Interlaminar enhancement process for composite laminated plate for fuselage and airfoils of unmanned plane

A composite material, interlayer reinforcement technology, applied in the field of composite material laminates, can solve the problems of weak impact resistance, resin-rich areas, compaction, etc., and achieve the effect of improving low-speed impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

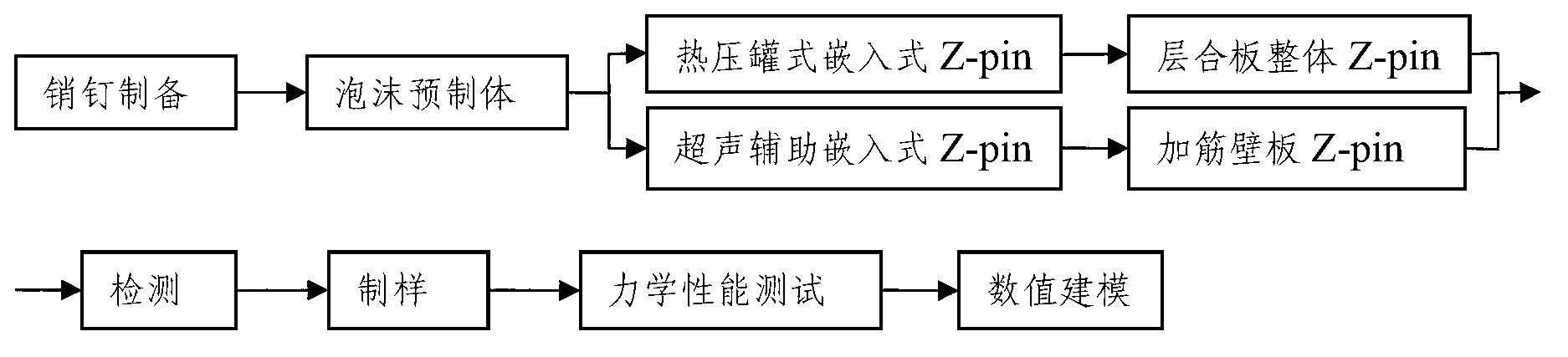

[0027] In the present invention, the process for interlayer reinforcement of composite material laminates for unmanned fuselage and wing includes the following steps:

