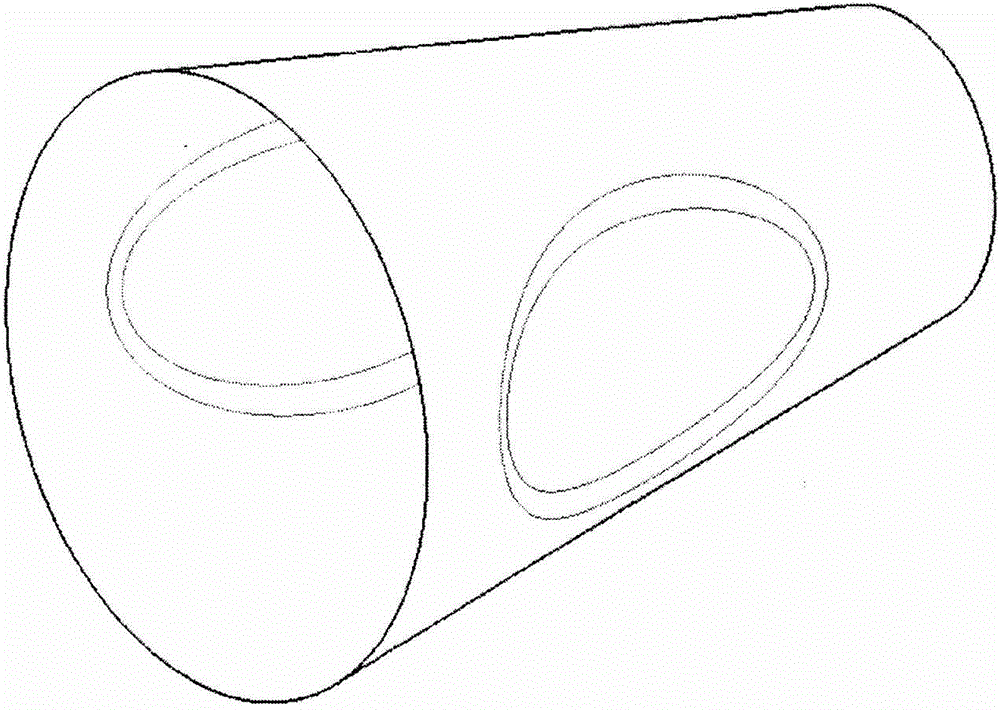

Integral forming method of composite material structural member comprising double-curved-surface profile structure

A composite material and integral molding technology, which is applied in the field of composite material molding, can solve the problems of unfavorable weight loss and comprehensive performance guarantee of the whole machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] A method for integral forming of a composite material structural part containing a hyperboloid surface structure, comprising the following steps:

