Patents

Literature

95 results about "Posterior composites" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

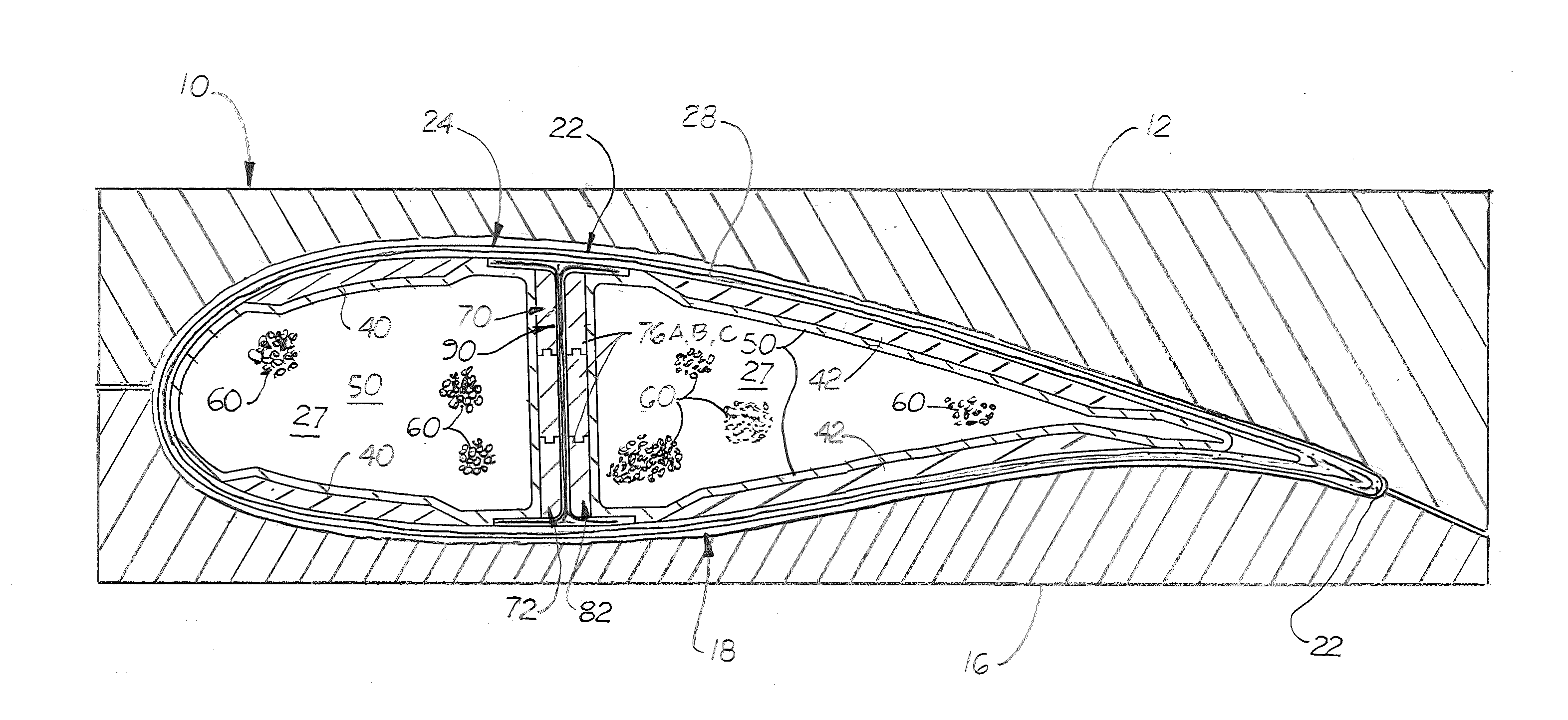

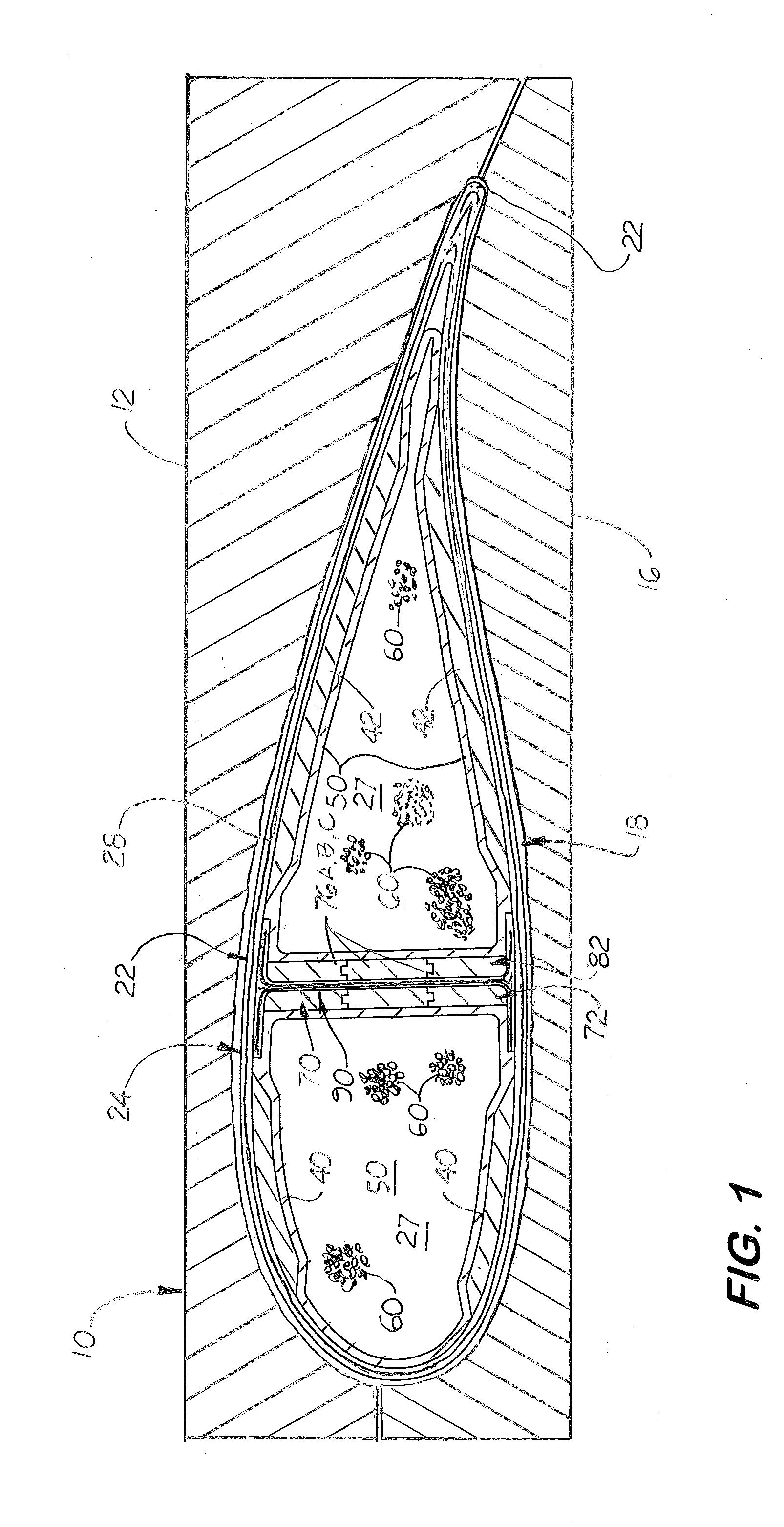

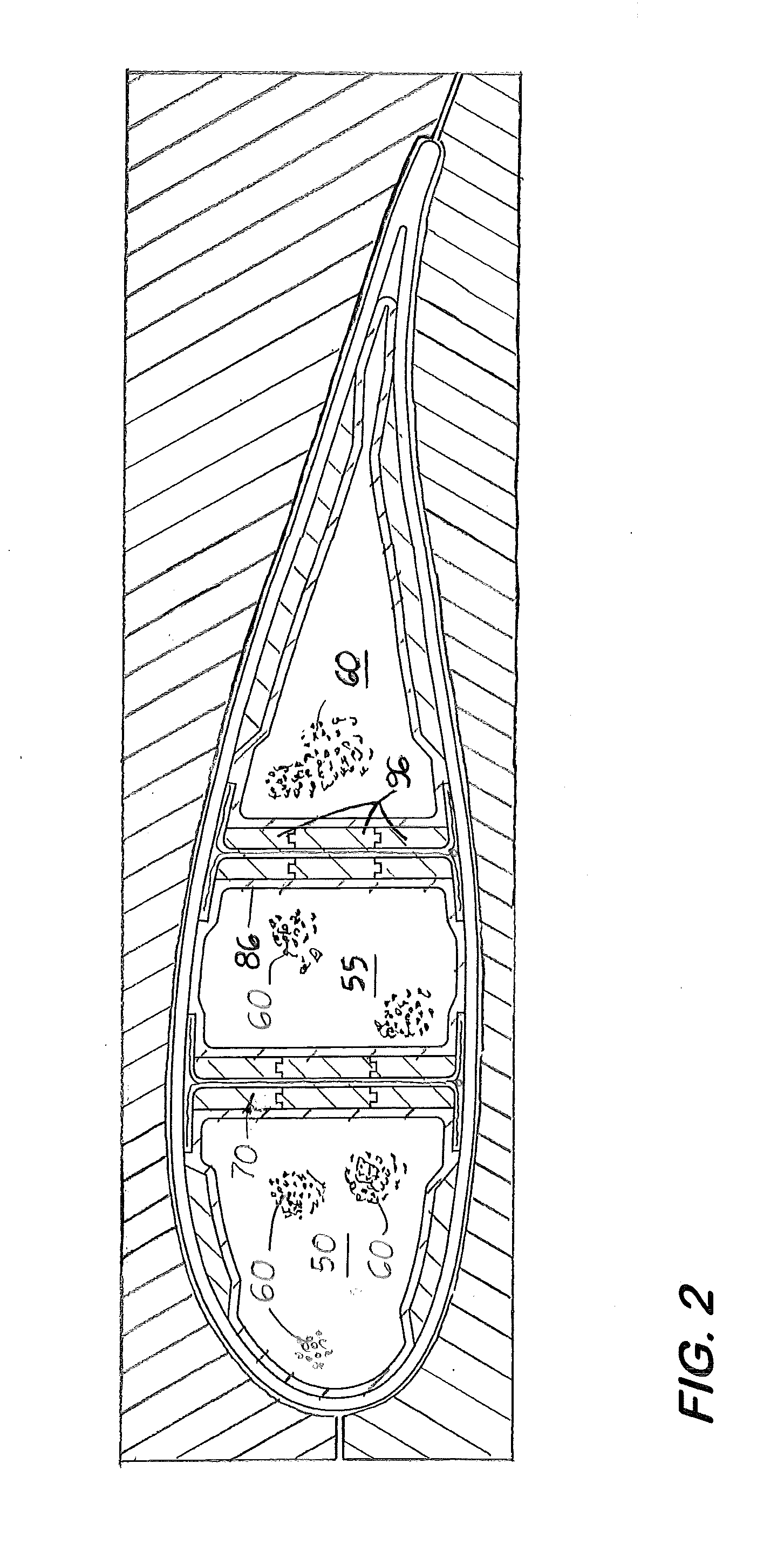

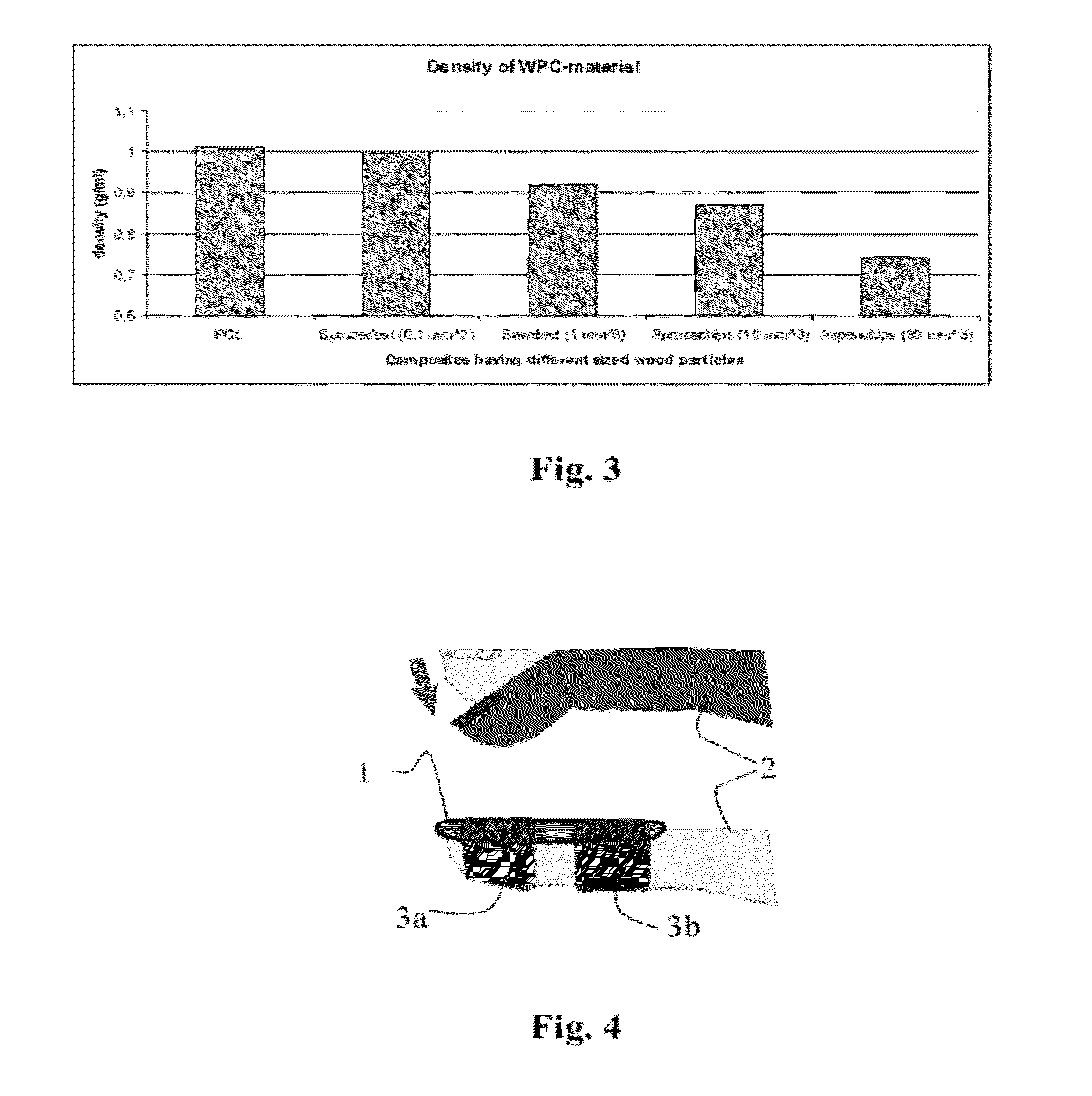

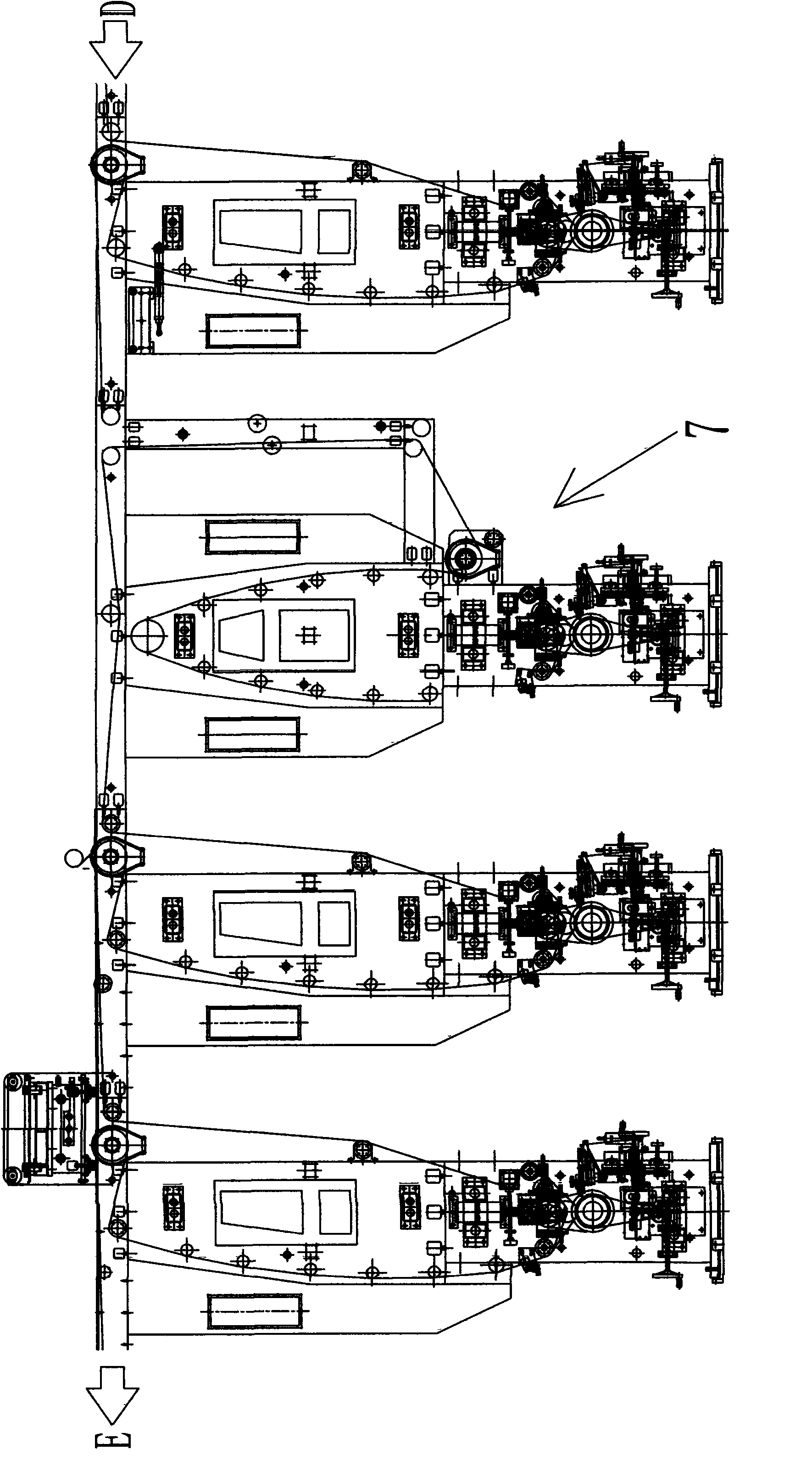

Method of Manufacturing Hollow Composite Parts with In Situ Formed Internal Structures

InactiveUS20130075025A1Easy to disassembleEvenly compactedFinal product manufactureConfectioneryEngineeringPosterior composites

