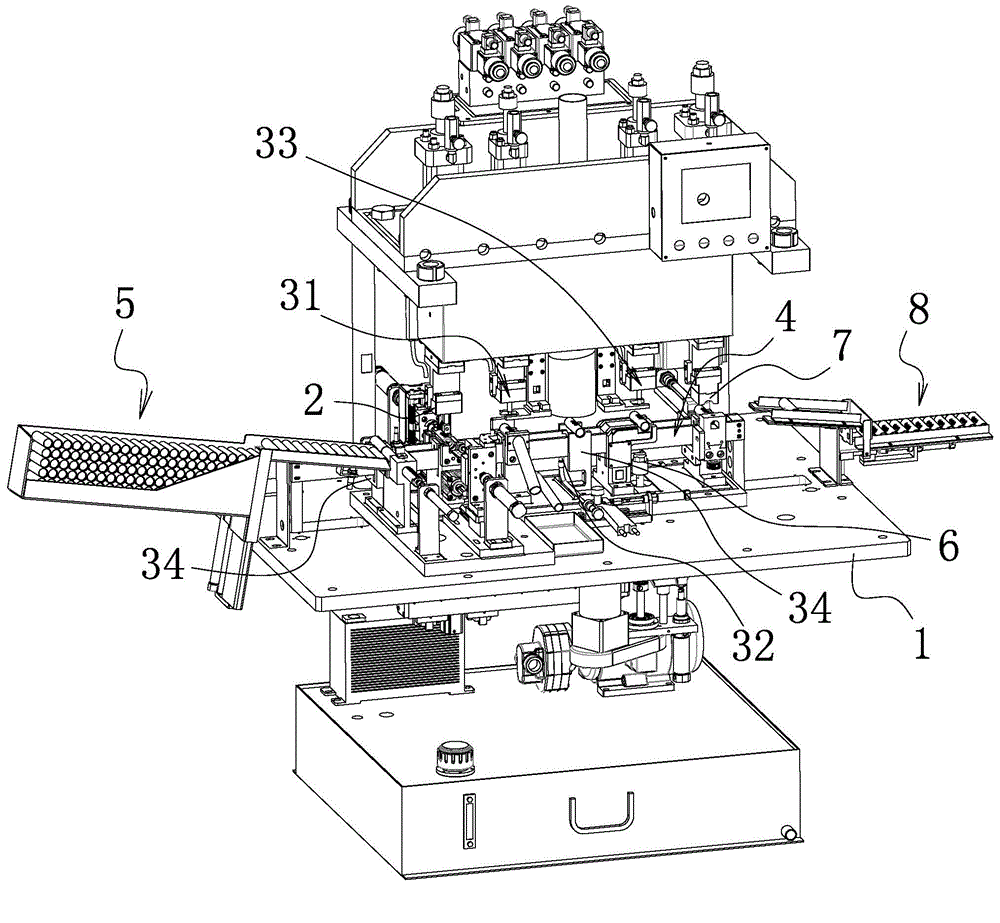

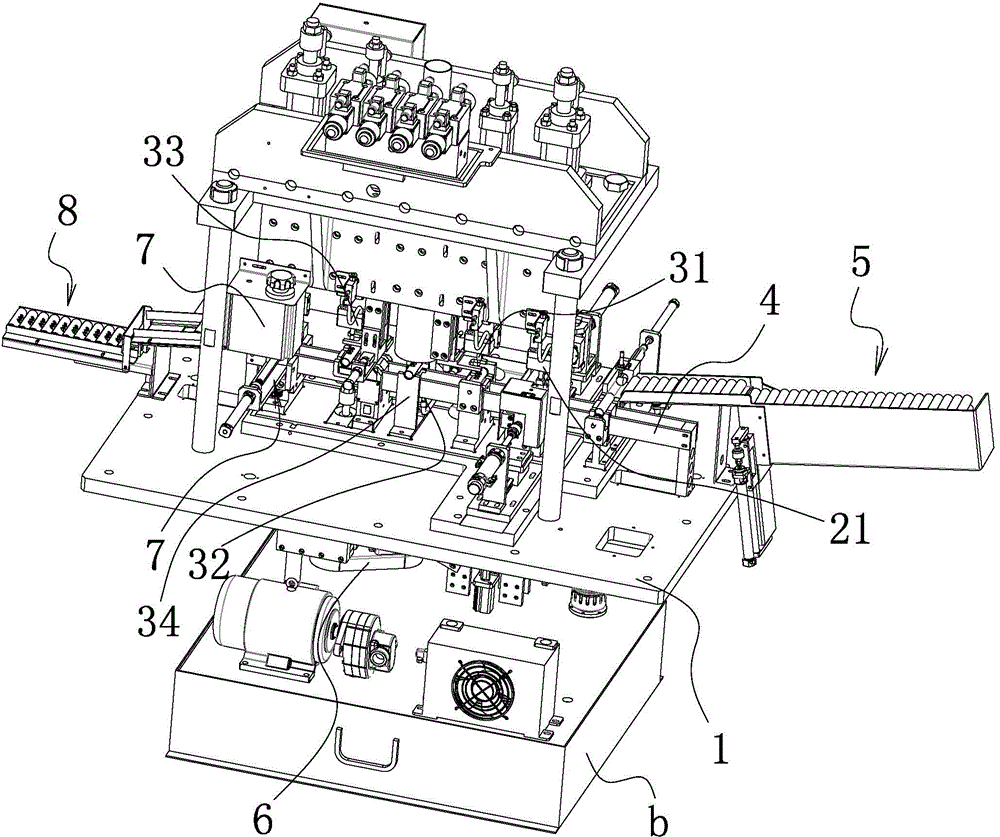

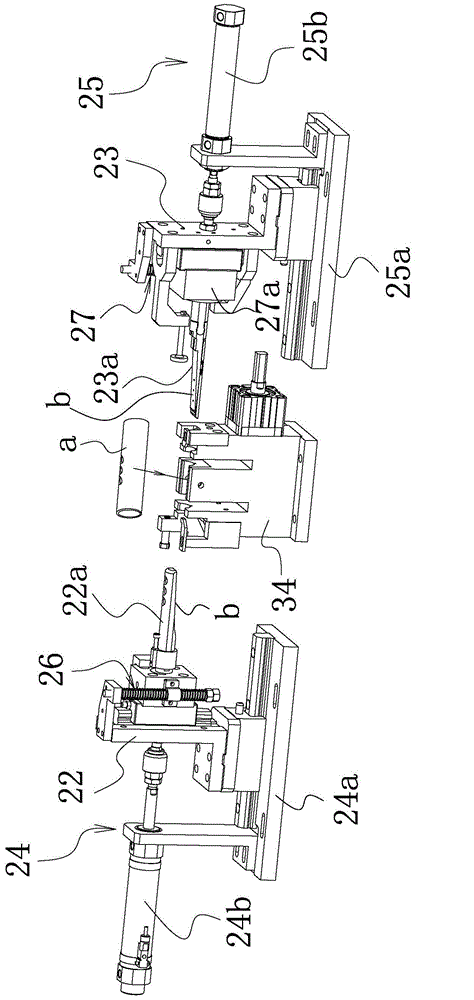

The invention belongs to the technical field of mechanical equipment and particularly relates to an integrated automatic punching and flanging machine for valve pipes. According to the integrated automatic punching and flanging machine for the valve pipes, the technical problems of low automation degree and poor product processing quality in the prior are solved. The integrated automatic punching and flanging machine for the valve pipes comprises a machine frame, wherein a large-hole punching device, a small-hole punching device, an annealing device and a hole flanging device are sequentially arranged on the machine frame; the large-hole punching device punches three large holes in a workpiece; the small-hole punching device punches a small hole opposite to the middle large hole in the workpiece; the annealing device anneals the workpiece; the hole flanging device flanges the outer side of the small hole; a plurality of pipe placement frames in one-to-one correspondence to the large-hole punching device, the small-hole punching device, the annealing device and the hole flanging device are arranged on the machine frame; a material transferring mechanism used for sequentially transferring the workpiece on all the pipe placement frames to enable the large-hole punching device, the small-hole punching device, the annealing device and the hole flanging device to sequentially process the workpiece is further arranged on the machine frame. The integrated automatic punching and flanging machine for the valve pipes has the advantages that the processing quality of products is improved, and the automation degree is high.

Owner:ZHUJI RUN TUO MECHANICAL AUTOMATION TECH

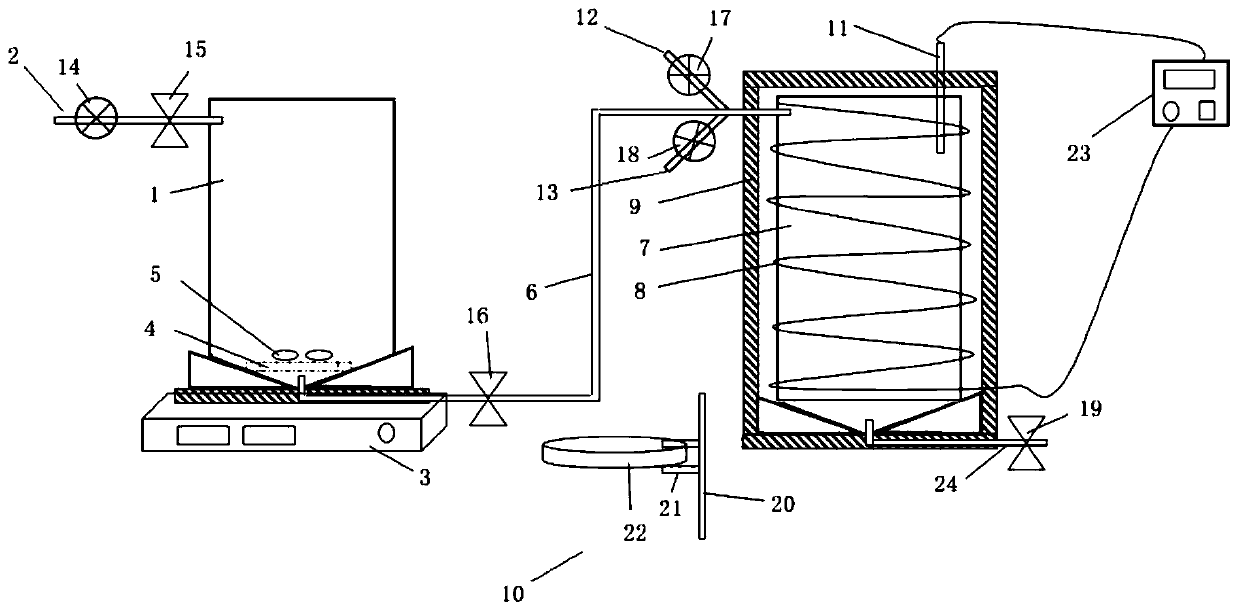

Self-checking common hydrogen-secondary hydrogen conversion device

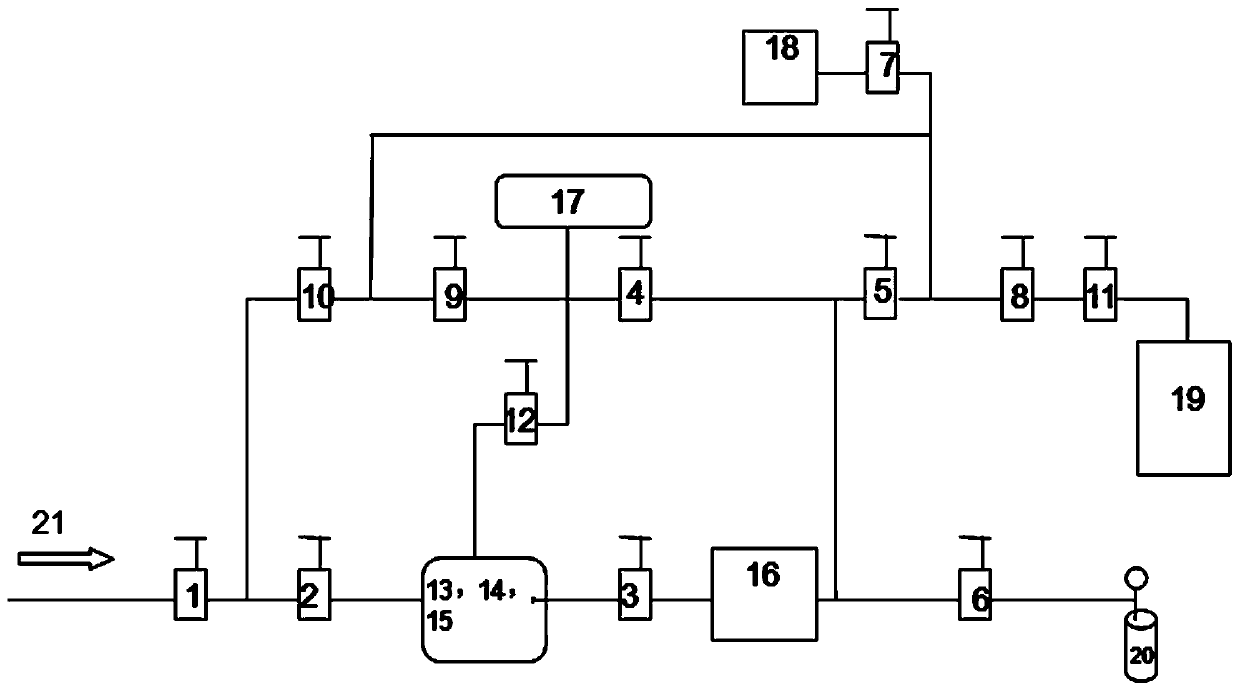

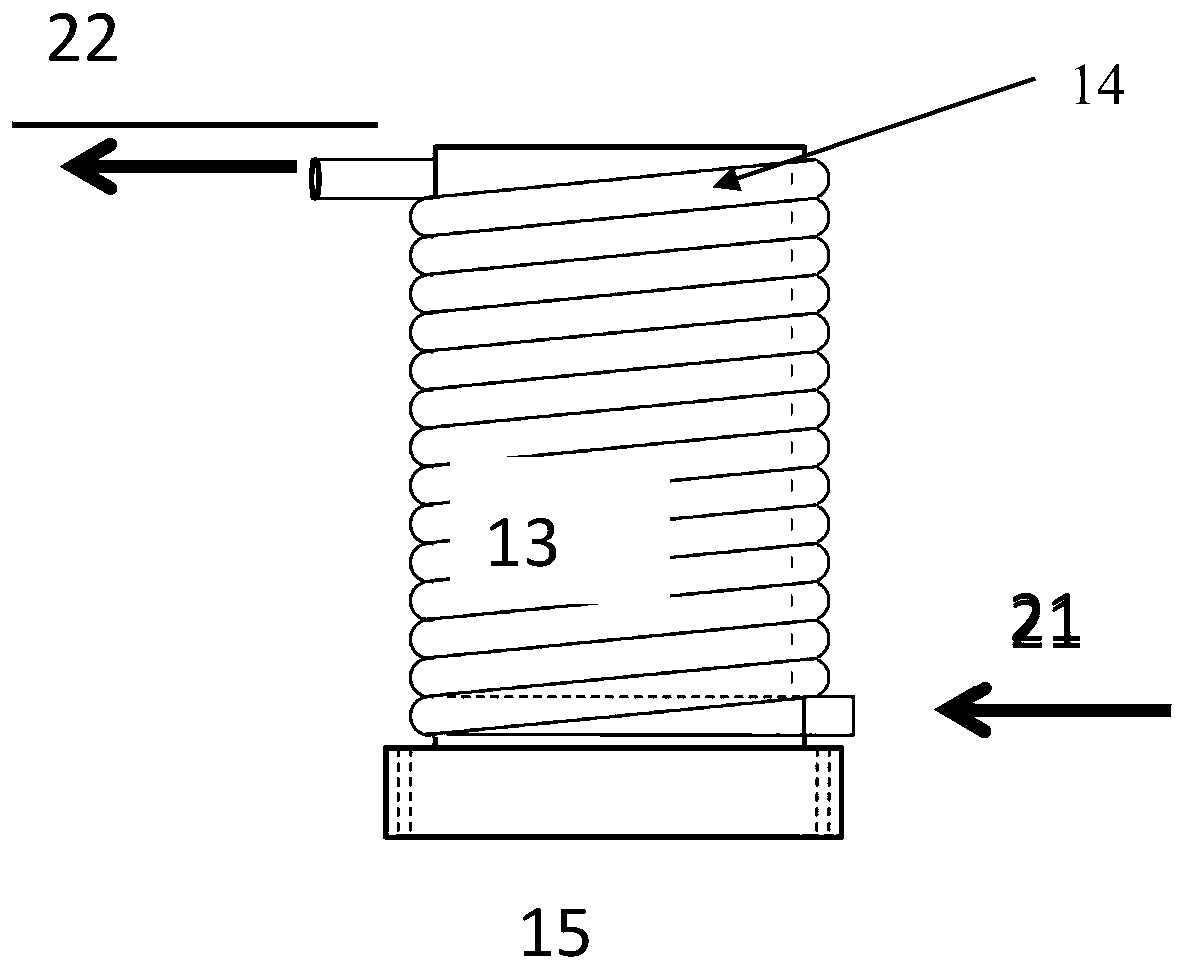

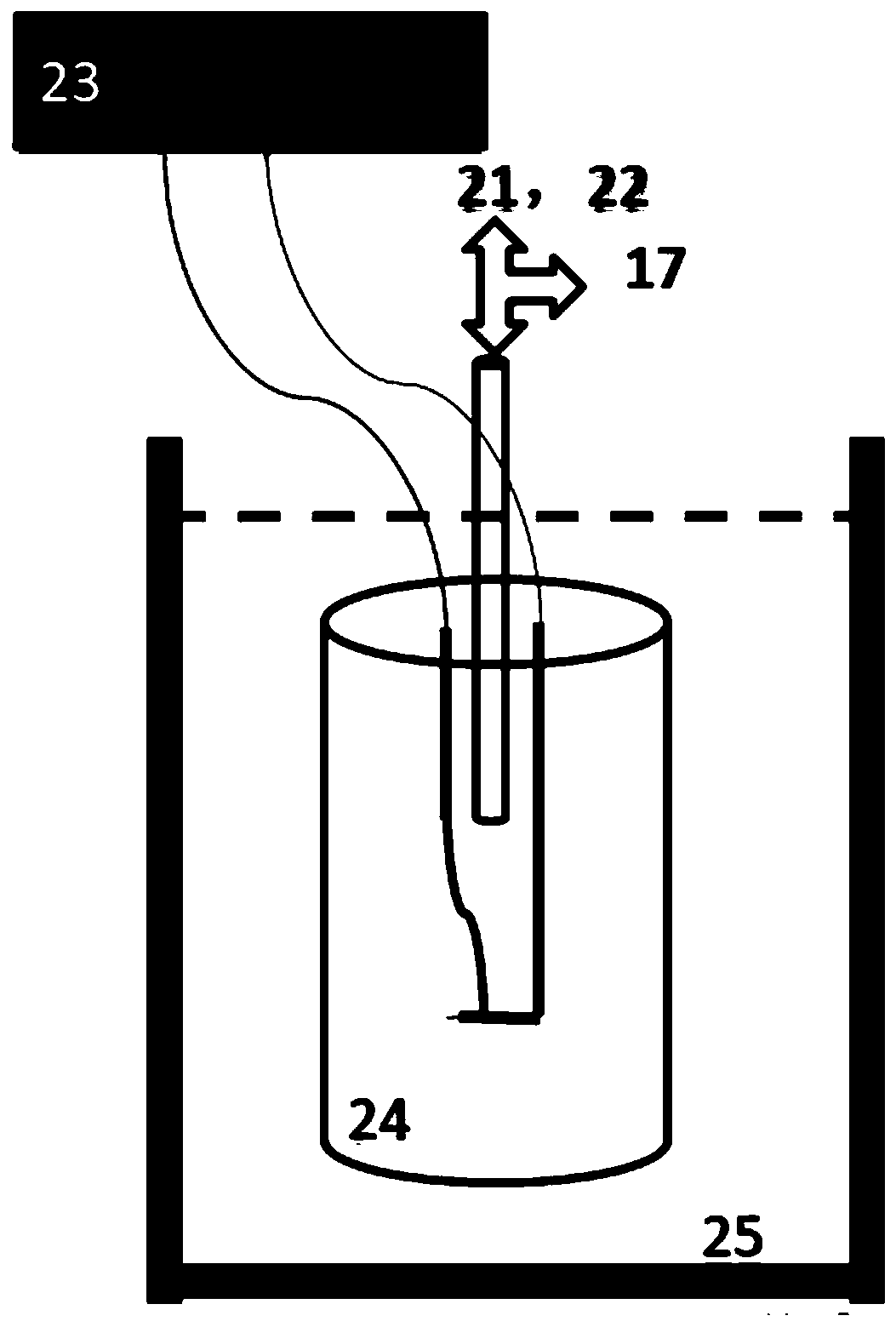

PendingCN111470472AContinuous rapid parahydrogenRealize automated manufacturingHydrogenMaterial resistancePtru catalystGas cylinder

The invention relates to a complete mechanical device, which is used for converting common hydrogen at a normal temperature into secondary hydrogen and is provided with an inspection system. The device comprises a vacuum gas path system, a catalytic conversion device, a purity inspection device and a gas storage cylinder, wherein the vacuum gas path system consists of a mechanical pump, a gas pathand a plurality of valves, and hydrogen enters the vacuum gas path and is prevented from being polluted by air in the vacuum gas path by controlling the valves. The catalytic conversion device is composed of a cold pump and a catalyst, common hydrogen generates secondary hydrogen through a low-temperature catalyst, and the flow rate is controlled by a flow meter to guarantee the catalytic efficiency. The purity inspection device is used for measuring the gas purity by adding liquid nitrogen and using a thermal conductivity method. The prepared pure secondary hydrogen gas is stored in an aluminum gas cylinder to prolong the service life. The device can quantitatively convert common hydrogen into secondary hydrogen, and is an common hydrogen-secondary hydrogen conversion device with integrated conversion and purity inspection functions.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

