Automatic preparation and strength testing device for concrete test block for building construction

A concrete test block and strength testing technology, which is applied in the direction of measuring device, using repeated force/pulsation force to test material strength, and preparation of test samples, can solve the problem of inability to perform strength test, increase construction trouble, and prolong construction cycle and other issues to achieve flexibility, reduce heat loss, and save energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

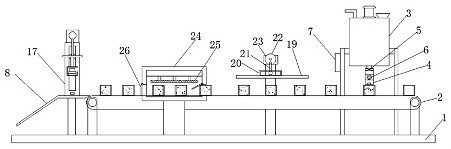

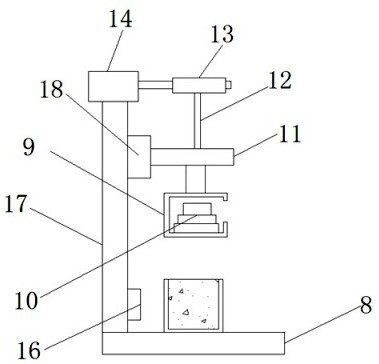

[0024] see Figure 1-2 According to an embodiment of the present invention, a concrete test block automatic preparation and strength testing device for building construction includes a bottom plate 1, a conveyor belt 2 is provided above the bottom plate 1, and a mixing box body 3 is provided at one end of the conveyor belt 2, The bottom of the mixing tank body 3 is provided with a discharge device, the discharge device includes a discharge pipe 4, the discharge pipe 4 is provided with an electromagnetic control valve 5, and one side of the electromagnetic control valve 5 is provided with A flow meter 6, one end of the discharge pipe 4 is fixedly provided with a first infrared sensor, the electromagnetic control valve 5, the flow meter 6 and the first infrared sensor are all electrically connected to the controller 7, and the stirring tank One side of the main body 3, and a beating and oscillating device is provided above the conveyor belt 2, and a drying device is provided on ...

Embodiment 2

[0026] see Figure 1-2, for the sliding device, the sliding device includes a slide rail 17, the inside of the slide rail 17 is provided with a slider 18, one side of the slider 18 is fixedly connected to one end of the hanger 11, and the hanger One end of 11 is provided with a sliding device, which can increase the stability of the hanger 11 in the lifting process, and increase the stability of the striking head 9 when the concrete test block is hit; for the striking vibration device, the striking vibration The device comprises an impact plate 19, one side of the impact plate 19 is fixedly provided with a chute 20, the inside of the chute 20 is provided with an L-shaped bar 21, and the end of the L-shaped bar 21 away from the chute 20 is connected to the The turntable 22 is connected, the L-shaped rod 21 is connected to the eccentric part of the turntable 22 through a movable pin, one side of the turntable 22 is connected to the output end of the second motor 23, and the stri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com