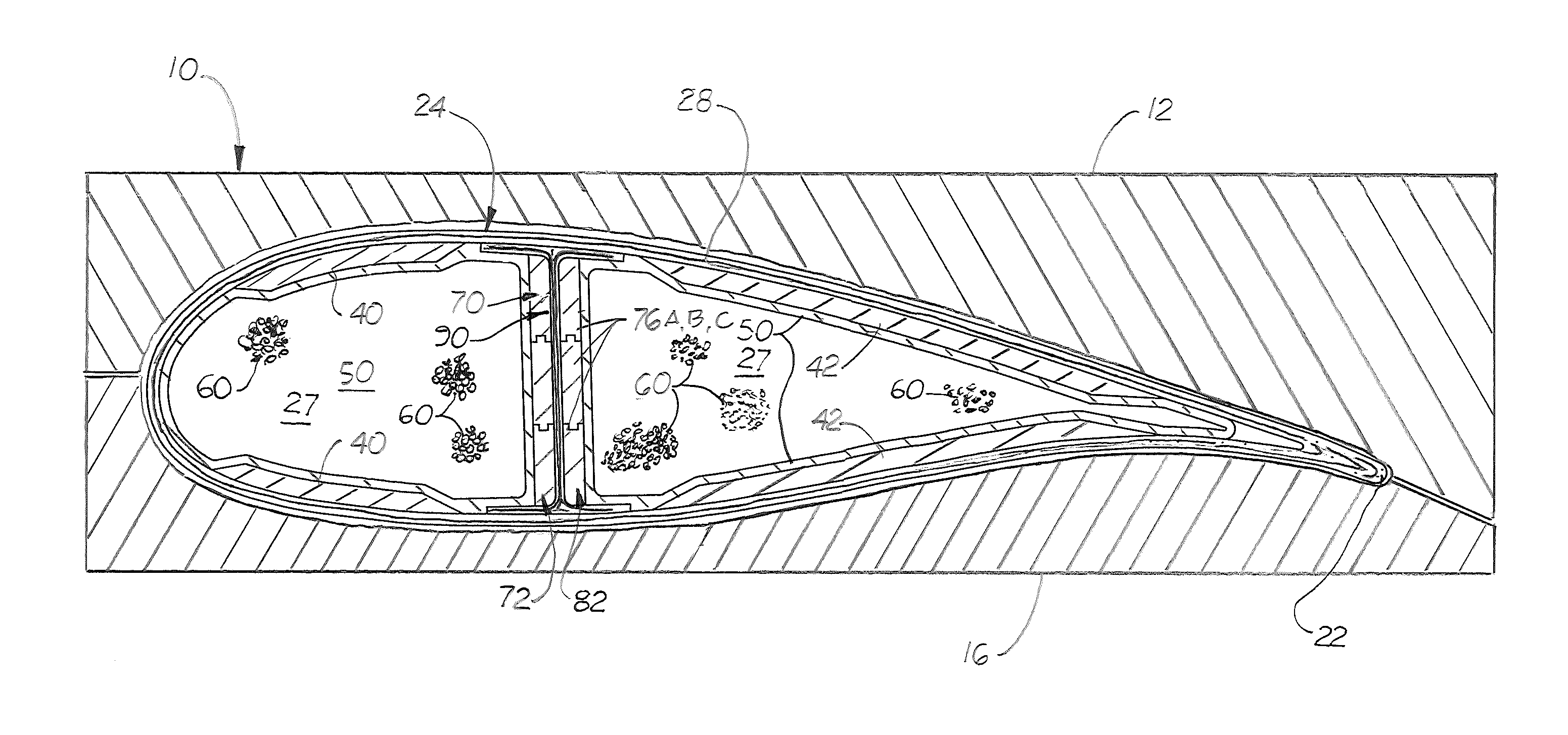

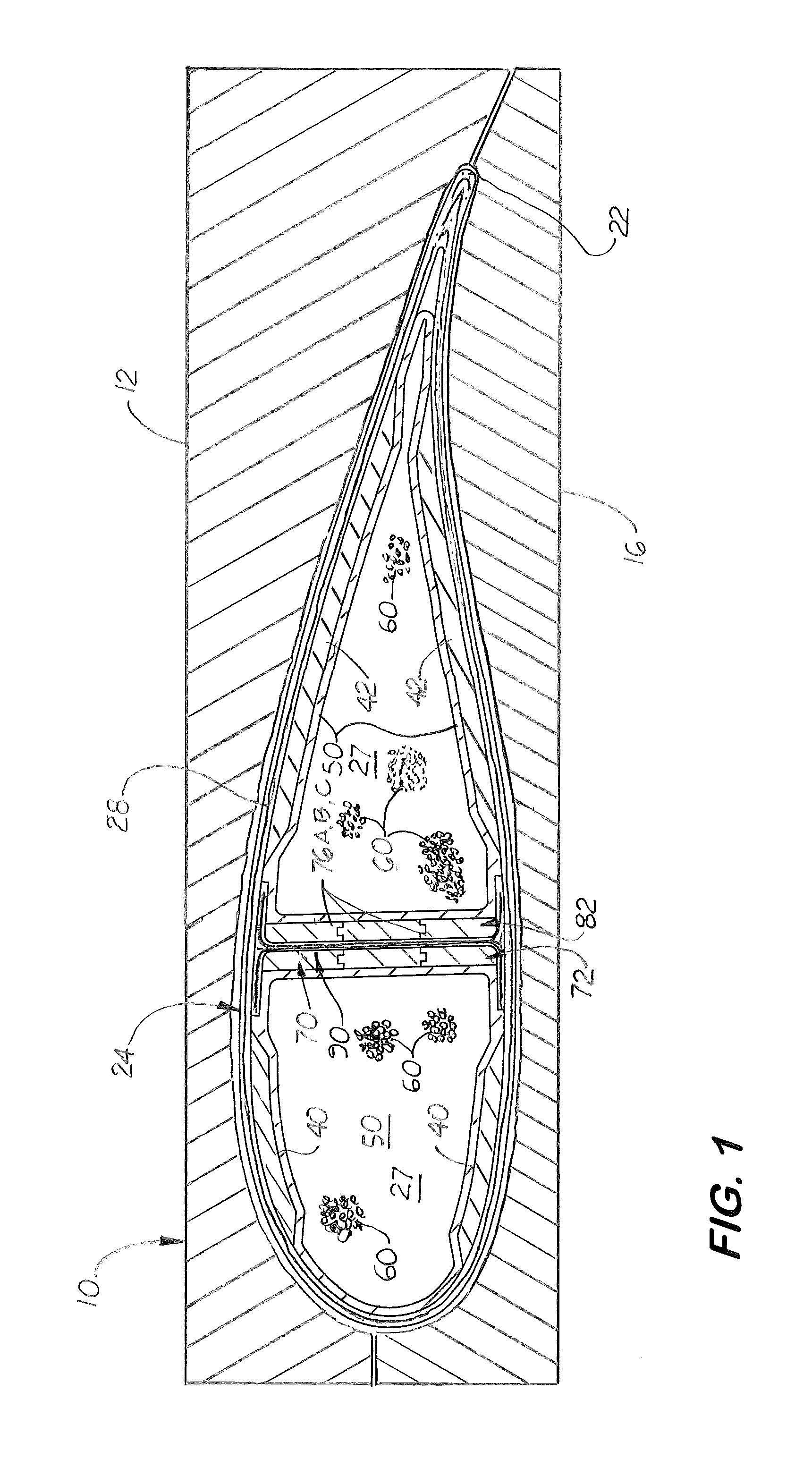

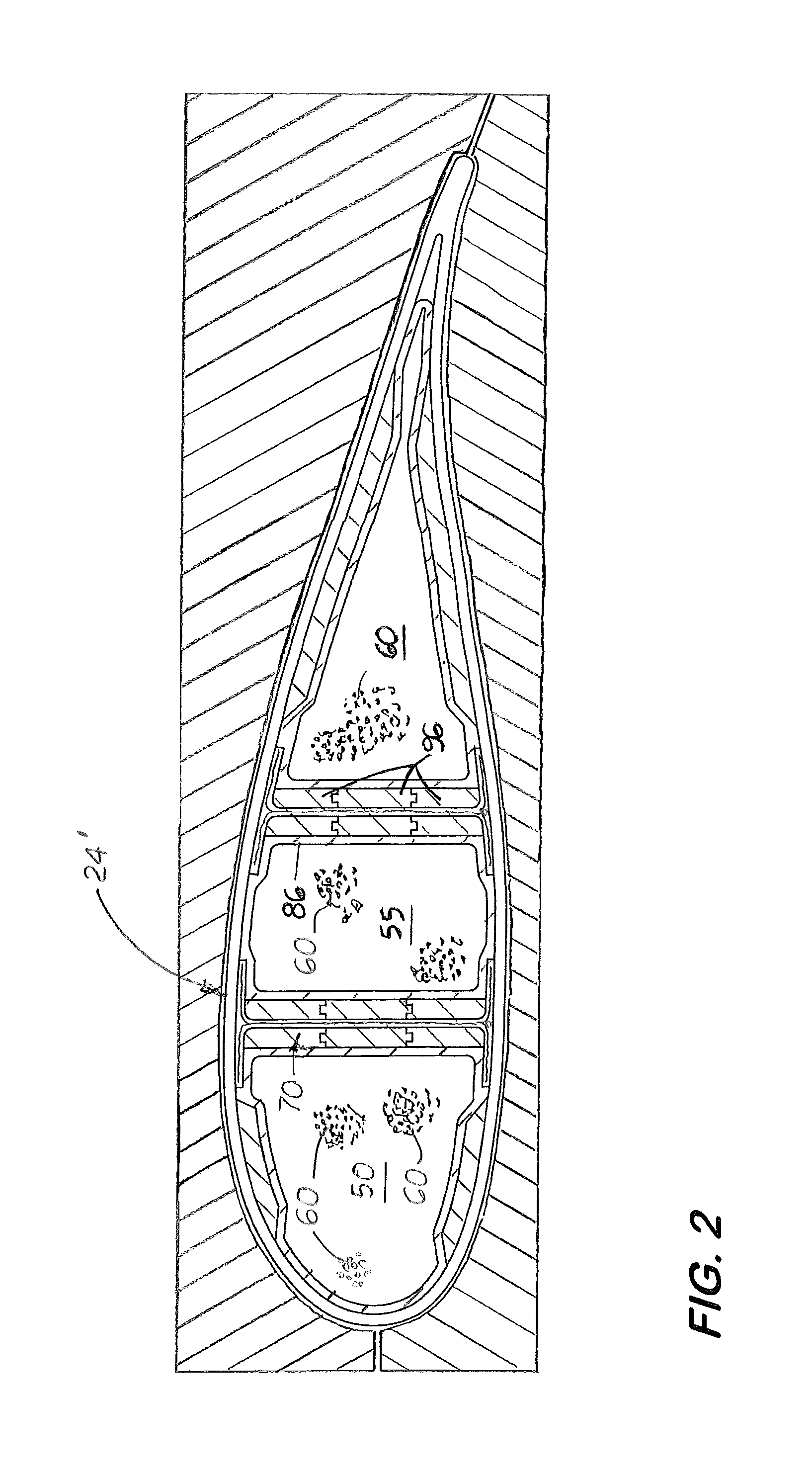

A method for manufacturing complex hollow composite parts with at least one internal structure formed in situ by laying laminated layers around a removable mandrel assembled inside the part's inner cavity. The inner mandrel is made up of two jig plate assemblies aligned in a parallel manner and space apart where the internal structure is to manufactured. Each jig plate assembly is made up of at least three jig plates stacked in an edge-to-edge manner Located on opposite sides of each jig plate assembly is an elastic envelope filled with spherical objects. When evacuated, the envelope collapses and relaxes and composite material may then laid up inside the inner cavity and around the envelopes. When exposed to a heat, the envelopes expand and in situ and form internal structures inside surface of the cavity. Each envelope and each jig plate assemblies can be easily dissembled and reused.

Owner:GUITTON MAURICE

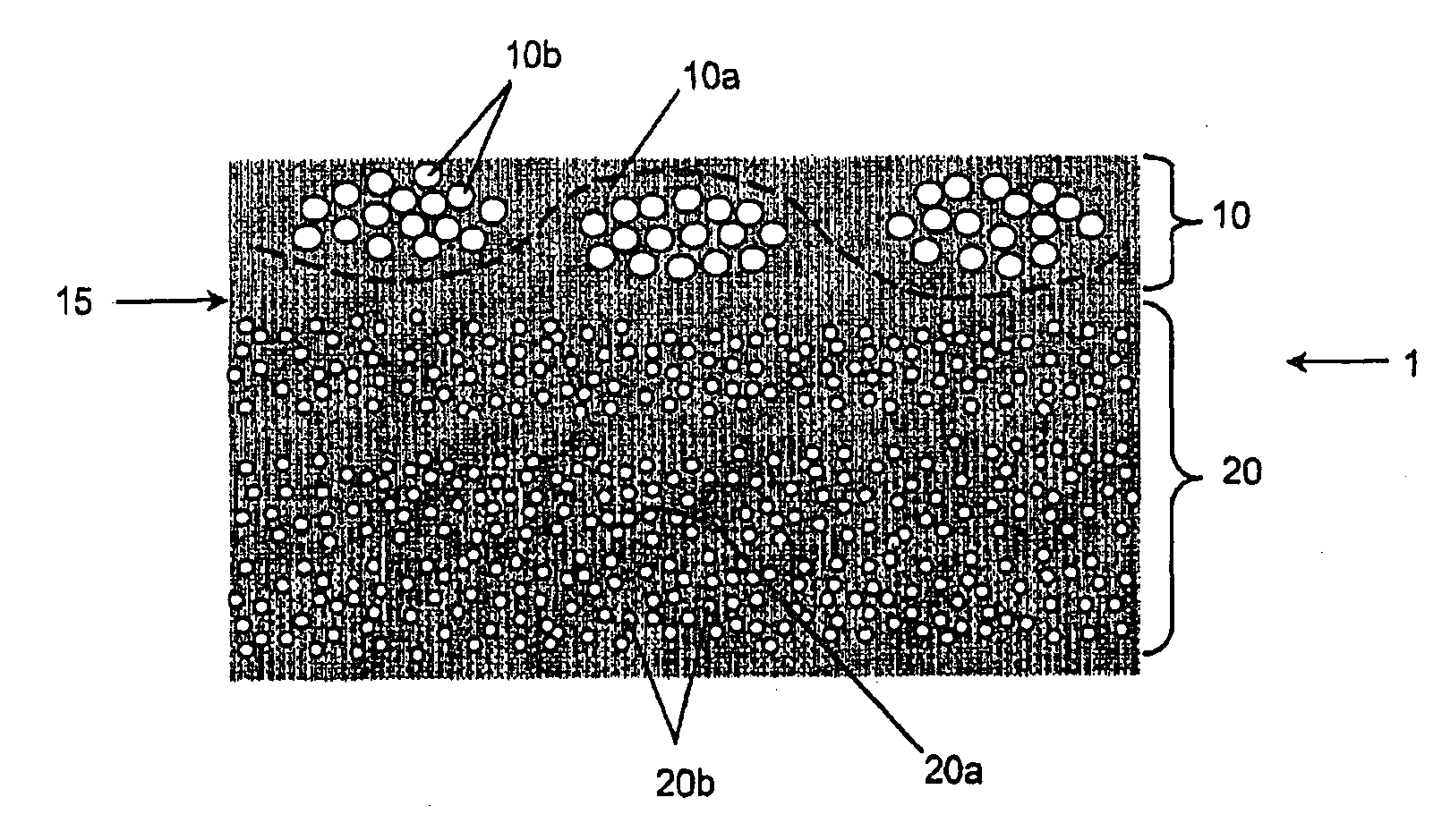

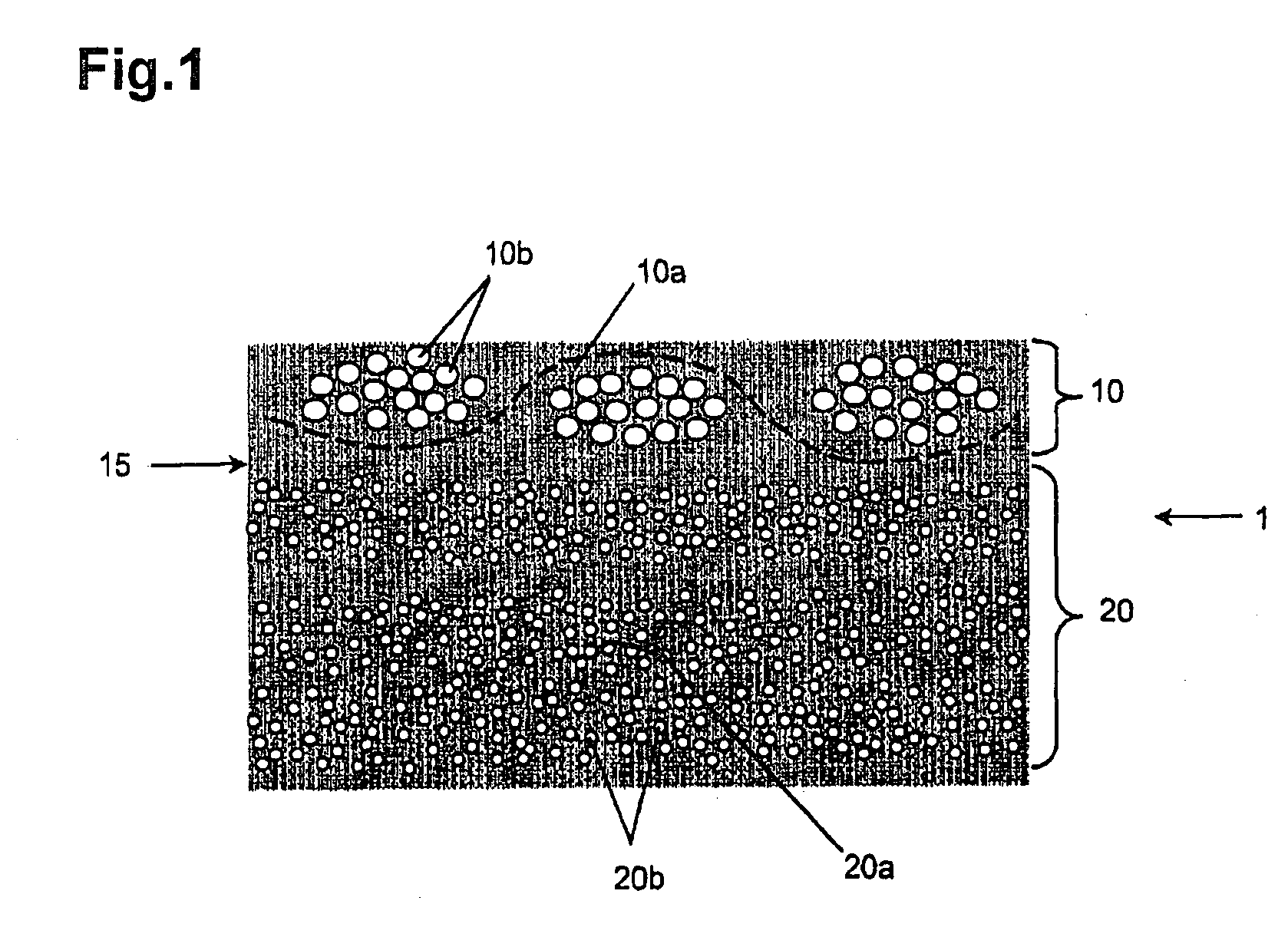

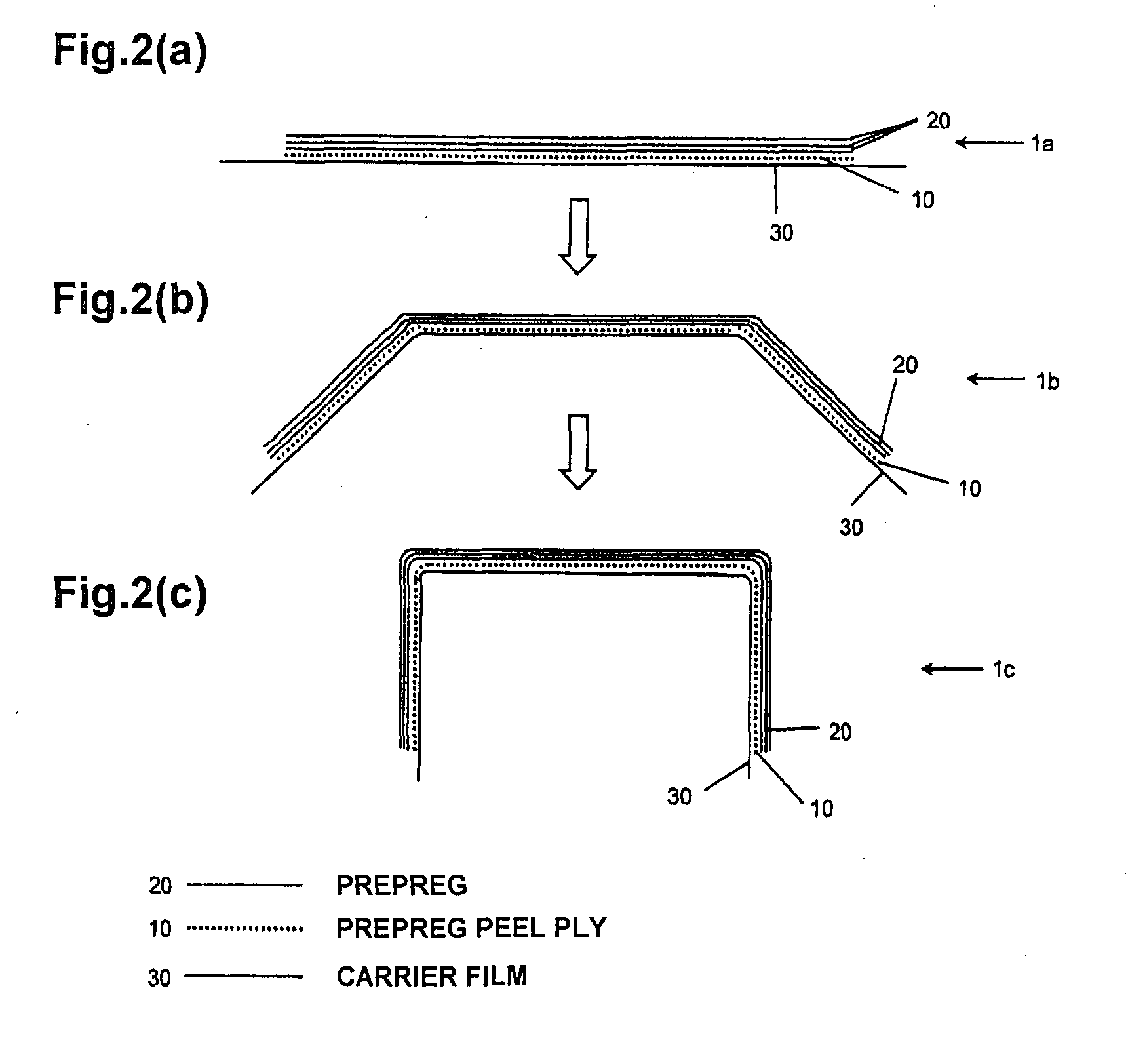

Prepreg peel ply for continuously forming composite material

InactiveUS20090239018A1Increasing the thicknessEasy to manufactureLayered productsThin material handlingPolyesterFiber

The invention provides a prepreg peel ply to be laminated on a surface of a composite material prepreg for forming a member having a concaved portion such as an H-shaped member, wherein the prepreg peel ply is peeled off after performing hardening so as to improve the adhesiveness of the surface of the composite material. A prepreg peel ply impregnated with resin having a hardening property substantially equivalent to that of the composite material prepreg is used as the peel ply to be laminated on a surface of the composite material prepreg. Through use of such prepreg peel ply, it becomes possible to apply a continuously formed prepreg material to form members having concaved portions, such as H-shaped members, and to form excellent members without voids. By using polyester or nylon as fiber material contained in the prepreg peel ply, the peel property can be improved, and the surface of the composite material prepreg will have a desirable roughness after peeling off the prepreg peel ply, according to which the adhesiveness of the surface is enhanced.

Owner:JAMCO

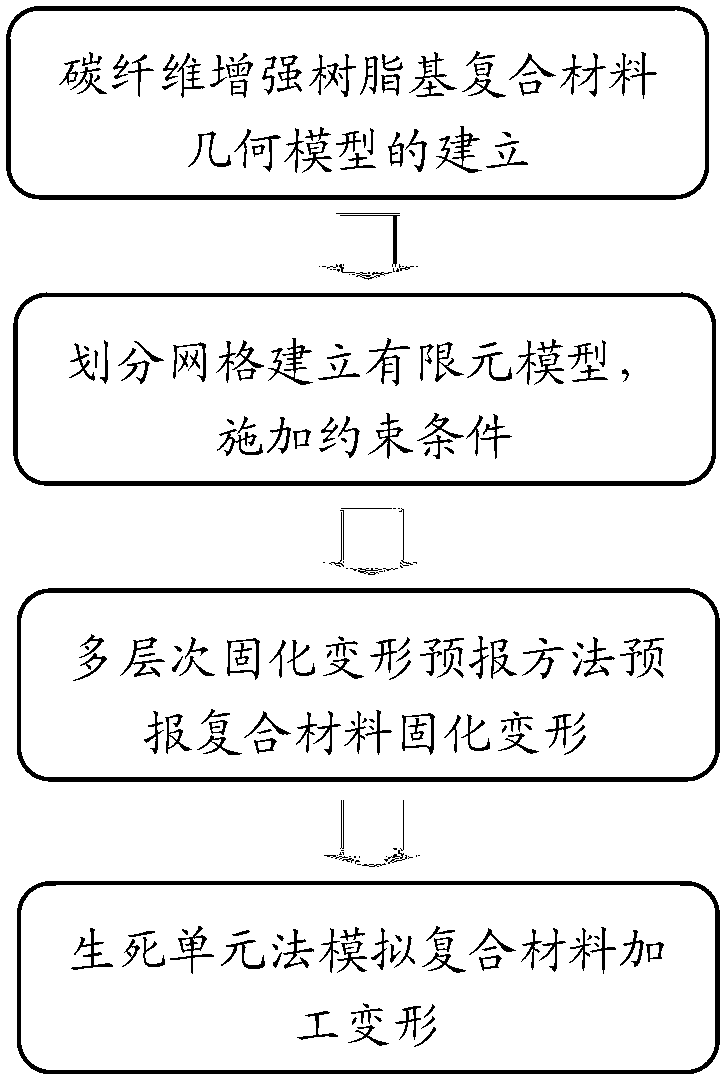

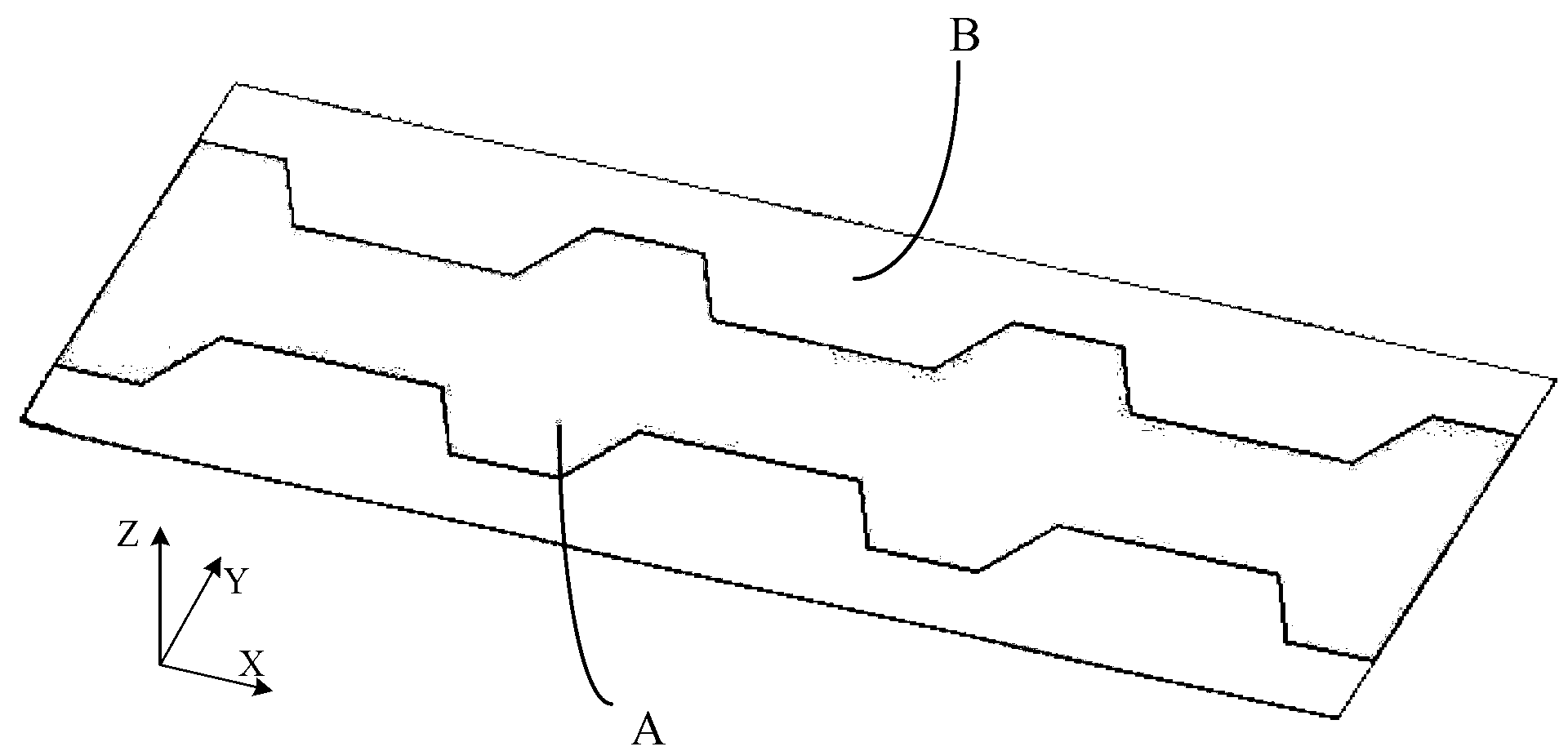

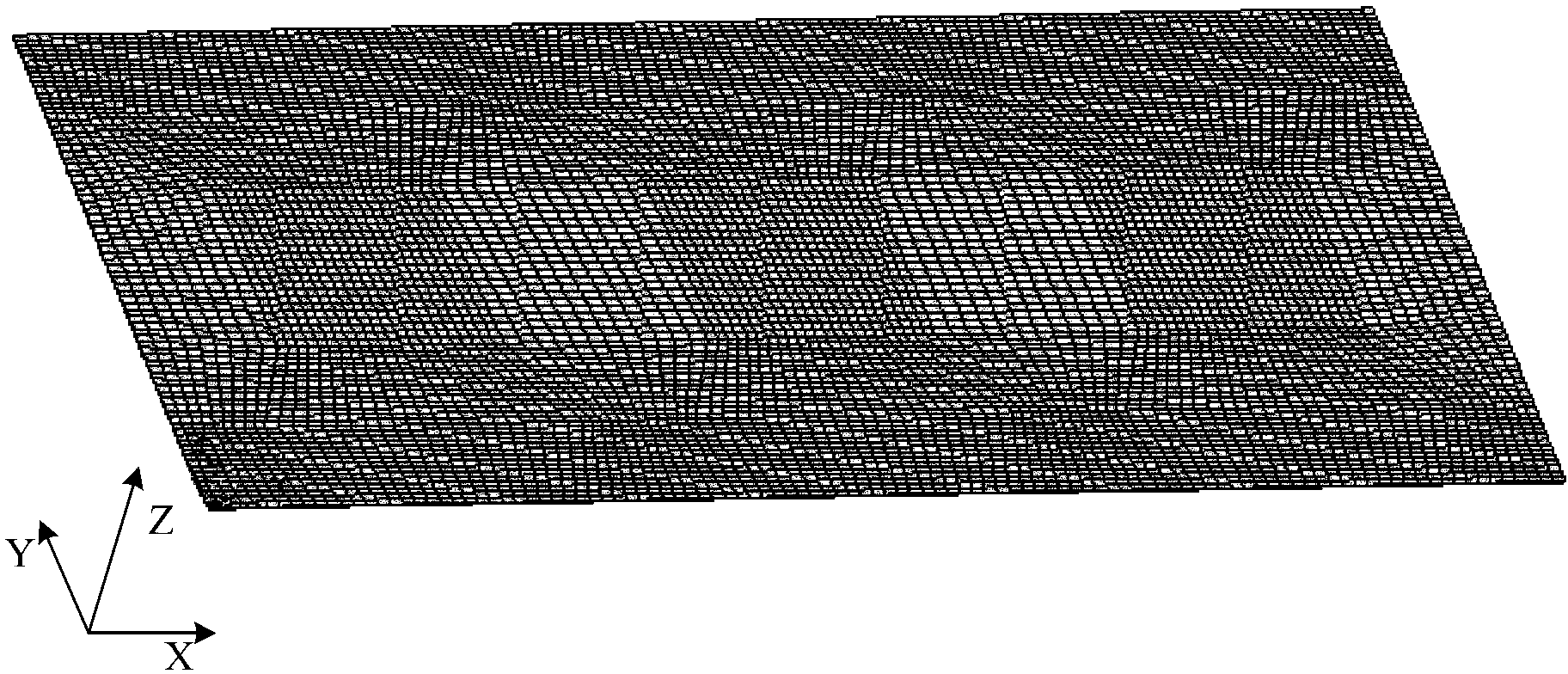

Simulation method for machining deformation of carbon-fiber-reinforced resin matrix composite

InactiveCN103294862ASolve the real problemEasy to masterSpecial data processing applicationsElement modelCarbon fibers

The invention provides a simulation method for machining deformation of carbon-fiber-reinforced resin matrix composite. The method includes: a, inputting modeling parameters in ANSYS software to build a geometric model; b, meshing the geometric model built in step a by a solid 185 unit, building a finite element model, and limiting the finite element model; c, simulating an autoclave process, calculating a solidification deformation value of the composite, and extracting a stress and strain distribution cloud graph; d, simulating a composite machining process by a method of killing or activating element to obtain machining deformation of the machined composite; and e, calculating the machining deformation value of the machined composite. The method has the advantages that simulation of accurate deformation prediction for the machining deformation of the carbon-fiber-reinforced resin matrix composite is realized, and the practical problems in composites engineering application are solved. The method is simple to operate and convenient to use. The software platform ANSYS is used, so that the method is well compatible and is convenient for technicians to master and use.