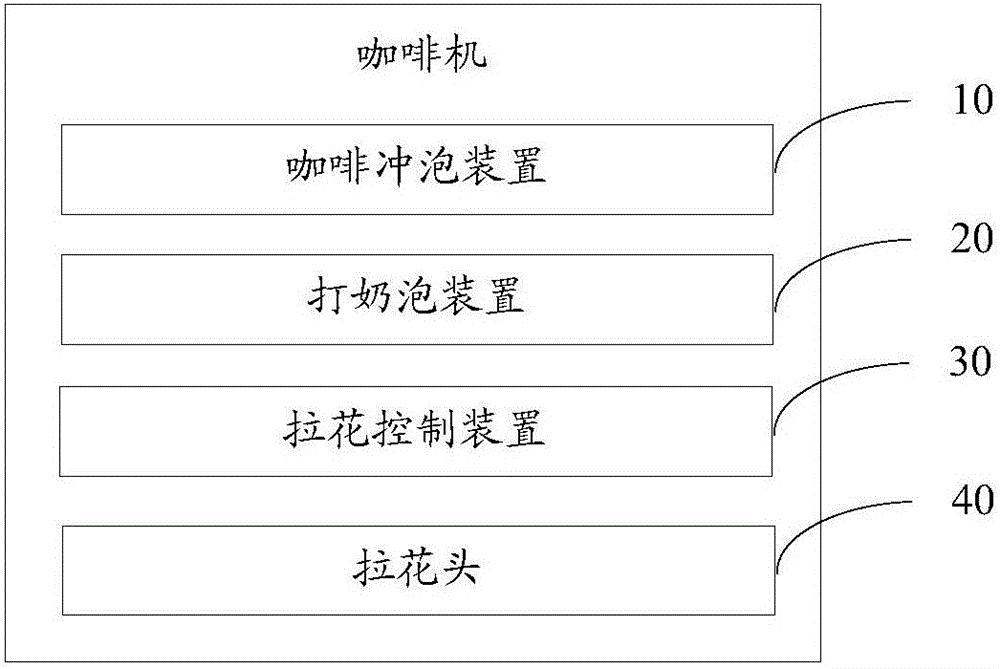

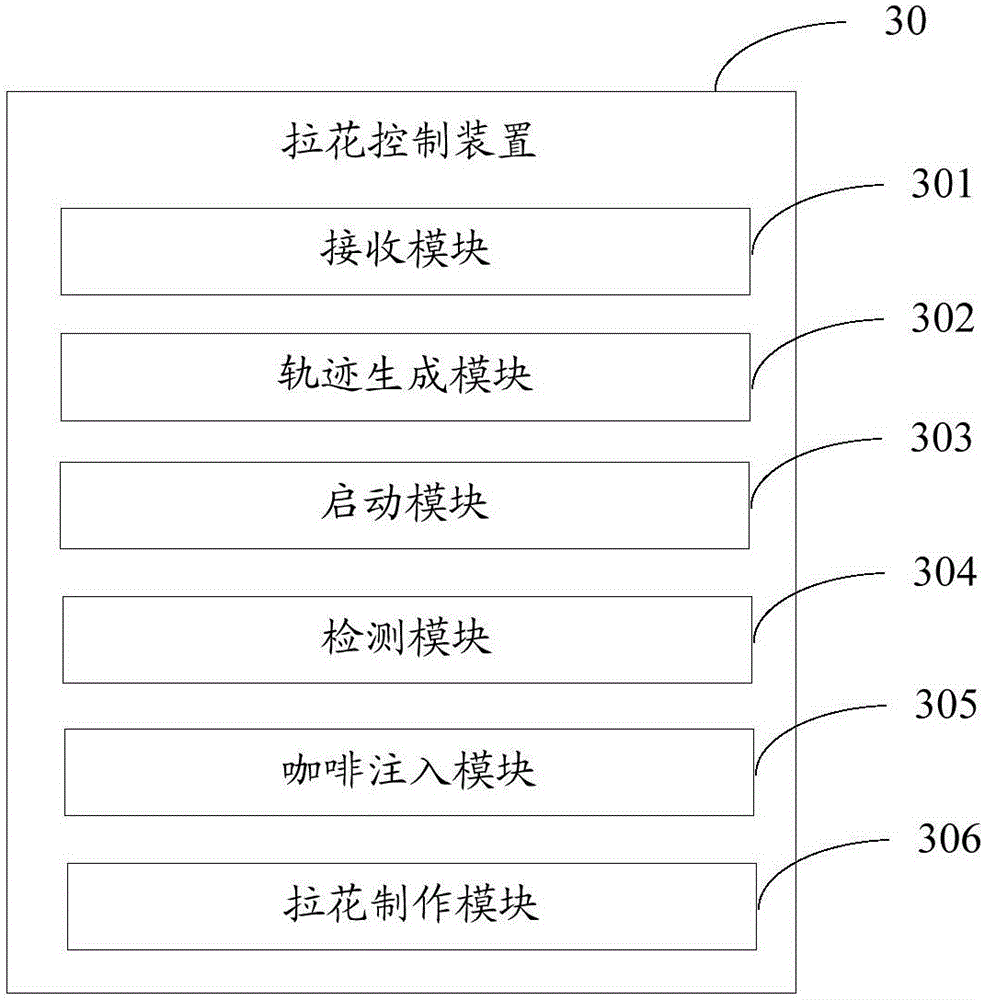

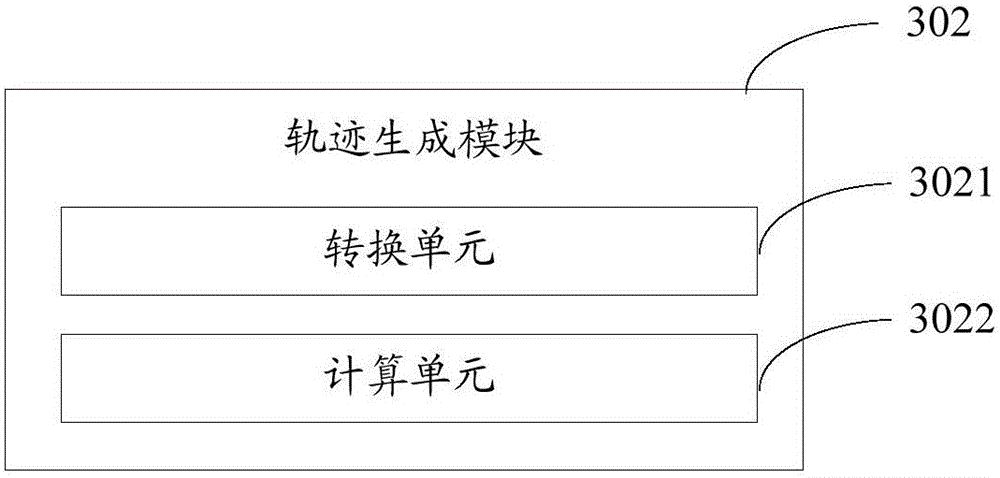

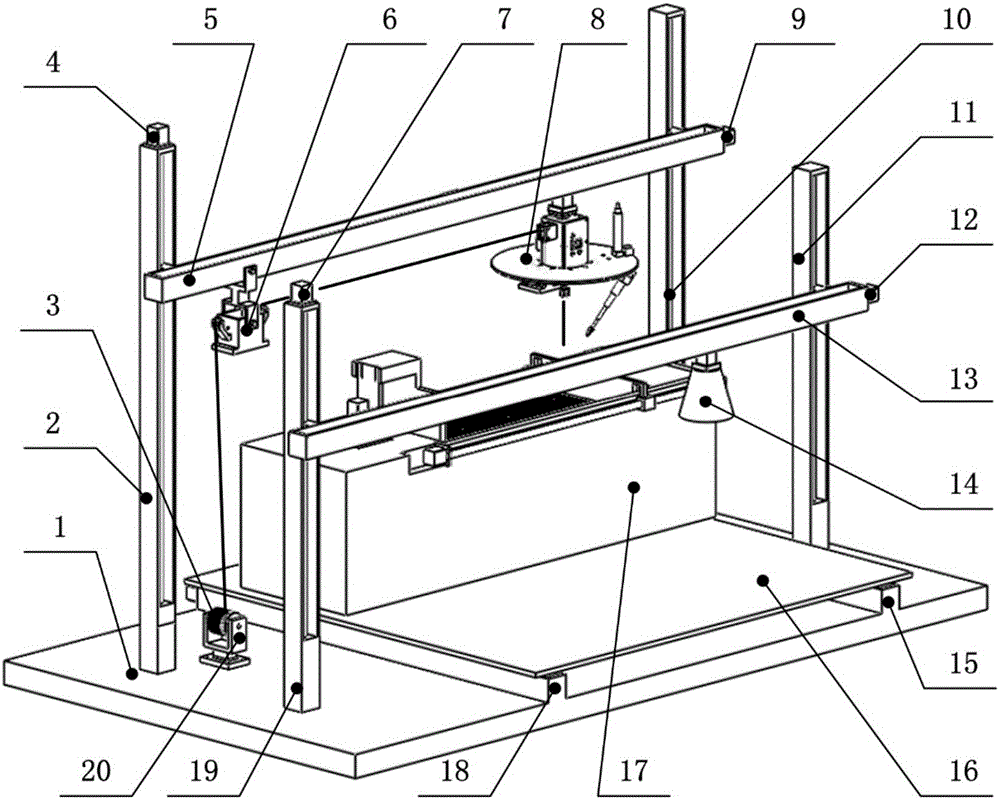

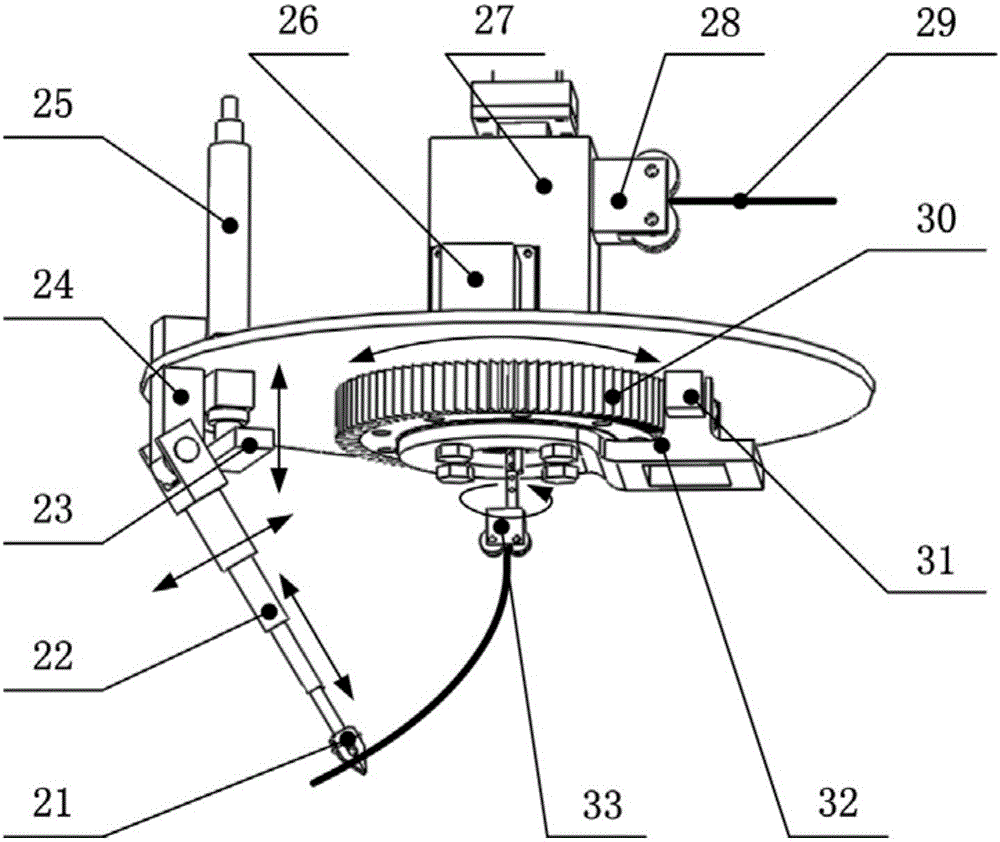

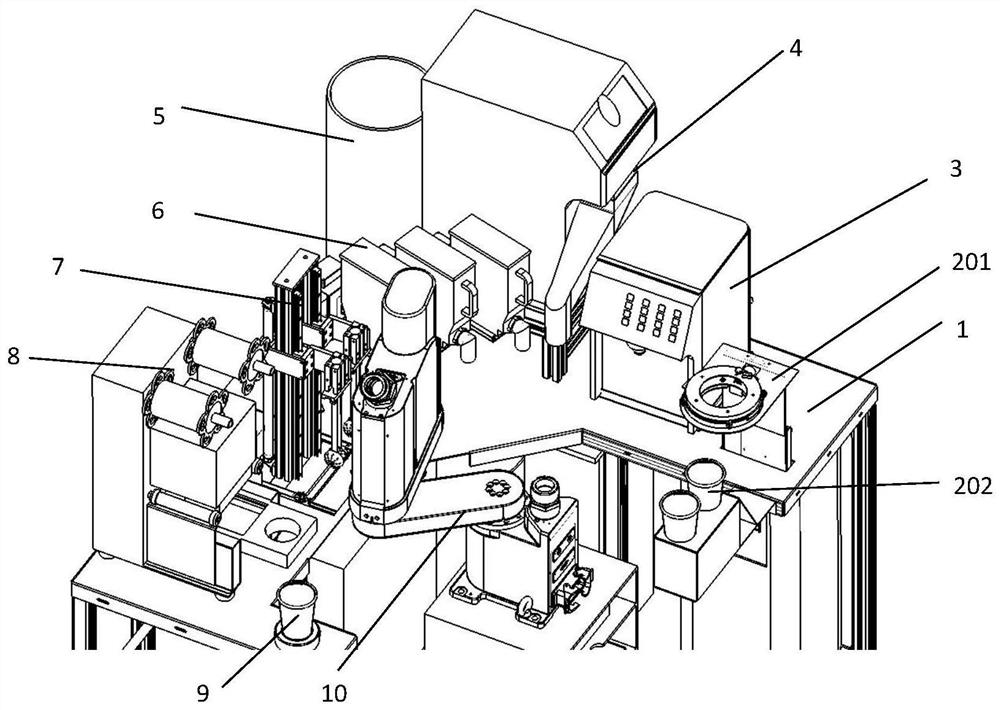

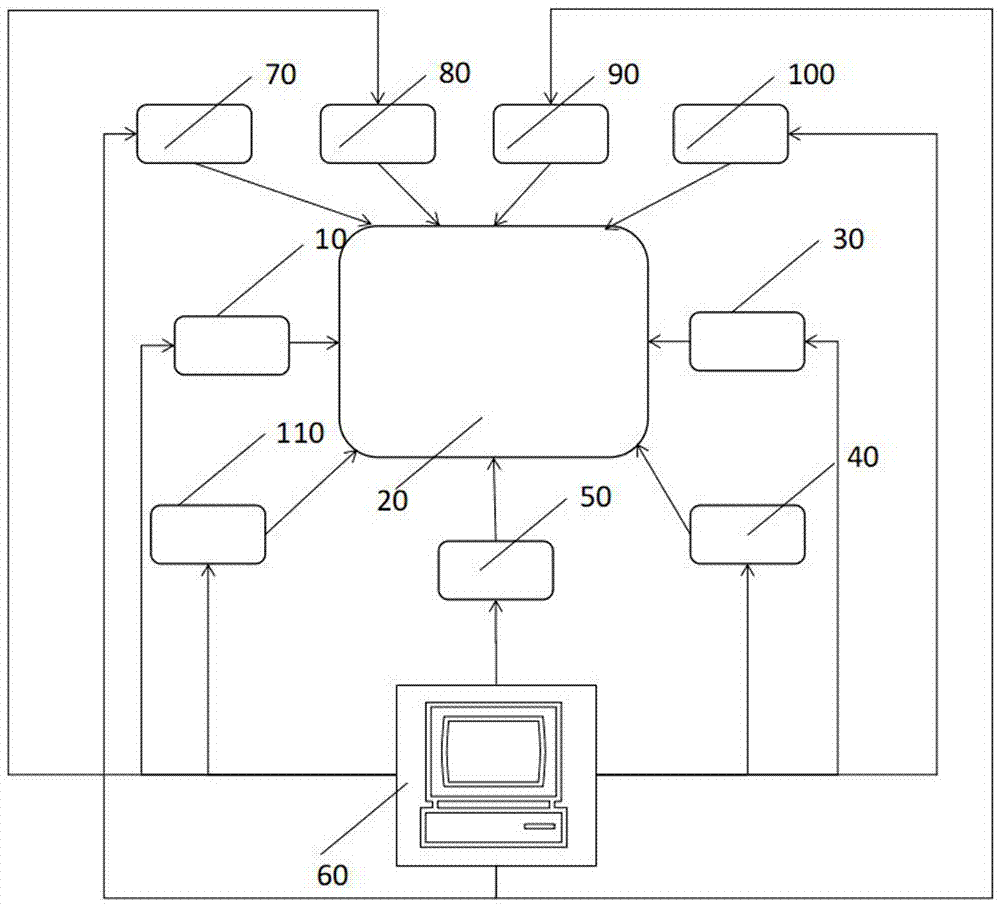

Coffer maker, system and method for preparing latte art coffee

The invention discloses a coffee machine, which at least includes a coffee brewing device, a milk frothing device, a pattern control device and a pattern head. The garland control device includes: a receiving module, used to receive coffee garland graphics and / or start instructions; a track generation module, used to generate a movement track for controlling the movement of the garland head; a start module, to start the coffee brewing device and the milk frothing device Prepare coffee and milk froth; detection module, used to detect the completion signal of coffee and milk froth; coffee injection module, used to control the coffee brewing device to inject coffee into the preset container; garland production module, used to control the garland head Inject milk foam into the container and control the movement of the deco head according to the movement track to form a coffee deco. The invention also discloses a coffee machine system and a method for making coffee latte art. The invention can realize the automatic production of coffee latte art, thereby enriching the functions of the coffee machine, and at the same time avoiding the tedious and complicated manual production of coffee latte art by the user.

Owner:ZTE CORP

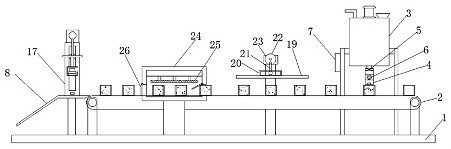

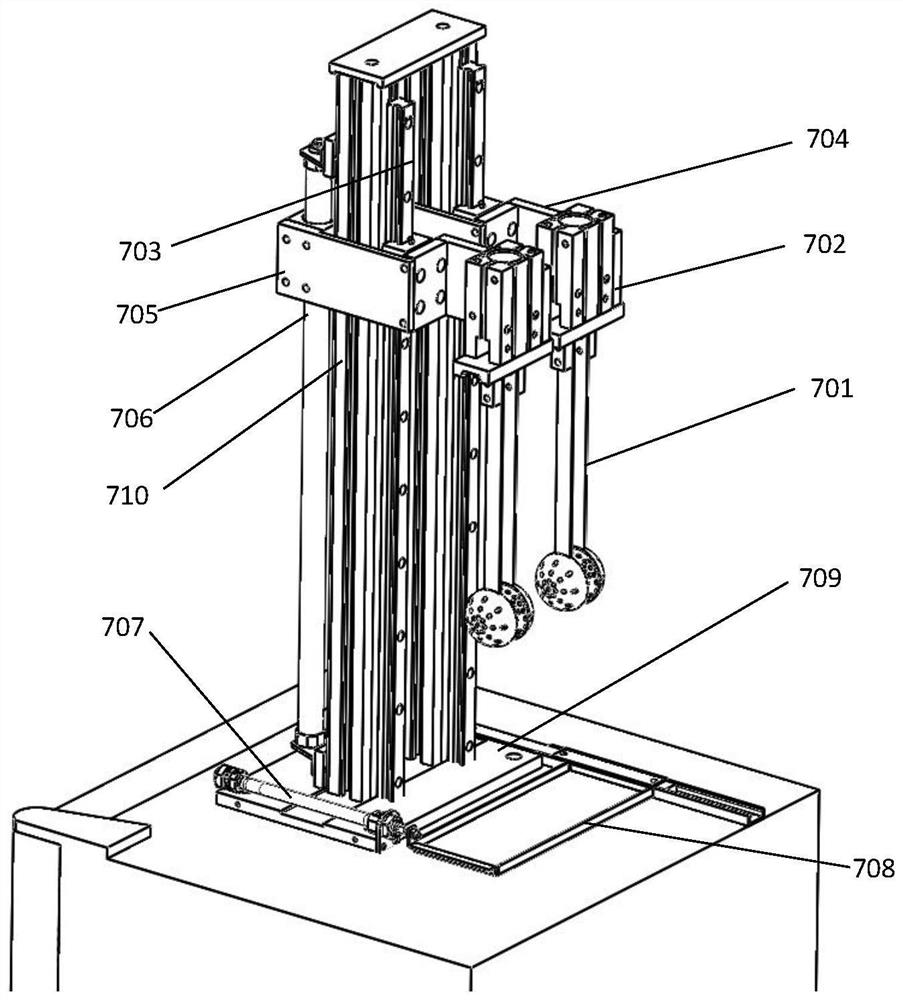

Carbon fiber sensing element embedding device and method based on rapid prototyping manufacturing technology

ActiveCN105881902ARealize automated manufacturingAdditive manufacturing apparatusFiberManufacturing technology

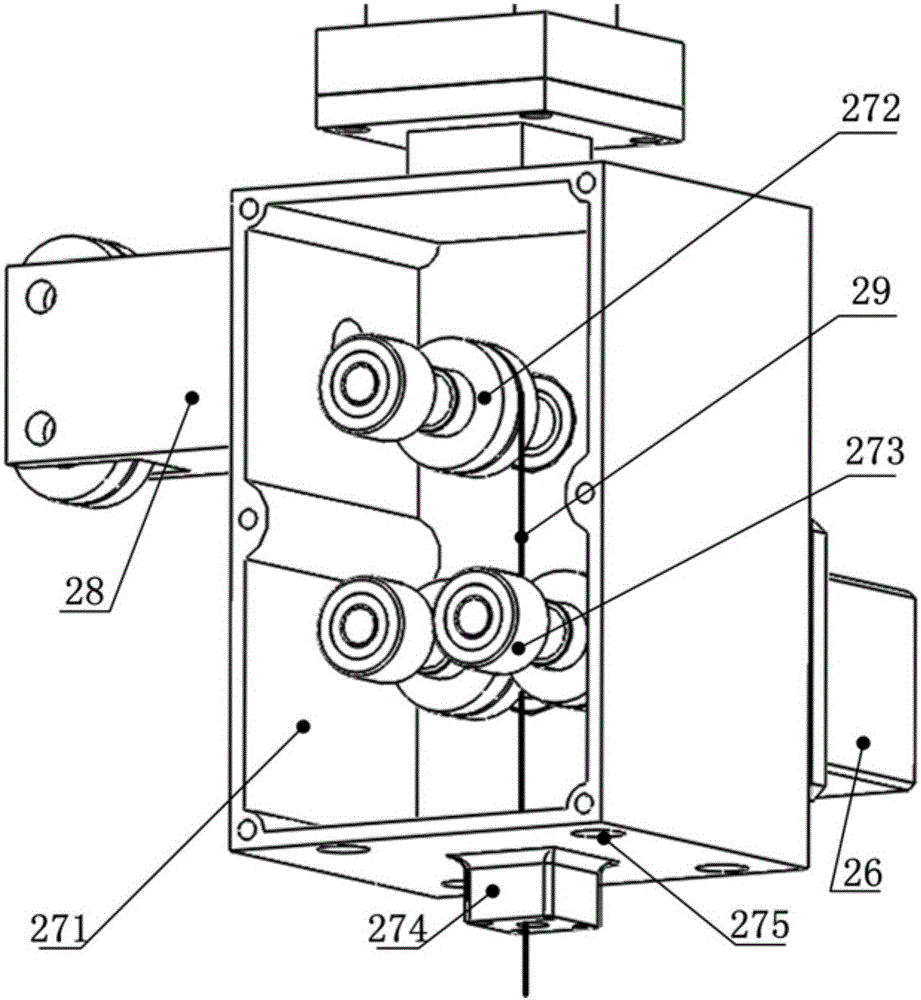

The invention discloses a carbon fiber sensing element embedding device based on the rapid prototyping manufacturing technology. The carbon fiber sensing element embedding device comprises a workbench, a lifting and horizontal moving module, a horizontal moving platform, a silk storage module, a silk placement module, a silk breaking module and a fiber silk fixing module, wherein the lifting and horizontal moving module is installed on the workbench; the horizontal moving platform is used for installing and moving any superimposed layer of a rapid prototyping manufacturing structure; the silk placement module is installed at the power output end of the lifting and horizontal moving module and used for pulling and embedding fiber silks from the silk storage module in any superimposed layer of the rapid prototyping manufacturing structure; the silk breaking module is used for cutting the tails of the fiber silks embedded in the rapid prototyping manufacturing structure; and the fiber silk fixing module is used for fixing the fiber silks in the embedding initial position. The invention further discloses a carbon fiber sensing element embedding method based on the rapid prototyping manufacturing technology. According to the carbon fiber sensing element embedding device and method based on the rapid prototyping manufacturing technology, by arranging the silk placement module and the horizontal moving platform, the fiber silks can be rapidly, effectively and automatically embedded in an entity structure, and a self-monitoring intelligent structure is automatically manufactured.