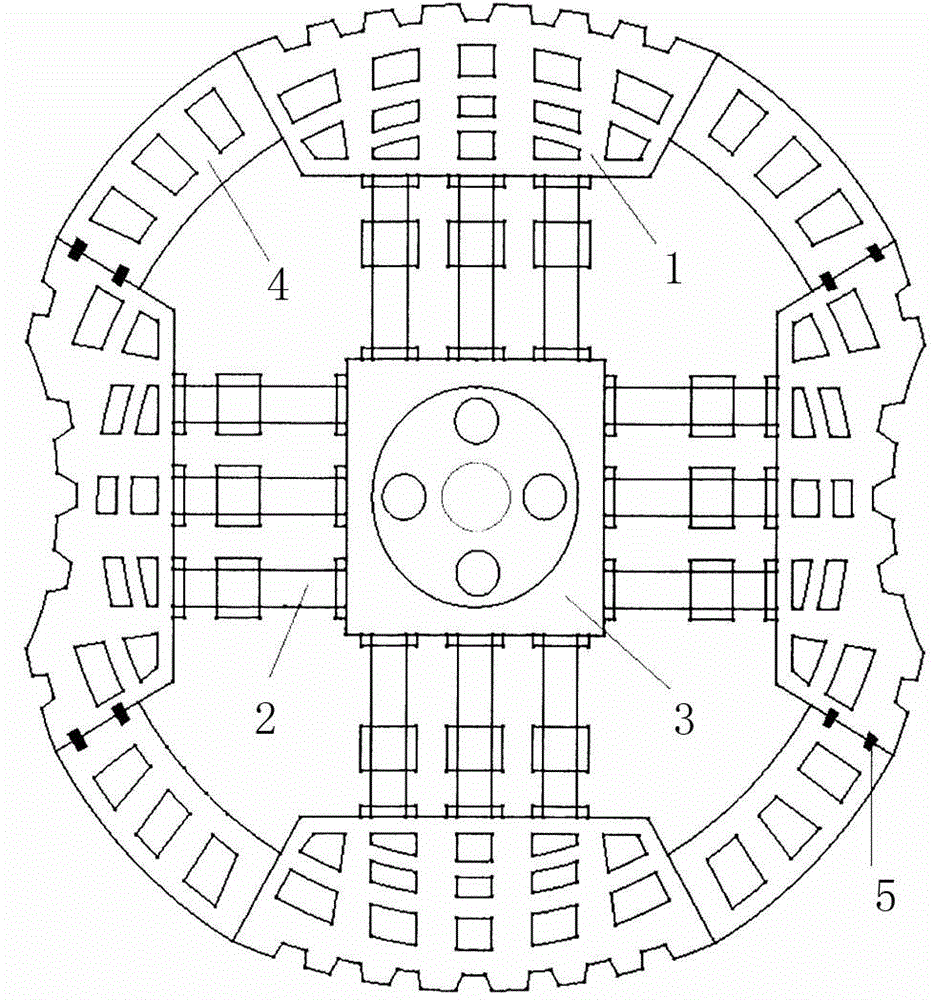

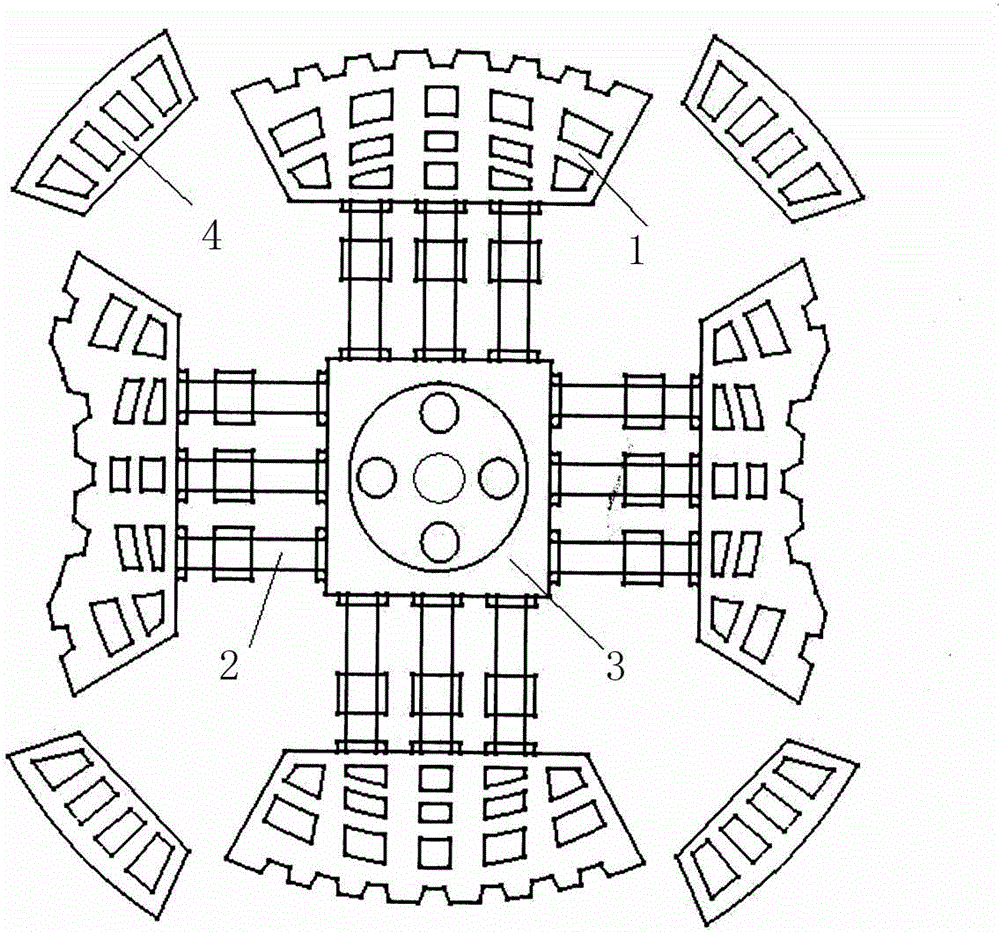

[0020] 1) if Figure 1 to Figure 4 As shown, a number of groups of hydraulic rods 2 are respectively arranged around the central main shaft 3, and wall panel forming tooling 1 is connected to the hydraulic rods 2. After the hydraulic rods are stretched out, between every two panel forming tooling The wall panel auxiliary tooling 4 is connected by fasteners, and the positioning block is used to make the wall panel auxiliary tooling 4 and the wall panel forming tooling 1 realize accurate positioning, so as to ensure that the outer circumference of the wall panel auxiliary tooling 4 and the wall panel forming tooling 1 is hyperbolic as a whole The overall forming tooling of the barrel section structure of the profile;

[0021] 2) Adhesive sealing material is used at the connection between the auxiliary panel tooling 4 and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com