Carbon fiber sensing element embedding device and method based on rapid prototyping manufacturing technology

A manufacturing technology and a technology of embedding devices, applied in the direction of additive processing, etc., can solve the problem of no manufacturing device or method, and achieve the effect of automatic manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] Below in conjunction with each accompanying drawing, the present invention is described in detail:

[0054] In this embodiment, the rapid prototyping manufacturing technology adopts photocuring molding technology, and a photocuring device is provided.

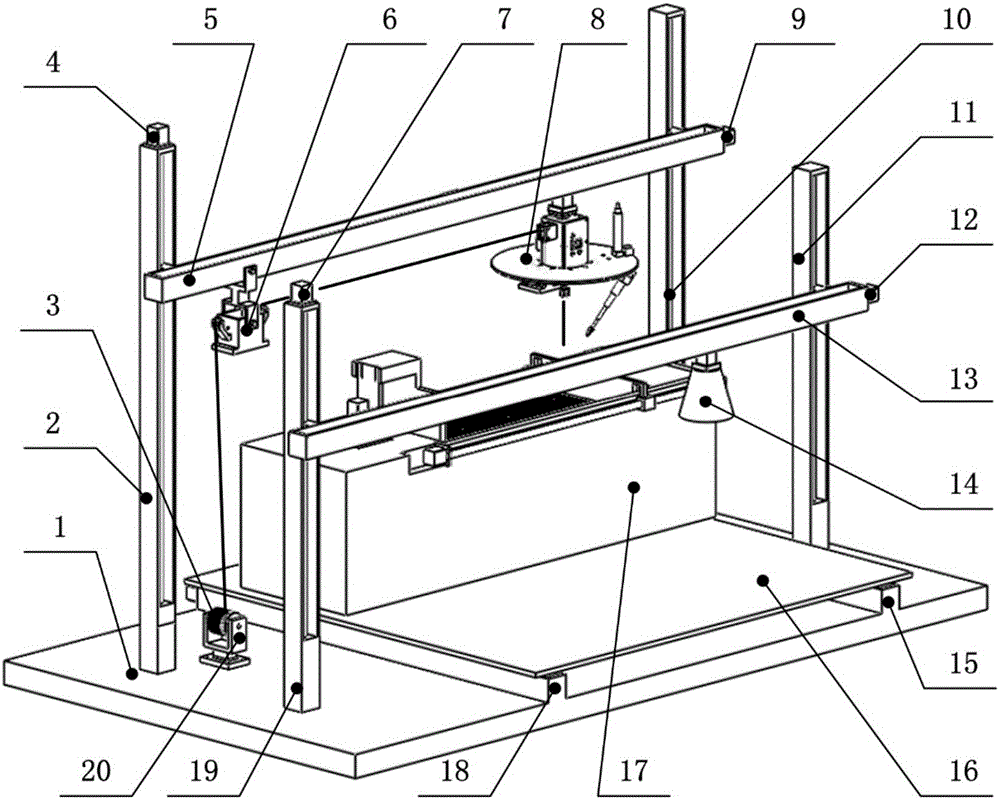

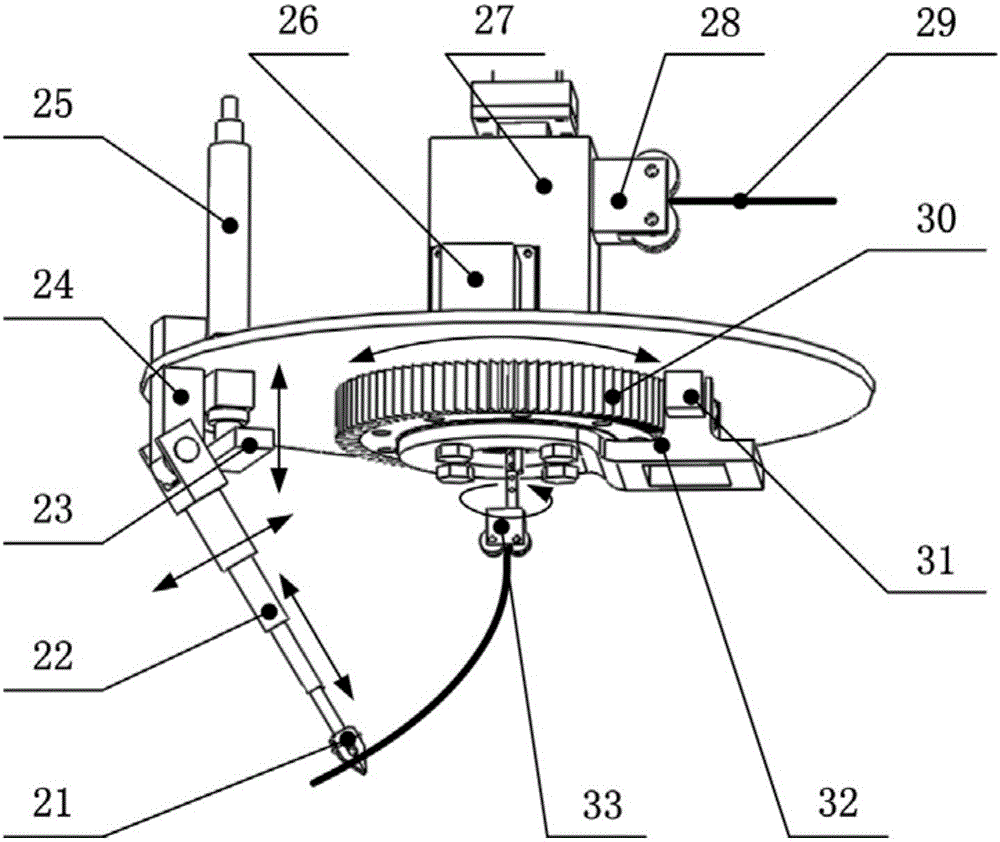

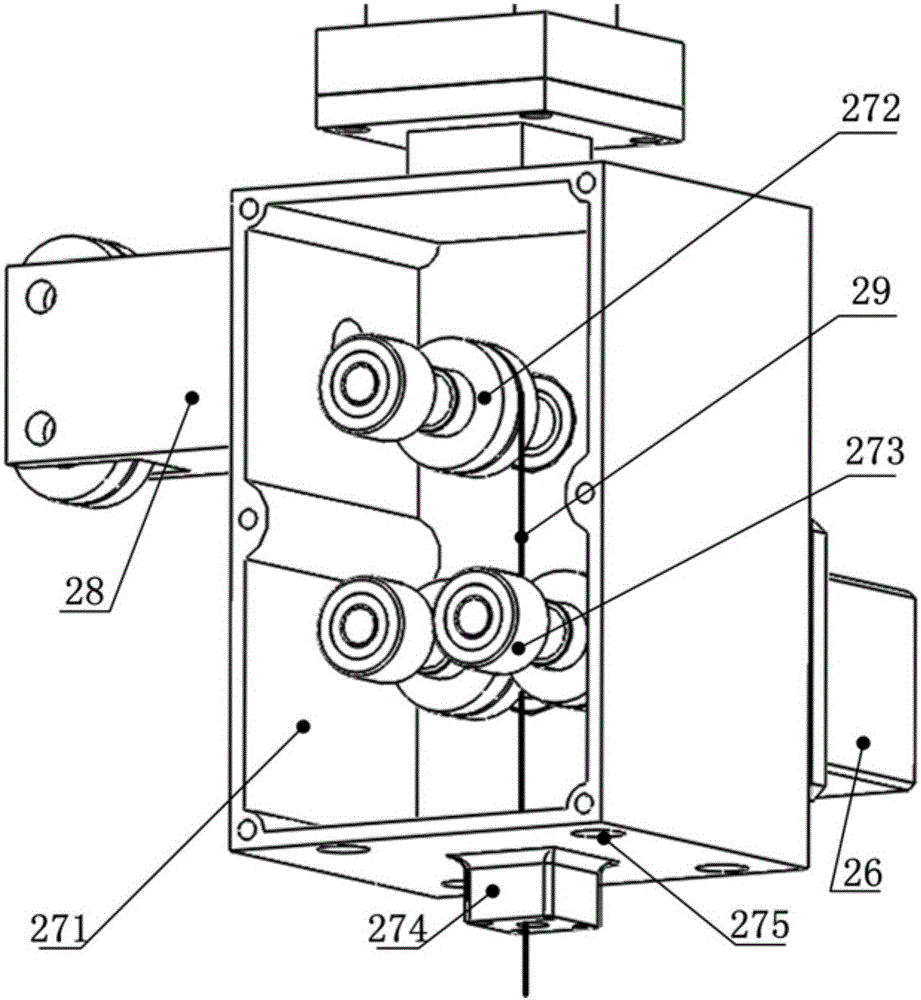

[0055] Such as figure 1 As shown, the carbon fiber sensing element embedded device based on the rapid prototyping manufacturing technology of this embodiment includes:

[0056] Fix the workbench 1 as the base of the whole device;

[0057] The lifting and translation module includes two columns (column 2 and column 10) and two cross columns (column 15 and column 18). A beam 5 is arranged on the two columns, and a drive is provided on the beam 5 and the column 2. Motor 4 and drive motor 9 and the ball screw that cooperates, column 10 is provided with guide rail slide block;

[0058] The horizontal mobile platform 16 is arranged on the cross column 15 and the horizontal column 18 of the fixed workbench 1 through a ball s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com