Owner:ZHEJIANG UNIV

Natural resource element level product manufacturing method and system

InactiveCN104951567AImprove the preparation effectHigh precisionFile access structuresGeographical information databasesNatural resourceThematic map

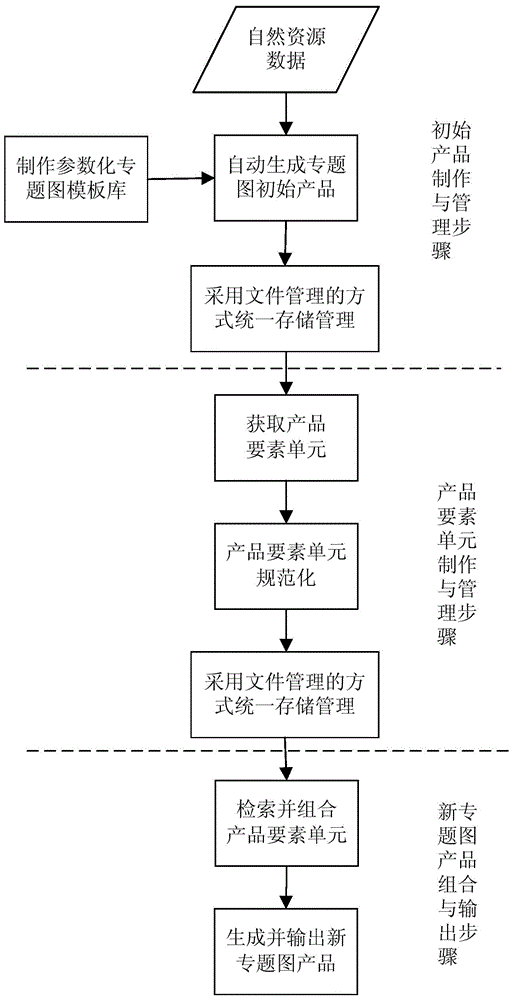

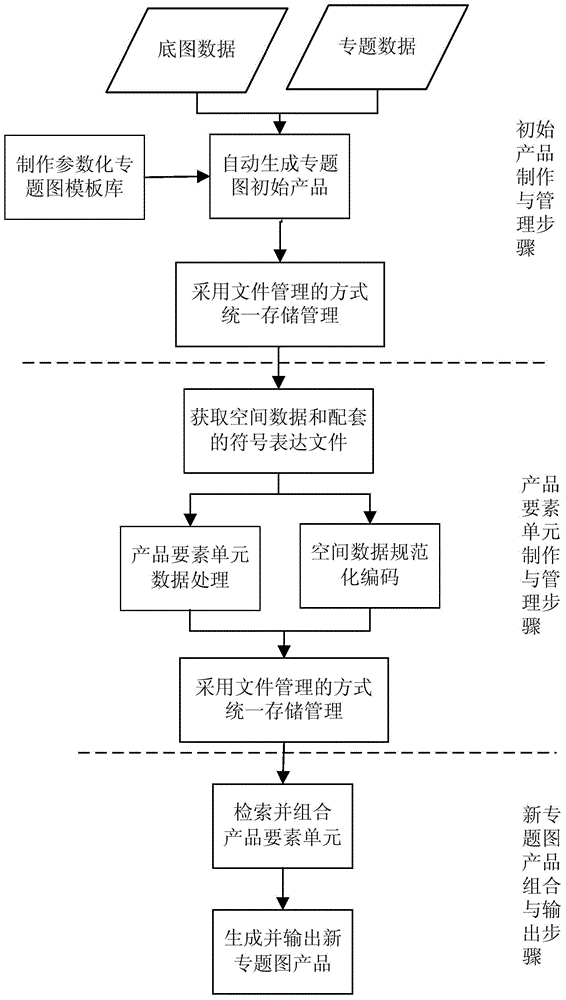

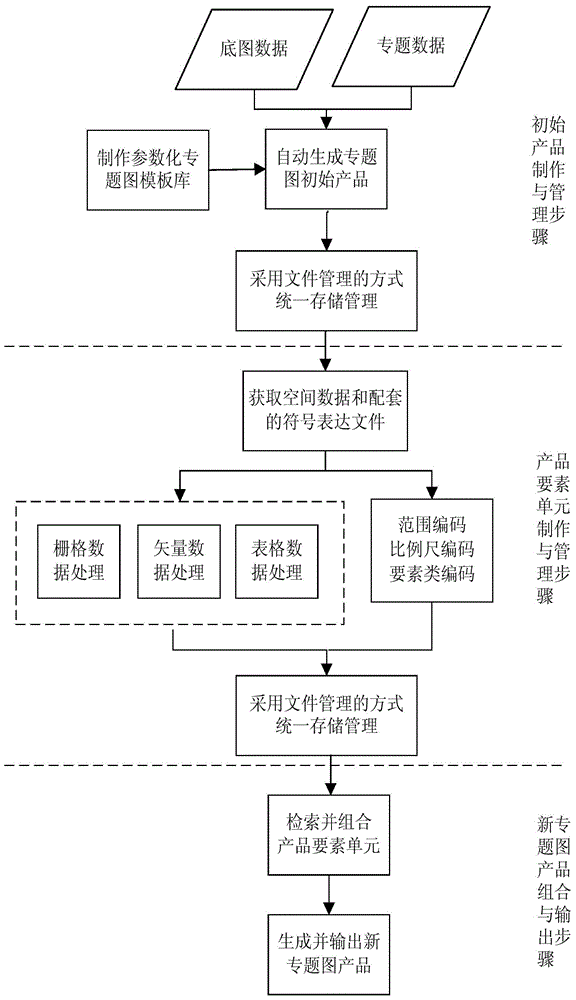

The invention relates to a natural resource element level product manufacturing method. The method comprises an original product manufacture and management step, a product element unit manufacture and management step and a new thematic map product combination and output step. Firstly, a parameterized thematic map template library is manufactured, collected natural resource data are loaded to generate thematic map original products automatically, and the generated thematic map original products are stored and managed unifiedly; product element units are obtained, subjected to normalized data processing and normalized encoding and unifiedly stored and managed in a file management manner; association retrieval of target product names of the unifiedly stored and managed product element units is established on the basis of an engine retrieval technique, and the required product element units generate and output new thematic map products after combined. With the adoption of the method, automation and parameterization of GIS (geographic information system) thematic map product manufacture are realized, and the manufacture effect, precision and efficiency of the natural resource element level products are greatly improved.

Owner:国家信息中心

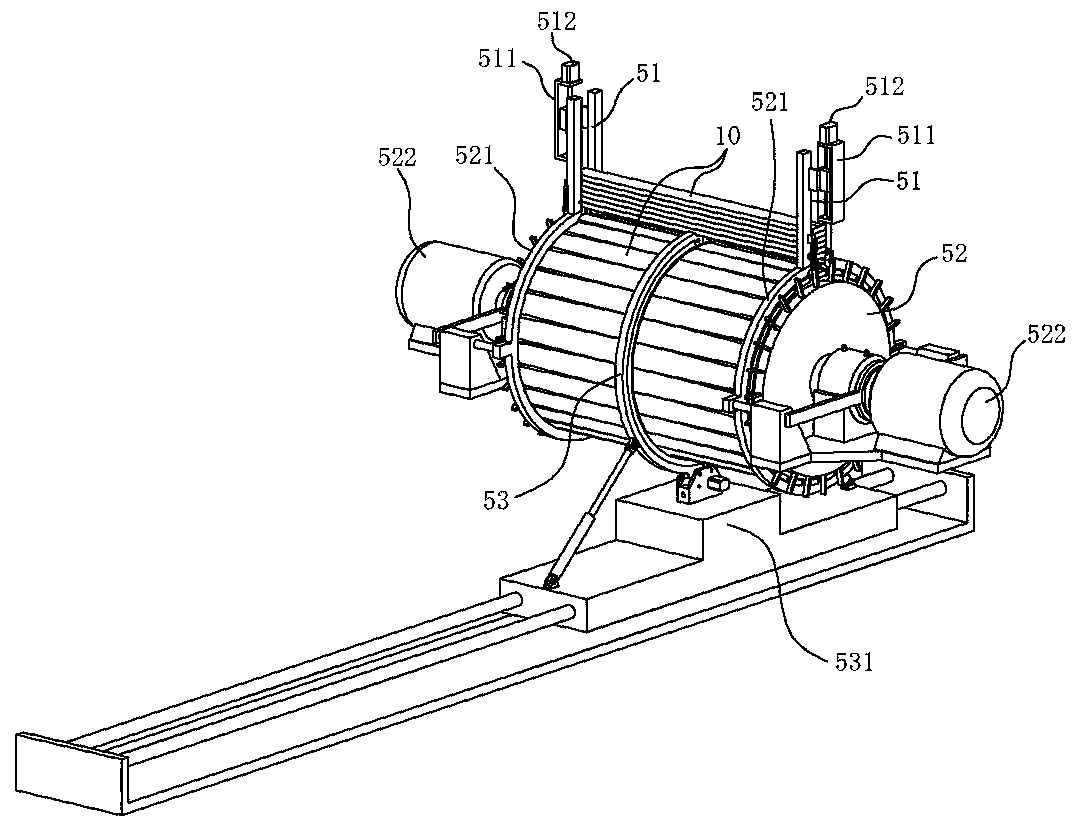

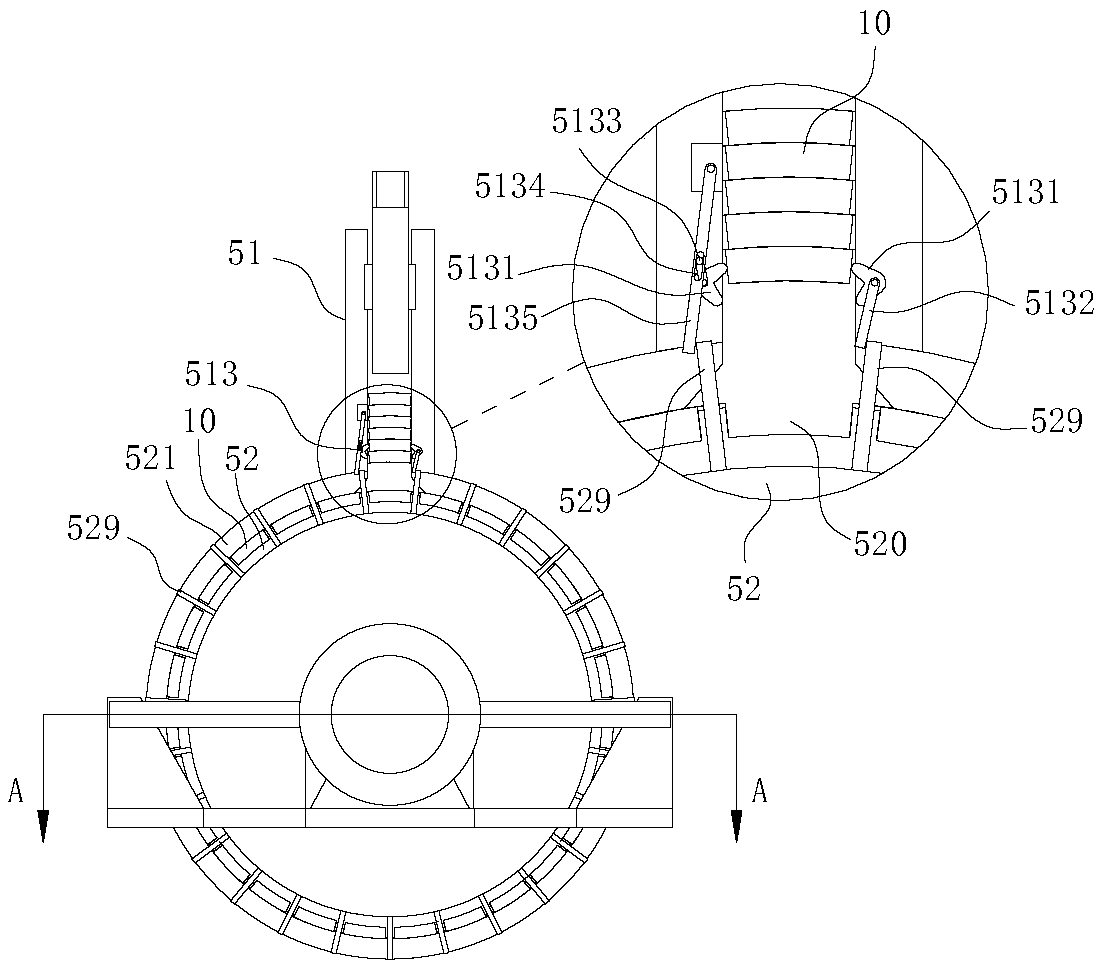

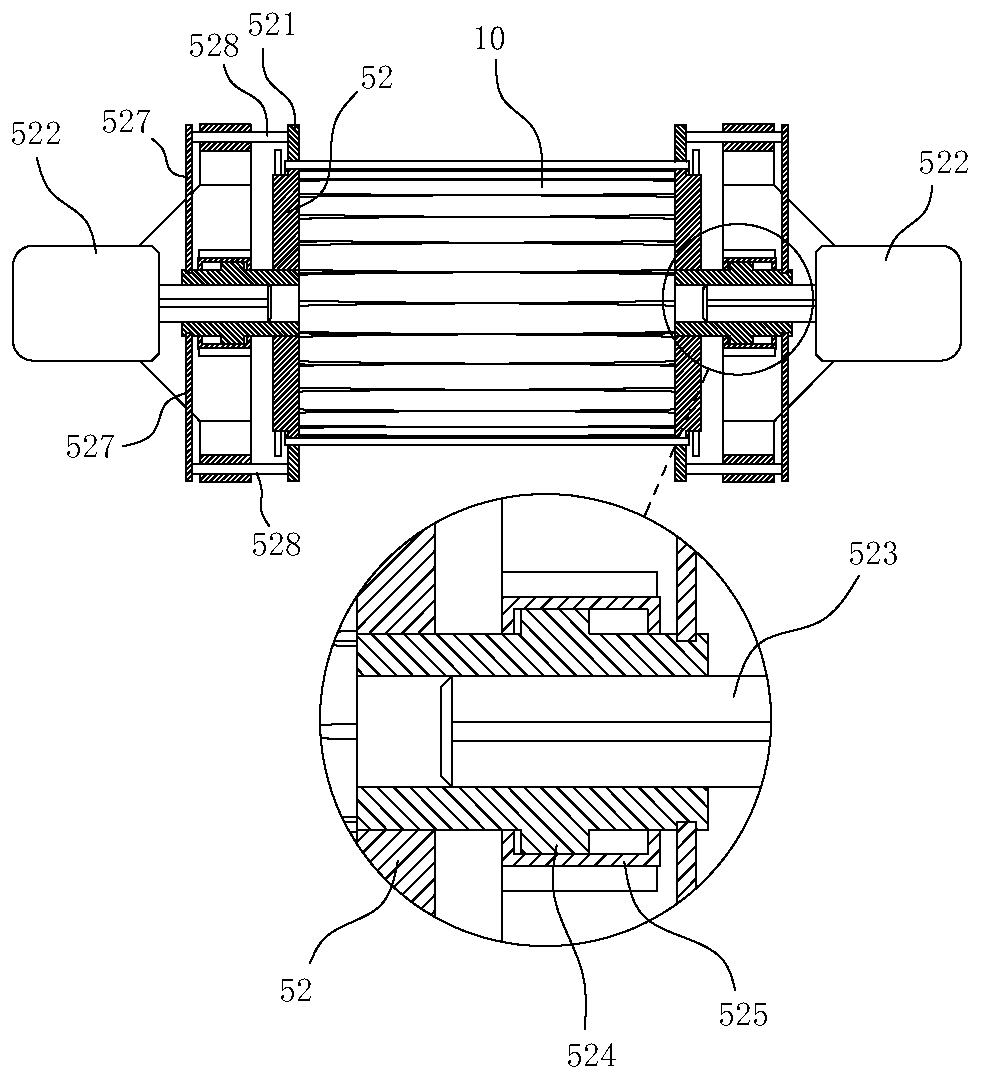

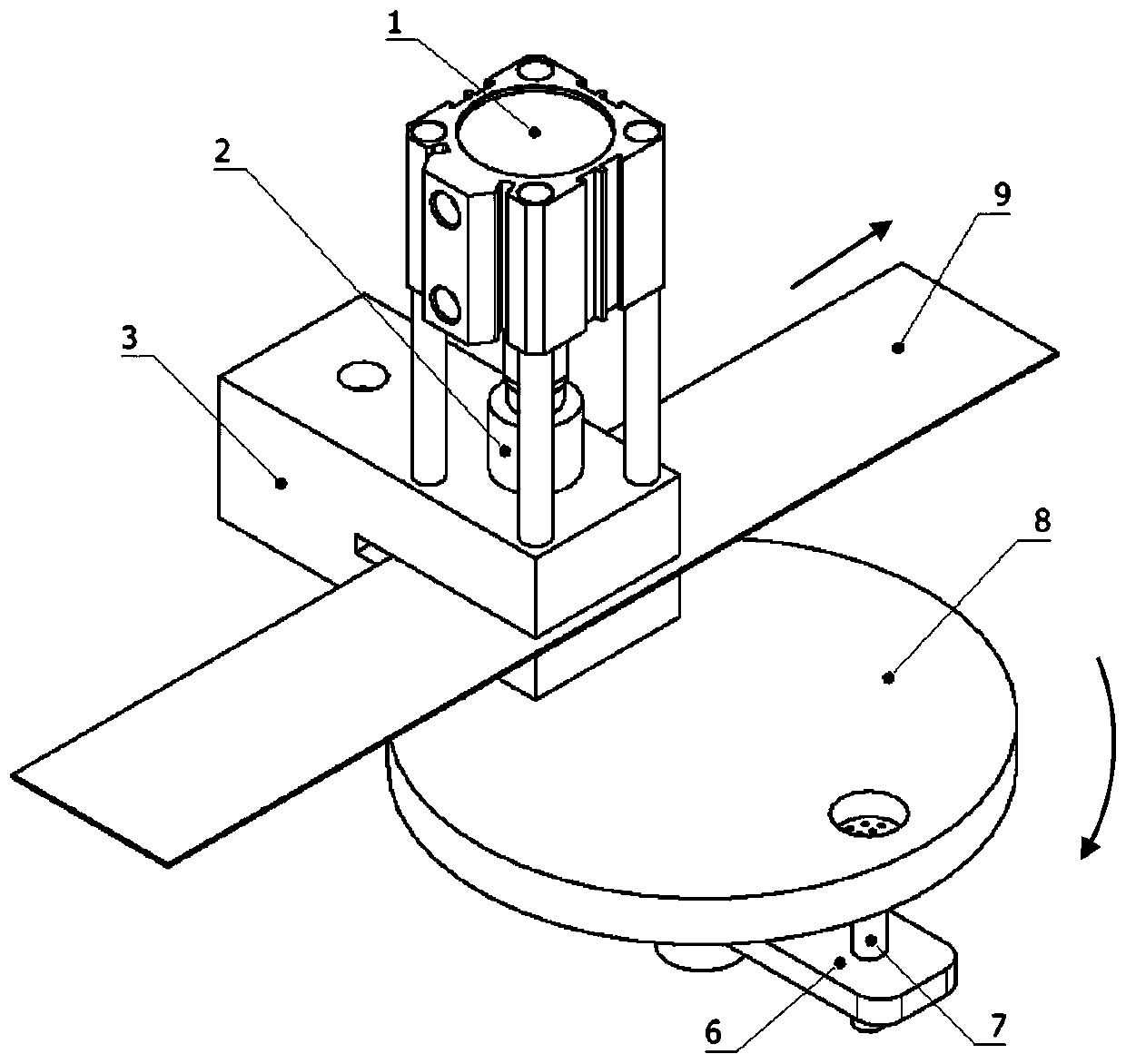

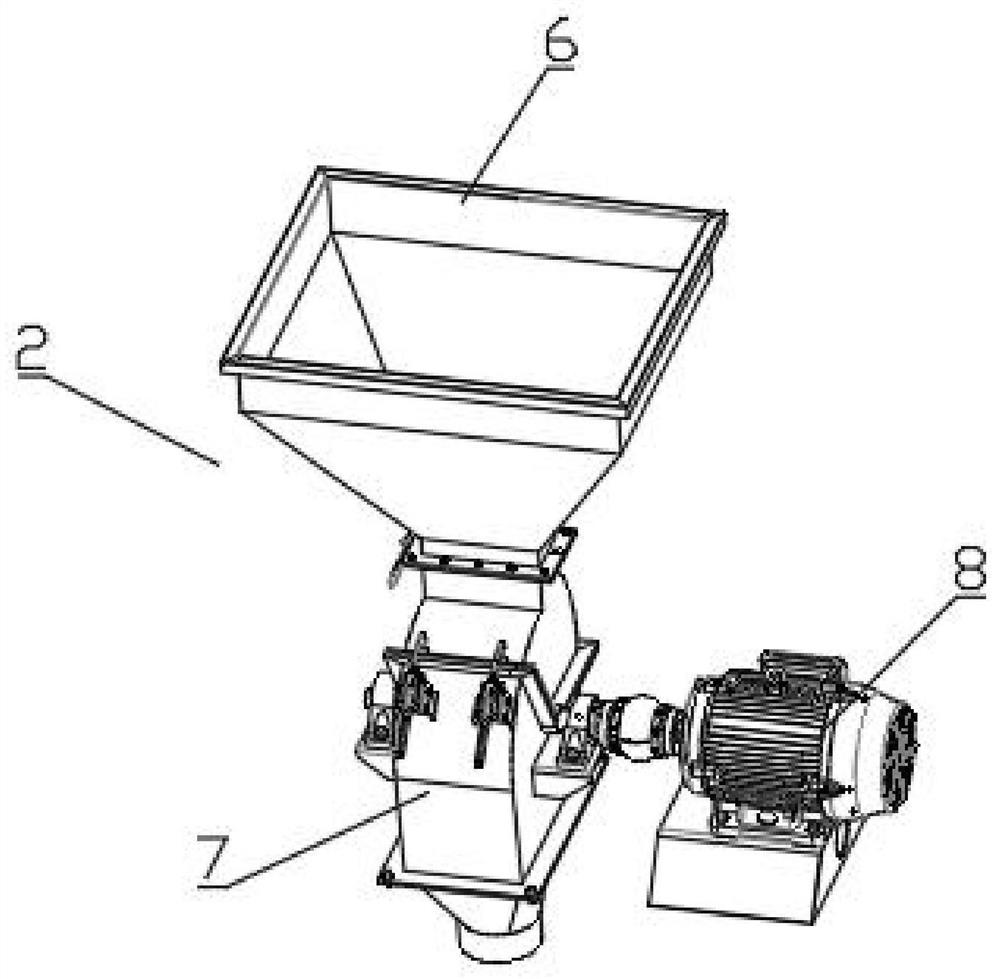

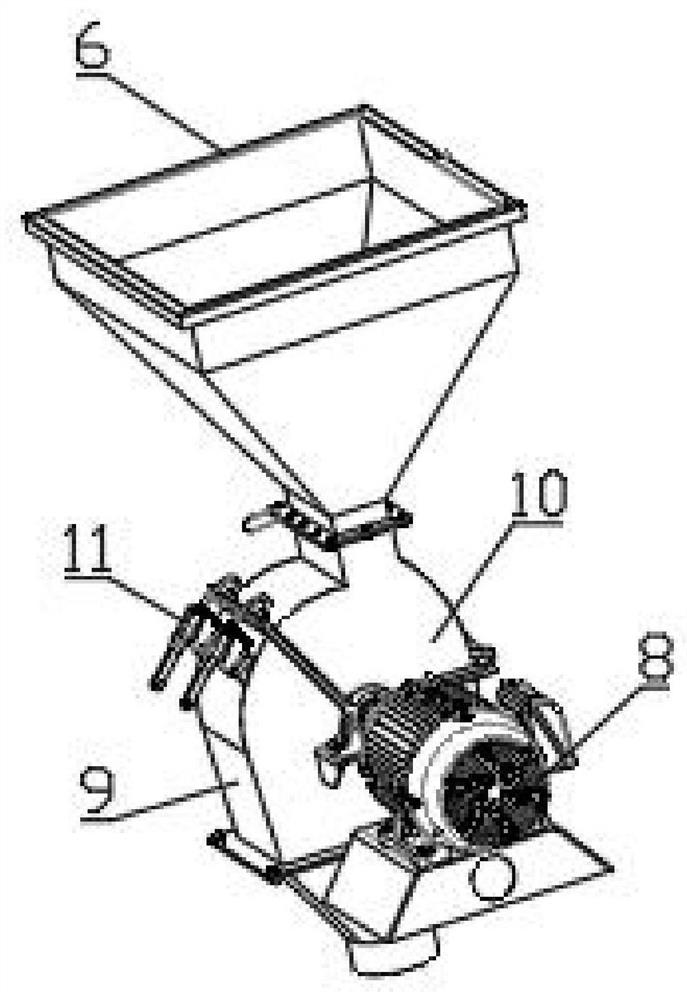

Cask material arranging and press-fitting system

ActiveCN110216754ARealize automated manufacturingIncrease productivityWood working apparatusConveyor partsInterference fitEngineering