Owner:SHANGHAI AIRCRAFT MFG +1

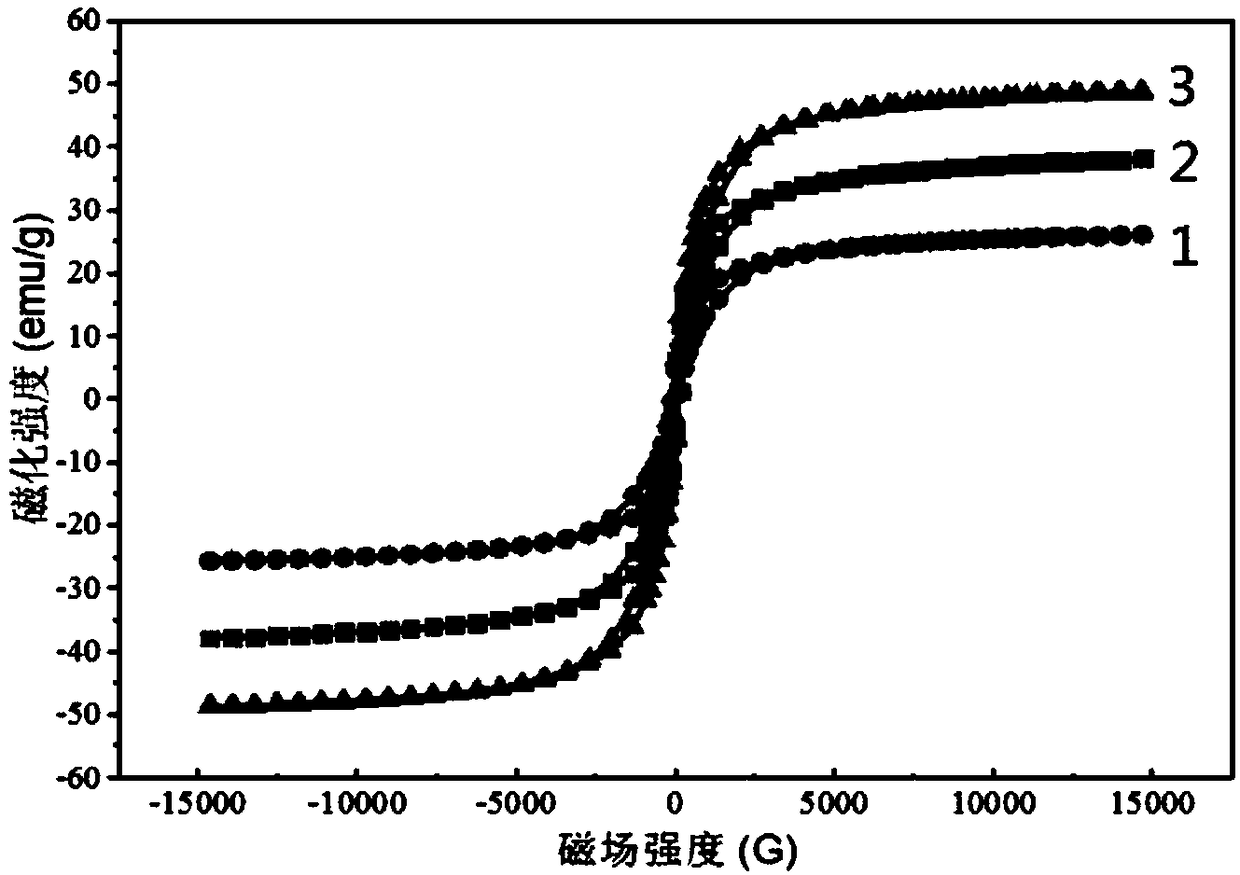

Cold treatment method for preparing high-toughness metal-base composite material

The invention relates to a cold treatment method for preparing high-toughness metal-base composite material, belonging to the technical field of material preparation. The method is that a pulsed magnet field is applied in the process of the deep cold treatment of the metal-base composite material to enable the material to have high toughness. By using the transient impact effect of the pulsed magnetic field, high-density dislocation structures in the material are enabled to move rapidly to induce the generation of nano twin crystals. After treatment, the composite material has organization characteristics of nanoscale coherent interfaces. The duration of the deep cold treatment is 1h-40h. The short-time pulsed magnetic field is applied at the later stage of the cold treatment, wherein the parameters the magnetic field: the magnetic induction intensity is 5-40T, the magnetic field frequency is 0.1-5Hz and the magnetic field treatment duration is 10-100s. The invention has the advantages that the solidification structure of the metal-base composite material prepared through the method is compact, the residual stress is small, the high-density nano twin crystals exist and the toughness of the composite material is synchronously and greatly improved.

Owner:JIANGSU UNIV

High performance epoxy resins composite material and preparation thereof

InactiveCN101407620AGood dispersionEasy to manufactureInorganic pigment treatmentCarbon nanotubeCarboxylic acid

The invention belongs to the technical field of nano materials, and particularly relates to a high-performance epoxide resin composite material and a preparation method. Carboxylic acid, chloroformylation, amination or hydroxylation are carried out to the carbon nano tube; and the carbon nano tube is modified by small molecular aromatic polyanhydride compound so as to prepare the carbon nano tube which carries acid anhydride group. The carbon nano tube is dispersed in epoxide resin substrate by ultrasonic oscillation and high-speed stirring, is cured by adopting organic acid anhydride curing agent so as to obtain the carbon nano tube / epoxide resin composite material. The invention leads the preparation of the carbon nano tube / epoxide resin composite material to be more convenient, the activity of taking part in reaction of the carbon nano tube is endowed, and acid anhydride group of the carbon nano tube and the epoxide resin group of the epoxide resin generate chemical cross linking, thus improving the dispersion of the carbon nano tube in the epoxide resin and obtaining high-performance epoxide resin composite material. Compared with the control sample, all the mechanical performance indexes of the cured composite material are improved by 5 percent to 300 percent and the volume resistivity is reduced by 3 to 9 order of magnitude.

Owner:TONGJI UNIV

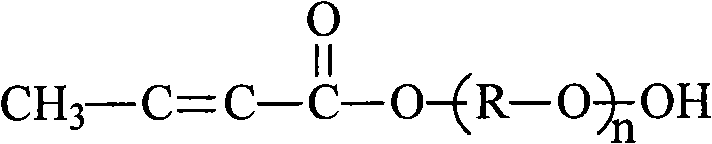

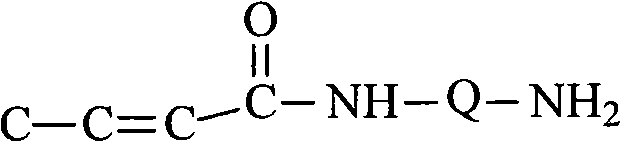

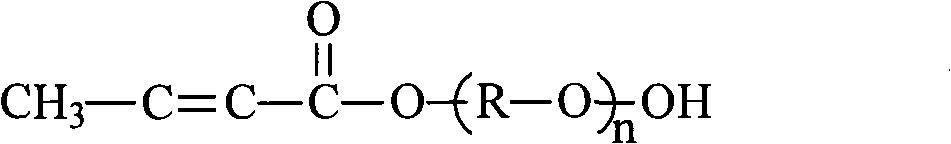

Carbon nano-tube / unsaturated polyester composite material and preparation thereof

The invention belongs to the technical field of nano materials, and particularly relates to a carbon nano tube / unsaturated polyester composite material and a preparation method thereof. The preparation method comprises the following steps: carboxylic acid and chloroformylation are carried out to the carbon nano tube, the carbon nano tube is modified by amino or hydroxyl acrylic ester compound, and the carbon nano tube which can carry polymerizable double bond. The modified carbon nano tube is dispersed in unsaturated polyester substrate, and cobalt iso-octoate and methyl ethyl ketone peroxide are adopted as an accelerating agent and a curing agent so as to prepare the carbon nano tube / unsaturated polyester composite material. The obtained composite material has higher heat stability and chemical stability. Compared with unsaturated polyester condensate which has same compositions and does not add the carbon nano tube, the volume resistivity of the cured composite material is reduced to 3 to 9 order of magnitude, and the surface resistivity is reduced to 3 to 8 order of magnitude. The invention has simple technique and more practicability. The composite material can be applied to the shell or coating of the equipment in the fields of manufacturing motors of electric appliances, chemical machines and the like.