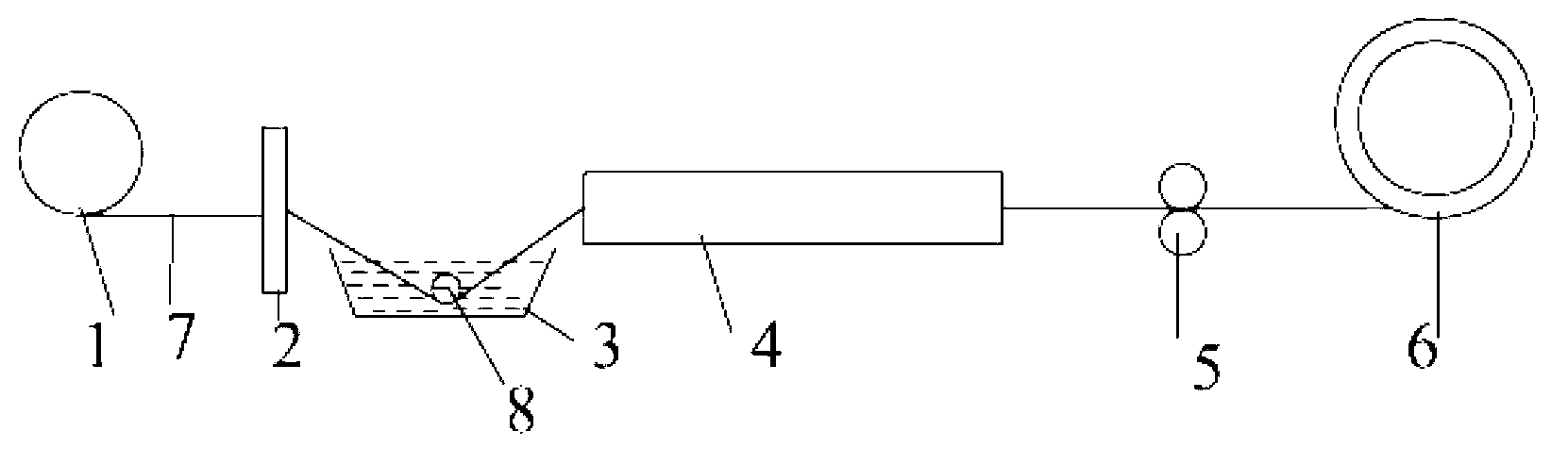

[0028] 1) Preparation of materials and equipment

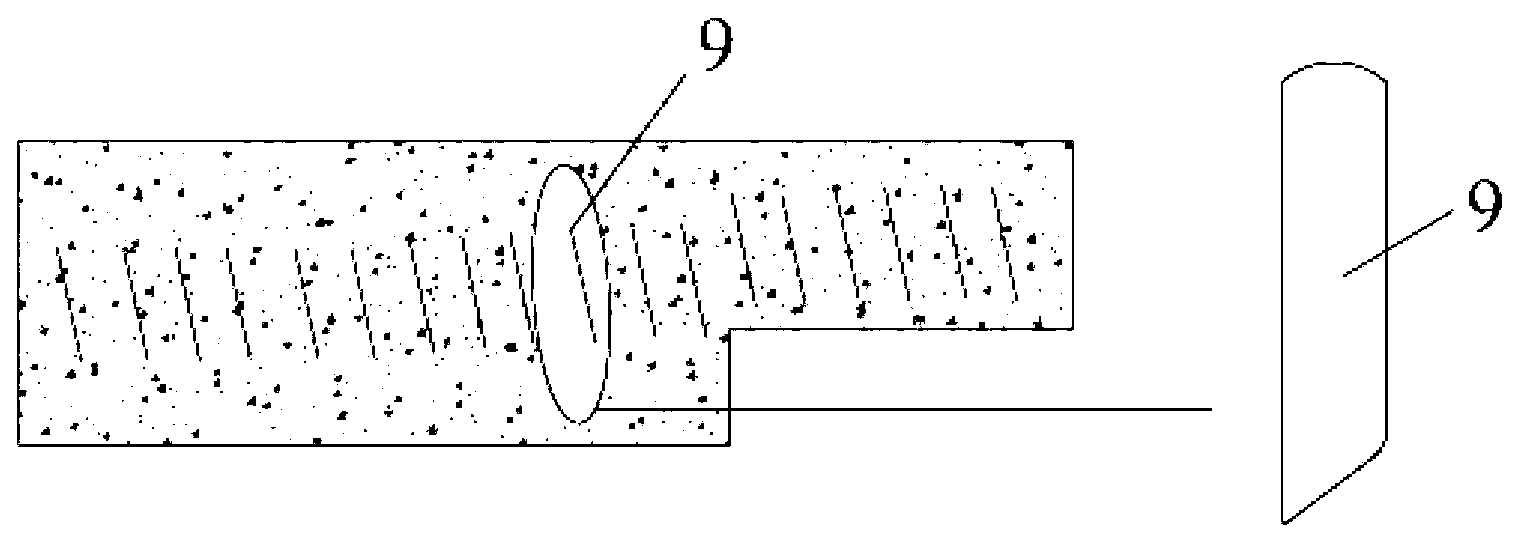

[0029] This step mainly involves the purchase of unidirectional carbon fiber tow, the purchase of mold materials, the construction of pultrusion process equipment, the manufacture of forming molds, the matrix resin system, and the determination of process parameters. The carbon-fiber-reinforced resin-based composite pin in the present invention is a pin with a very small diameter (usually between 0.15mm and 1.5mm in diameter). The diameters are: Ф0.4mm, Ф0.6mm, Ф0.8mm, Ф1.0mm, Ф1.2mm. In the follow-up process, different composite material pins are made by controlling the amount of carbon fiber, and the glue content of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com