The invention belongs to the field of wine cask manufacturing and processing, and particularly relates to a cask material arranging and press-fitting system. The system comprises an arranging device,a transfer device and a press-fitting device, wherein the arranging device comprises a storage tank and an arranging roller, the transfer device is positioned between the arranging device and the press-fitting device and is used for transferring the annular cask wall arranged by the arranging device to the press-fitting device, the press-fitting device comprises a cask turnover mechanism, a hoop feeding mechanism and a press-fitting mechanism, wherein the cask turnover mechanism is used for overturning the cylindrical annular cask wall into a conical annular cask wall, the hoop feeding mechanism is used for transferring hoops to the small-diameter end of the conical annular cask wall one by one, and the pressing mechanism is used for pushing the hoops from the small-diameter end of the annular cask wall to the large-diameter end of the annular cask wall, so that the hoops are arranged on the annular cask wall in a sleeved mode and are in interference fit with the annular cask wall. Thecask material arranging and press-fitting system has the technical effects that the automatic distribution, transfer and hoop press-fitting of the cask material can be realized, so that the automaticmanufacturing of the cask wall is realized, the production efficiency and the consistency of products are improved.

Owner:合肥秋力鸣家具有限公司

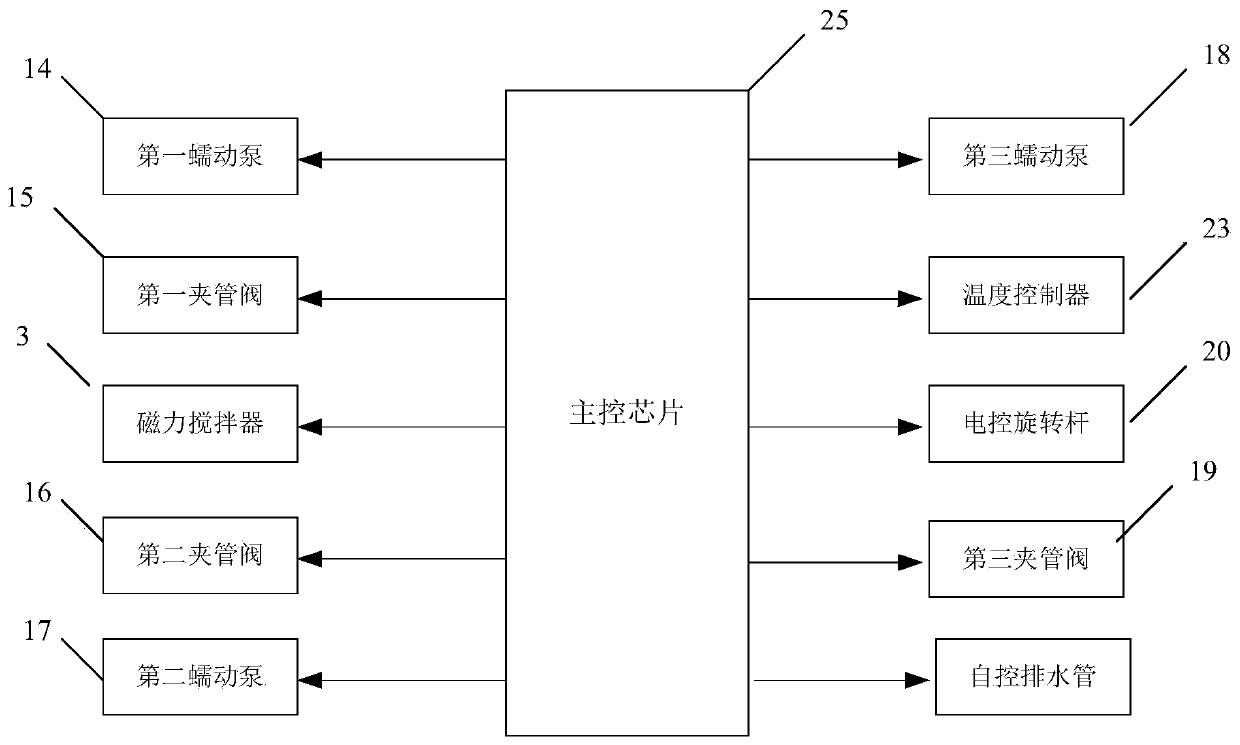

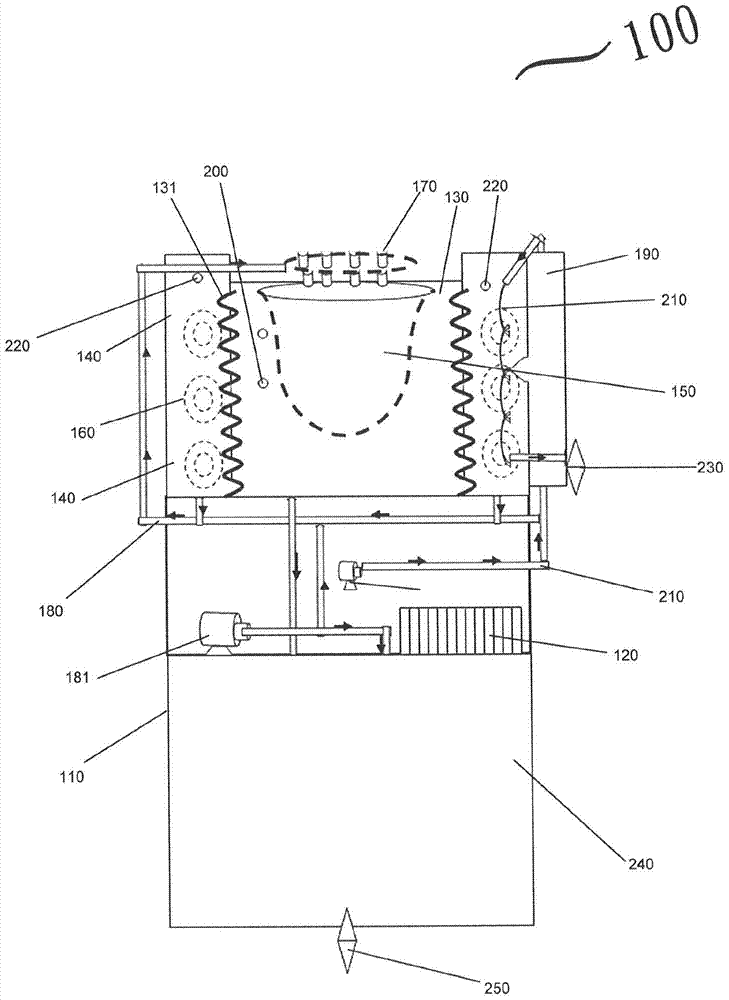

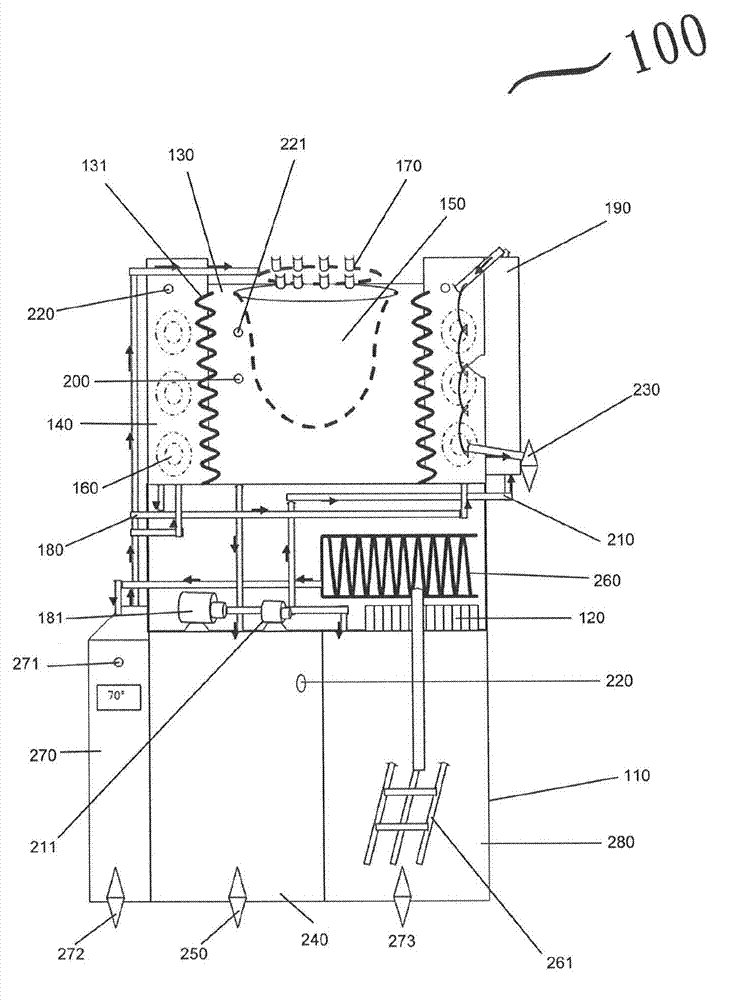

Fluid synthesis preparation device for preparing Fe3O4 magnetic nanoparticles, and control method thereof

ActiveCN110156090ARealize automated manufacturingReduce decreaseFerroso-ferric oxidesFluid controlMagnetite Nanoparticles

The invention relates to a fluid synthesis preparation device for preparing Fe3O4 magnetic nanoparticles, and a control method thereof. The defect that devices capable of preparing the Fe3O4 magneticnanoparticles do not exist in the prior art is overcome. The device comprises a first micro-reaction chamber assembly and a second micro-reaction chamber assembly, the first micro-reaction chamber assembly comprises a first micro-reaction chamber, the upper end of the first micro-reaction chamber is connected with an ethylene glycol supply tube, the bottom of the first micro-reaction chamber is funnel-shaped, the first micro-reaction chamber is placed on a magnetic stirrer, a sieve plate is arranged in the first micro-reaction chamber, a magneton is placed on the sieve plate, the front end ofa silicone tube is connected to the bottom of the first micro-reaction chamber, and the tail end of the silicone tube is connected to the upper end of the second micro-reaction chamber assembly. The preparation device capable of synthesizing the Fe3O4 magnetic nanoparticles cooperates with the fluid control method based on a pump valve to realize automatic preparation of the Fe3O4 magnetic nanoparticles.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

Hong Kong style milk tea making device

ActiveCN104706216AEfficient refrigeration unitShorten heating timeBeverage vesselsProcess engineeringHeating system

The invention discloses a Hong Kong style milk tea making device. The device comprises a shell, a control unit arranged in the shell, a tea making unit and a milk making unit, wherein the tea making unit comprises two water tanks, a circulating pipeline system and a temperature detecting device so that tea baking and tea impacting can be completed at a constant temperature. The milk making unit comprises a milk heating system for a container for containing milk used for making tea milk so that the milk in the container can be heated to a preset temperature. Through the Hong Kong style milk tea making device, tea baking and tea impacting can be performed at the constant temperature, and on the basis of the heat transfer principle, the evaporated milk is heated through a control valve and the control unit so that the purposes of sterilization and disinfection can be achieved. The Hong Kong style milk tea making device is further provided with a part for making frozen milk tea, hot tea water is frozen through a freezing and refrigerating device, heat released when the tea water is cooled is absorbed through a heat source collecting device, and then, the device is cooled through circulating water. Electricity is saved to a large extent due to the device, hot and cold milk tea can be automatically made, and labor cost can be saved to the maximum extent.

Owner:乔扬科技发展有限公司

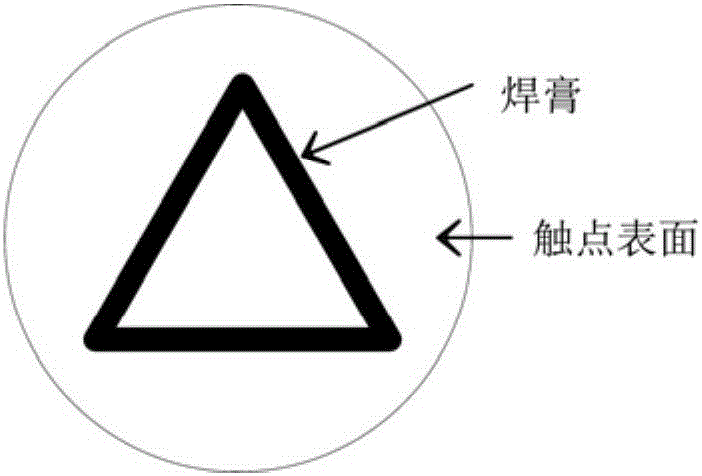

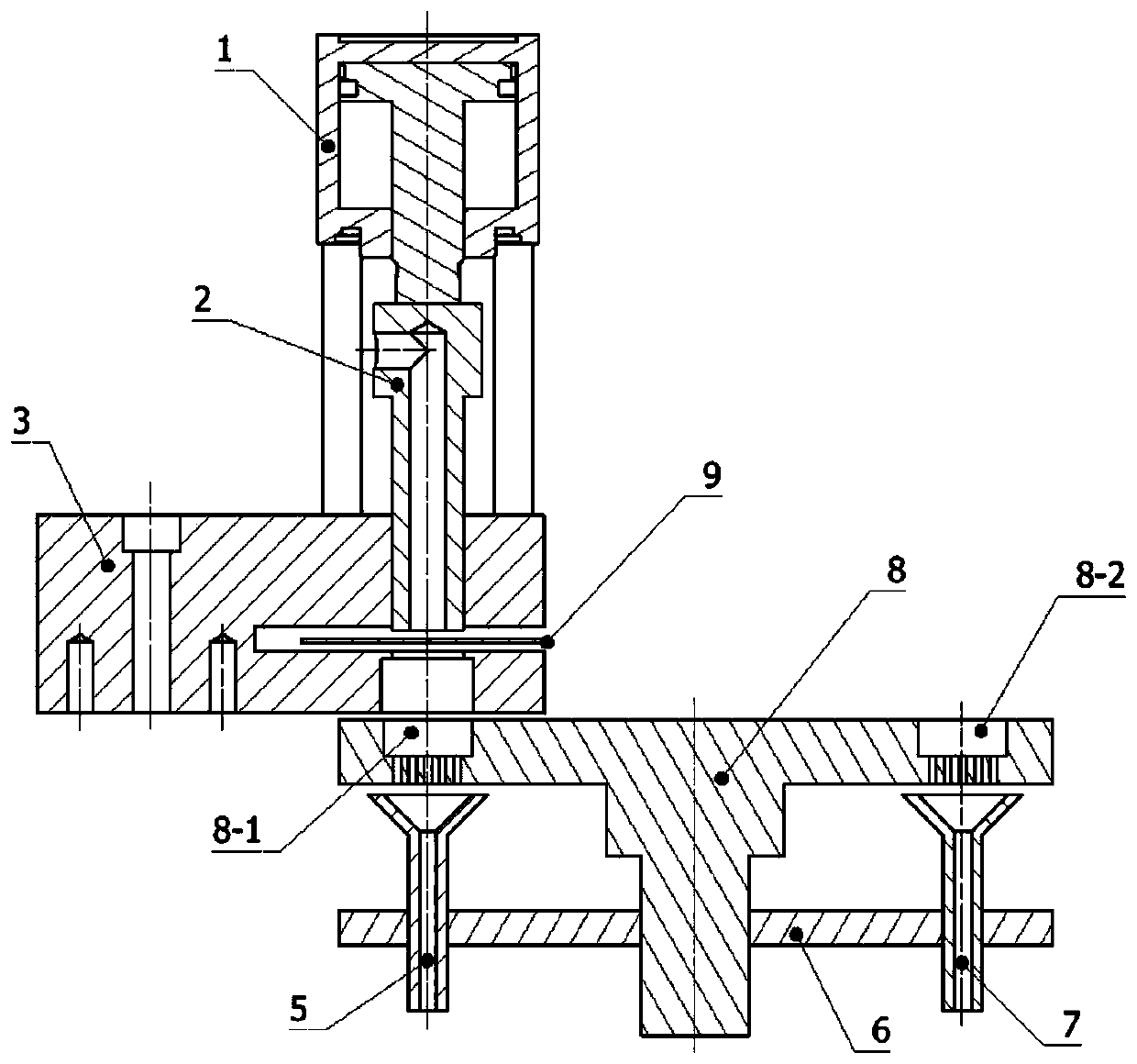

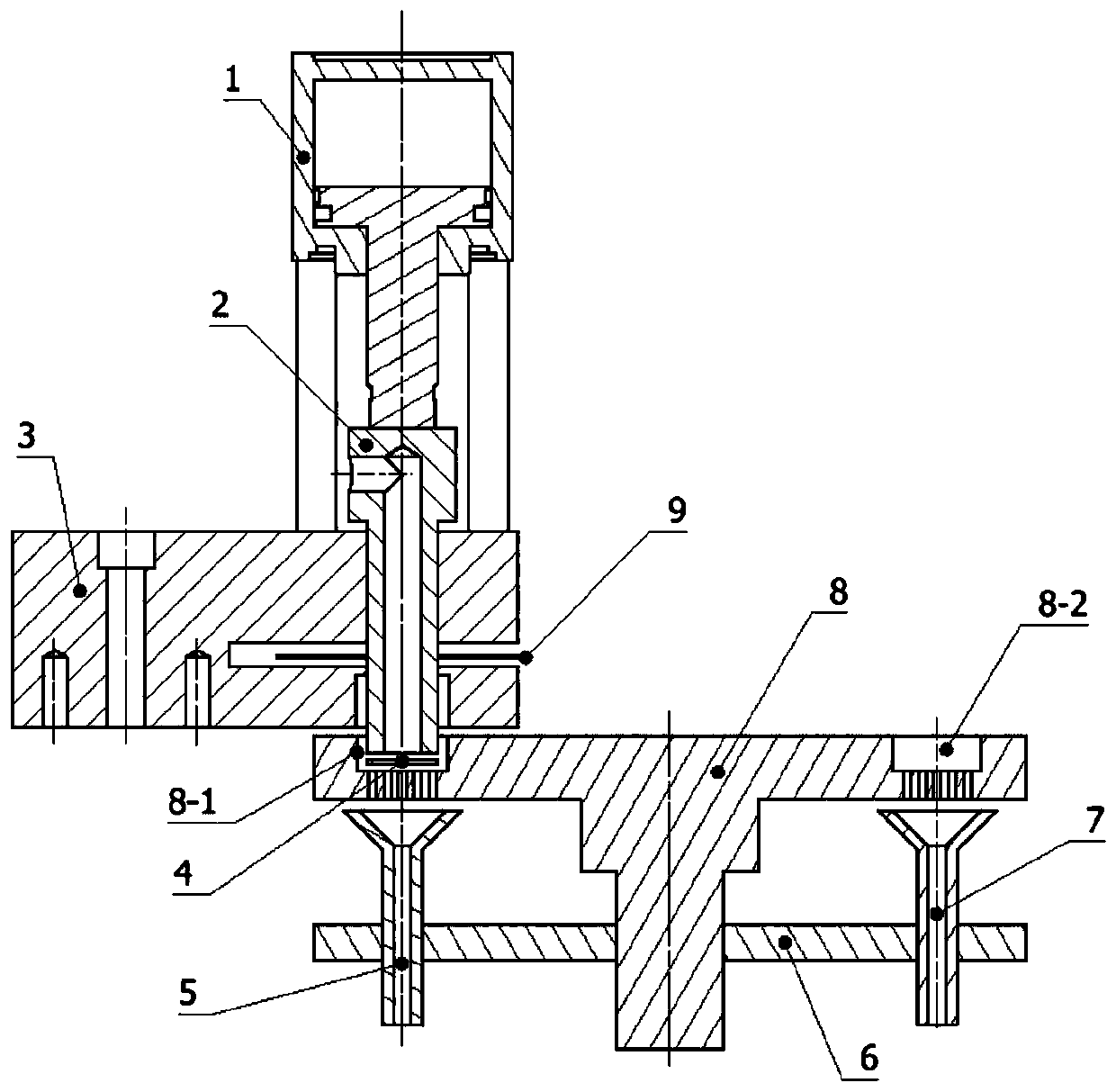

Method for coating brazing filler metal layer

InactiveCN106216793ARealize automated manufacturingRealize automatic continuous weldingSoldering apparatusWelding/soldering/cutting articlesMetallurgySolder paste

The invention provides a method for coating a brazing filler metal layer. The method comprises the steps that firstly, the surface of a contact is painted with soldering paste, specifically, painting is achieved by adopting manual pasting equipment or automatic pasting equipment for quantitative and fixed-point pasting; and secondly, the soldering paste is heated, so that the soldering paste melts and spreads after being heated, and the brazing filler metal layer is formed on the surface of the contact. According to the method, quantitative and fixed-point accurate painting of the soldering paste can be achieved through an automatic pasting system, and efficient pre-coating of the brazing filler metal layer is achieved. Besides, flux can be evenly mixed in the soldering paste, the flux is stilled reserved after the soldering paste melts and spreads, thus, welding can be directly carried out after the contact is coated with the brazing filler metal layer, and no extra brazing filler metal or brazing flux needs to be added; and continuous automation can be achieved in the welding process, so that the labor cost is greatly reduced.