Owner:TONGJI UNIV

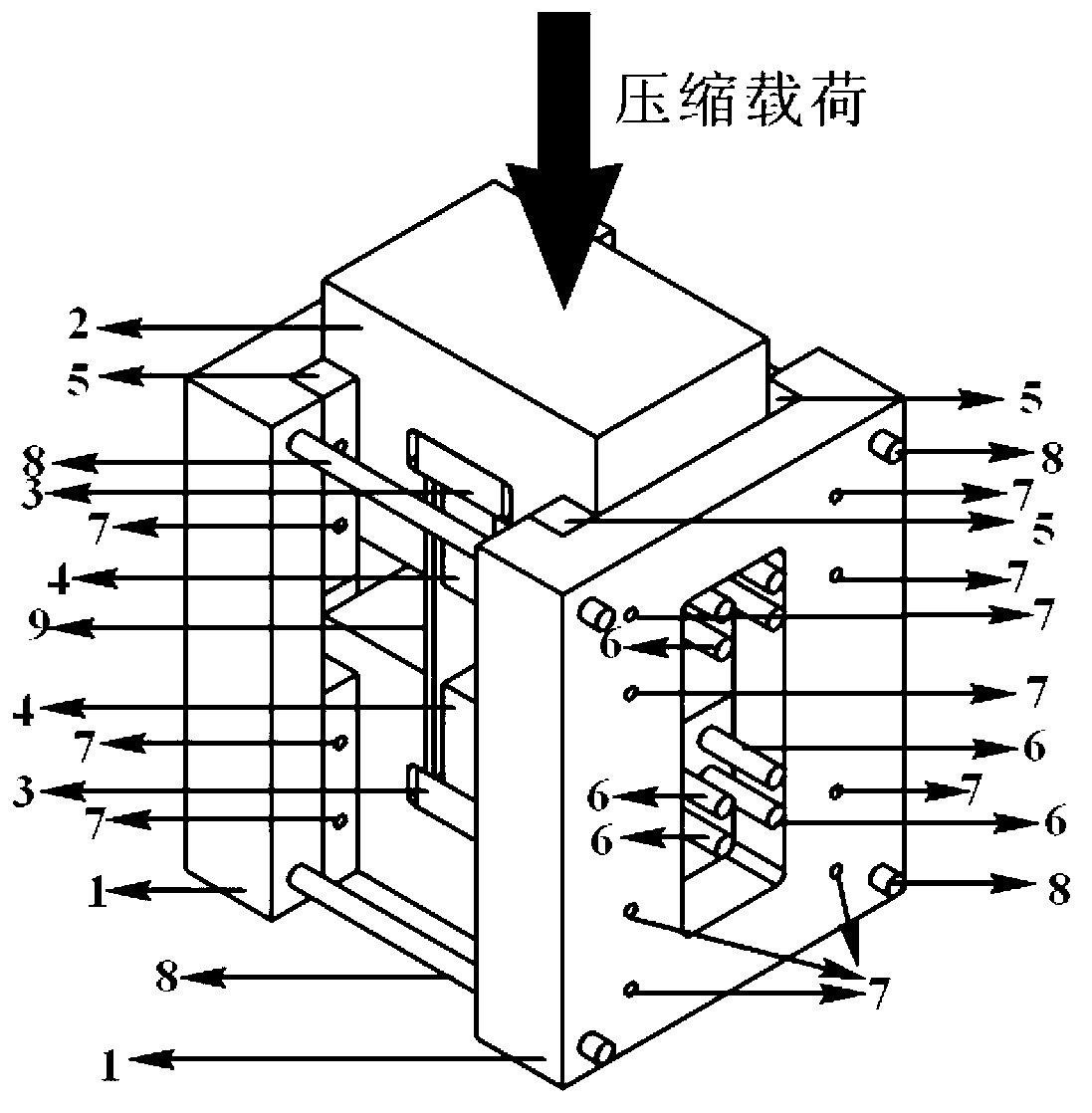

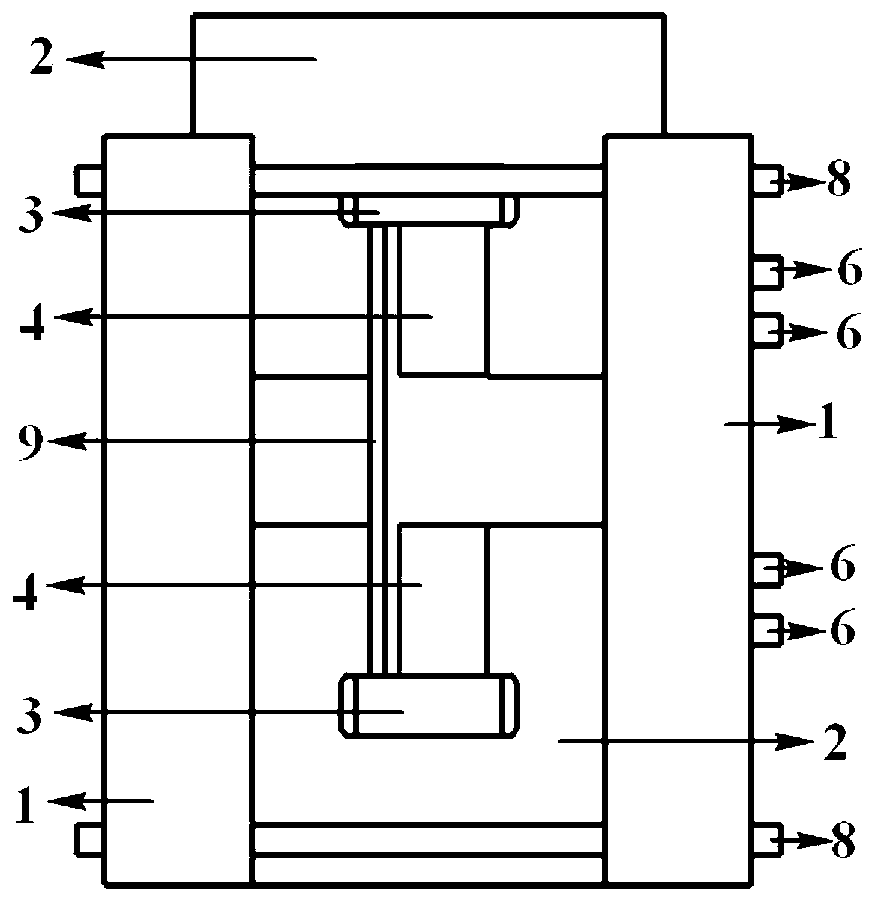

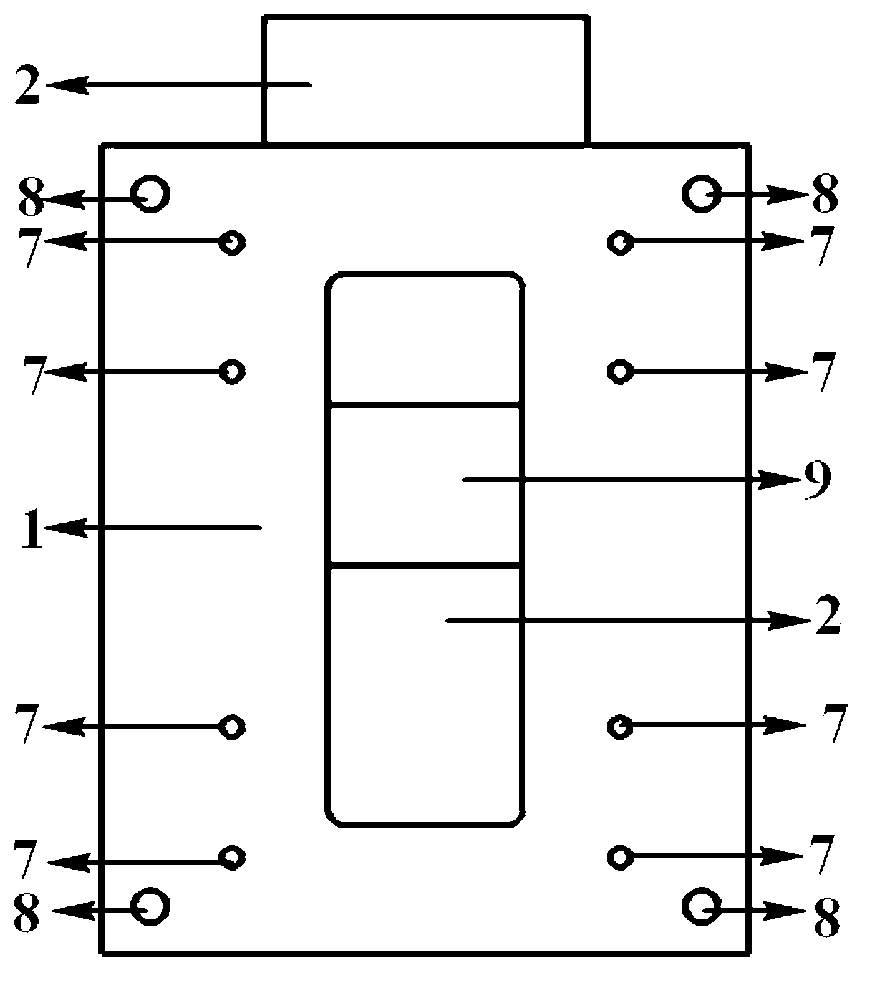

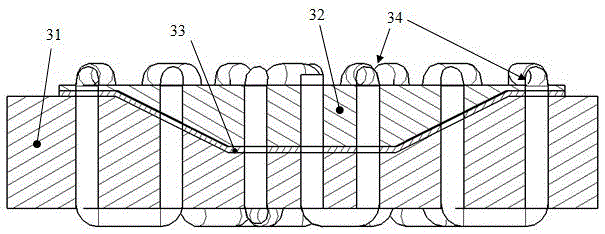

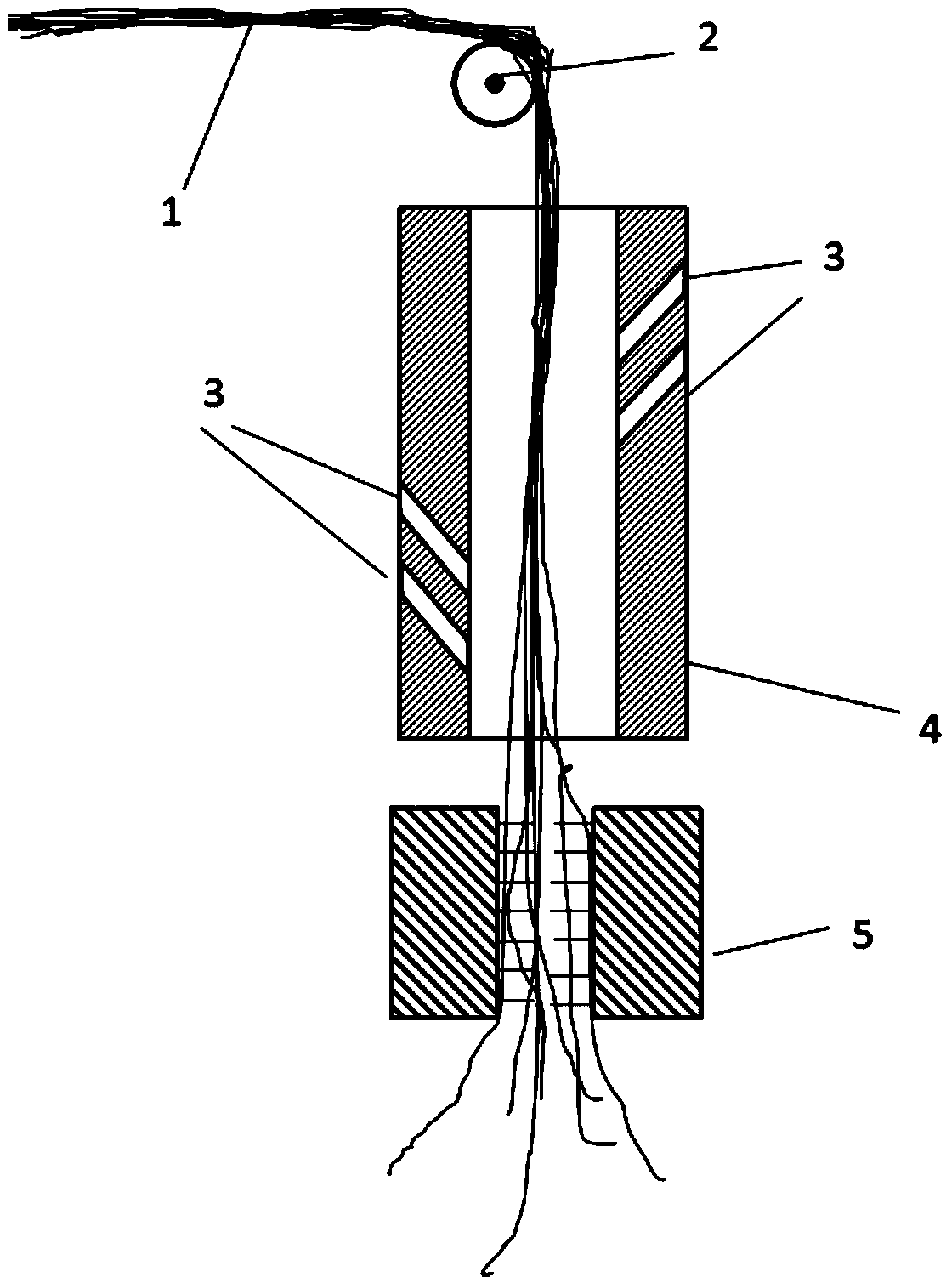

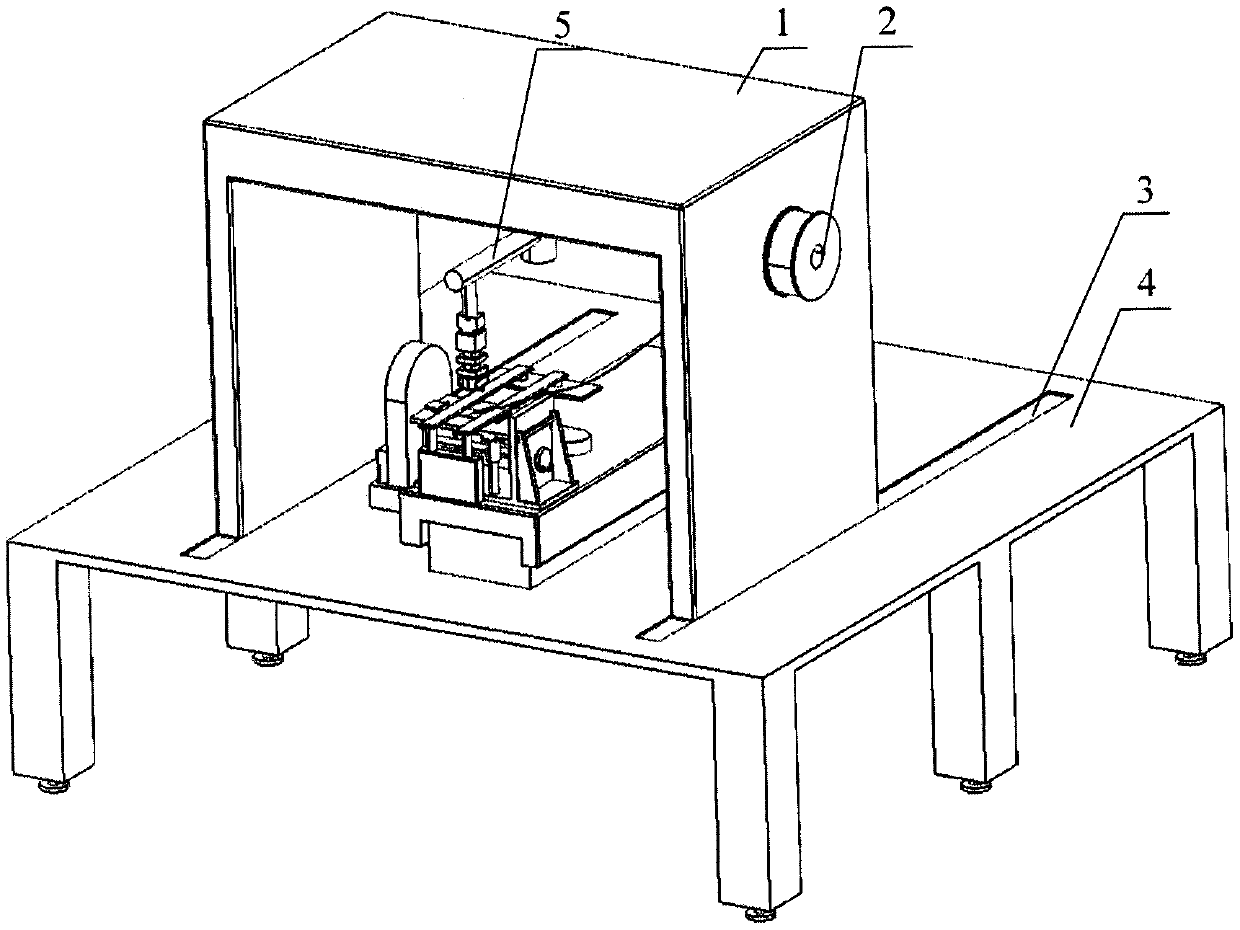

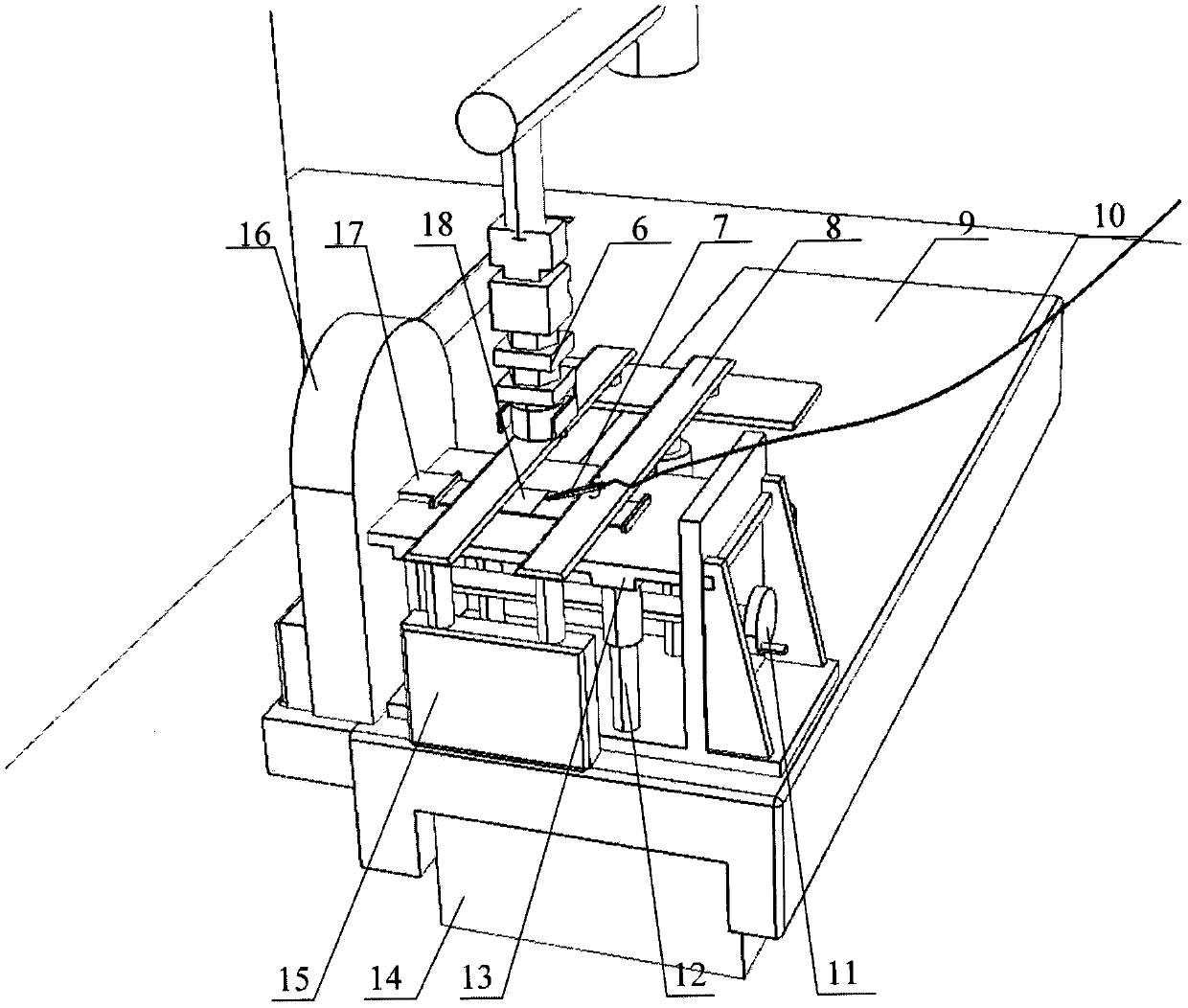

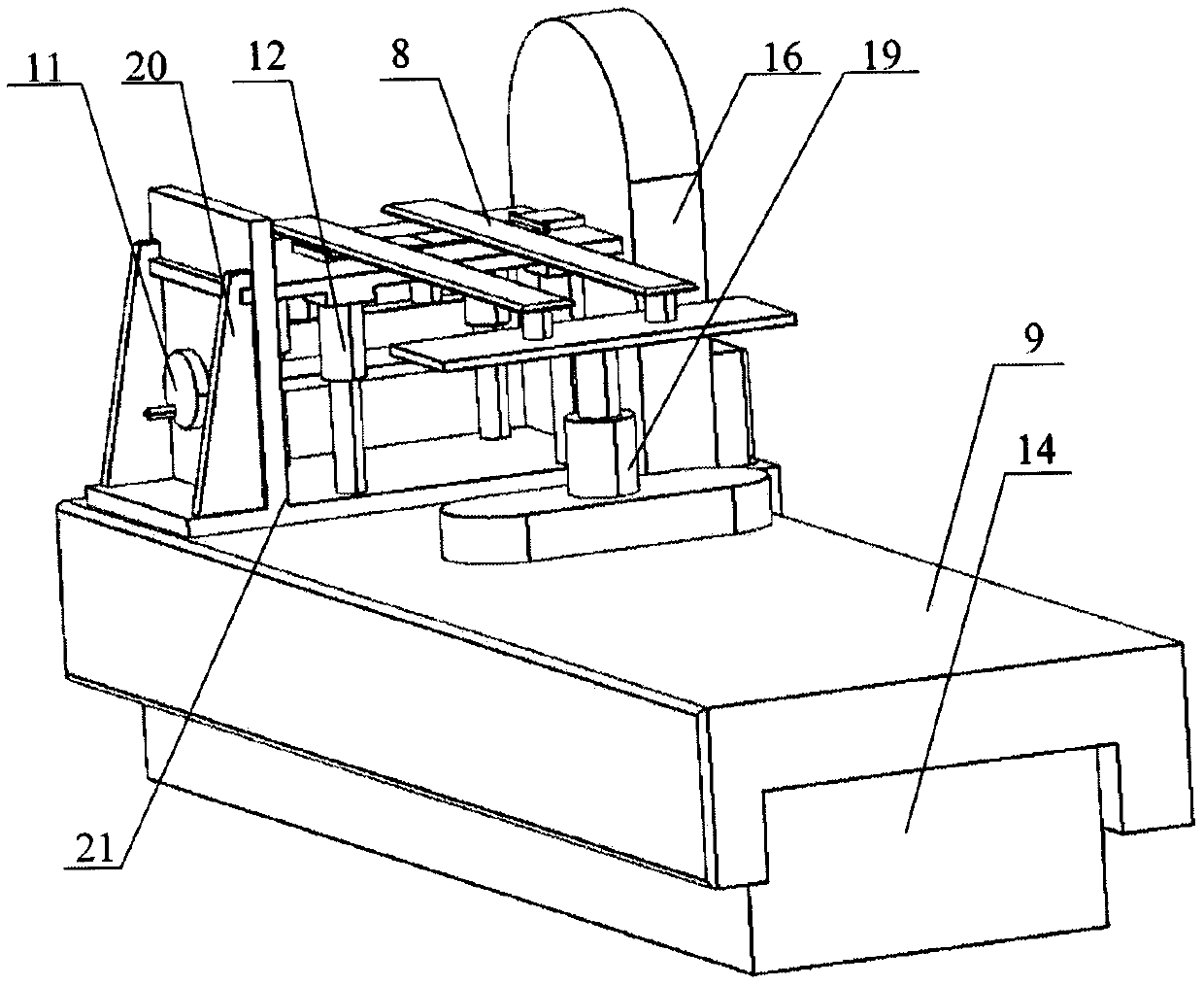

Compression fatigue testing device and method for low-speed impacted composite material laminate

InactiveCN103293059AGuaranteed neutralityWon't breakMaterial strength using tensile/compressive forcesLow speedPosterior composites

The invention discloses a compression fatigue testing device and method for a low-speed impacted composite material laminate. The device comprises two guide units, two load units, two transmission units, two fixing units, eight sliding rail units, eight bolt tightening units, sixteen bolt connecting units and four screw rod connecting units. The problem that a test piece cannot be fixed in a compression fatigue test of the composite material laminate with initial low-speed impact damage is solved, so that the test piece is not required to be cut after the low-speed impact test and can be directly applied to the compression fatigue test, and the centering property of the test piece is guaranteed while the test piece is fixed through certain parts provided according to the invention.

Owner:BEIHANG UNIV

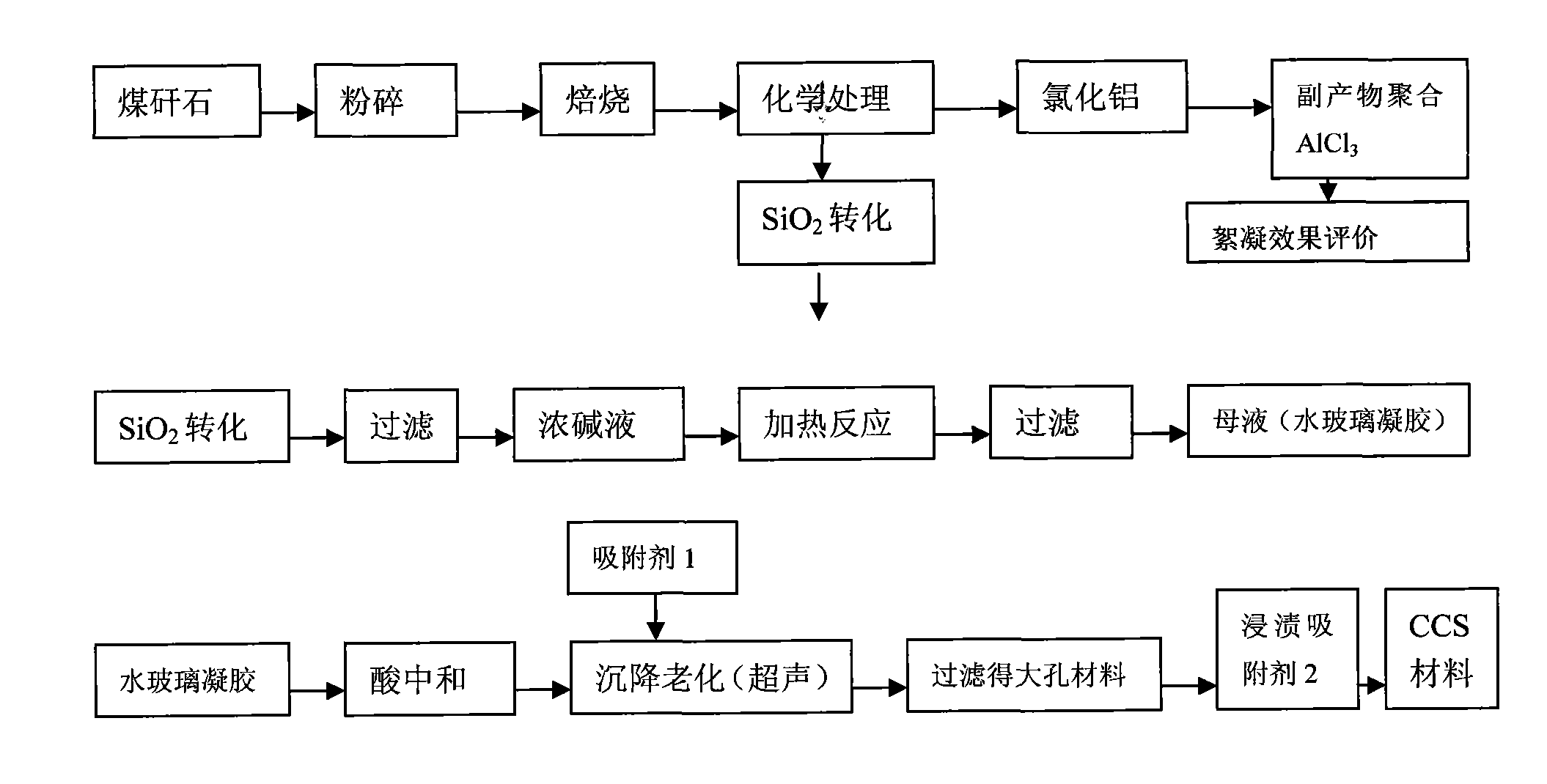

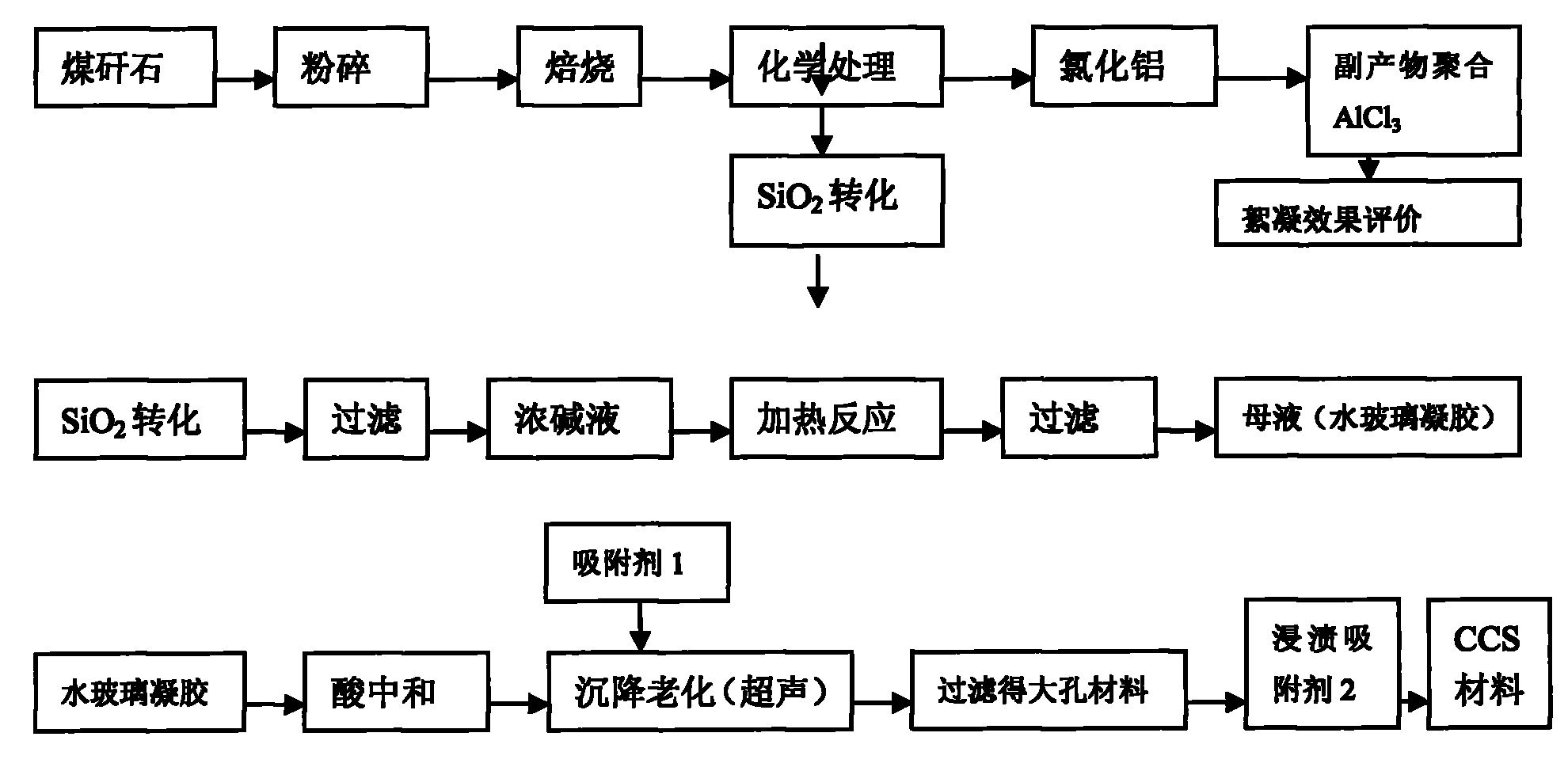

Method for preparing carbon dioxide capture material with coal gangue and polyethylene

InactiveCN101804332ALow costImprove the capture effectProductsReagentsAluminium chlorideAluminum Ion

The invention relates to a method for preparing a carbon dioxide capture material by utilizing the technology that coal gangue is taken as a raw material to develop a new material, and loading polyethylene, which comprises the following steps that: the coal gangue is crushed and roasted at high temperature; acid is added and fully stirred; aluminum oxide in the coal gangue is reacted with hydrochloric acid to obtain a product solution containing aluminum chloride, silica is separated from aluminum ions by filtering to obtain an aluminum chloride filtrate, and the filtrate is further reacted to obtain polyaluminium chloride; residual solids obtained after filter contain the silica, and concentrated alkali is heated to prepare a silicate solution; and the polyethylene and the acid are used for deposition treatment, so that the polyethylene is deposited on silica particles to obtain mesoporous particles. The material has high cold compressive strength and room-temperature capture capability, and can be heated to 105 DEG C to release carbon dioxide; and then a composite material can continue to capture carbon dioxide to be repeatedly used.

Owner:SHANXI LUAN MINING GRP

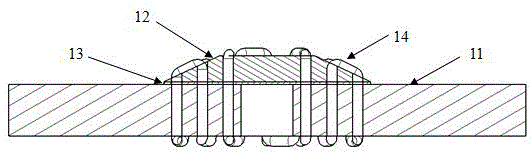

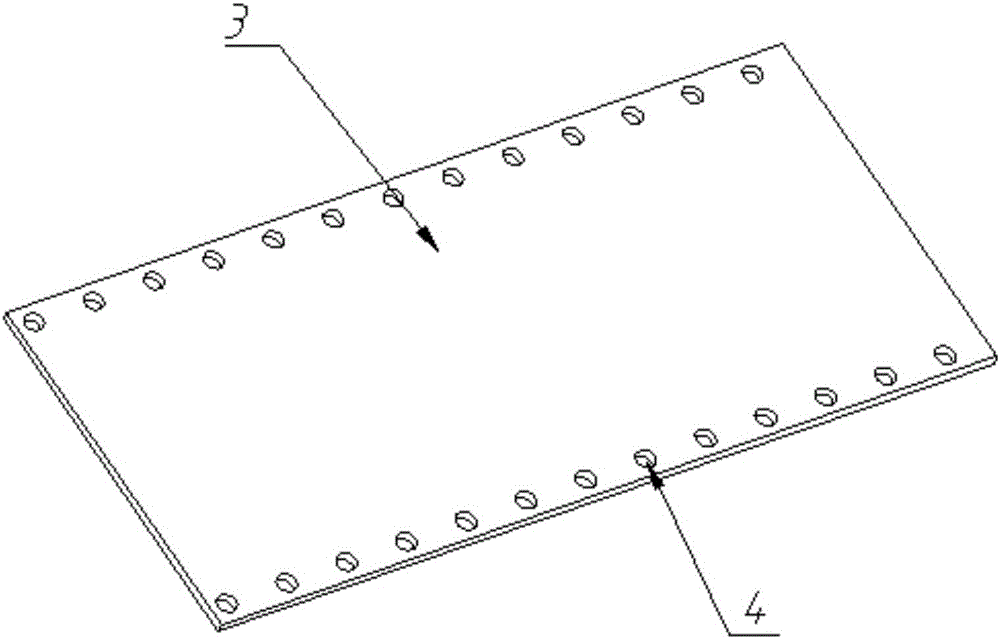

Repairing structure with composite repairing piece and method for forming repairing structure

InactiveCN105153950AReduce the risk of useLittle impact on performanceAdhesive processes with surface pretreatmentAdhesive processes with adhesive heatingPosterior compositesMechanical property

The invention discloses a repairing structure with a composite repairing piece and a method for forming the repairing structure and belongs to the technology of composite repairing. The repairing structure is composed of a repaired damaged composite structure, the composite repairing piece, glue between the composite repairing piece and the composite structure, and a sewing thread steeped with a cementing compound. Firstly, small holes penetrating through the repairing piece, the damaged composite structure and a glue layer between the repairing piece and the damaged composite structure are machined in a repairing piece repairing part; secondly, the sewing thread steeped with the cementing compound sequentially penetrates into the small holes; lastly, curing is carried out at the regulated temperature and pressure, so that the sewing thread are bonded to the repairing piece around the sewing thread and the damaged composite structure together, and thus the repairing structure with the repairing piece is formed. By means of the repairing structure formed through the method, the influence on the performance in a composite laminated plate face is small, the environmental sensitivity is reduced, and the weight of the structure is slightly increased; in addition, the bonding effect between the composite repairing piece and the repaired structure can be improved, so that the mechanical property and the reliability of the repairing structure with the composite repairing piece are improved, and the use risk of the repaired composite structure is lowered.

Owner:刘龙权

Method of manufacturing hollow composite parts with in situ formed internal structures

InactiveUS8668800B2Evenly compactedEasy to disassembleMouldsFinal product manufactureEngineeringPosterior composites

A method for manufacturing complex hollow composite parts with at least one internal structure formed in situ by laying laminated layers around a removable mandrel assembled inside the part's inner cavity. The inner mandrel is made up of two jig plate assemblies aligned in a parallel manner and space apart where the internal structure is to manufactured. Each jig plate assembly is made up of at least three jig plates stacked in an edge-to-edge manner Located on opposite sides of each jig plate assembly is an elastic envelope filled with spherical objects. When evacuated, the envelope collapses and relaxes and composite material may then laid up inside the inner cavity and around the envelopes. When exposed to a heat, the envelopes expand and in situ and form internal structures inside surface of the cavity. Each envelope and each jig plate assemblies can be easily dissembled and reused.

Owner:GUITTON MAURICE

Quartz fiber reinforced silica ceramic composite material densification method

The present invention belongs to the technical field of inorganic materials, and particularly relates to a quartz fiber reinforced silica ceramic composite material densification method, which comprises: respectively weighing high hydrogen content silicon oil, tetraethyl orthosilicate, deionized water, a catalyst and quartz powder, and stirring in water bath to obtain an impregnating solution; and dipping a quartz fiber reinforced silica ceramic composite material dried to achieve a constant weight state into the impregnating solution, carrying out a vacuum treatment, co-placing the composite material and the impregnating solution into a constant-temperature and constant-humidity drying oven, continuously dipping, and then curing to obtain the finished product. According to the present invention, the preparation method is scientific and rational and is simple to perform, the density and the compressive strength of the material are significantly improved, the dielectric constant and the dielectric dissipation factor of the densified material are substantially unchanged, and the influence on the tensile strength and the flexural strength of the material during the low temperature treatment is little.