Owner:SHANGHAI HIWAVE COMPOSITE MATERIALS CO LTD

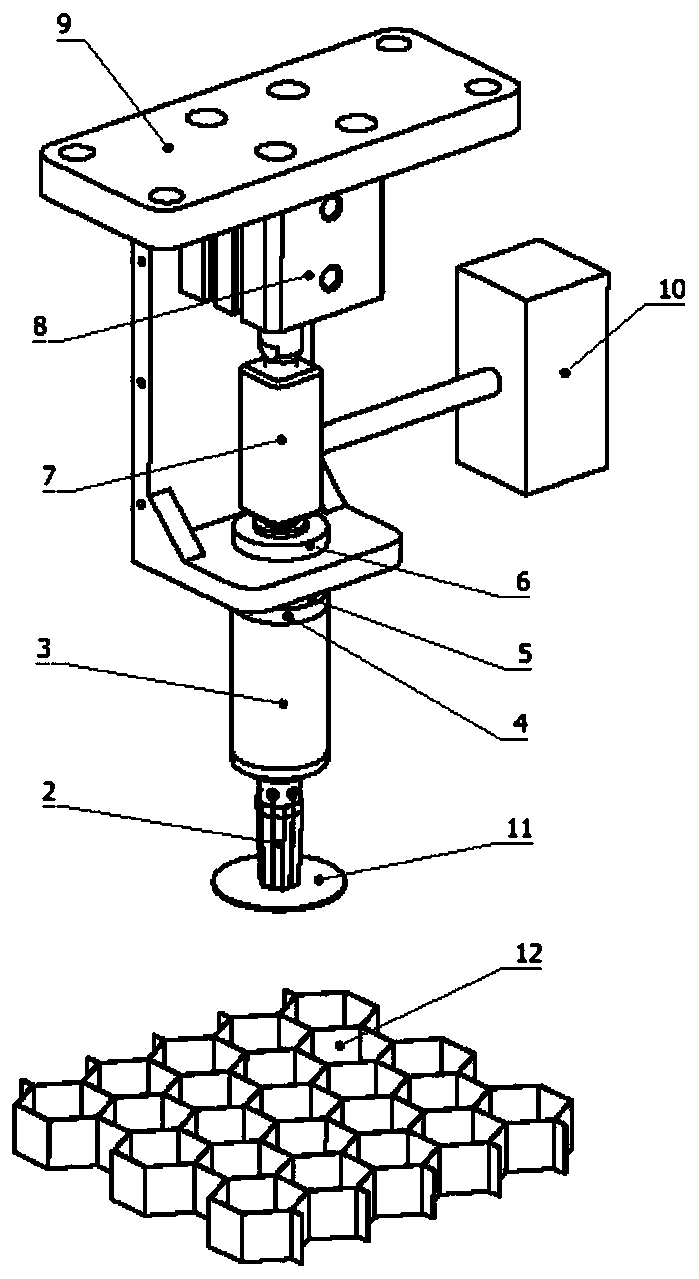

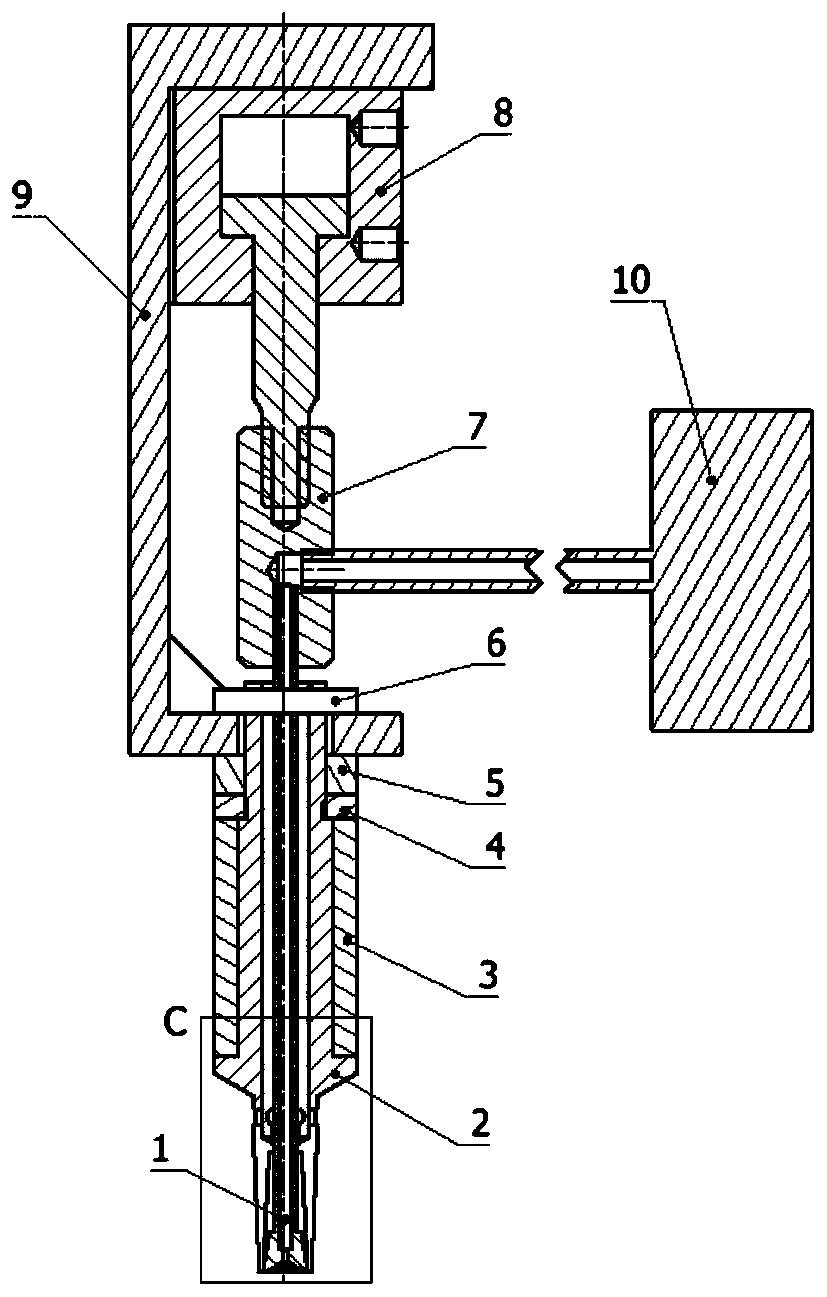

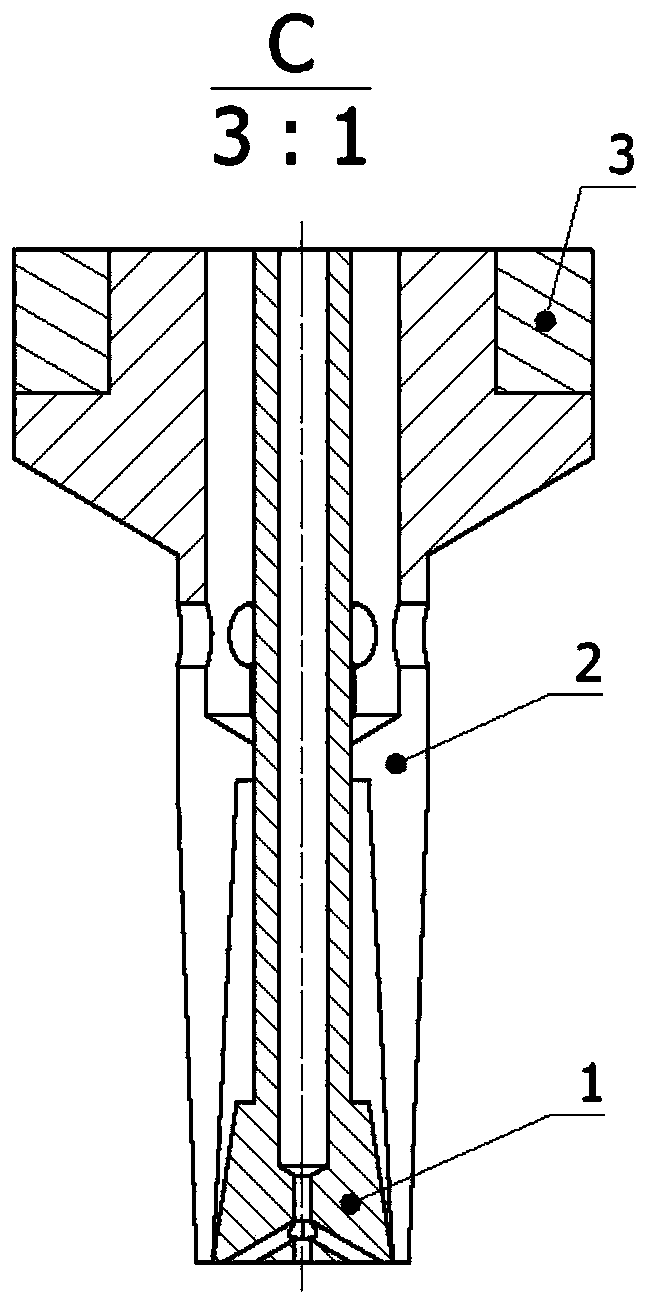

Automatic preparation device and method for composite honeycomb silencing cap blank

ActiveCN111206408ASolve the problem of difficult accurate blankingSolve the problem of easy falling off and wrinklingSevering textilesHoneycombMechanical engineering

The invention belongs to the technical field of intelligent manufacturing, and relates to an automatic preparation device and method for a composite honeycomb silencing cap blank. The invention provides the automatic preparation device and method for the composite honeycomb silencing cap blank. By setting the inside of a stamping knife as a hollow structure, air suction can be carried out to absorb the blank, and air blowing is carried out to blow down the blank so as to ensure that the blank is accurately transported out and meanwhile, is not adhered to the stamping knife, thereby solving problems of poor consistency, low efficiency and urgency of upgrading automatic equipment, which are caused by a case that currently, the composite honeycomb silencing cap blank is depended on manual shearing. The blank uses a woven fabric as a raw material, and has the characteristics that the blank is soft in texture, easy to generate burrs, easy to wrinkle, has static electricity and the like; thecut blank has problems that a falling position is random, the blank is easy to adhere to other articles in the falling process, the blank cannot be accurately blanked, the stamping knife is easy to take up the blank when moving up and the like; and the cut blank has problems that the blank is easy to fly off and the like in the blank transferring process; and automatic preparation of the composite honeycomb silencing cap blank is implemented.

Owner:CHINA PRECISION ENG INST FOR AIRCRAFT IND AVIC

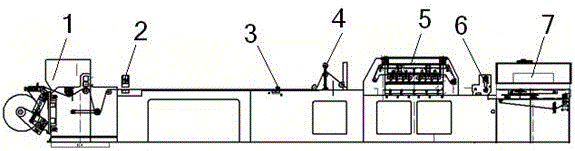

Manufacturing method and system device of aluminum foil port sealed air bag

PendingCN106696346AImprove production efficiencyPracticalPaper-makingBox making operationsPunchingAssembly line

Disclosed is a mechanical manufacturing method and device of an aluminum foil port sealed bag. According to the manufacturing processes of the aluminum foil port sealed bag, part of the processes which have large difficulty and low efficiency in manual production are arranged, and by means of an assembly line mode, automatic processing and manufacturing are achieved. The automatic processing and manufacturing comprises at least seven processes of feeding, punching, silica gel mounting, automatic shaping and edge-folding, middle sealing, cutting-off and end sealing. Feeding, punching, silica gel mounting, automatic shaping and edge-folding, middle sealing, cutting-off and end sealing are connected in series through the assembly line mode, so that assembly line automated operation of the aluminum foil port sealed bag is achieved. By adopting the automatic assembly line mode, the aluminum foil port sealed bag is manufactured, so that the production efficiency and quality are improved greatly.

Owner:株洲市完全科技有限公司

Automatic preparation and strength testing device for concrete test block for building construction

InactiveCN111610115AImprove stabilityEvenly placedPreparing sample for investigationMaterial strength using repeated/pulsating forcesArchitectural engineeringControl valves

The invention discloses an automatic preparation and strength testing device for a concrete test block for building construction. The device comprises a bottom plate; a conveying belt is arranged above the bottom plate; a stirring box body is arranged at one end of the conveying belt; a discharging device is arranged at the bottom of the stirring box body; the discharging device comprises a discharging pipe; an electromagnetic control valve is arranged on the discharging pipe; a flow meter is arranged on one side of the electromagnetic control valve; a first infrared sensor is fixedly arrangedat one end of the discharging pipe; the electromagnetic control valve, the flow meter and the first infrared sensor are all electrically connected with a controller; and a beating and vibrating device is arranged on one side of the stirring box body and located above the conveying belt. The device has the beneficial effects that the structure is simple, the concrete test block can be automatically prepared, the labor intensity of workers is greatly reduced, meanwhile, the strength of the prepared concrete test block can be tested, and the safety of building use is improved.

Owner:张延东

Composite implantation device of composite honeycomb noise elimination cap

ActiveCN111559086AImprove production efficiency and product qualitySimple installationDomestic articlesHoneycombPumping vacuum

The invention belongs to the technical field of intelligent manufacturing, and relates to a composite implantation device of a composite honeycomb noise elimination cap. Through a mandrel, a deformingbody is stretched to be opened and closed, the implantation device has the shrinking and expanding function, the problem of tight compacting of a noise elimination cap blank and the inner wall of a composite honeycomb is solved, the tail end of the deforming body is designed to a hexagonal cone body with the large upper and the small lower, during expansion, the deforming body can make contact with the hexagonal inner wall of the composite honeycomb as many as possible by more areas, except that the mandrel can stretch the deforming body to shrink and expand, the interior of the mandrel is through and communicates with a vacuum generator, an air hole in the bottom of the mandrel can be vacuumized to suck the blank, a heating ring is mounted on the deforming body, the implantation device can be heated, a rubber layer can be heated and cured, multiple functions of sucking, implanting, blank compacting, rubber layer heating and curing and the like are composited into a whole, the deviceis greatly simplified, production efficiency and product quality are improved, and the automatic implantation of the composite honeycomb noise elimination cap is achieved.

Owner:CHINA PRECISION ENG INST FOR AIRCRAFT IND AVIC

Integral forming method of composite material structural member comprising double-curved-surface profile structure

InactiveCN104369395ARealize automated manufacturingOvercome the disadvantages of not easy demouldingEngineeringPosterior composites

The invention relates to an integral forming method of composite material structural member comprising a double-curved-surface profile structure. The integral forming method comprises the following steps: 1), arranging hydraulic rods around a central spindle, and connecting a wall board assisting tool between each two wall board forming tools through a fastening member after the hydraulic rods are unfolded, where the hydraulic rods are connected with wall board forming tools; 2), bonding a sealing material between the wall board assisting tools and the wall board forming tools; 3), coating a demoulding agent on the outer surface of an integral forming tool, winding prepreg on the surface of the integral forming tool, and making an uncured composite material blank; 4), integrally encapsulating the double-curved-surface composite material blank and the integral forming tool, and utilizing an autoclave for curing and forming; 5), after curing and forming, realizing easy demoulding. By the integral forming method, on the basis that integral forming of the composite material structural member of a machine body tail section structure is realized, effective integral demoulding of the composite material structural member after curing can be realized.

Owner:SHENYANG AIRCRAFT CORP

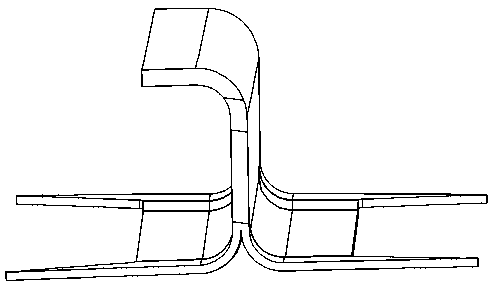

Forming method for J-shaped composite material rib

InactiveCN110385863ARealize continuous bending actionSolve the deformationDomestic articlesEngineeringForming processes

The invention discloses a forming method for a J-shaped composite material rib. The forming method comprises the following steps: laying a prepreg sheet on a left lower pressing block and a right lower pressing block of a bending and forming die; compacting the prepreg sheet by using a left middle layer pressing block and a right middle layer pressing block; drawing the prepreg sheet by using a drawing bar and bending the prepreg sheet into an n labyrinth shape; cutting the prepreg sheet in the n labyrinth shape to form a labyrinth-like shape; removing the drawing bar and moving the left lowerpressing block, the right lower pressing block, the left middle layer pressing block and the right middle layer pressing block to the middle and compacting the prepreg sheet into a T shape; and translating an upper layer pressing block and bending T-shaped prepreg into in a J shape. Compared with the prior art, the production of C-shaped preforms and Z-shaped preforms is not needed, the problem that the preforms which are manually laid in the forming process are easy to deform is solved, and the quality is ensured; and meanwhile, continuous bending action of the J-shaped composite material rib is realized, the efficiency is improved, and automatic manufacturing can be realized.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

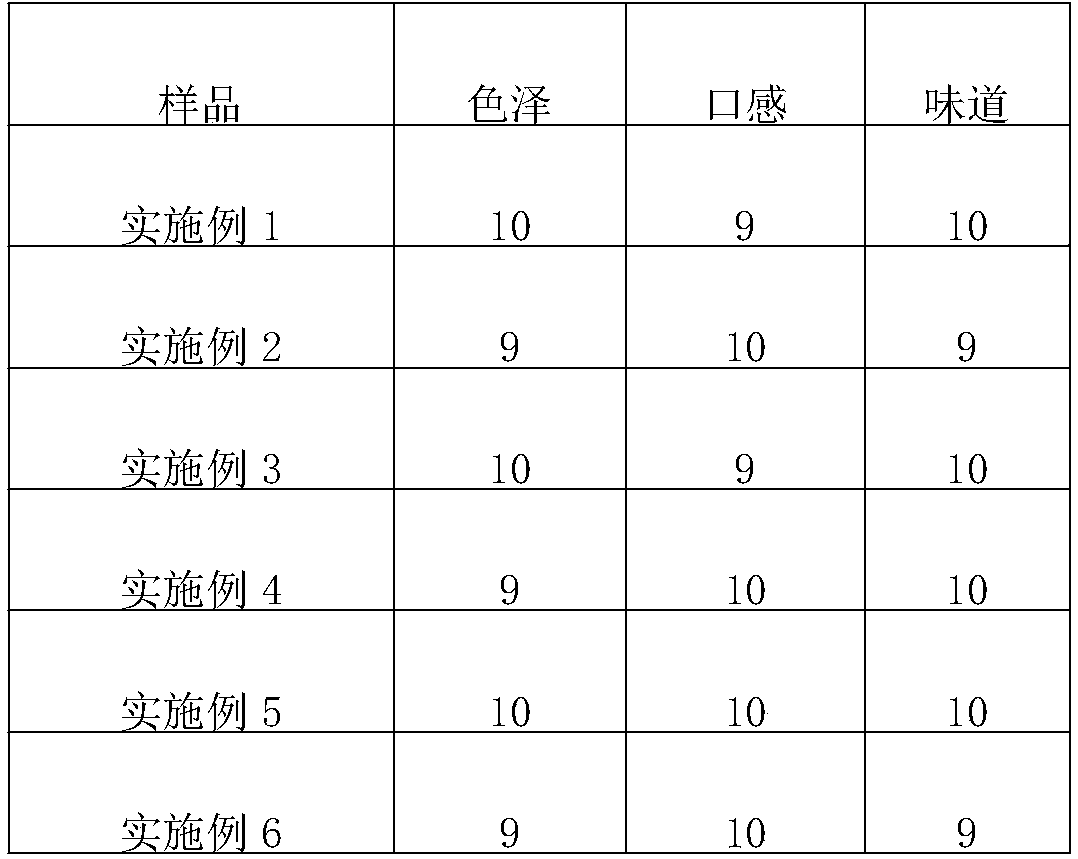

Method for preparing furong meat

The invention discloses a method for preparing furong meat. The method comprises the steps of pretreatment of pork, pickling, steaming, frying, mixing, stir frying and the like. The furong meat obtained by the method has unique flavor, fresh and tender taste and rich nutrition, is beneficial to human body absorption, has an attractive color, has no mutton smell and fishy smell of meat, smell of blood and harmful smell, the meat is delicious, the chewing feeling is very good, and the color, flavor and taste are good; no food additive and no preservative are added, the product is non-toxic and harmless, safe and healthy and has effects of tonifying qi-blood, tonifying deficiency, treating malnutrition, inducing diuresis, tonifying the spleen, removing pain or numbness and carrying out apocenosis, removing speckles, nourishing skin, clearing away heat and toxic materials and the like; after passing the inspection, the finished product is sent into a vacuum packaging machine in an asepticstate for vacuum packaging, so that the expiration date of the product is prolonged, carrying and transport are facilitated, the whole process is implemented in an automatic cooking device, the furongmeat is automatically manufactured, the requirements on occasions where a large number of meals need to be prepared are met, manpower and material resources are saved, and the production costs are reduced.

Owner:NANNING UNIV

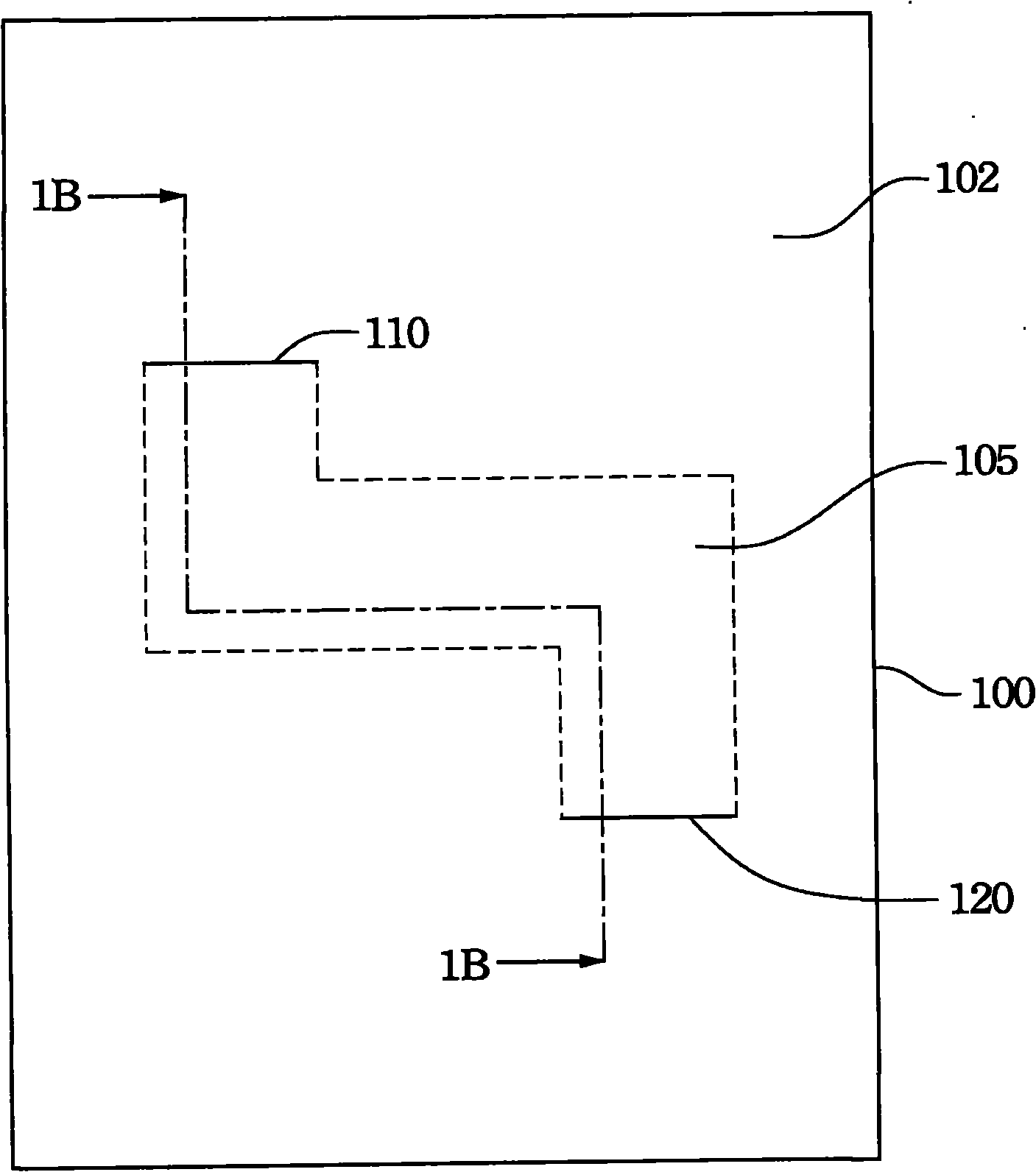

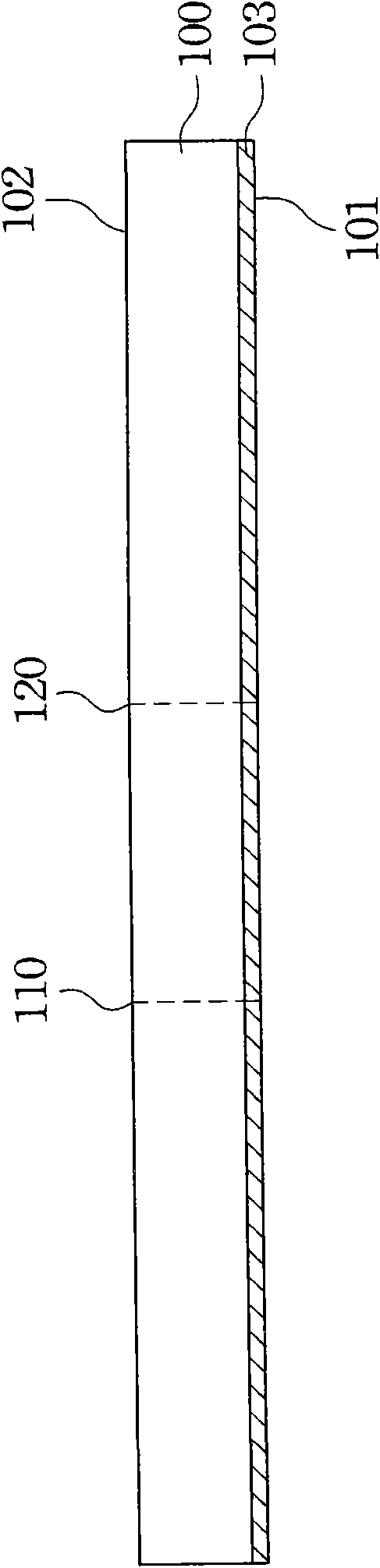

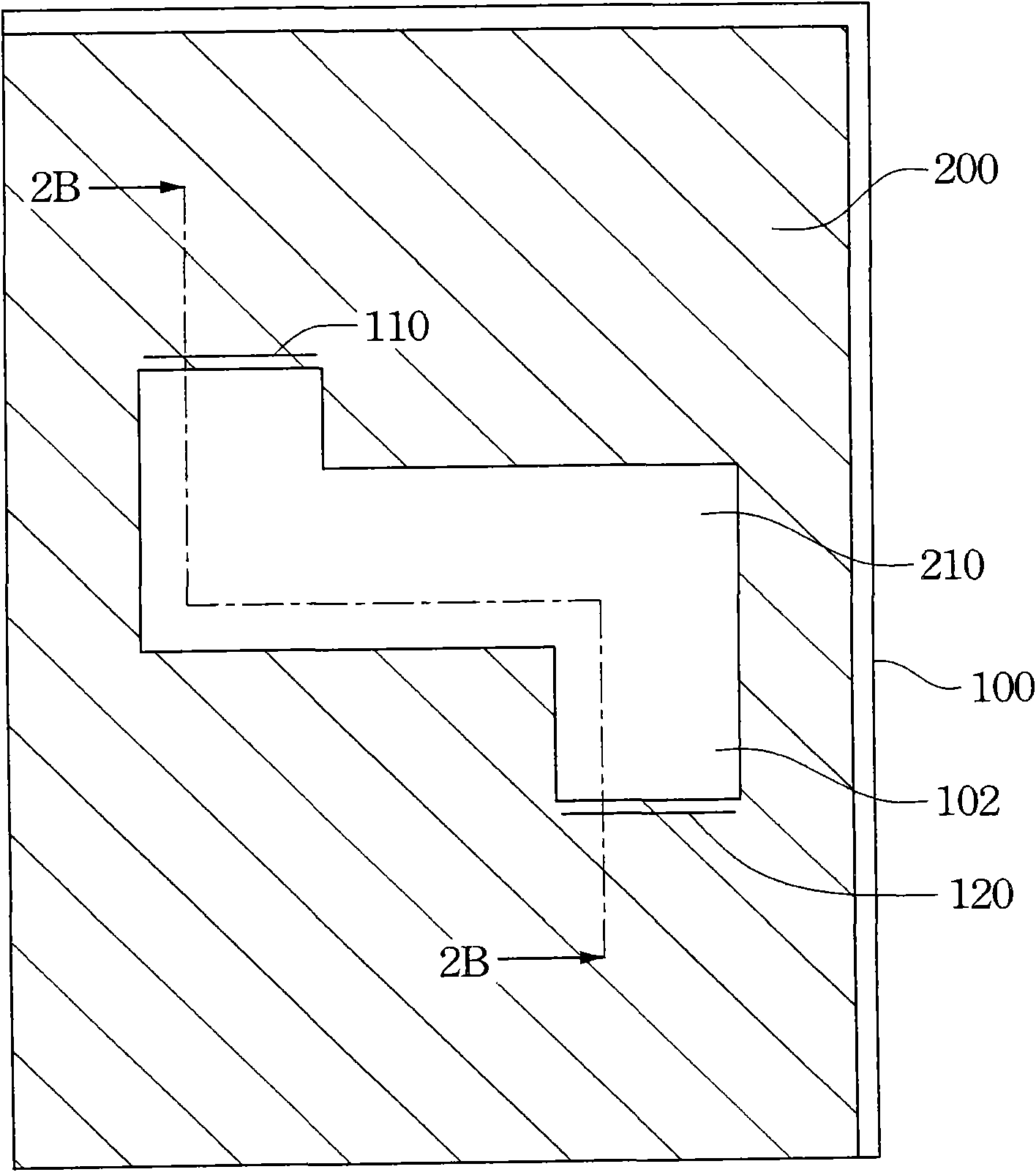

Manufacture method of flexible and rigid composite circuit board

ActiveCN102149254ARealize automated manufacturingImprove pass ratePrinted circuit assemblingMultilayer circuit manufactureEngineeringFlexible circuits

The invention discloses a manufacture method of a flexible and rigid composite circuit board. The method comprises the steps of: completely clamping a flexible circuit board between two rigid substrates and laminating into a whole; and then, forming cutting lines to remove the excess parts of the rigid substrates and expose the flexible circuit board.

Owner:TRIPOD WUXI ELECTRONICS

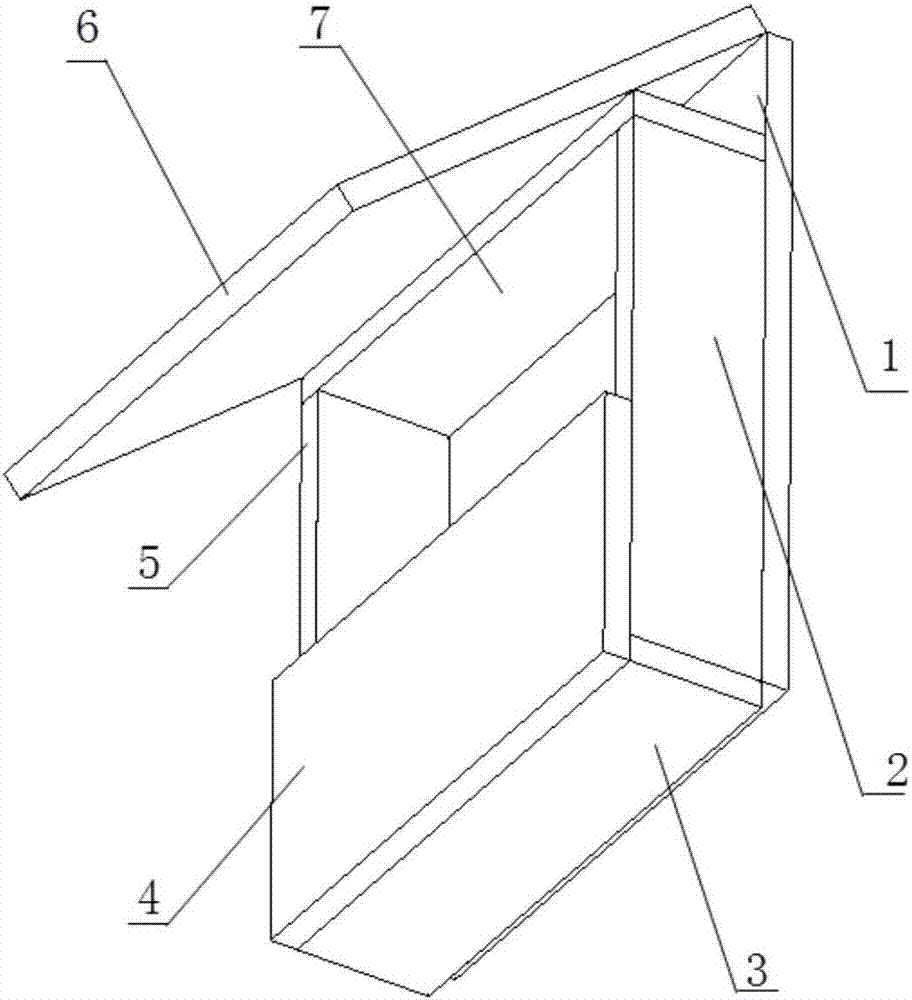

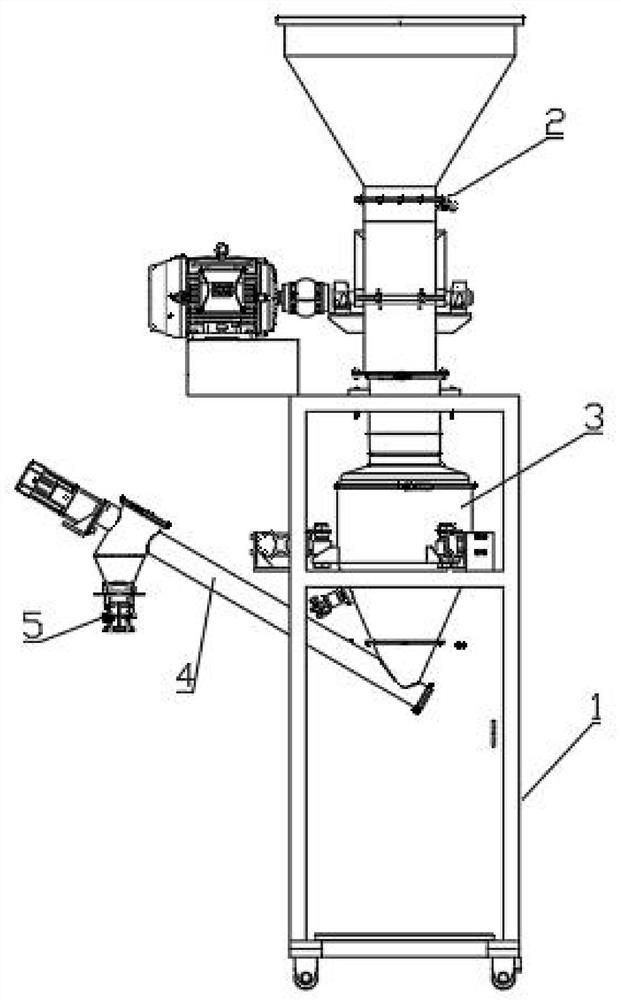

Artificial nest and full-automatic artificial nest manufacturing machine

InactiveCN107087557AReasonable structureRealize fully automatic productionBird housingsEavesEngineering

The invention provides an artificial nest. A nest cell body is composed of a back plate, a frame which is installed on the front surface of the back plate and composed of four rectangular plates, a baffle plate in the front of the frame and an eave plate on the top of the back plate. The plates are the same in thickness, and one edges of the plates are the same in width. The invention further provides a full-automatic artificial nest manufacturing machine which comprises a transmission cutting unit and a mold assembling unit. According to the artificial nest and the full-automatic artificial nest manufacturing machine, one complete plate can be used for completing artificial nest manufacturing from cutting to assembling and connecting of the artificial nest in a full-automatic mode, the modeling of the manufactured artificial nest is suitable for various birds to live in, the effects of sheltering from wind and rain and keeping the temperature are achieved, low-cost mass production can be achieved, and particularly the requirements for the artificial nest number and quality of a bird attracting project can be met.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

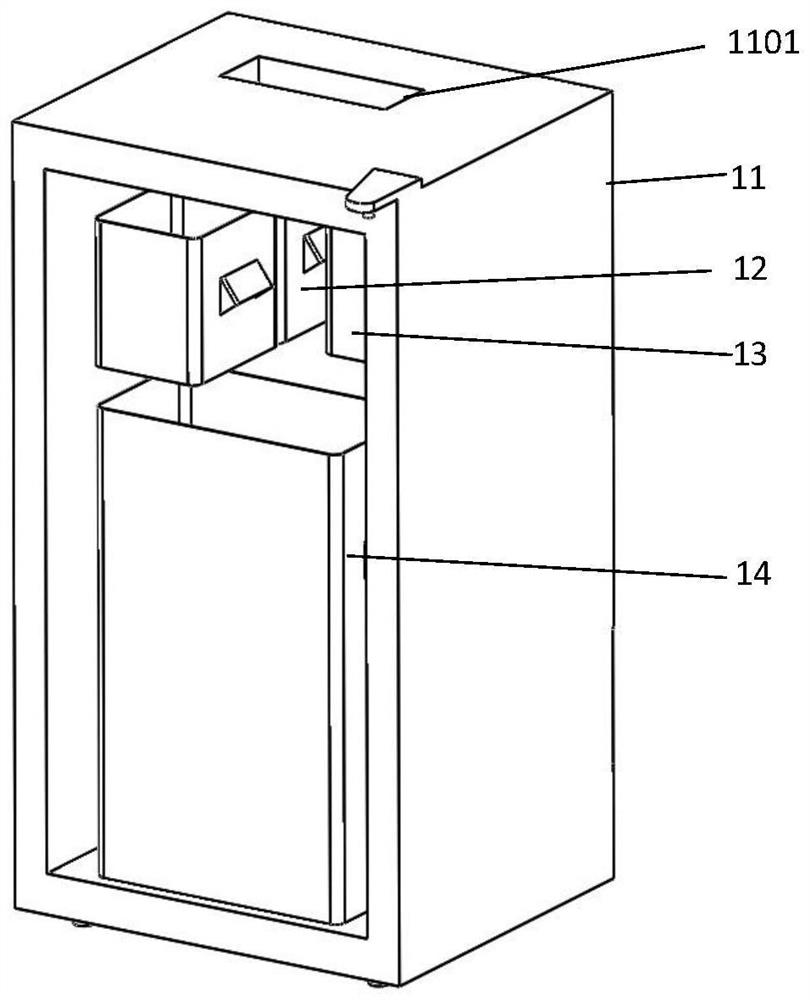

Full-automatic milk tea making equipment

ActiveCN113712432AGuaranteed uniformityThe amount added is accurateBeverage vesselsApparatus for dispensing fluids/granular materialsProcess engineeringSUGAR/WATER

The invention discloses full-automatic milk tea making equipment, which belongs to the technical field of milk tea automation equipment. The equipment comprises a joint robot, a low-temperature box, a pearl feeding barrel, a sugar supply machine, a water heater, an ice maker, a normal-temperature water supply machine, a tea barrel, a cup discharging mechanism and a cup sealing machine, wherein the cup discharging mechanism and the cup sealing machine are arranged around the joint robot and inside the main frame, the pearl feeding barrel and the milk feeding barrel are both placed in the low-temperature box, multiple discharging faucets are used for supplying liquid raw materials to milk tea cups, and the bottoms of the multiple discharging faucets are sequentially connected with the water heater, the tea barrel, the normal-temperature water supply machine and the milk feeding barrel through water inlet pipes; a solid-liquid separation mechanism is used for taking out mixed liquid of pearls and sweet water from the pearl feeding barrel and draining the sweet water, and then pearl particles are placed into the milk tea cup clamped by the joint robot. The equipment can realize automatic milk tea making, replaces manual work and is suitable for full-automatic unmanned selling.

Owner:杭州千岛湖瑞淳机器人研究院有限公司

Method for cooking noodle with curried steak

The invention relates to a method for cooking noodle with curried steak. The method comprises the steps of preserving, frying, cutting and stir frying. The made noodle with curried steak has the advantages of unique flavor, rich smell, and abundant nutrition; the specially-produced automatic cooking equipment can be cooperated, automatic production of the noodle with curried steak is achieved, and the method is especially suitable for massive meal preparation occasion, such as large-scale factory or office building.