Owner:SHANDONG RES & DESIGN ACADEMY OF IND CERAMICS

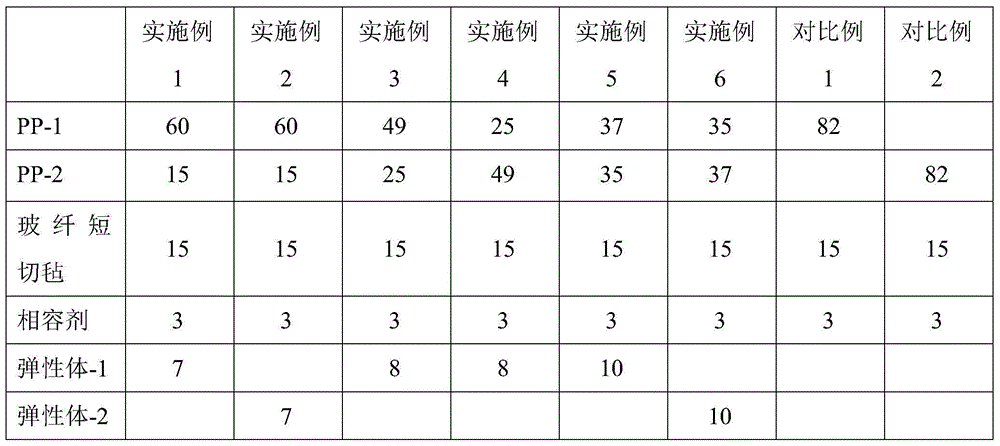

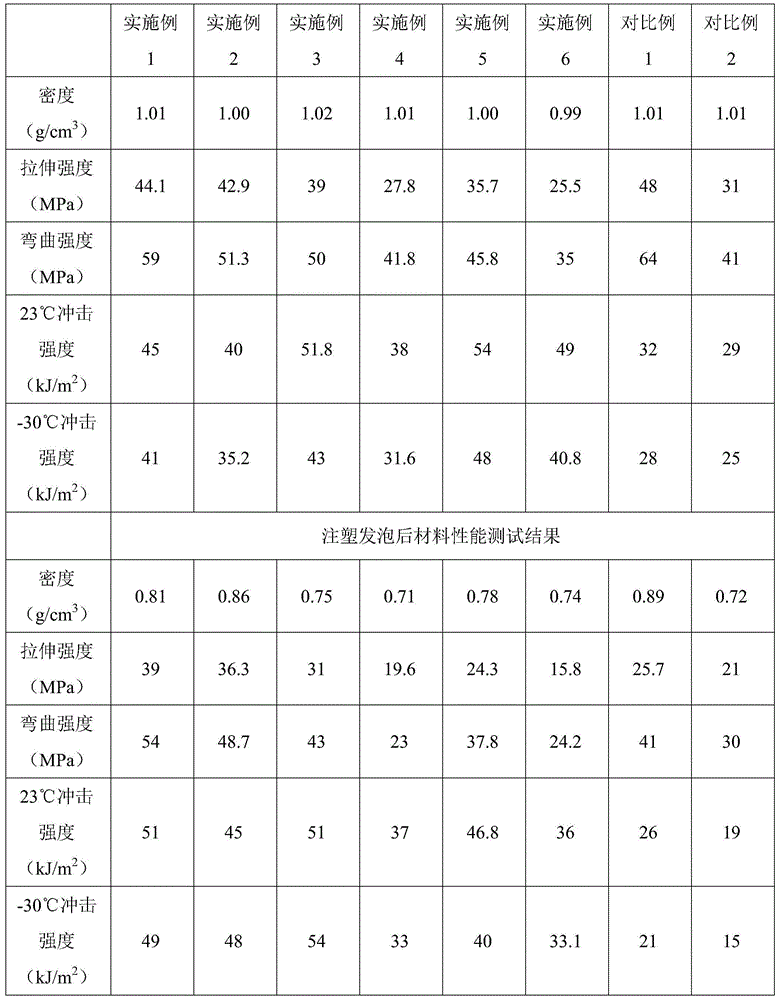

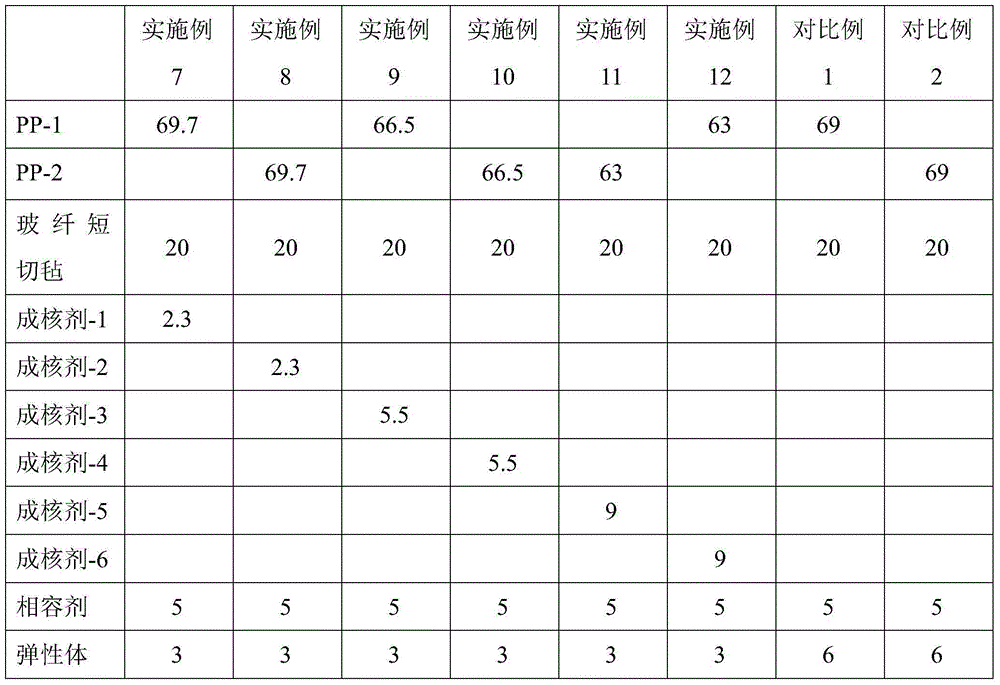

High-performance glass fiber reinforced polypropylene composite material specially used for micro-foaming and preparation method thereof

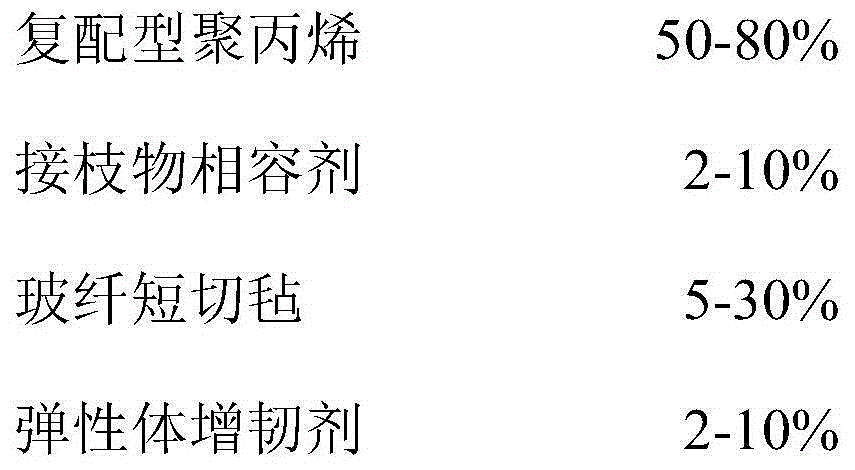

ActiveCN104945737AGood value for moneyConducive to the retention of mechanical propertiesElastomerPolypropylene composites

The invention relates to a high-performance glass fiber reinforced polypropylene composite material specially used for micro-foaming. The composite material is characterized by comprising the following components in percentage by weight: 50-80% of composite polypropylene, 2-10% of a graft compatilizer, 5-30% of a chopped glass fiber mat and 2-10% of an elastomer flexibilizer, totaling 100%, wherein the composite polypropylene is formed by compounding high-rigidity homo polypropylene HCIPP and high melt strength polypropylene HMSPP, wherein a high-rigidity homo polypropylene HCIPP substrate is beneficial to the retention rate of the mechanical property of the composite material after foaming; the high melt strength polypropylene HMSPP can ensure cell uniformity, structure integrity and reasonable distribution; and the added multi-monomer-block copolymer is capable of improving the interface condition of the composite material. Therefore, after micro-foaming, the composite material is greatly reduced in density, is not greatly reduced in tensile strength and bending strength and is improved in impact strength. The composite material is a polymer-based composite material having outstanding advantages of light weight, high strength and high cost performance.

Owner:中广核俊尔(上海)新材料有限公司

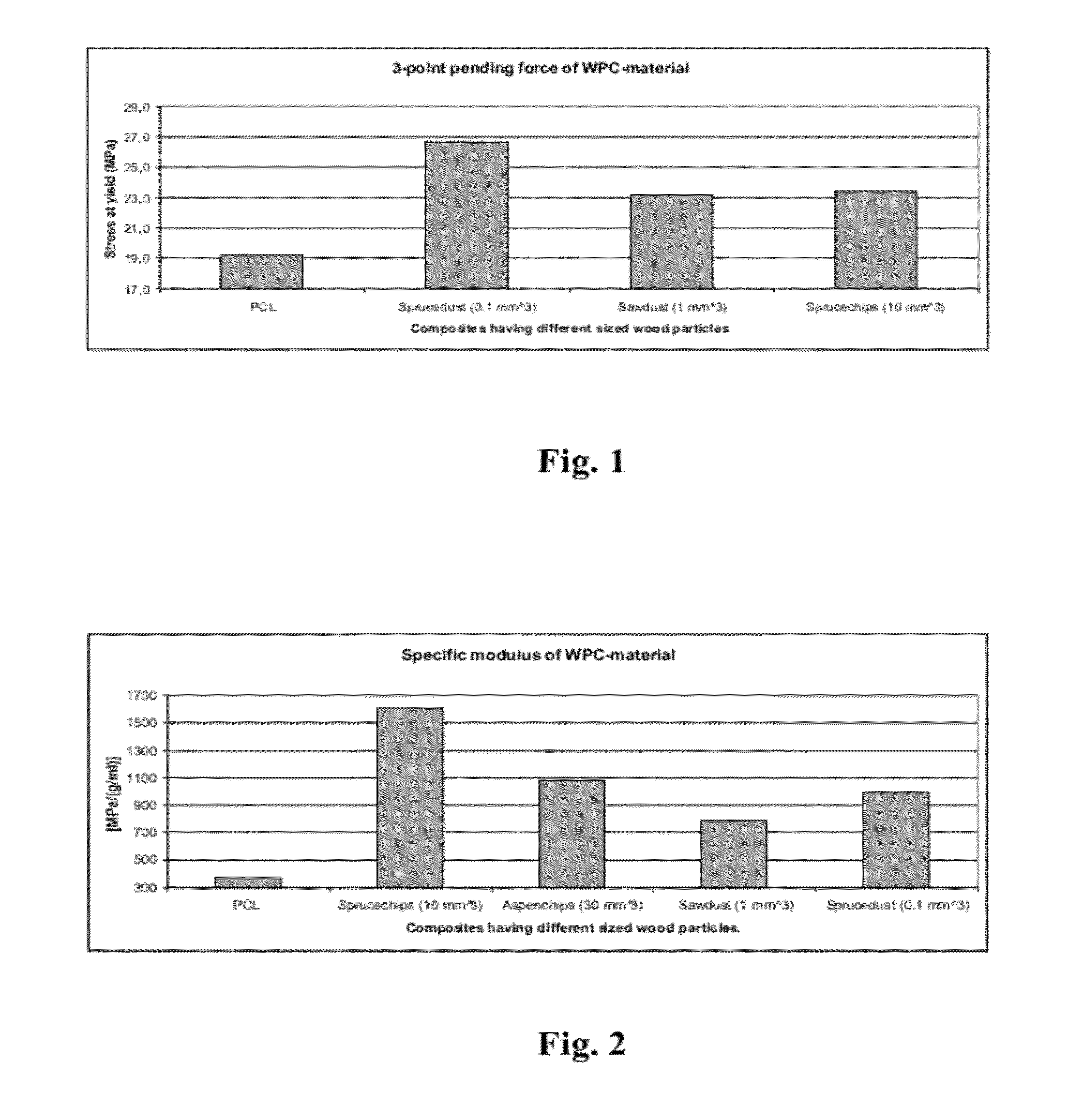

Novel composite materials comprising a thermoplastic matrix polymer and wood particles

The present invention concerns a novel low-temperature thermoplastic wood-biopolymer composite comprised of small wood particles and a polycaprolactone (PCL) homopolymer for use in medical procedures including orthopedic casting or splinting. The material is made from a thermoplastic composite that softens when heated to approximately 60° C., after which it can be formed directly on the patient. The composite then retains its shape as it cools down. The material is composed of epsilon caprolactone homopolymer reinforced with discontinuous short length wood particles.

Owner:ONBONE

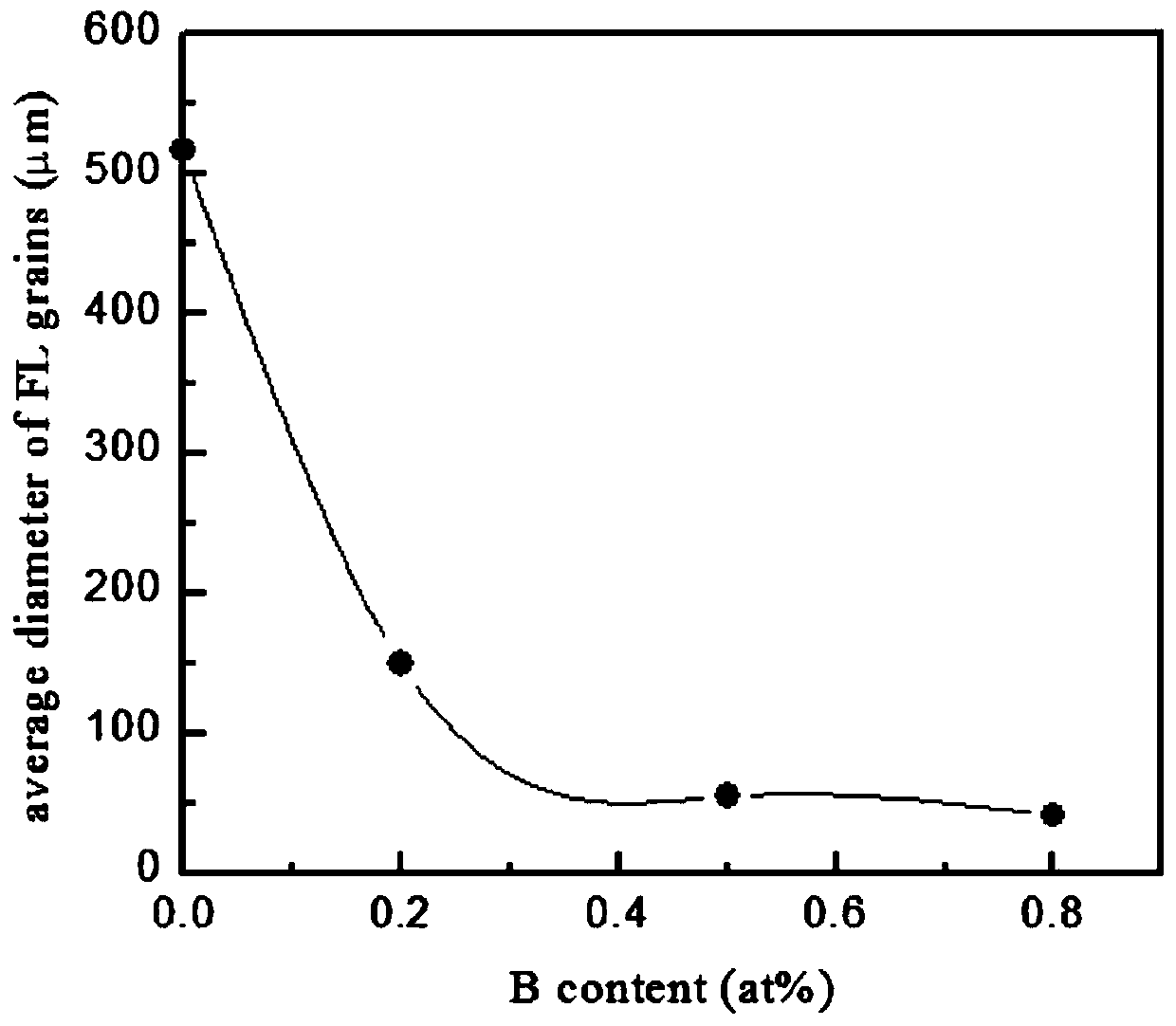

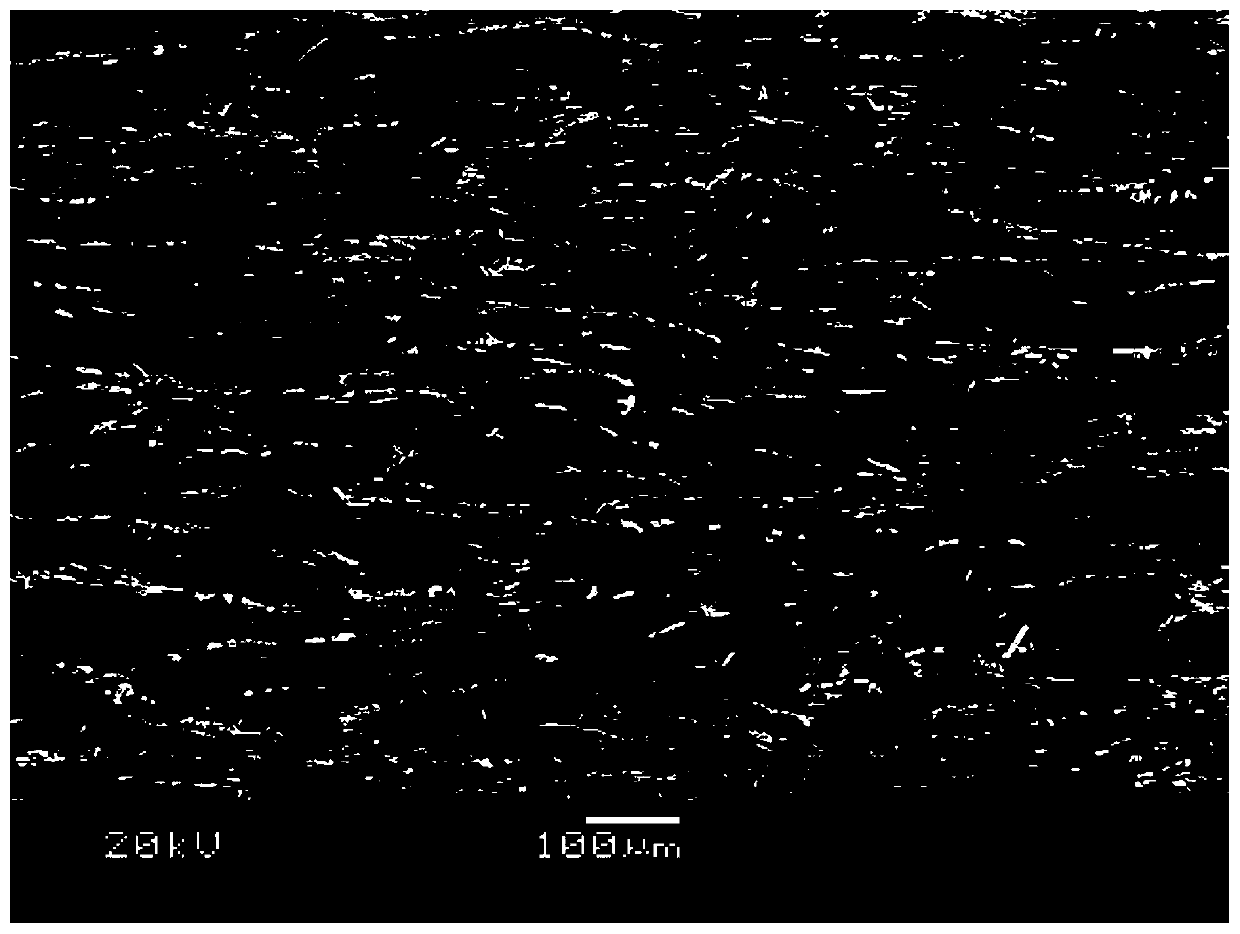

TiAl-based composite material and thermal mechanical treatment method thereof

PendingCN110643851AThere is no interface reaction problemImprove thermal processing performancePlastic propertyPosterior composites

The invention relates to a TiAl-based composite material enhanced by a TiB2 crystal whisker self-generated in situ as well as a thermal mechanical treatment method thereof. A proper amount of elementB is added in TiAl alloy according to an element B adding control quantity calculation formula, a slight secondary TiB2 crystal whisker is self-generated in situ through eutectic reaction of L->beta+TiB2 and L+beta->alpha+TiB2 and generation of thick granular primary TiB2 phase is avoided, so that the TiB2 crystal whisker enhanced TiAl-based composite material can be prepared by a ingot metallurgymethod. Then, the TiB2 / TiAl composite material can be prepared into a thin crystal bar material or a thin crystal cake blank through package sheathing hot extrusion or package sheathing forging, theslight TiB2 crystal whisker is crushed into short crystal whiskers, and a thin crystal mesh basket-shaped tissue or a thin crystal full-slice-sheet tissue can be obtained through treatment by a special heat treatment process. The TiB2 / TiAl composite material has high strength from room temperature to high temperature (850 DEG C) and has excellent room-temperature plasticity, so the TiB2 / TiAl composite material has good prospect in the field of aerospace.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

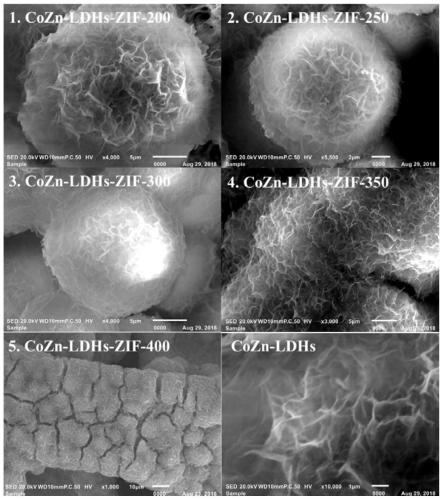

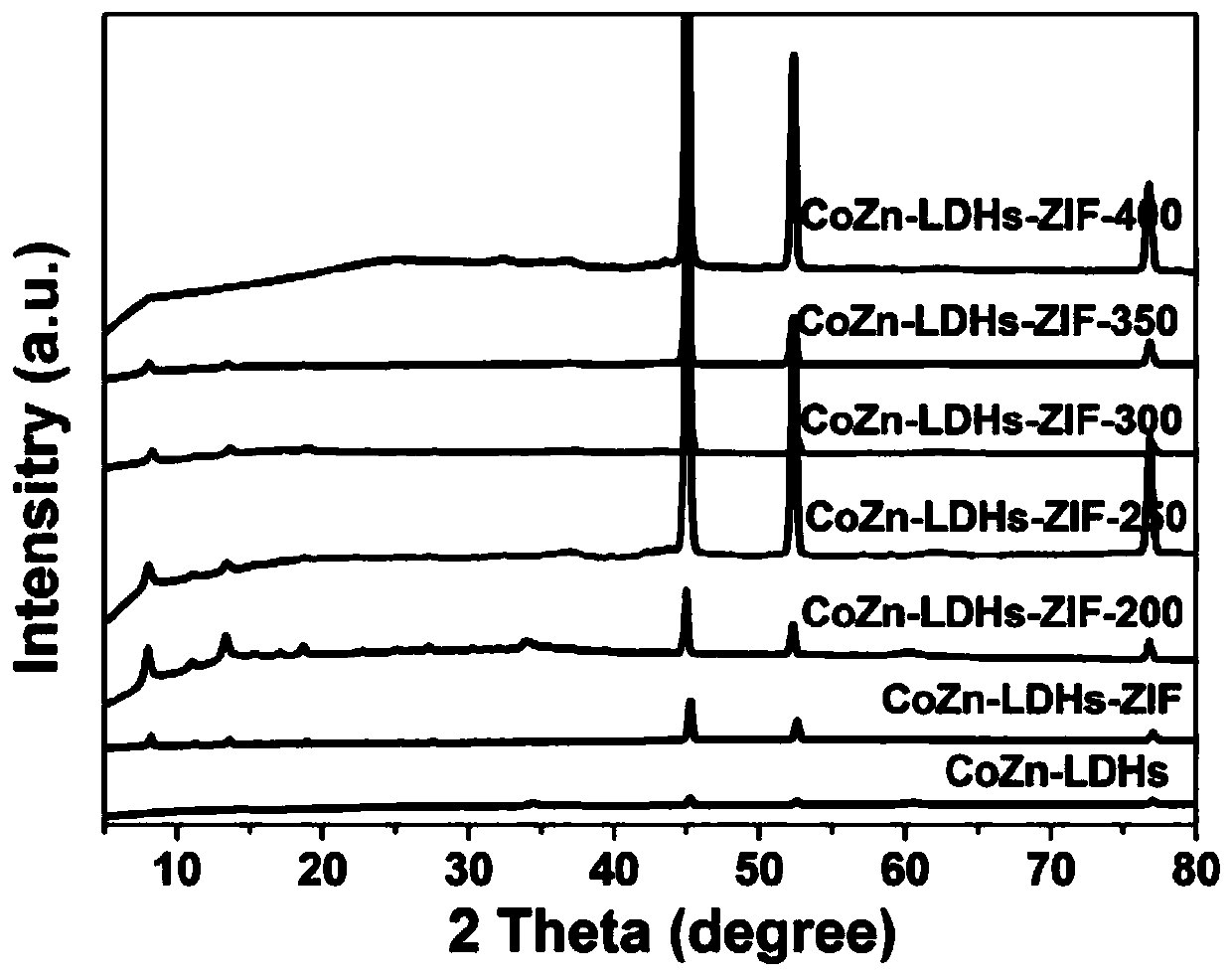

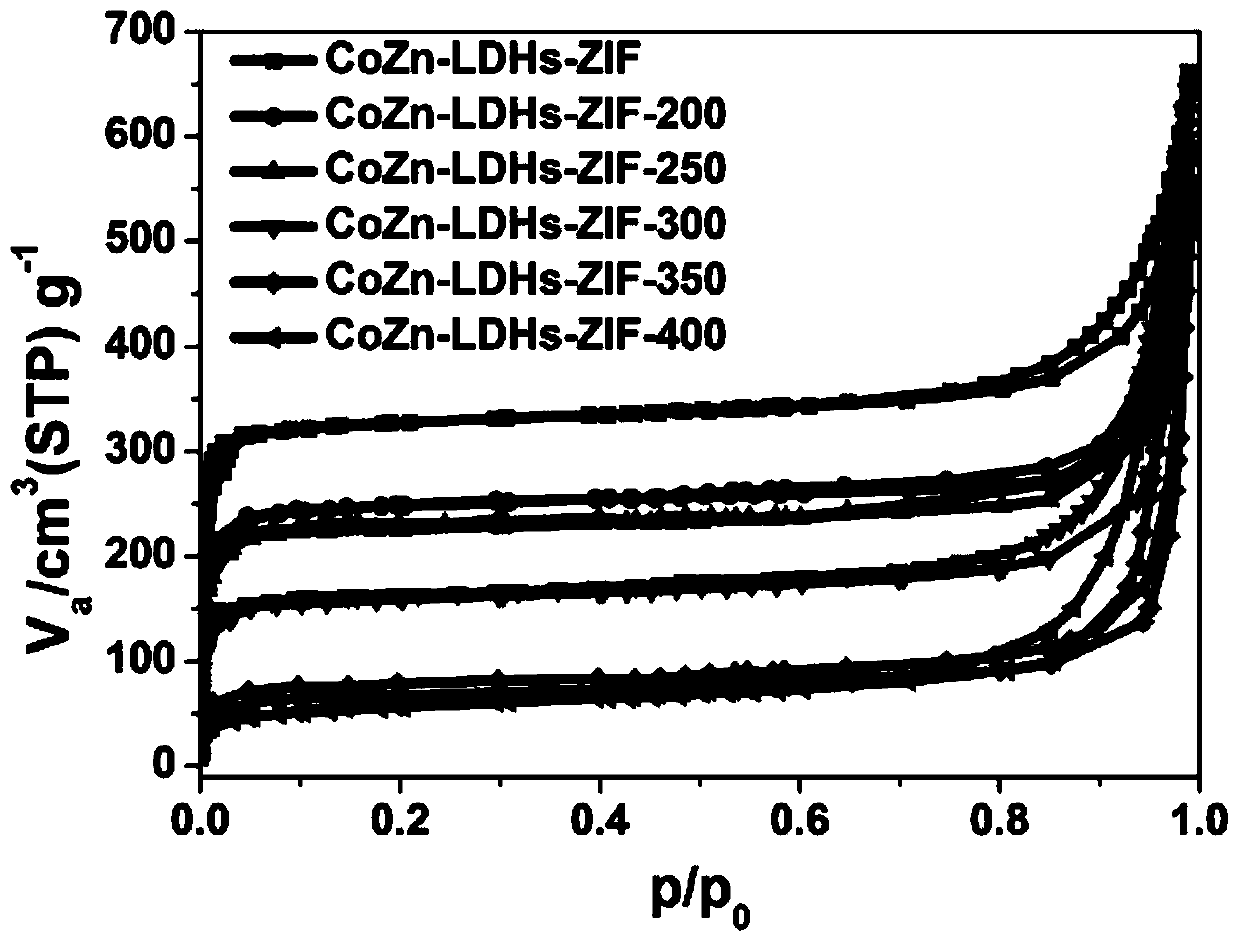

CoZn-LDHs-ZIF@C composite structure material with electrocatalytic water total decomposition performance as well as preparation method and application

InactiveCN110075853AHigh catalytic activityImprove catalytic stabilityMetal/metal-oxides/metal-hydroxide catalystsElectrodesDecompositionOxygen evolution

The invention belongs to the field of inorganic nano catalytic materials and particularly relates to a CoZn-LDHs-ZIF@C composite structure material with electrocatalytic water total decomposition performance as well as a preparation method and an application. The prepared CoZn-LDHs-ZIF@C composite structure material adopts a multilevel structure morphology, wherein CoZn-LDHs is of a layered structure, a ZIF compound is particles with uniform size, and the specific surface area of the composite material after low-temperature heat treatment is 1125.1-193.0 m<2> / g. Prepared samples CoZn-LDHs-ZIF@C-200, CoZn-LDHs-ZIF@C-250, CoZn-LDHs-ZIF@C-300, CoZn-LDHs-ZIF@C-350 and CoZn-LDHs-ZIF@C-400 show excellent electrocatalytic hydrogen evolution and oxygen evolution performance in an alkaline electrolyte and water total decomposition performance. The method has the advantages of being simple, mild in reaction condition, convenient to operate, low in energy consumption and the like.

Owner:UNIV OF JINAN

Preparation method of continuous carbon fiber enhanced copper-based composite material

The invention provides a preparation method of a continuous carbon fiber enhanced copper-based composite material. A method of adhering and curing copper powder on the surface of a continuous carbon fiber through organogel is adopted, the thickness of a copper layer adhering to the surface of the carbon fiber can be controlled, and therefore the content and the interval of the carbon fiber in a composite material after hot pressing sintering are controlled, so that the carbon fiber is distributed in a copper base body in parallel, and the copper-based composite material high in carbon fiber content can be prepared. According to the preparation method, a carbon fiber surface copper plating process complicated in process is omitted, cost is extremely low, operation is easy, and industrialized production can be achieved; and the electrical conduction performance and the strength of the carbon fiber enhanced copper-based composite material obtained through the preparation method are obviously superior to those of a carbon fiber enhanced copper-based composite material prepared through an existing impregnation method, and broad application prospects are achieved.

Owner:HEBEI COLLEGE OF IND & TECH

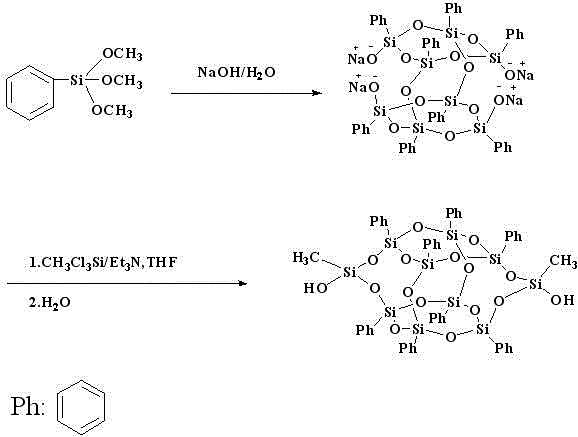

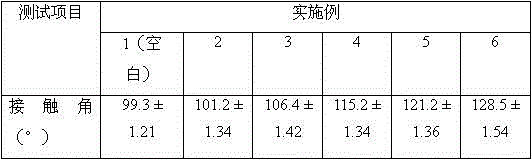

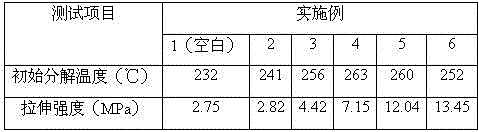

Preparation method of plant-oil-based polyurethane composites modified by dual-layer cage type silsesquioxane

ActiveCN105860018AImprove mechanical propertiesImprove thermal stabilityDecompositionIsophorone diisocyanate

The invention discloses a preparation method of plant-oil-based polyurethane composites modified by dual-layer cage type silsesquioxane, and belongs to the technical field of polymer composites. Plant-oil-based polyurethane is synthesized with plant-oil-based polyhydric alcohol and isophorone diisocyanate (IPDI) as the raw materials, and a series of plant-oil-based polyurethane composites are synthesized with organic-inorganic hybrid material dual-layer cage type silsesquioxane (DDSQ) as the modifier. Environment-friendly renewable plant-oil-based polyhydric alcohol serves as the raw material, the composites are chemically modified by dual-layer silsesquioxane of a regular cage type structure for overcoming the defects of plant-oil-based polyurethane, and the thermal performance, mechanical performance and water resistance of the modified composites are improved to different extents. Compared with ordinary plant-oil-based polyurethane, the initial decomposition temperature of the composites is increased by 31 DEG C, and the tensile strength is improved by nearly four times.

Owner:JIANGNAN UNIV

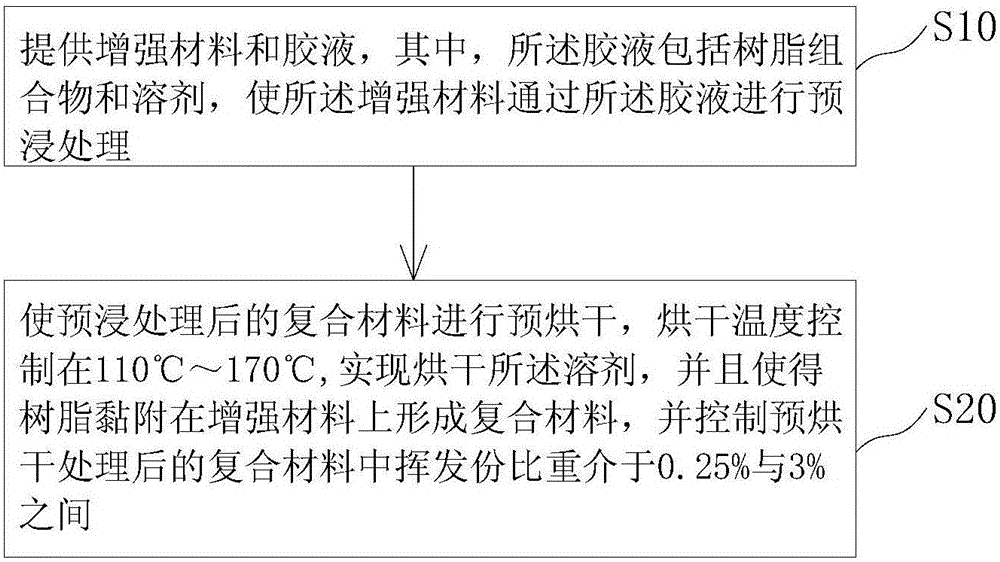

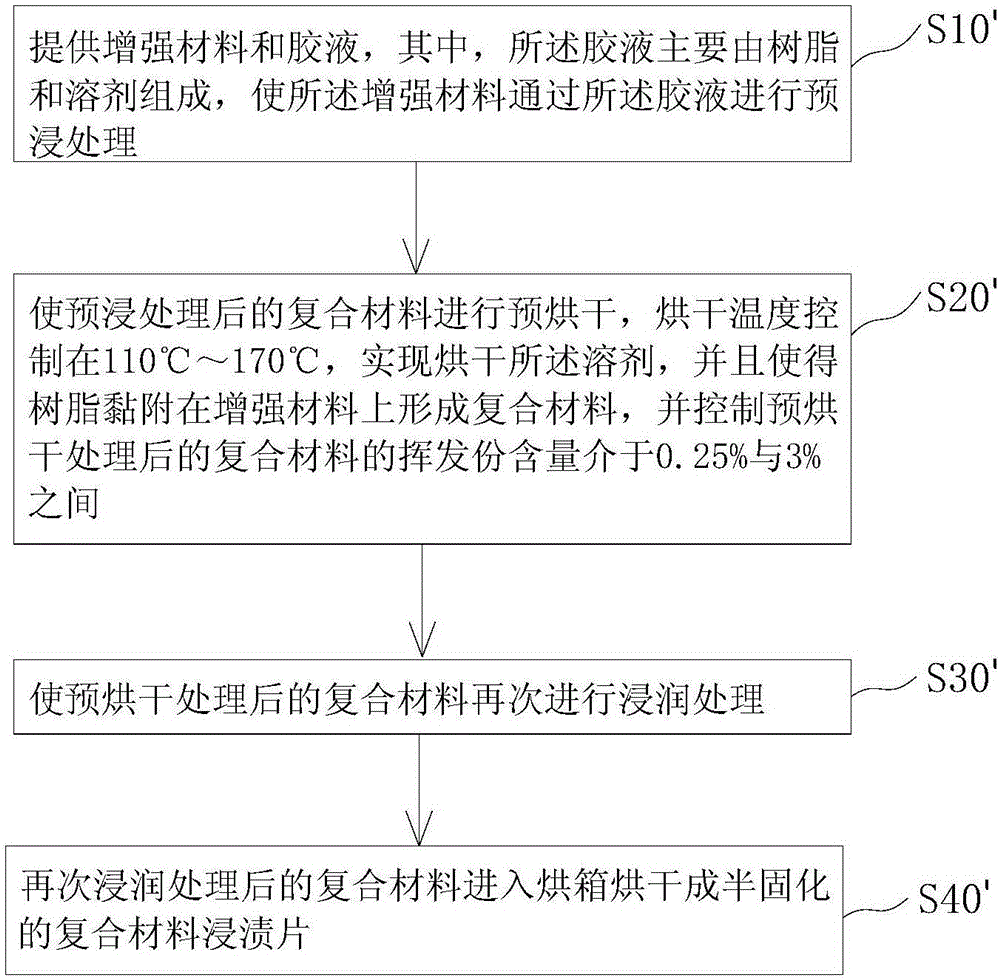

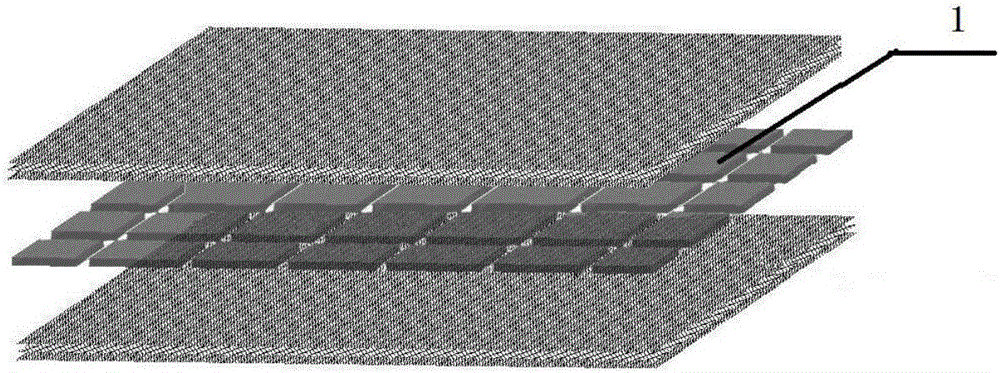

Dipping method, dipping piece and laminating plate

InactiveCN105153451AHigh resin contentImprove reliabilitySynthetic resin layered productsPosterior compositesSolvent

The invention discloses a dipping method. The method includes the steps of S10, conducting presoaking, wherein reinforcing materials and glue are provided, the glue comprises resin composite and solvent, and the reinforcing materials are presoaked in glue; S20, conducting pre-drying, wherein the presoaked composite is pre-dried, the drying temperature is controlled between 110 DEG C and 170 DEG C, solvent is dried away, resin is attached to the reinforcing materials to form the composite, and the proportion of volatile matter in the pre-dried composite is controlled between 0.25% and 3%. By strictly controlling the pre-drying temperature and controlling the content of volatile matter in the pre-dried composite between 0.25% and 3%, the reliability of a prepared dipping piece and a corresponding laminating plate is well kept, and good industrial application prospects are achieved.

Owner:GUANGDONG SHENGYI SCI TECH

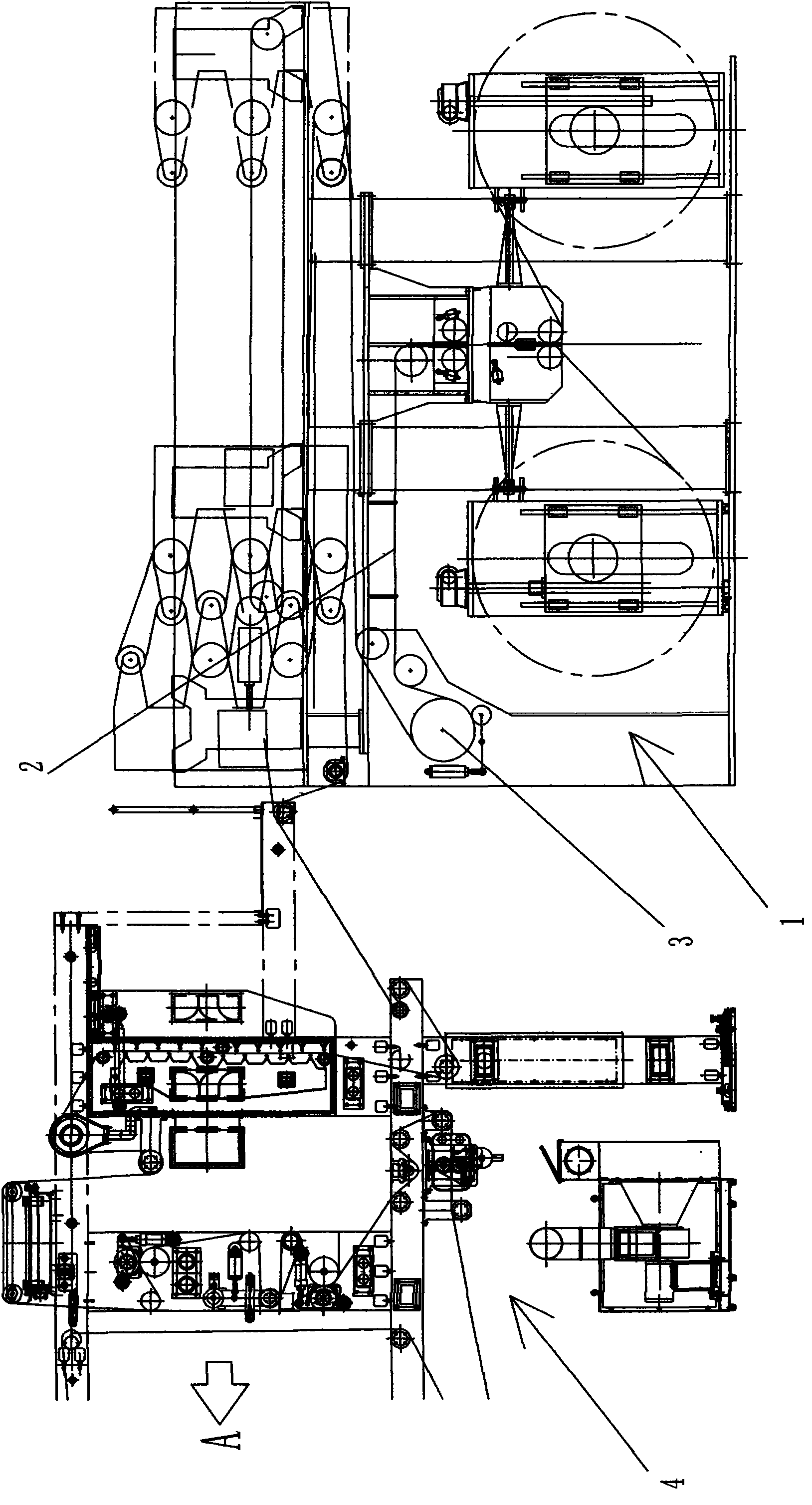

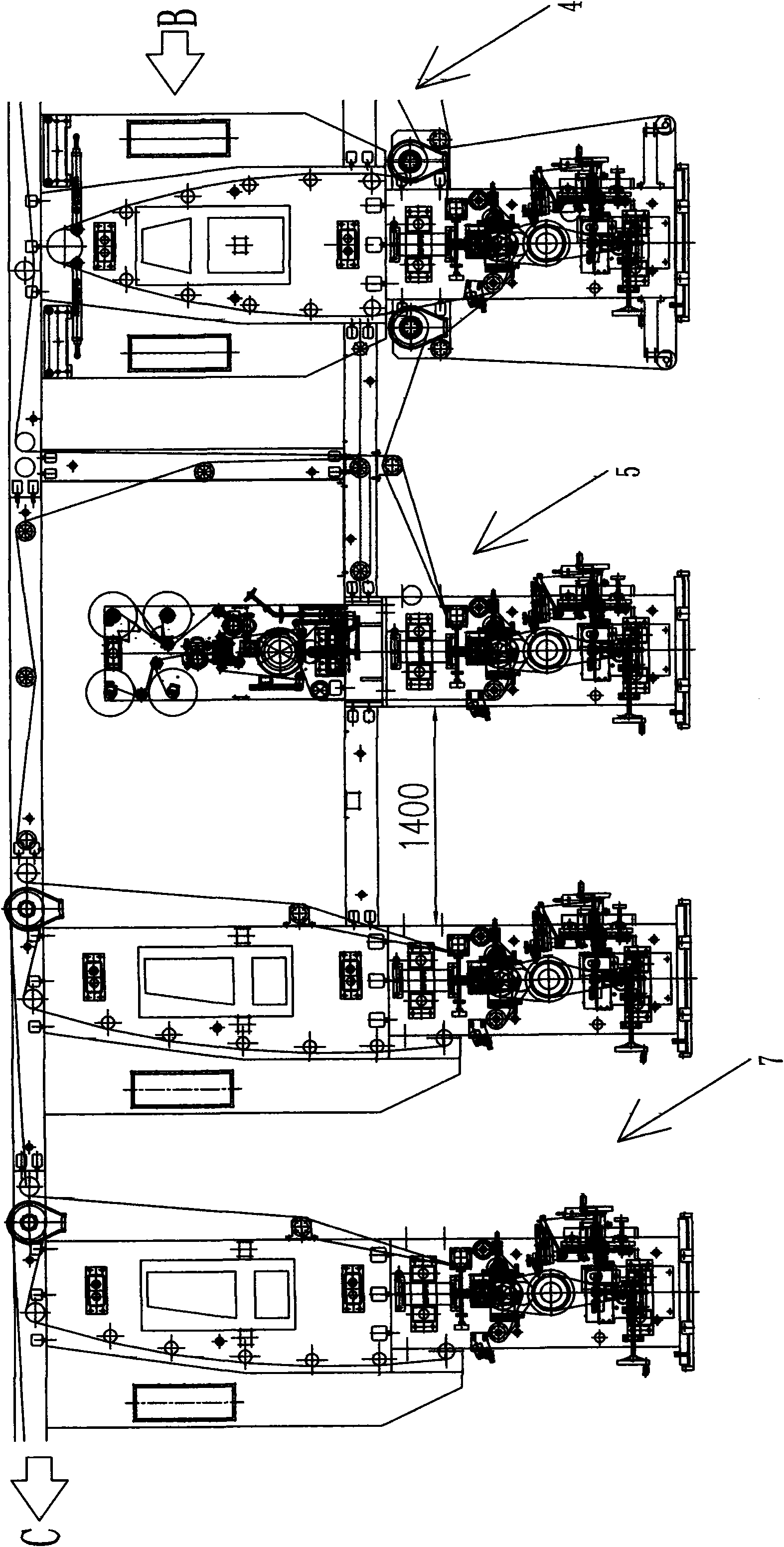

New process for realizing inline positioning and cold stamping of intaglio printing and transferring of positioned C2

ActiveCN101941338AReduce production processQuality Control and ImprovementOther printing apparatusRolling paperPulp and paper industry

The invention relates to a new process for realizing inline positioning and cold stamping of intaglio printing and the transferring of a positioned C2, which comprises the following steps: a. rolling paper is placed into a unwinding device of a printing machine; b. the rolling paper is pulled to a discharging pull roll; c. afterwards, the paper moves into a first printing color unit for printing pattern; d. after being printed by the first printing color unit, the paper moves into a cold stamping unit, a transfer layer on a transfer film arranged in the cold stamping unit is positioned on the paper by the cold stamping; e. the paper moves into a multicolor printing color unit for printing pattern; f. after being subject to printing the pattern by the multicolor printing color unit, the paper moves into another positioning and cold stamping unit to enable other patterns to be positioned by the cold stamping; g. the paper moves into a C2 transferring unit for positioning and transferring, so that the convex and concave patterns on the transfer film are reflected on the paper coated with UV glue, and then, a procedure of cured stripping or stripping prior to curing should be carried out by using composite materials; and h. the stripped paper is cut off by a cutting device to finish the whole process.