Owner:惠州市格农科技有限公司

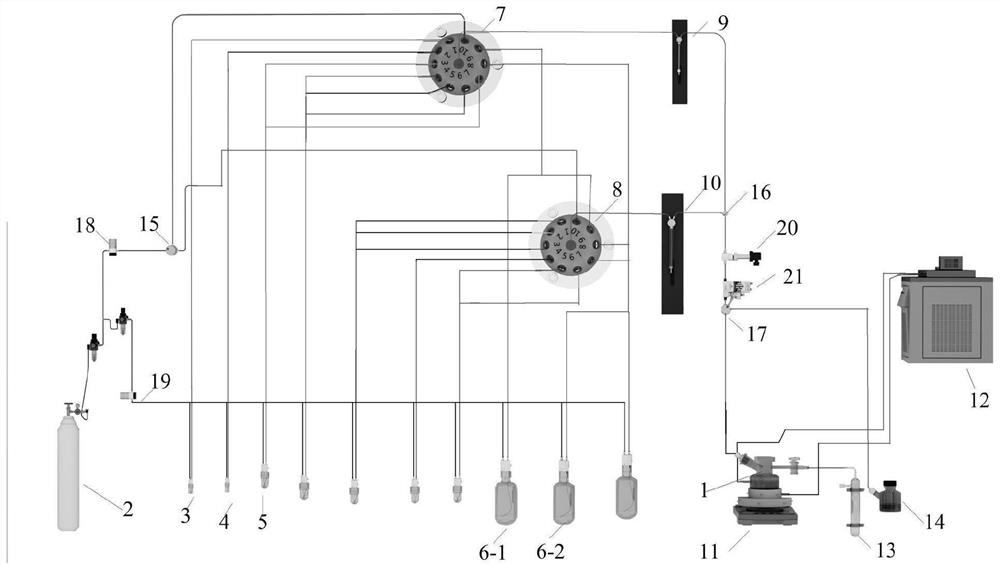

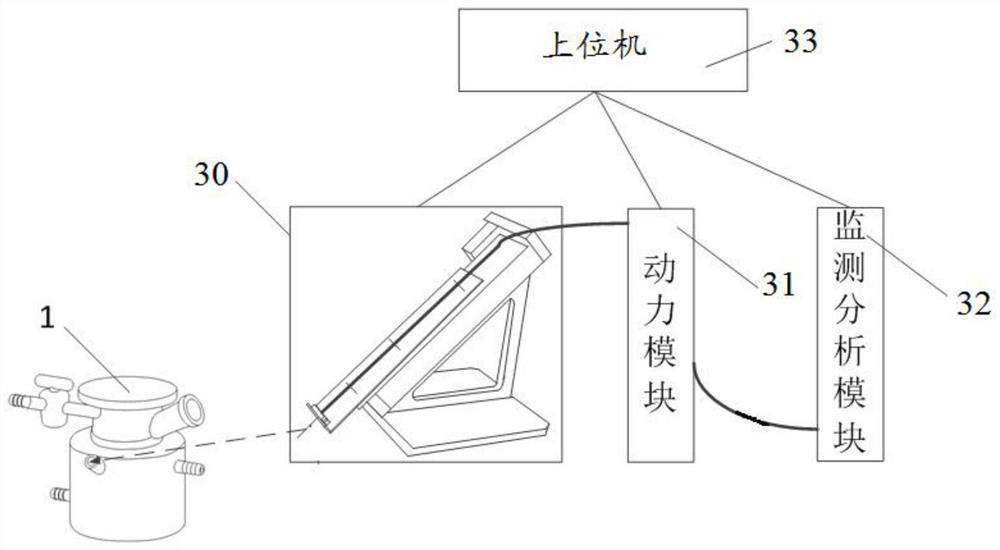

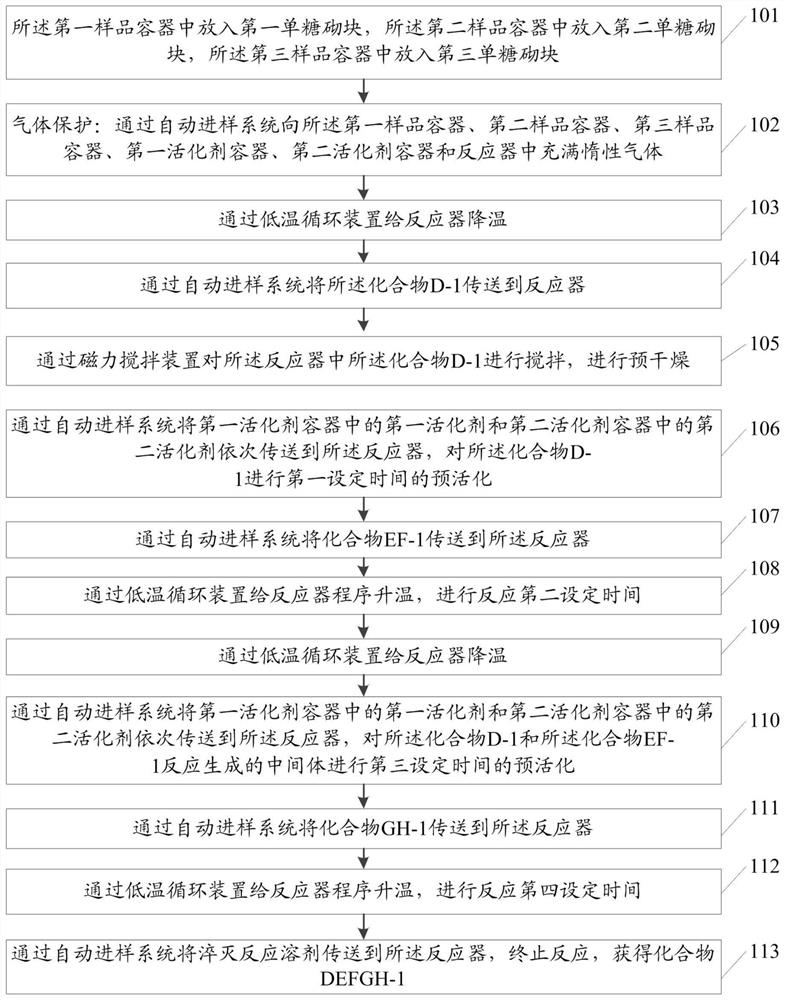

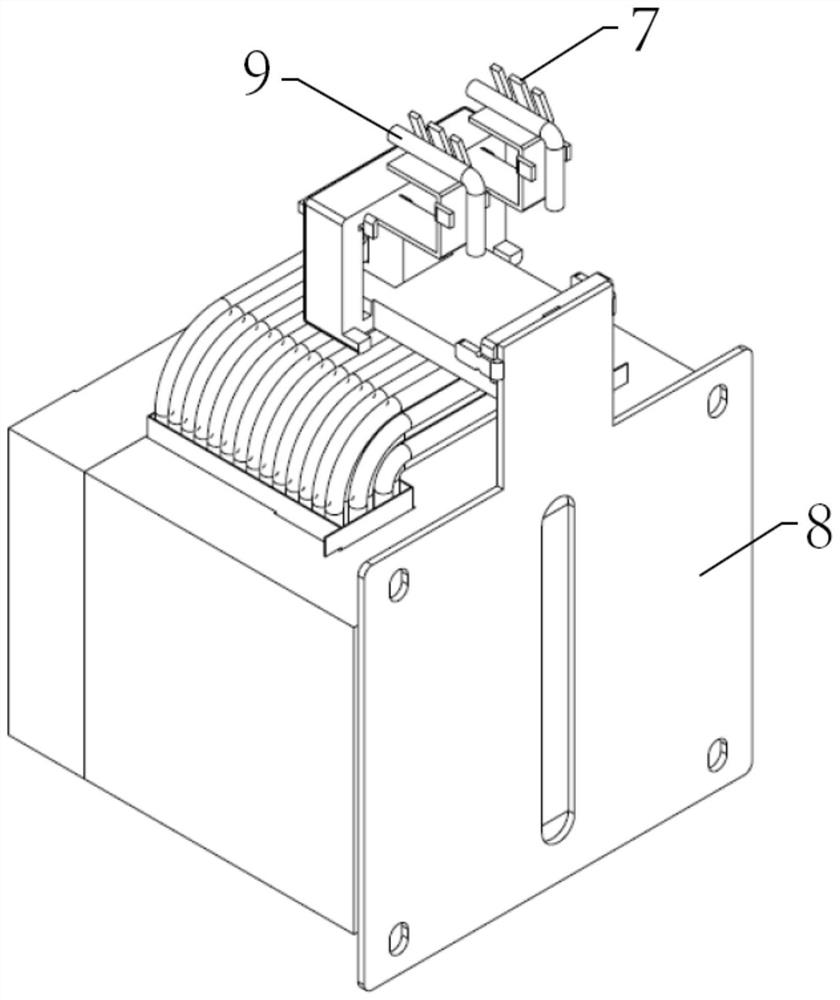

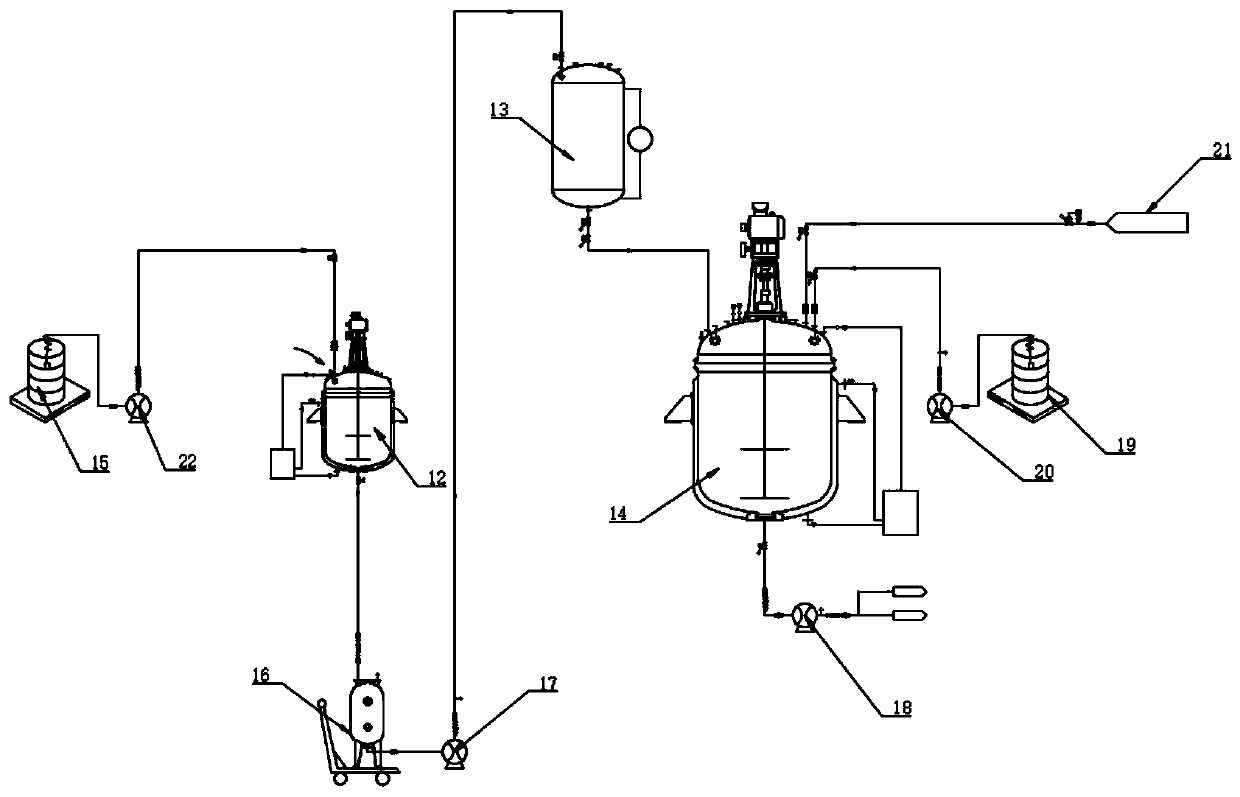

Automatic preparation method of fondaparinux sodium pentasaccharide intermediate

ActiveCN112552359ARealize automated manufacturingImprove acquisition efficiencySugar derivativesSugar derivatives preparationTemperature controlProcess engineering

The invention relates to an automatic preparation method of a fondaparinux sodium pentasaccharide intermediate. The method is based on an automatic preparation device. According to the method, automatic preparation of three components (D+EF+GH) is realized through automatic sample injection and automatic sampling and monitoring, the fully-protected fondaparinux sodium pentasaccharide intermediate(formula I) is obtained, and automatic synthesis of the fondaparinux sodium pentasaccharide intermediate is realized, so that the manpower can be saved, the efficiency and productivity are improved, and relatively high safety and reproducibility are achieved; direct online monitoring can be realized, the real-time state of a reaction is convenient to optimize and monitor, and meanwhile, the automatic temperature control can better meet the requirements of the reaction on heating and cooling; a pre-activation one-kettle mode is adopted, so that the separation frequency is reduced, and the operation is convenient; and a common ester protecting group is selected, relatively high stereoselectivity and yield are achieved, a universal deprotection method can be used, and the method has importantsignificance in reducing the production cost of fondaparinux sodium and achieving large-scale production. The definition of each substituent in the formula I is the same as the definition in the specification.

Owner:PEKING UNIV

Cooking method of Chinese prickly ash mutton chop-rice meal

The invention discloses a cooking method of a Chinese prickly ash mutton chop-rice meal. The cooking method comprises preserving, frying, slicing and stir-frying. The Chinese prickly ash mutton chop-rice meal has a unique local flavor and a thick Chinese prickly ash taste and is rich in nutrients. Through use of an automatic cooking device, the Chinese prickly ash mutton chop-rice meal can be automatically prepared and is especially suitable for occasion such as a large-scale factory or an office building with large-scale meal preparation requirements.

Owner:惠州市格农科技有限公司

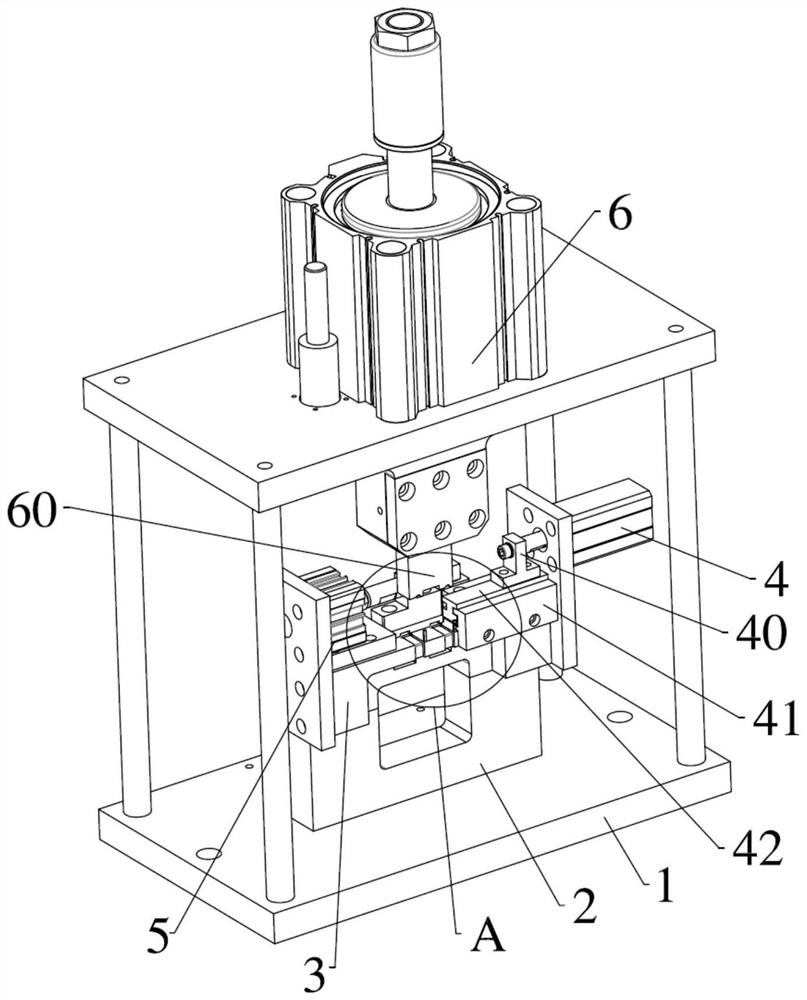

Variable-frequency electric reactor claw terminal crimping device

PendingCN112072438AReduce investmentReduce dependenceLine/current collector detailsElectrical performanceMechanical engineering

The invention relates to the technical field of terminal crimping jigs, in particular to a variable-frequency reactor claw terminal crimping device, which comprises a mounting frame, a reactor fixingseat and a terminal claw positioning base, and is characterized in that the reactor fixing seat is fixed on a bottom plate of the mounting frame, and the terminal claw positioning base is mounted on the reactor fixing seat; pushing and flattening structures used for pushing and flattening the clamping jaws and wire fixing structures used for pulling wires are installed on the portions, located atthe two ends of the terminal clamping jaw positioning base, of the electric reactor fixing base respectively, and flattening structures used for flattening the clamping jaws after the pushing and flattening structures push and flatten the clamping jaws are installed on a top plate of the mounting frame. According to the invention, the working efficiency is greatly improved, and the labor intensityof operators is reduced; the manufactured variable-frequency electric reactor clamping jaw covered wire product is high in appearance consistency, the connecting wire is almost prevented from fallingoff, and the product quality is improved; and the high-voltage and impedance qualification rate is high, and the electrical performance is very stable.

Owner:HEFEI ECRIEE TAMURA ELECTRIC

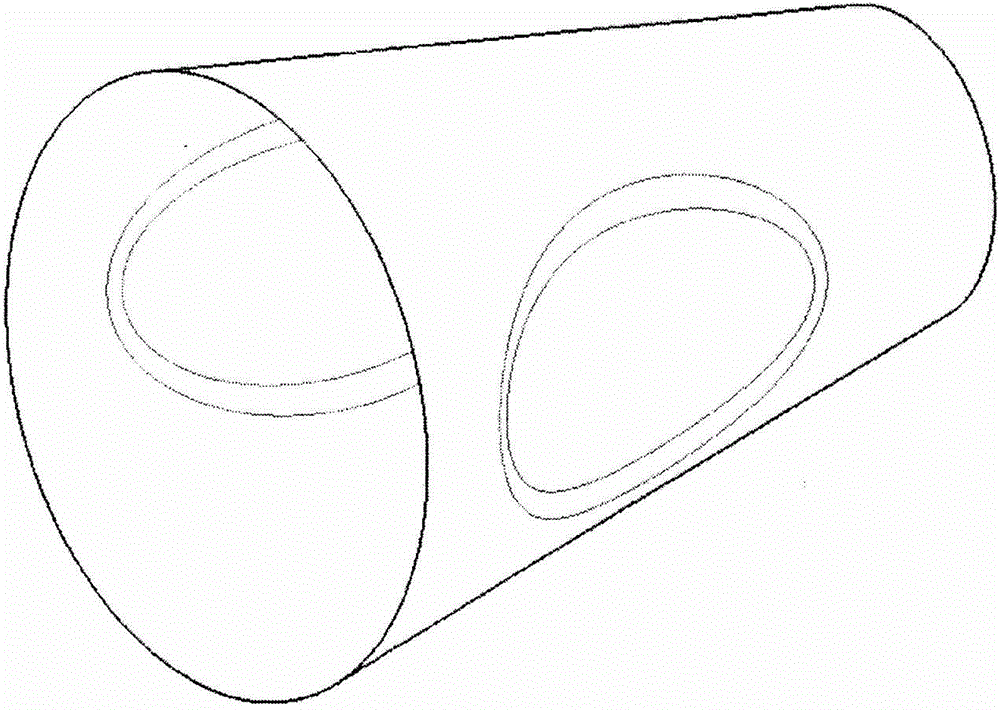

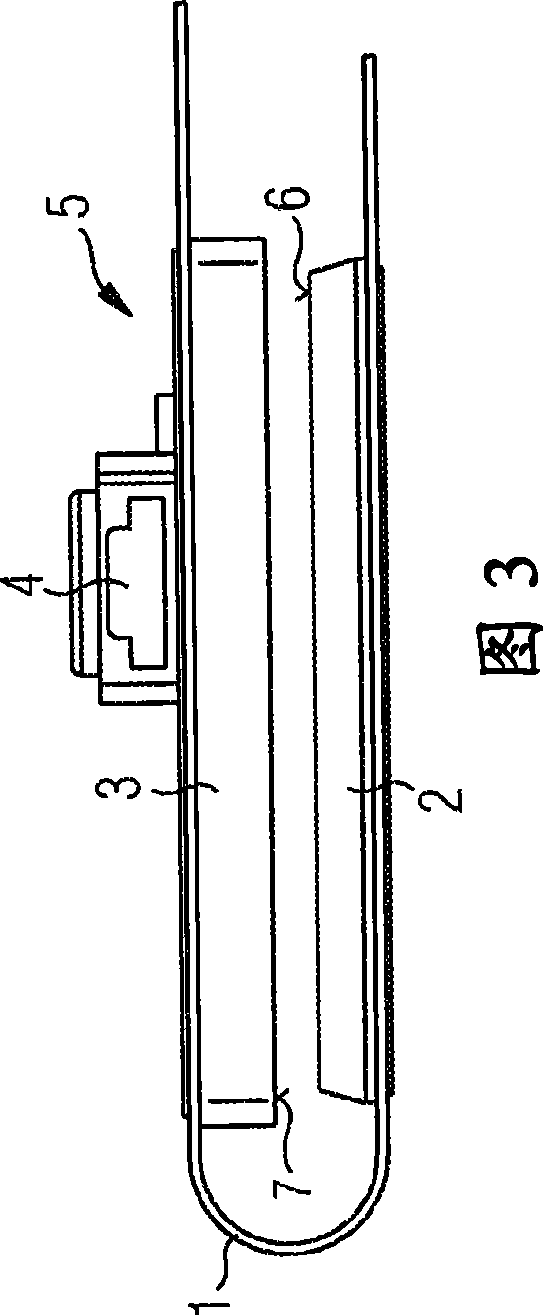

Fuel filter and process for producing a fuel filter

InactiveCN101400425AImprove retentionSmall sizeMembrane filtersStationary filtering element filtersFuel filter

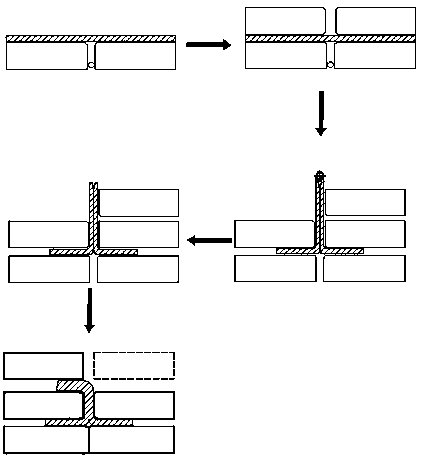

The invention relates to a fuel filter 5 and to a process for producing a fuel filter, the fuel filter consisting of a filter fabric 1, a support body 2, 3 which consists of plastic and has a pump connection stub 4 attached thereto, the support body consisting of a first filter part 2 and a second filter part 3, the two filter parts 2, 3 each having a peripheral edge 8, 9 which accommodates a filter fabric 1, and connecting elements 15, 16, 18-22 being arranged on the two filter parts 2, 3 such that, when the two filter parts 2, 3 are adjoined, the surfaces 6, 7 of the two filter parts 2, 3 facing away from the filter fabric 1 come to rest on one another, such that the connecting elements 15, 16, 18-22 of the two filter parts 2, 3 interact with one another.

Owner:CONTINENTAL AUTOMOTIVE GMBH

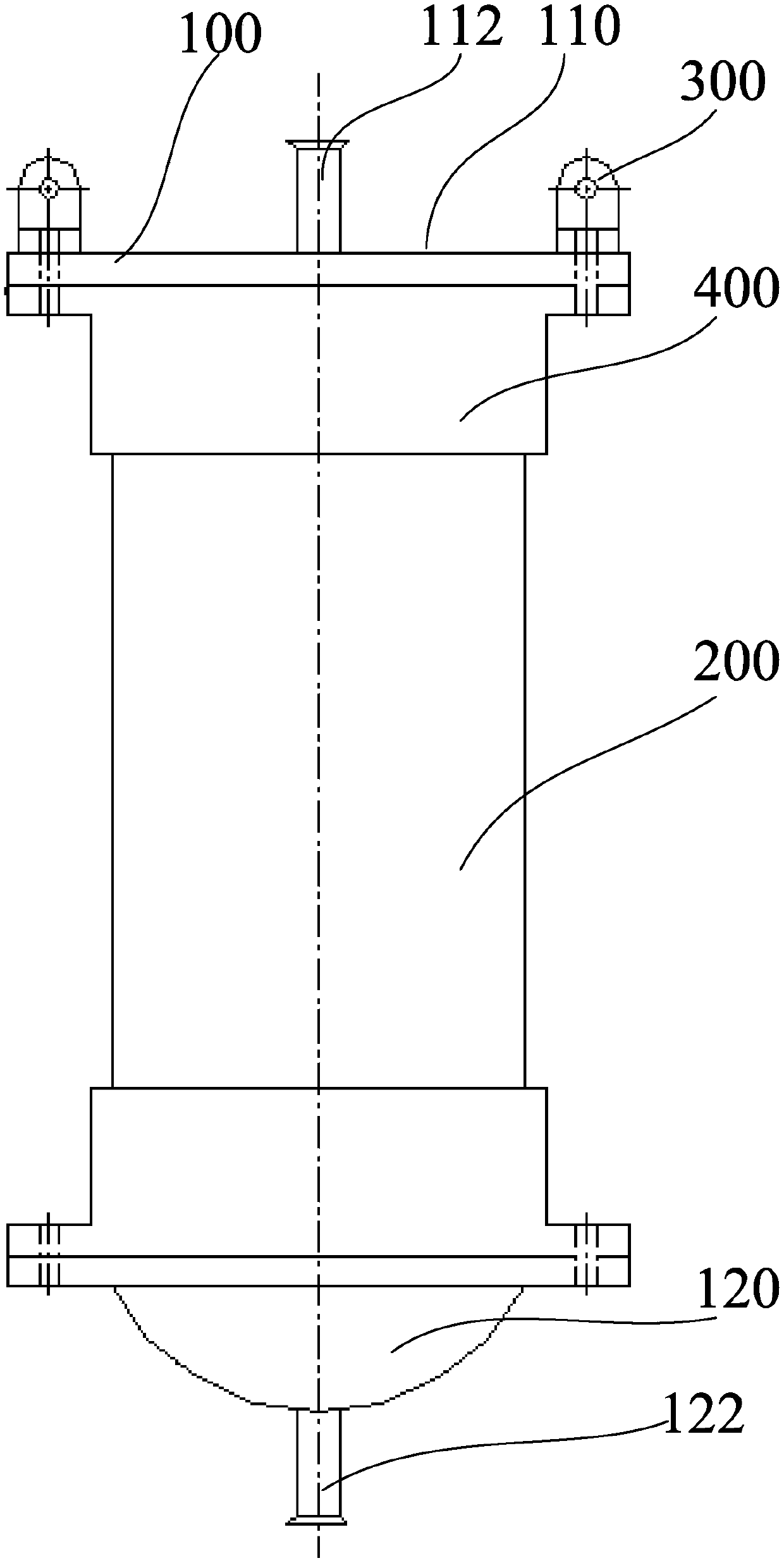

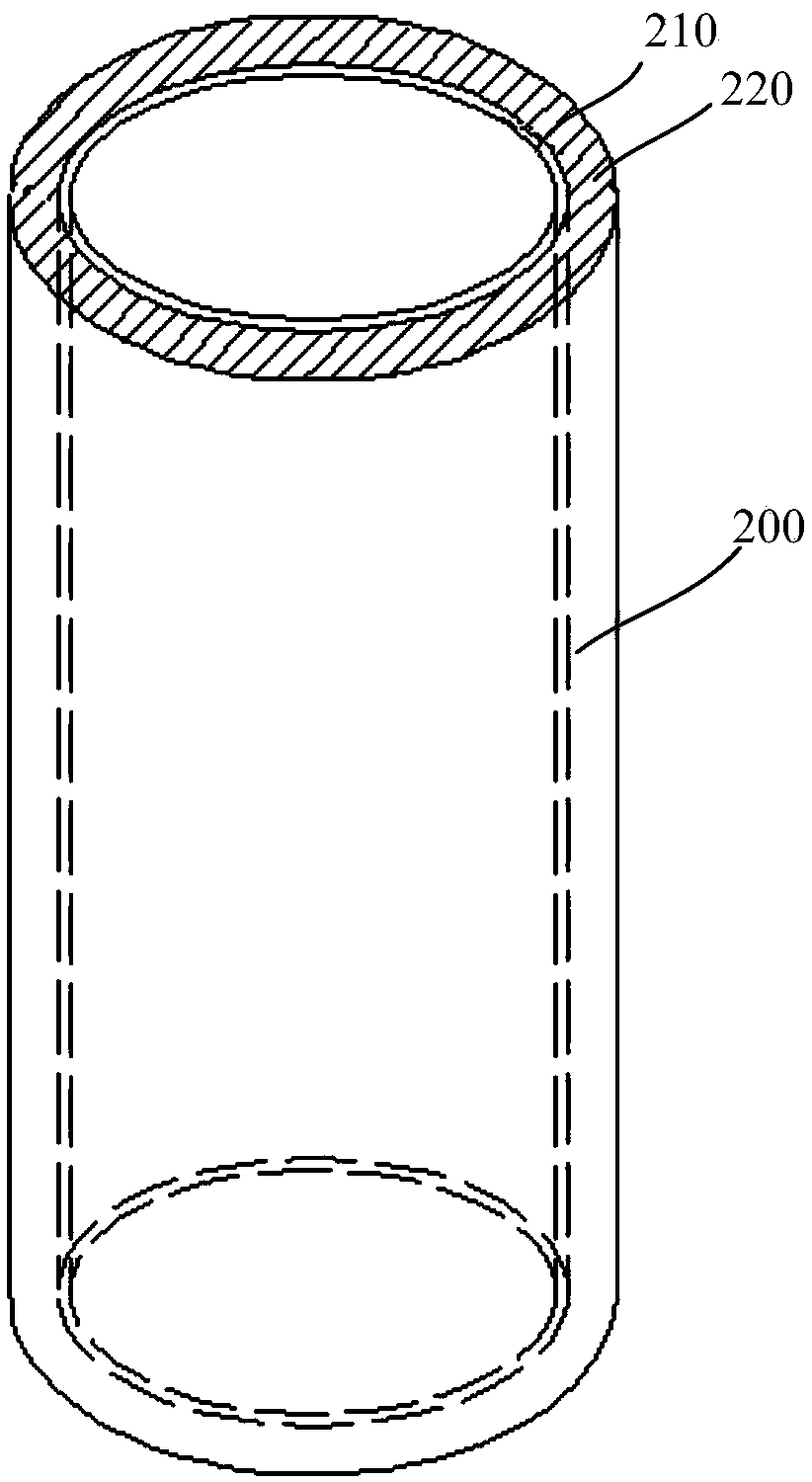

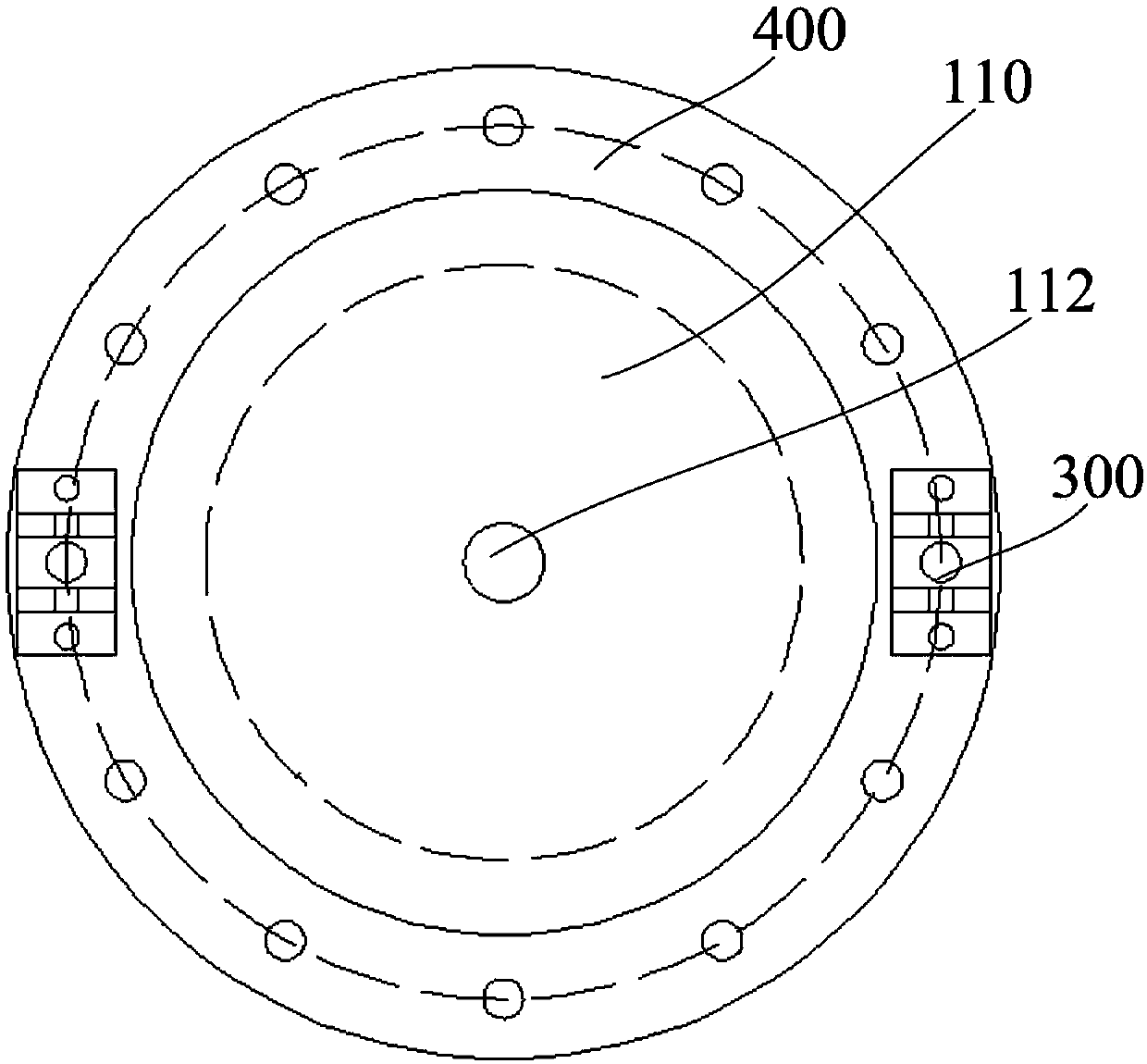

Anti-ionizing radiation container and preparation method thereof

InactiveCN109659054AStrong designabilityAchieve lightweightShieldingPortable shielded containersFiberSurface cover

The invention discloses an anti-ionizing radiation container, which comprises an end cap and a container body. The end cap is used for sealing the container body, the container body comprises a linerlayer and a fiber and metal wire composite layer wound on the outer surface of the liner layer, the fiber and metal wires are loaded with a resin system, and the fiber and metal wires cover the outersurface of the liner layer. The invention also discloses a preparation method of the anti-ionizing radiation container.

Owner:CHINA GENERAL NUCLEAR POWER OPERATION +4

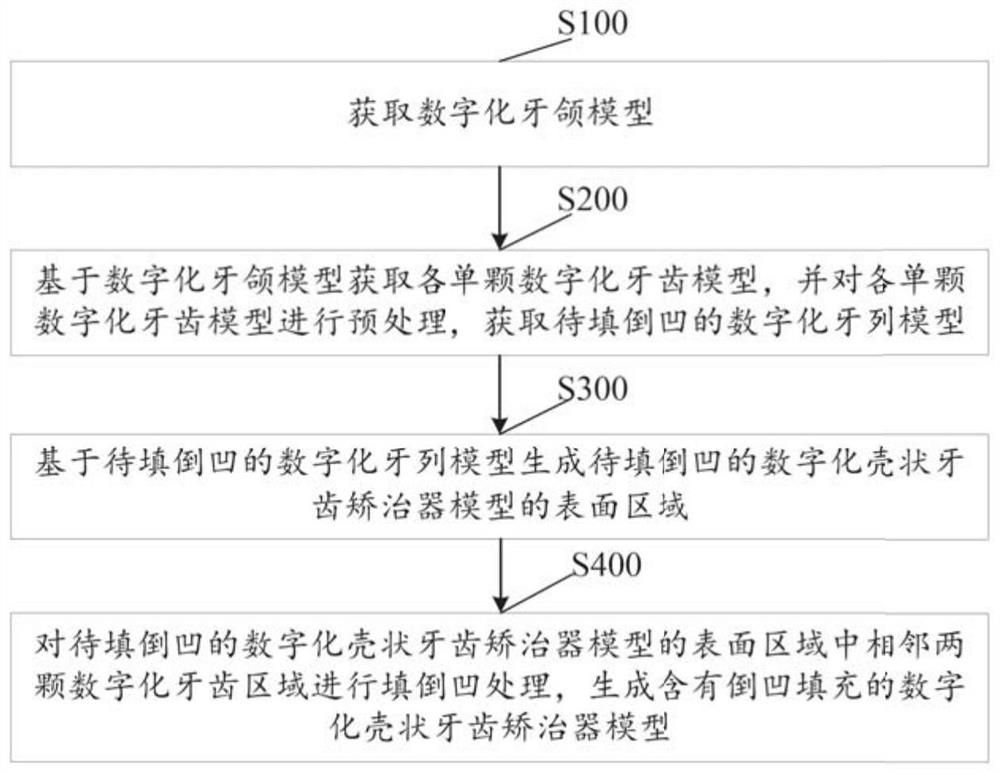

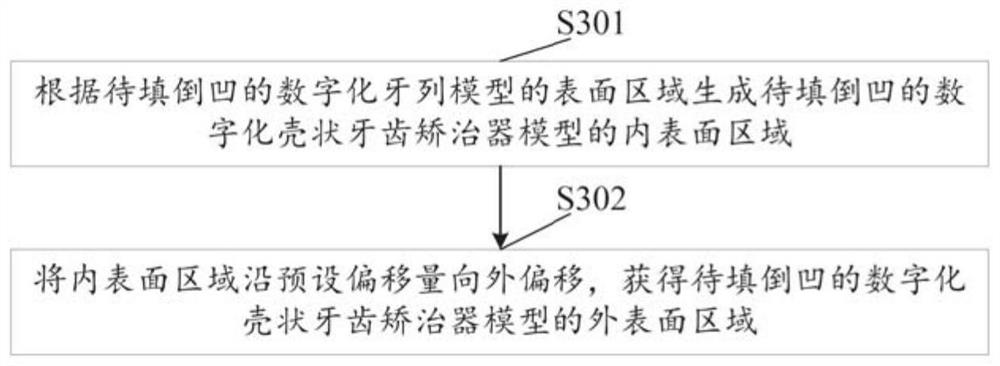

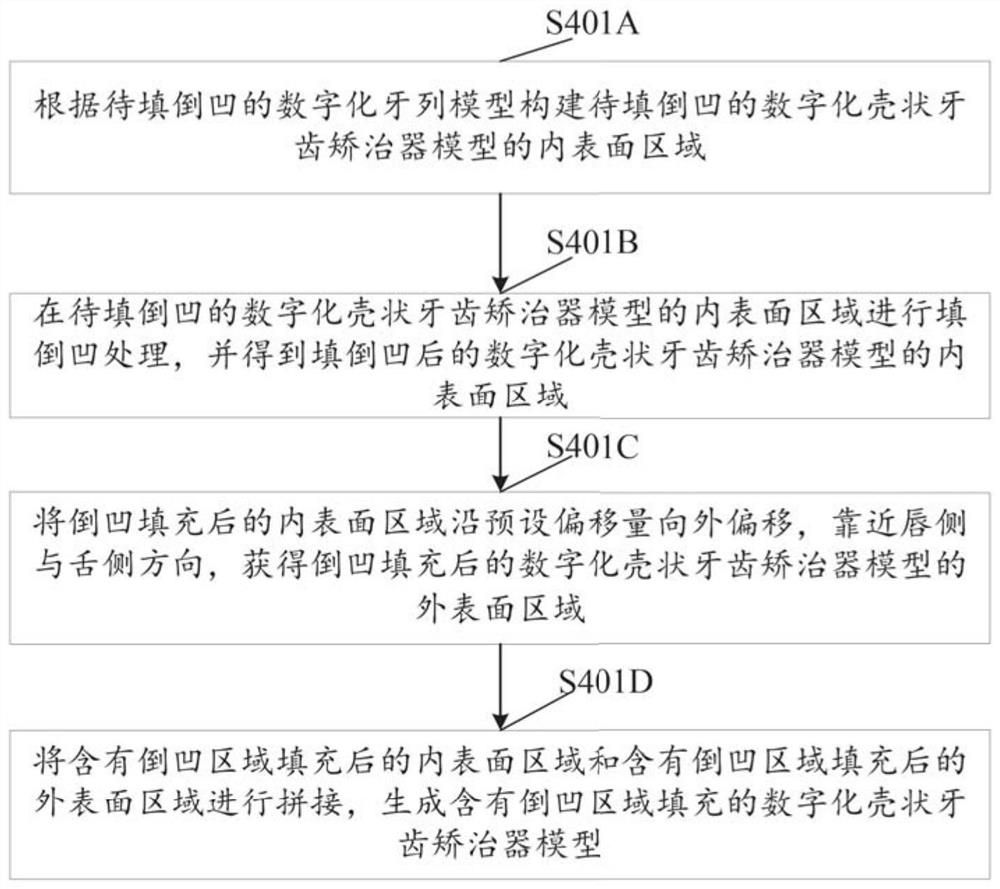

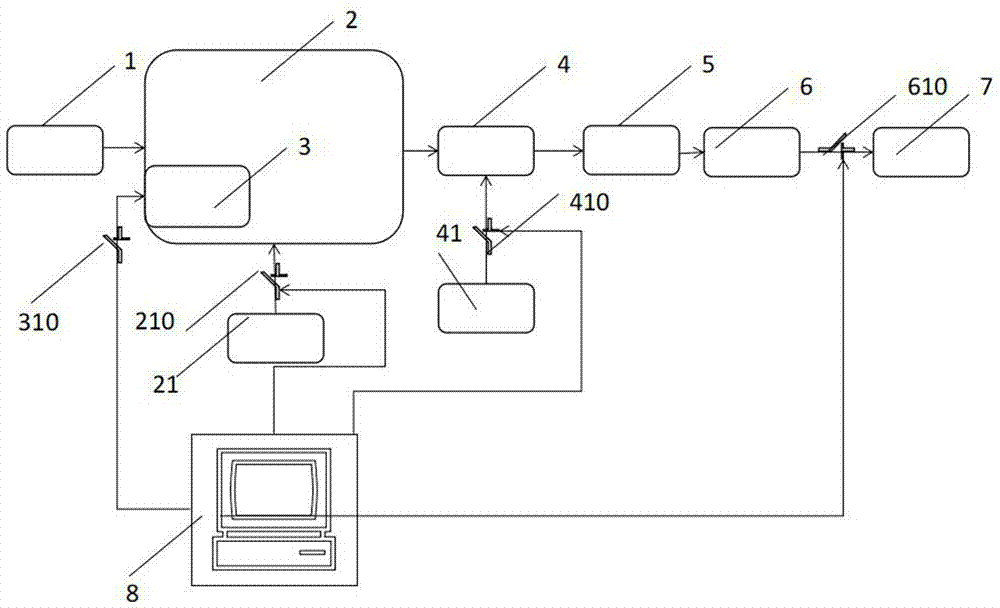

Design method, manufacturing method and system for digital shell-shaped dental appliance

ActiveCN111839763ARealize automated manufacturingIncrease productivityAdditive manufacturing apparatusOthrodonticsDentitionBiomedical engineering

The invention provides a design method, manufacturing method and system of a digital shell-shaped tooth appliance. The design method comprises the following steps: acquiring a digital dental model, obtaining each single digital tooth model based on the digital dental model, preprocessing each single digital tooth model to obtain a digital dentition model to be filled with undercut, generating a surface area of the digital shell-shaped dental appliance to be filled with the undercut based on the digital dentition model to be filled with the undercut, and performing undercut filling treatment ontwo adjacent digital tooth areas in the surface area of the digital shell-shaped tooth appliance to be undercut-filled to generate the digital shell-shaped tooth appliance containing undercut filling. By designing the digitized shell-shaped tooth appliance with the undercut filling function, manual undercut filling can be avoided, automatic preparation of the shell-shaped tooth appliance can be achieved, and then the production efficiency and quality of the shell-shaped tooth appliance can be improved.

Owner:SHANGHAI SMARTEE DENTI TECH CO LTD

Wastewater automatic decoloring device

InactiveCN107540173ARealize automated manufacturingRealize full automationMultistage water/sewage treatmentWaste water treatment from textile industryMaster controllerControl valves

The invention provides a wastewater automatic decoloring device which comprises a filter tank, wherein the filter tank is communicated with a first sedimentation tank; the first sedimentation tank iscommunicated with a decoloring tank; the decoloring tank is communicated with a decoloring agent generating device through a third control valve; the decoloring agent generating device comprises a formaldehyde dropping device, a reactor, a urea dropping device, a catalyst dropping device, a heater and a master controller; the formaldehyde dropping device, the urea dropping device, the catalyst dropping device and the heater are all controlled by the master controller. The wastewater automatic decoloring device provided by the invention can realize automatic preparation of a decoloring agent, and thus can realize a total automatic process of wastewater treatment together with other technologies of wastewater treatment.

Owner:FOSHAN BAOYUEMEI SCI & TECH CO LTD

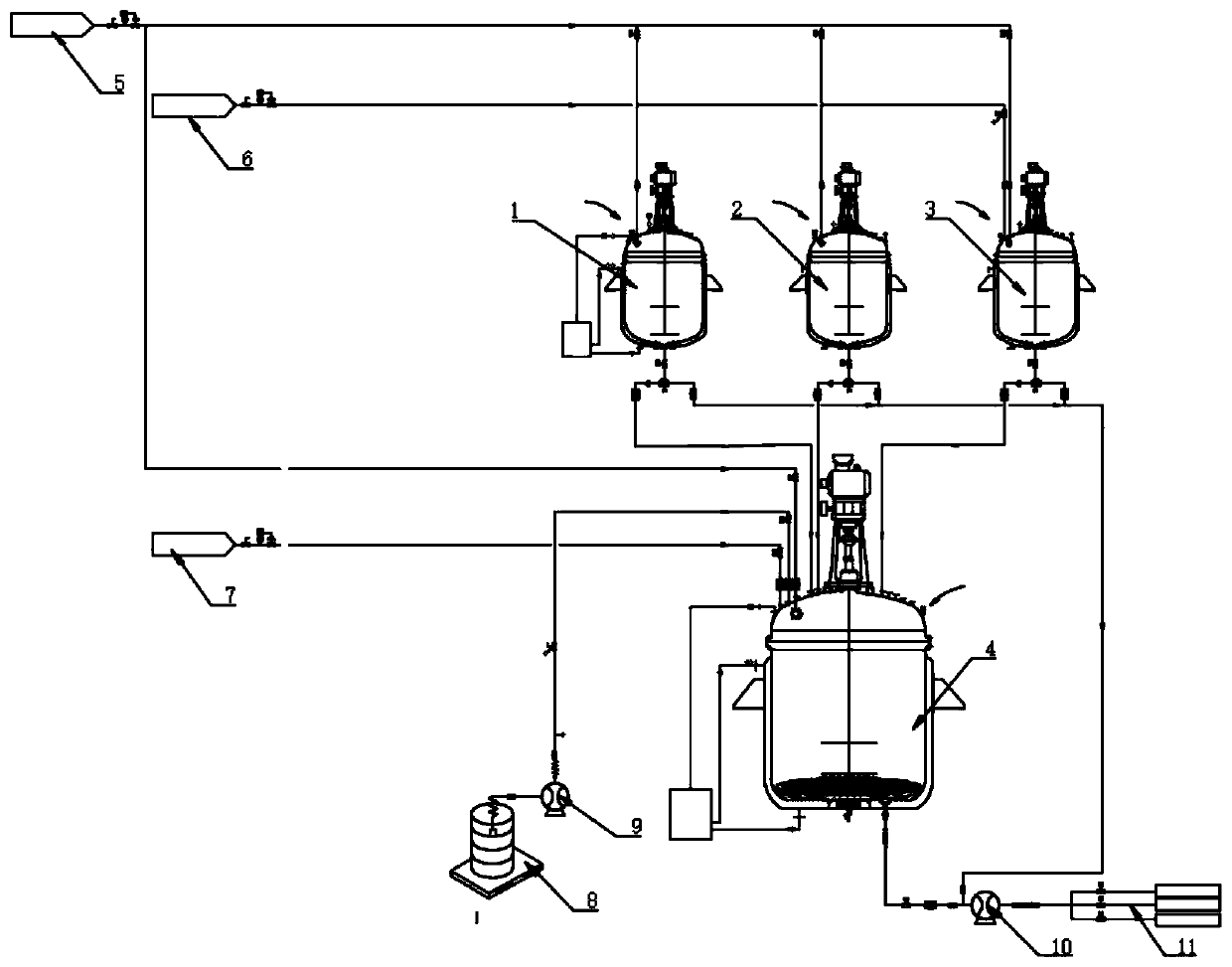

Production system for polypeptide drugs

InactiveCN110283229AHigh degree of automationHigh degree of intelligencePeptide preparation methodsBuffer tankBiological activation

The invention discloses a production system for polypeptide drugs. The production system comprises a polypeptide synthesis production system and a polypeptide cracking production system, wherein the polypeptide synthesis production system comprises an activation tank, a first buffer tank, a second buffer tank, a synthesis reactor, a first material storage tank, a second material storage tank, a third material storage tank, a fourth material storage vat, a first centrifugal pump, a second centrifugal pump and a waste liquid treating system; discharging openings of the activating tank, the first buffer tank and the second buffer tank are all simultaneously connected with the synthesis reactor and the waste liquid treating system; a discharging opening of the synthesis reactor is divided into two paths; one path of the discharging opening discharges resin, and the other path of the discharging opening is connected with the waste liquid treating system. The production system for the polypeptide drugs, provided by the scheme, can realize automatic preparation of the polypeptide drugs, and is high in automatic degree as well as safe and reliable in preparation process; meanwhile, the pollution to environment can be effectively avoided and thereby better environment friendliness is realized.

Owner:上海友尹化工科技有限公司

Solanum pseudocapsicum inoculation method based on hericium erinaceus cultivation

InactiveCN112314332AWell mixedSimple structureCultivating equipmentsMushroom cultivationBiotechnologyMicrobiology

The invention discloses a solanum pseudocapsicum inoculation method based on hericium erinaceus cultivation. The method comprises the following steps of inoculating coralloid hericium erinaceus flowers onto a mother strain culture medium through tissue separation, carrying out mother strain culture under aseptic conditions, according to the following culture condition, sleeving an opening of a fungus bag on the outer wall of a bottom cylinder, enaling two groups of connecting rods to be close to each other, driving a movable plate to rotate along a lower fixed plate, and enabling two groups ofjackets to clamp and fix the fungus bag on the bottom cylinder; then, starting a feeding motor to drive a feeding screw to rotate, inputtng a mixture in a mixing tank into a discharging pipe along aspiral feeding pipe, then, enabling the mixture to enter the fungus bag along a connecting funnel and the bottom cylinder, then controlling an air cylinder to work, taking down the fungus bag from thebottom cylinder, sterilizing the fungus bag, after sterilizing, inoculating the mother strain under the aseptic condition, and obtaining a coralloid hericium erinaceus mother strain; and culturing the inoculated fungus bag in a dark place, and inoculating the coralloid hericium erinaceus. According to the method, the inoculation efficiency of the coralloid hericium erinaceus is greatly improved.

Owner:安徽亲耳菌业科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com