Owner:ZHONGSHAN SOTECH PRINTING MACHINERY CO LTD

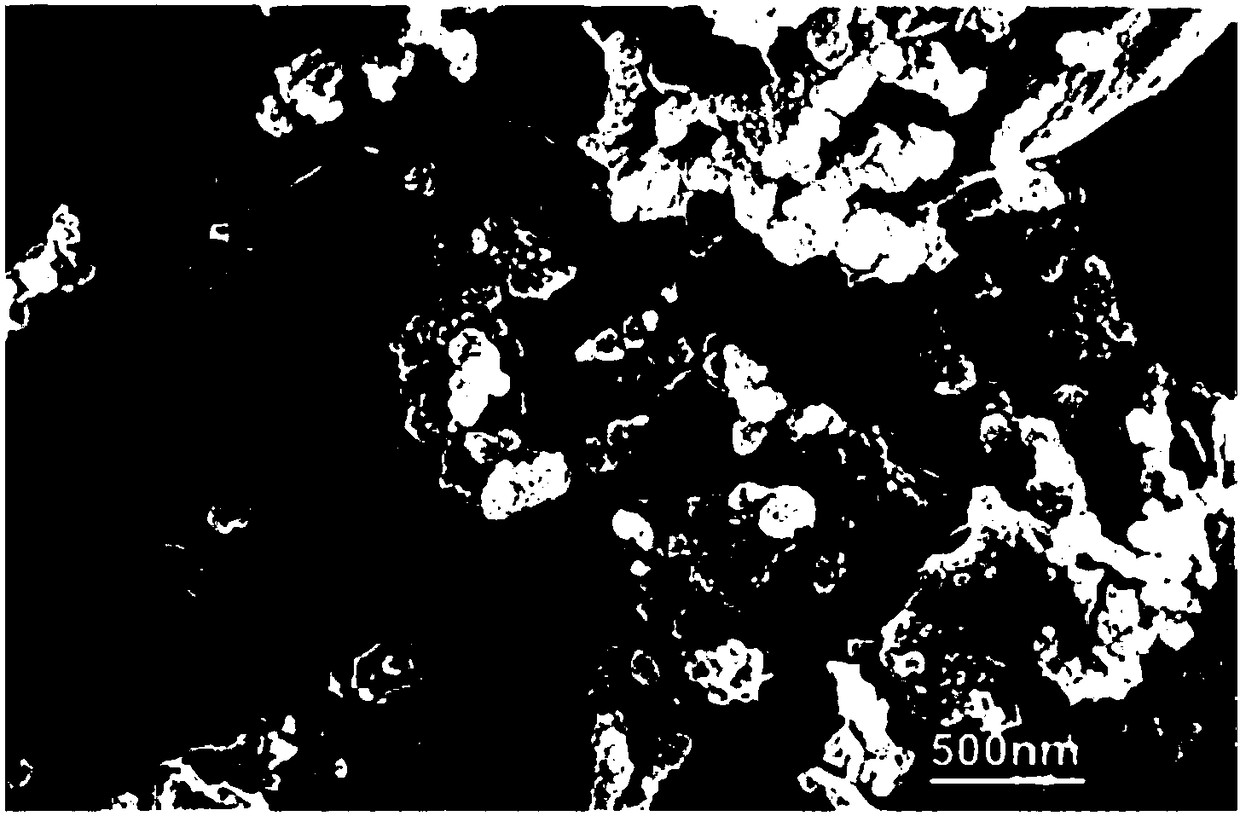

Preparation method of green composite nano magnetic material for effectively removing heavy metals in environment

InactiveCN108187623AWide variety of sourcesNo risk of secondary pollutionOther chemical processesWater contaminantsFiltrationPosterior composites

The invention discloses a preparation method of a green composite nano magnetic material for effectively removing heavy metals in an environment. The invention relates to the field of environmental functional materials, and particularly relates to a preparation method of a composite nano magnetic material. The invention aims at solving the technical problems that a current method of a biochar improved composite material is fussy, raw materials are expensive and meanwhile, a modified or improved material still has a certain risk of the secondary pollution to the environment and the like. The method comprises the following steps of 1, carrying out the pretreatment of biomass waste; 2, carrying out the thermal conversion from biomass to biochar; 3, carrying out the mixed culture of the biochar and ferric iron in a liquid phase; 4, carrying out a reduction reaction on suspension liquid by utilizing a liquid-phase deposition method, so as to obtain a nano zero-valent iron loaded carbon material, flushing, carrying out suction filtration, and oven-drying to obtain the green composite nano magnetic material. The green composite nano magnetic material is used for removing the heavy metalsin the environment, within a short time, has better removal capacity for six common heavy metals in the environment, and meanwhile, has higher magnetism; the removal efficiency reaches 95 percent or above, and the recycling is facilitated.

Owner:HARBIN INST OF TECH

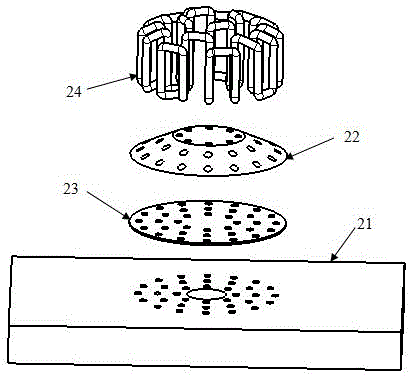

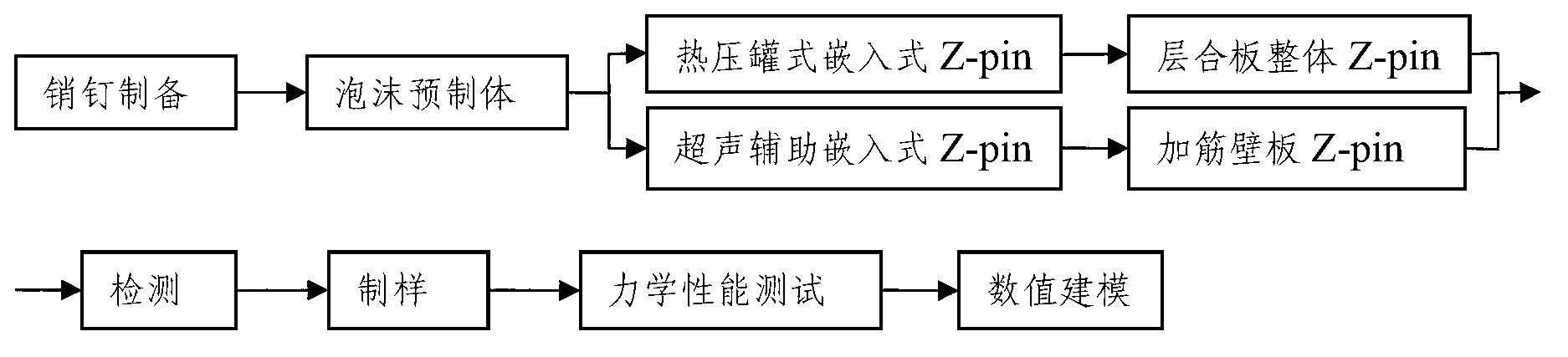

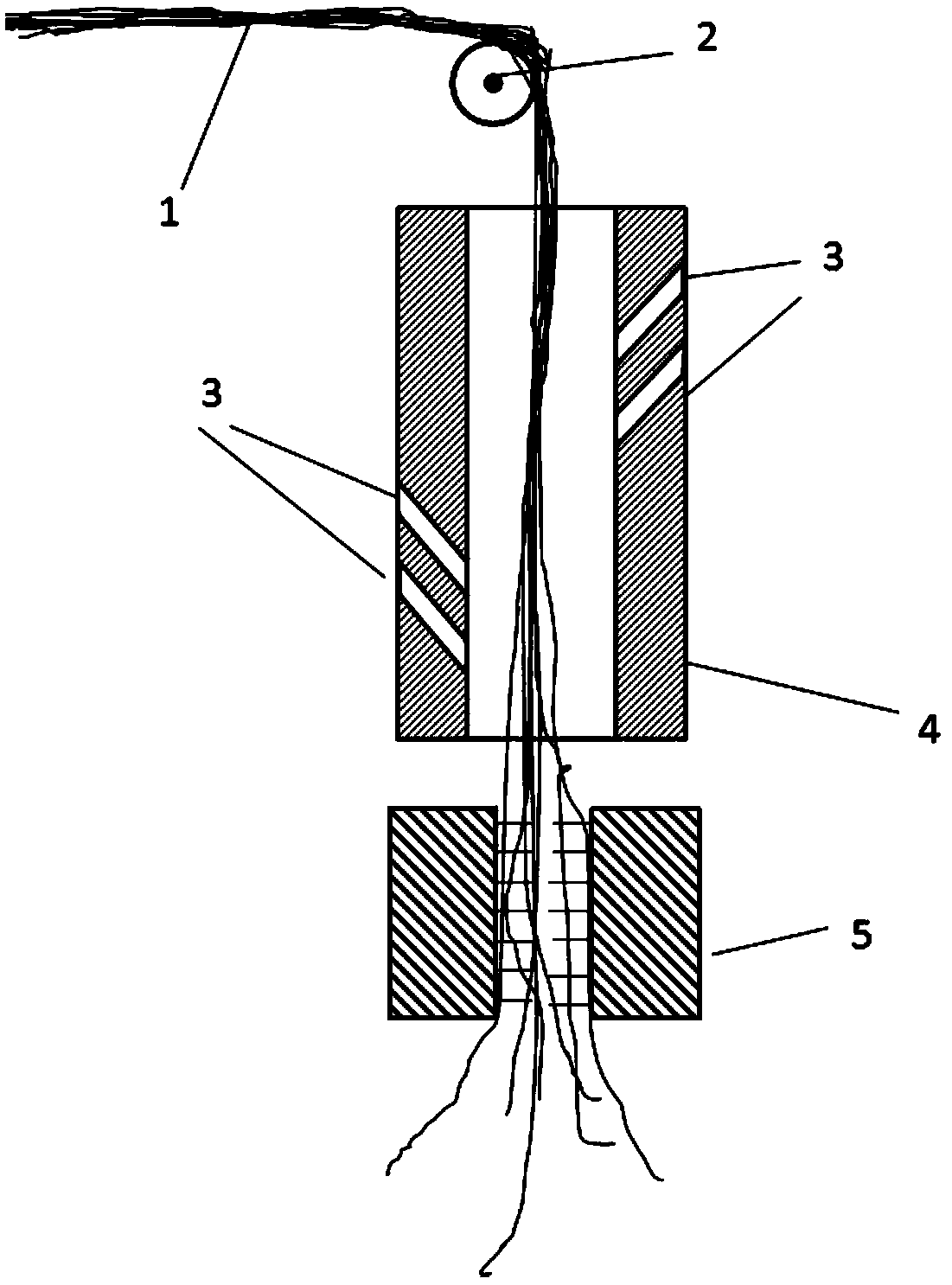

Interlaminar enhancement process for composite laminated plate for fuselage and airfoils of unmanned plane

The invention discloses an interlaminar enhancement process for a composite laminated plate for a fuselage and airfoils of an unmanned plane. The interlaminar enhancement process comprises the following steps of: (1) preparing carbon fiber-reinforced resin matrix composite pins by utilizing a pultrusion molding process; (2) preparing a foam preform containing the carbon fiber-reinforced resin matrix composite pins; (3) implanting the carbon fiber-reinforced resin matrix composite pins in the foam preform into the composite laminated plate for the fuselage and the airfoils of the unmanned plane; and (4) testing mechanical properties of the composite laminated plate after the carbon fiber-reinforced resin matrix composite pins are implanted. By utilizing the process, the anti-low speed impact capability of the structure of the composite laminated plate for the unmanned plane, in particular the anti-interlaminar shearing strength of a stiffened structure of the composite laminated plate can be improved, and a solid foundation is laid for realizing light weight and low cost of the composite laminated plate.

Owner:AEROSPACE SHENZHOU AIRCRAFT

Preparation method of continuous carbon fiber reinforced aluminum-based composite material

The invention provides a preparation method of a continuous carbon fiber reinforced aluminum-based composite material. According to the preparation method provided by the invention, the thickness of an aluminum layer adhered to the surface of the carbon fiber can be controlled by adopting a method of adhering curing aluminum powder to the surface of continuous carbon fiber through organogel, so that the content and the spacing of the carbon fiber in a composite material after hot pressing sintering can be controlled, the carbon fiber can be parallelly distributed in an aluminum matrix, and analuminum-based composite material with high carbon fiber content can be prepared. The preparation method disclosed by the invention is low in cost and easy to operate and is capable of realizing industrialized production; the strength of the carbon fiber reinforced aluminum-based composite material obtained through the preparation method provided by the invention is obviously superior to that of the carbon fiber reinforced aluminum-based composite material prepared through an existing infiltration method, and a wide application prospect is obtained.

Owner:江苏戍卫新材料科技有限公司

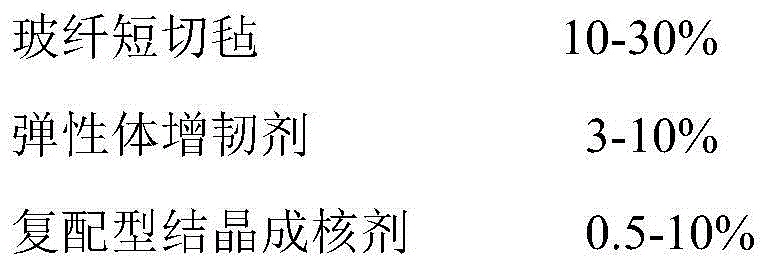

High-impact-resistance low-temperature-resistant glass-fiber-reinforced polypropylene composite material and preparation method thereof

InactiveCN104945741AIncrease cooling crystallization rateImprove impact resistanceElastomerGlass fiber

The invention relates to a high-impact-resistance low-temperature-resistant glass-fiber-reinforced polypropylene composite material and a preparation method thereof. The invention is characterized in that the high-impact-resistance low-temperature-resistant glass-fiber-reinforced polypropylene composite material is prepared from the following raw materials in percentage by weight: 50-80% of polypropylene, 2-15% of graft compatilizer, 10-30% of glass fiber chopped felt, 3-10% of elastomer toughener and 0.5-10% of compound crystal nucleator. In order to solve the problem of poor low-temperature toughening effect in the traditional elastomer, nucleators and auxiliary nucleators for different crystal forms are compounded to regulate the crystal structure and content of the base phase and interface phase in the polypropylene composite material, thereby improving the normal-temperature / low-temperature impact property (especially notch impact property at the low temperature of lower than -30 DEG C) of the reinforced polypropylene composite material on the premise of avoiding over reduction of the rigidity of the composite material. The performance testing indicates that the retentivity of the normal-temperature stretching and bending strength of the modified composite material is 90% above, the low-temperature (-40 DEG C) notch strength can be enhanced by 80-120%, and the comprehensive properties are obviously better than those of the conventional elastomer toughened modified material.

Owner:中广核俊尔(上海)新材料有限公司

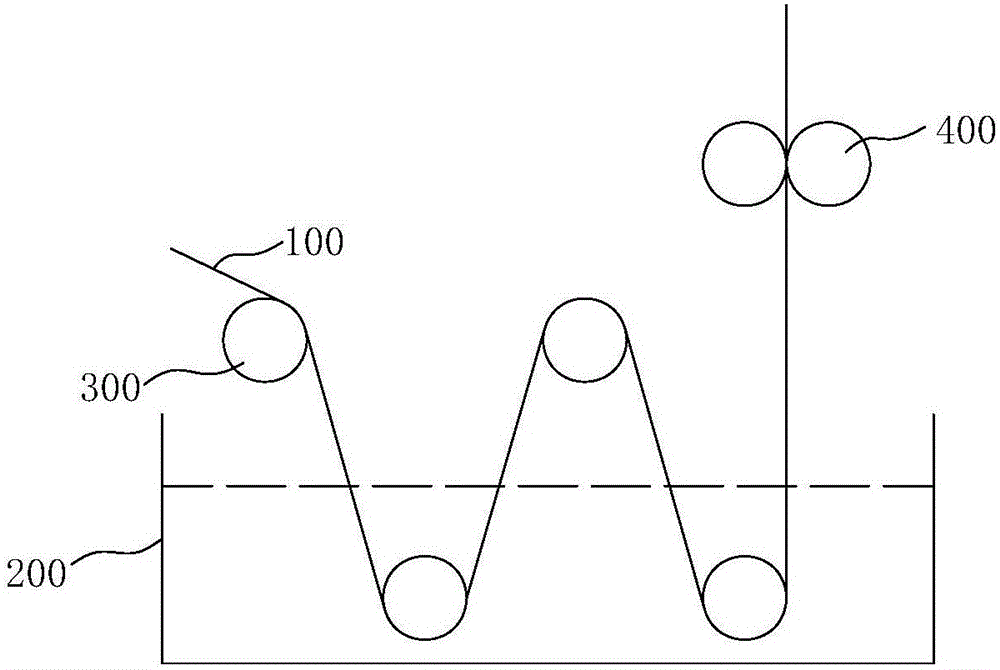

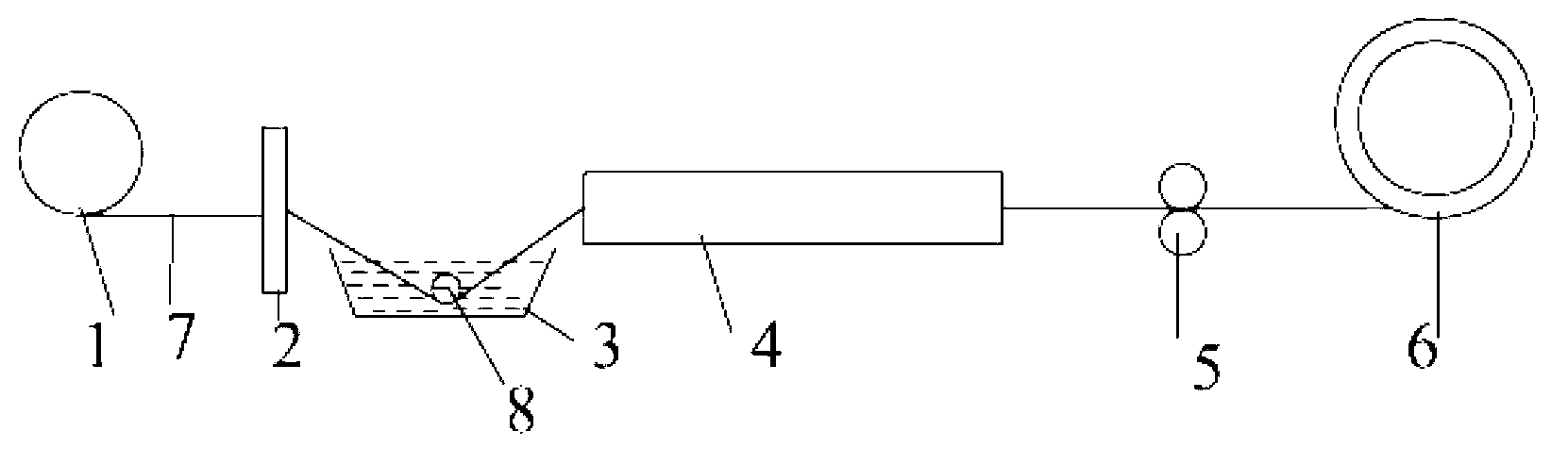

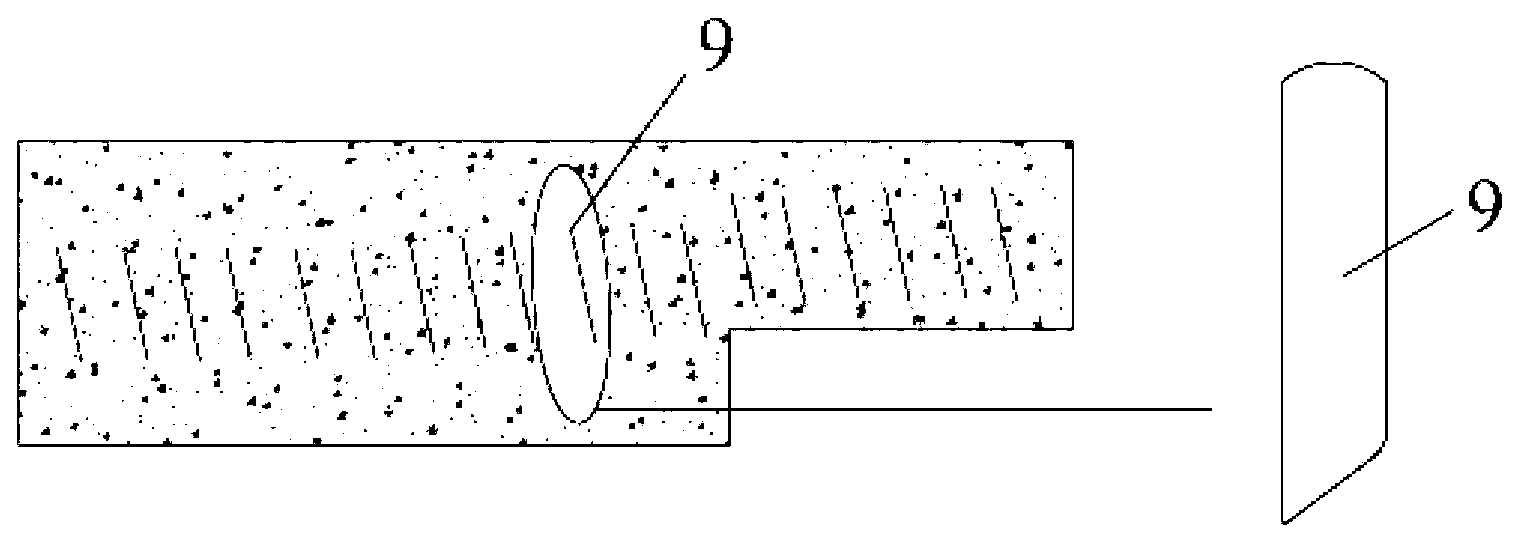

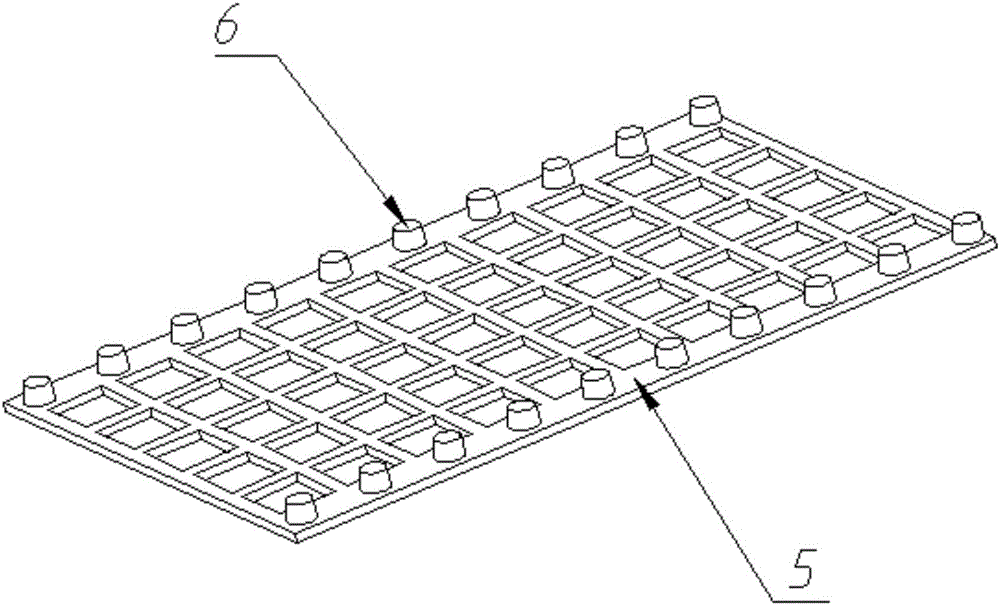

Preparing method and system for damping layer in embedded type co-curing composite material

ActiveCN106000815AIncrease profitImprove production efficiencySpraying apparatusPretreated surfacesBand shapeSpray method

The invention discloses a preparing method and system for a damping layer in an embedded type co-curing composite material. The method comprises the steps that firstly, strip-shaped composite material prepreg and a strip-shaped spraying template are prepared, a set hollow pattern is arranged on the spraying template, and the size of the spraying template is matched with the size of the composite material prepreg; secondly, under the action of conveying rollers, the composite material prepreg and the spraying template are synchronously fed, the spraying template is pressed above the composite material prepreg, a damping glue material is sprayed in a spraying area, the damping layer is obtained, and the width of the spraying area is larger than or equal to the width of a to-be-sprayed area of the composite material prepreg; thirdly, the composite material prepreg and the spraying template are separated, and after separation, the final shape obtained after a damping material on the composite material prepreg is diffused is the preset shape; and fourthly, the damping layer is dried. The damping layer is prepared through a spraying method, and the preparing efficiency of the damping layer can be greatly improved.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

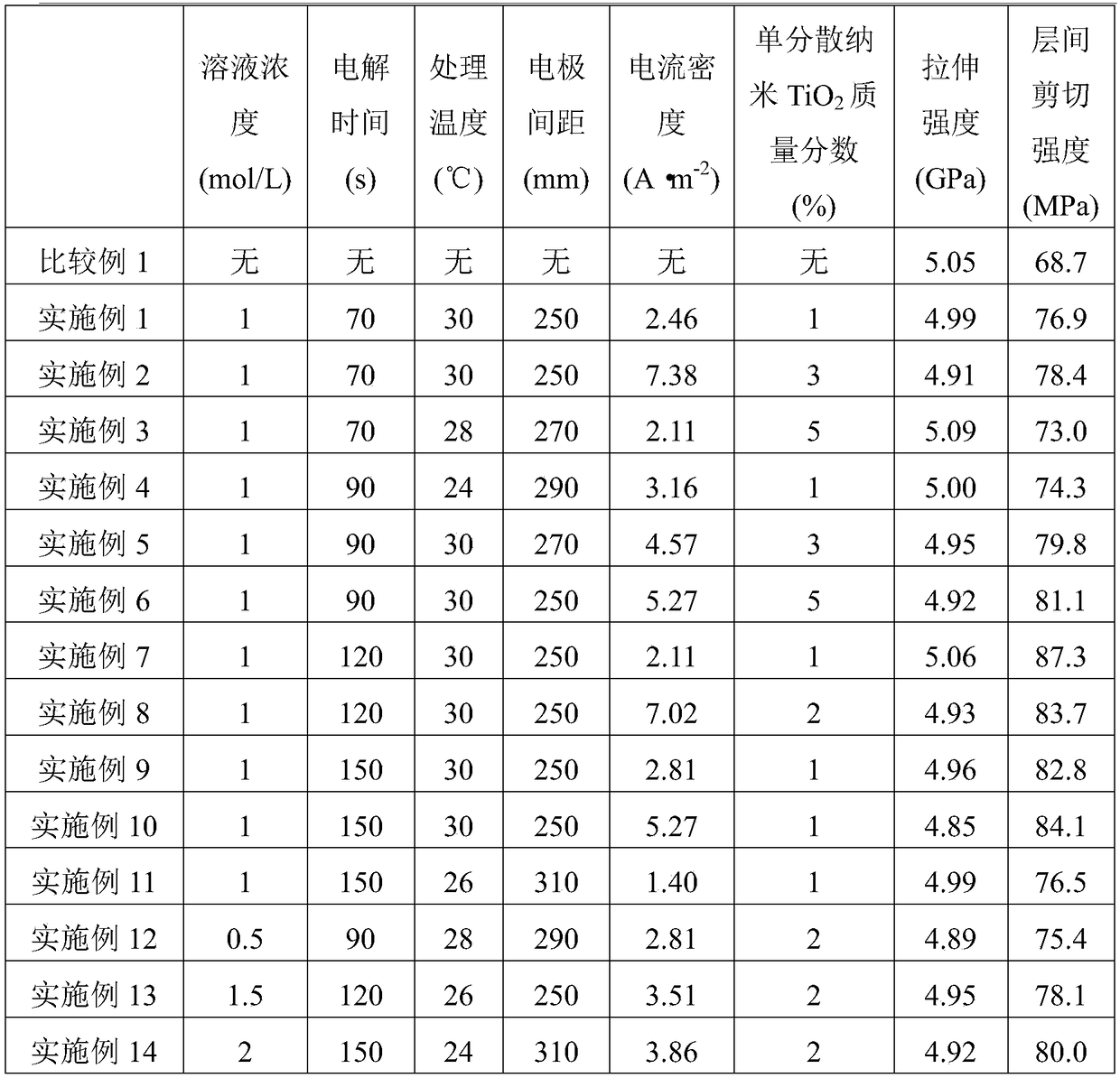

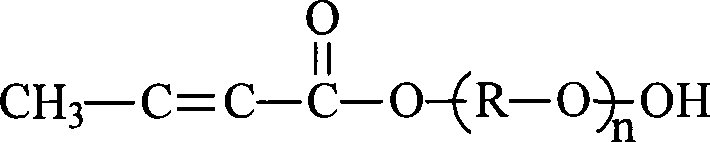

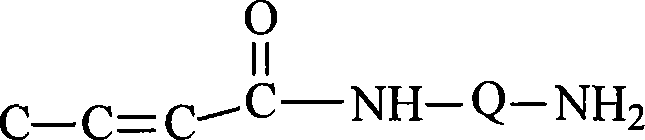

Surface treatment method of dry-jet wet-spun carbon fibers

The invention relates to a surface treatment method of dry-jet wet-spun carbon fibers, and belongs to the technical field of carbon fiber surface treatment. The dry-jet wet-spun carbon fibers with thecarbon content of more than 90% are subjected to electrochemical surface treatment with a graphite plate as a cathode, an ammonium bicarbonate aqueous solution with the molar concentration of 0.01-4mol / L as an electrolyte solution at the electrolytic temperature of 10-40 DEG C via a continuous electrochemical treatment device, the treatment time is controlled at 10-300 s, and the current densityis adjusted to 0.1-10 A*m<-2>, and the electrode spacing is 150-400 mm; after treatment, the product is washed with 100 DEG C water, sized by water-borne epoxy resin doped with 0.1-10 mass% of monodisperse nano-TiO2, and finally rolled up. After being treated by the method, the composite material has the interlayer shear strength increased, and at the same time, the tensile strength of the carbonfibers has no loss. In addition, nano-TiO2 not only plays a reinforcing role, but also improves the combination of the carbon fibers and resin.

Owner:BEIJING UNIV OF CHEM TECH

Nitride-ceramic high-temperature wear-resistant coating and preparing method thereof

InactiveCN106116700ASolve the technical problems of permeable porous bodiesHigh hardnessWear resistantAluminium hydroxide

The invention belongs to the field of ceramic wave-transmitting materials, and in particular relates to a nitride ceramic high-temperature wear-resistant coating and a preparation method thereof. It is made of material, grinding balls and organic binder solution; the material includes the following components: component A, feldspar, quartz and calcium carbonate; component A includes lithium carbonate, aluminum hydroxide and quartz powder. The coating has a good combination with the substrate, and can be precisely cold processed. The internal structure of the coating is uniform and dense without pores, the surface has no cracks, no water absorption, and the coating has high hardness. After coating, the dielectric constant of the composite material has basically no change compared with that before coating, and the dielectric loss has been reduced to a minimum of 9×10 ‑4 . The invention improves the moisture absorption of the porous silicon nitride, improves the ablation resistance and erosion resistance of the material, and enhances the environmental adaptability of the porous low-density nitride ceramics. The invention also provides a preparation method thereof, which has the advantages of scientific rationality, easy implementation, short production cycle and low investment cost.

Owner:SHANDONG RES & DESIGN ACADEMY OF IND CERAMICS

Carbon nano-tube / unsaturated polyester composite material and preparation thereof

The invention belongs to the technical field of nano materials, and particularly relates to a carbon nano tube / unsaturated polyester composite material and a preparation method thereof. The preparation method comprises the following steps: carboxylic acid and chloroformylation are carried out to the carbon nano tube, the carbon nano tube is modified by amino or hydroxyl acrylic ester compound, and the carbon nano tube which can carry polymerizable double bond. The modified carbon nano tube is dispersed in unsaturated polyester substrate, and cobalt iso-octoate and methyl ethyl ketone peroxideare adopted as an accelerating agent and a curing agent so as to prepare the carbon nano tube / unsaturated polyester composite material. The obtained composite material has higher heat stability and chemical stability. Compared with unsaturated polyester condensate which has same compositions and does not add the carbon nano tube, the volume resistivity of the cured composite material is reduced to 3 to 9 order of magnitude, and the surface resistivity is reduced to 3 to 8 order of magnitude. The invention has simple technique and more practicability. The composite material can be applied to the shell or coating of the equipment in the fields of manufacturing motors of electric appliances, chemical machines and the like.

Owner:TONGJI UNIV

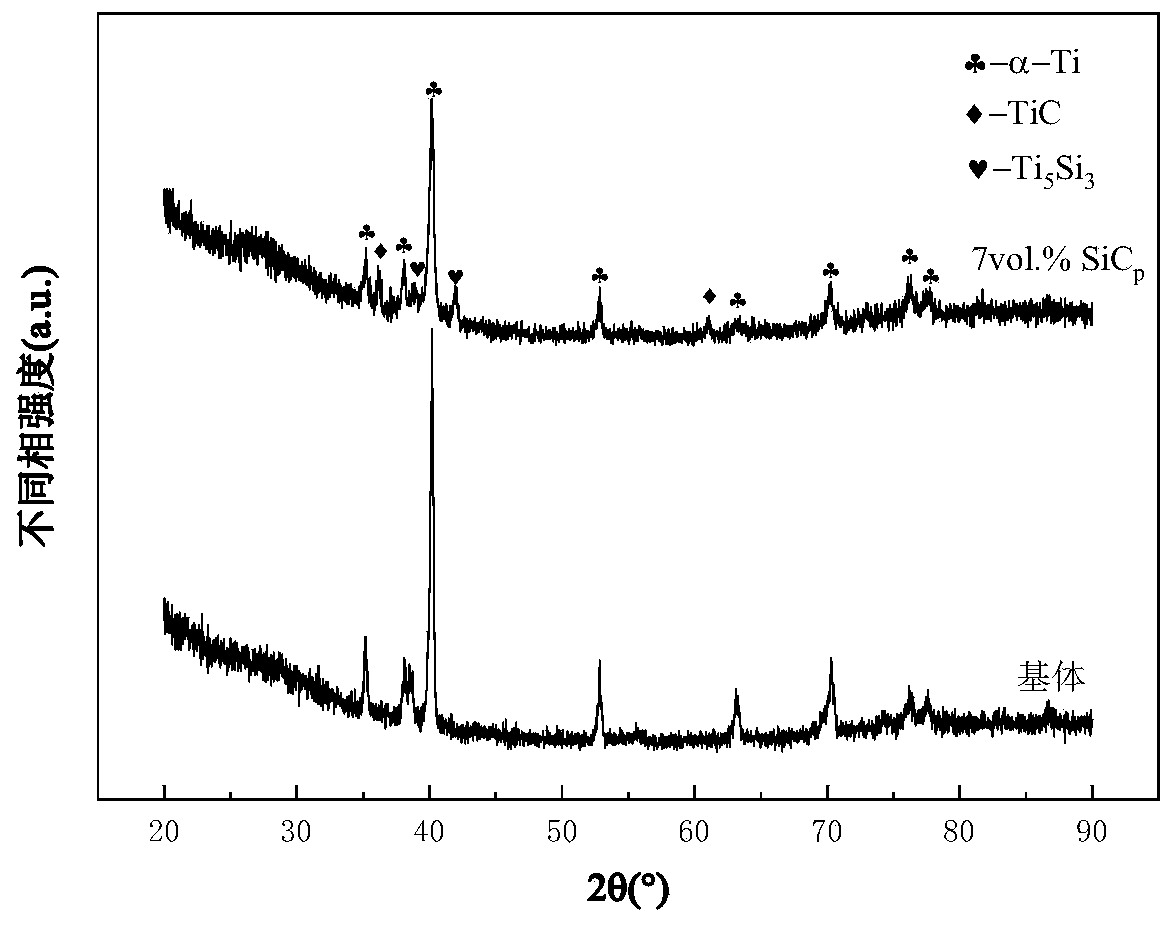

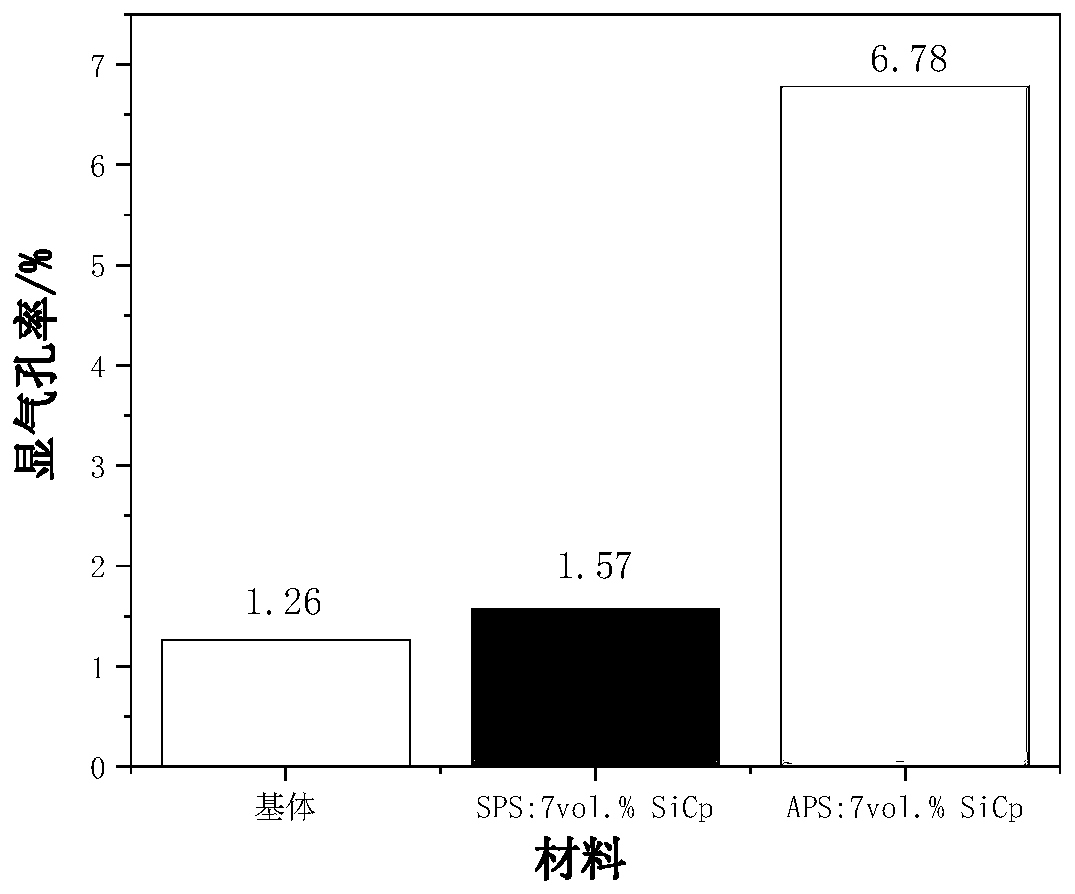

Preparation method of high-performance high-temperature titanium-alloy-based composite material

ActiveCN110735063ALow apparent porosityObvious improvement in hardnessTitanium matrix compositesTitanium

The invention relates to a preparation method of a high-performance high-temperature titanium-alloy-based composite material. The method is characterized in that the titanium-alloy-based composite material is prepared taking 90 wt.% of Ti alloy powder as a matrix, and 7 vol.% of SiCP reinforcing body powder is subjected to discharge plasma sintering in-situ reaction so as to generate TiC and Ti5Si3 reinforced phase. The preparing method comprises the following steps of 1, preparing powder by using an atomization method; 2, carrying out wet grinding on the 7 vol.% of SiCP reinforcing body powder; 3, carrying out wet grinding on the mixing powder including the matrix and the reinforcing body powder; 4, carrying out drying in a vacuum drying box; 5, carrying out dry grinding; 6, screening for200 meshes; 7, performing discharge plasma sintering under a sintering temperature of 1350 DEG C and a sintering pressure of 50 MPa; and 8, carrying out solid solution aging. According to the method,the microhardness of the composite material is 724.56 HV, the oxidation weight of the composite material is 1.7305 mg.cm<-2>, and the thickness of a composite oxide film is about 16 microns after high-temperature oxidation for 100 hours at 750 DEG C.

Owner:JIANGSU UNIV

Laser wire filling welding method and equipment for thermoplastic composite material butt joint structure

ActiveCN110126283AImprove stabilityImprove mechanical propertiesCleaning using liquidsMolten stateCarbon fibers

The invention relates to a laser wire filling welding method and equipment for a thermoplastic composite material butt joint structure. The laser wire filling welding method comprises the following steps that a material selected and used in the thermoplastic composite material butt joint structure laser wire filling welding process is carbon fiber reinforced thermoplastic plastic (CFRTP), and thesize of the carbon fiber reinforced thermoplastic plastic is 50mm x 25mm x 3.0mm; fastening pressing plates on the upper surface of the CFRTP composite material are adjusted to prevent a thermoplasticcomposite material from generating arch bend deformation in the welding process; and a wire feeder and a wire filling head are utilized to place filling resin at a welding line, laser acts on the filling resin in the welding process to make the filling resin be in a molten state, pressure is applied to one end of the CFRTP composite material butt joint structure, a molten state resin material flows, diffuses and solidifies under the action of external pressure, and a welding joint is formed. By means of the laser wire filling welding method and equipment for the thermoplastic composite material butt joint structure, a set of special tooling fixture equipment is designed aiming at the CFRTP thermoplastic composite material laser welding butt joint structure, and a solid foundation is laidfor application and development in the future of the CFRTP composite material laser welding technology.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

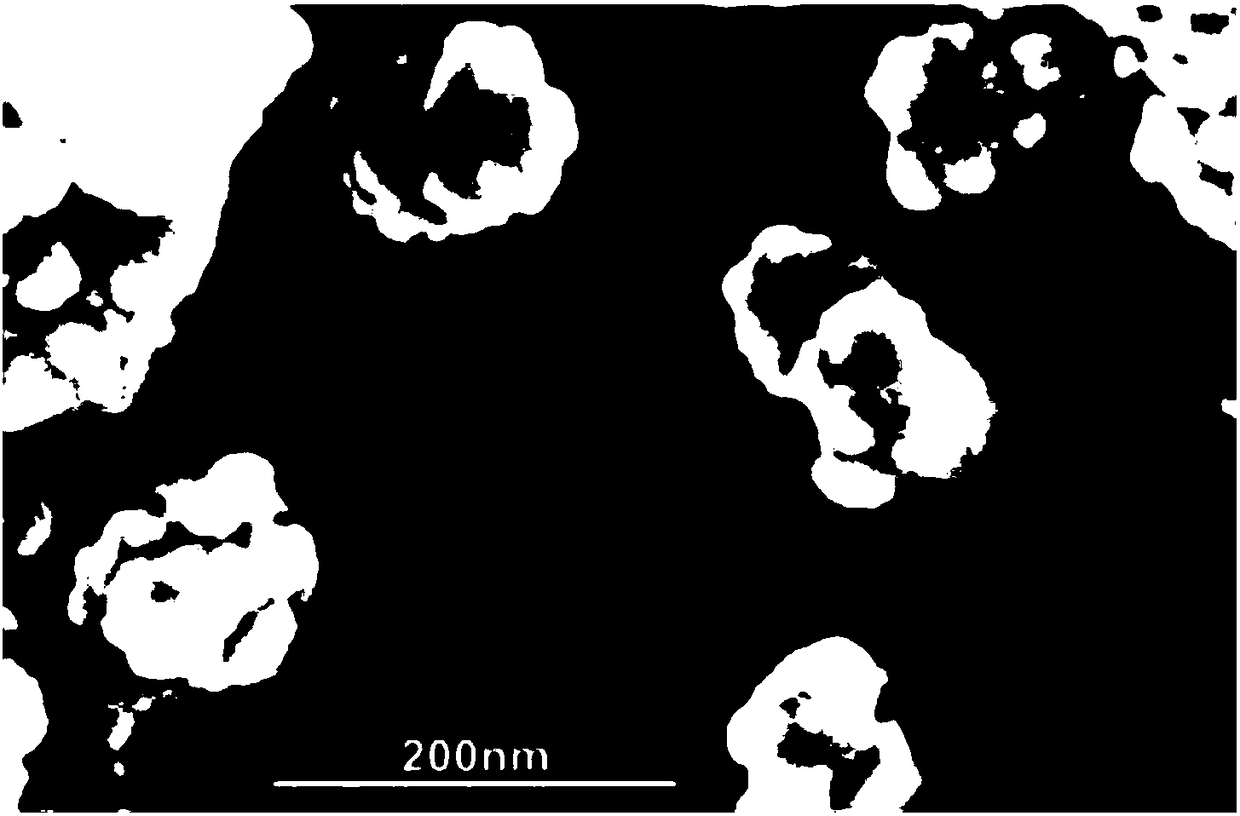

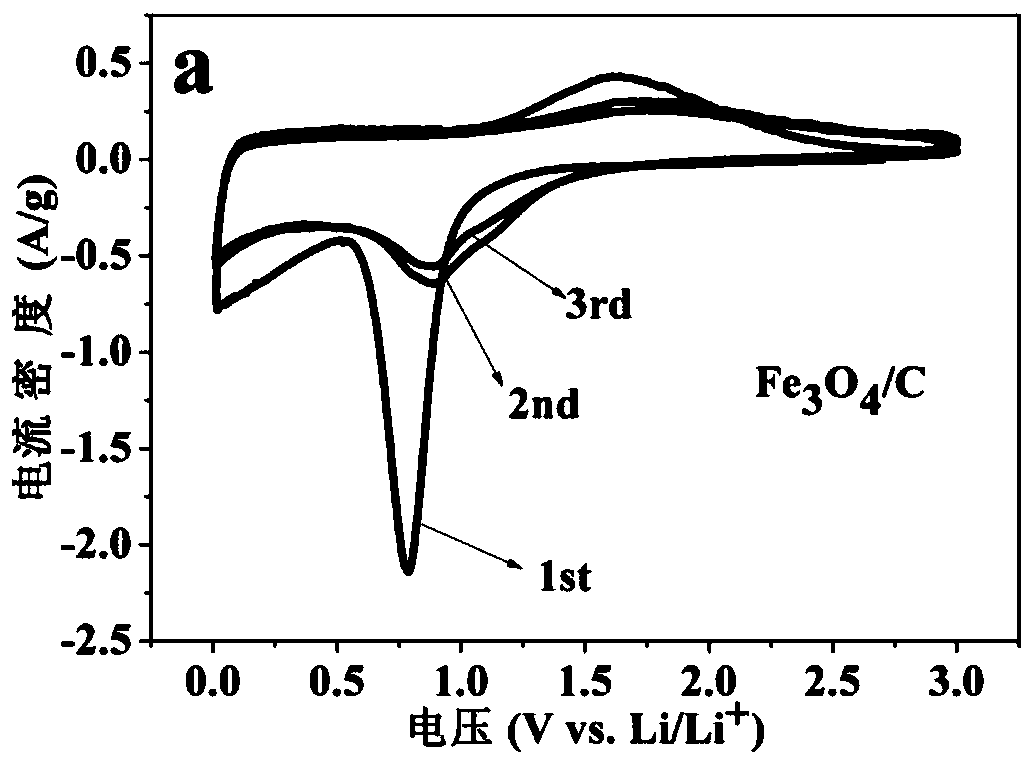

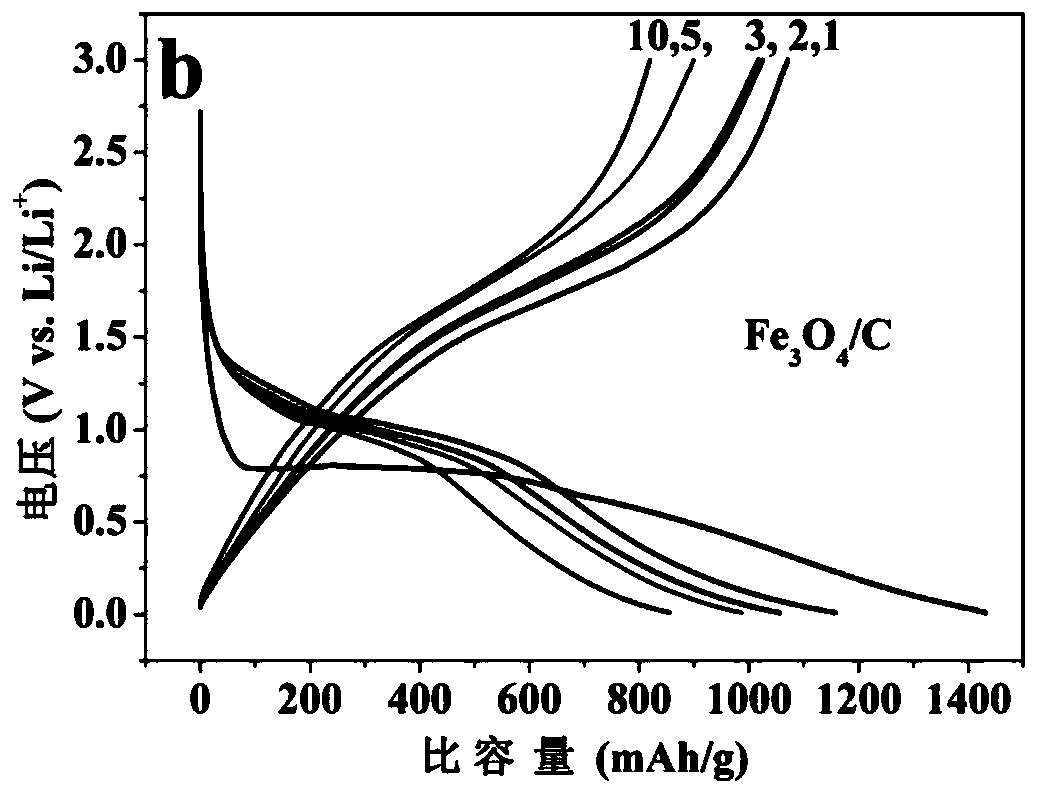

In-situ carbon-coated Fe3O4 composite material, preparation method thereof and application thereof in lithium ion battery

ActiveCN111244440AStable structureCoating thickness controllableSecondary cellsNegative electrodesPosterior compositesLithium-ion battery

The invention relates to an in-situ carbon-coated Fe3O4 composite material as well as a preparation method thereof and an application thereof in a lithium ion battery, and belongs to the technical field of lithium ion batteries. The preparation method comprises the following steps of adding a trivalent Fe salt aqueous solution into a BFA aqueous solution to form a gel precipitate; drying the gel precipitate to obtain BFA-Fe; carrying out carbonization treatment on the obtained BFA-Fe, so that the in-situ carbon-coated Fe3O4 composite material is prepared, the surfaces of Fe3O4 particles are comprehensively coated with the in-situ carbon, the surface coating uniformity is good, the coating thickness of the surface carbon material is controllable, and the structure of the coated composite material is more stable.

Owner:合盛科技(宁波)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com