Preparing method and system for damping layer in embedded type co-curing composite material

A composite material and preparation system technology, which is applied in the field of preparation of composite material components and damping layers in embedded co-cured composite materials, can solve the problems of reduced surface molecular activity of the damping layer, difficulty in manufacturing complex patterns, and poor bonding performance. , to improve the utilization rate, improve the damping effect, and realize the effect of continuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] Attached below Figure 1 to Figure 13 And the examples further illustrate the present invention.

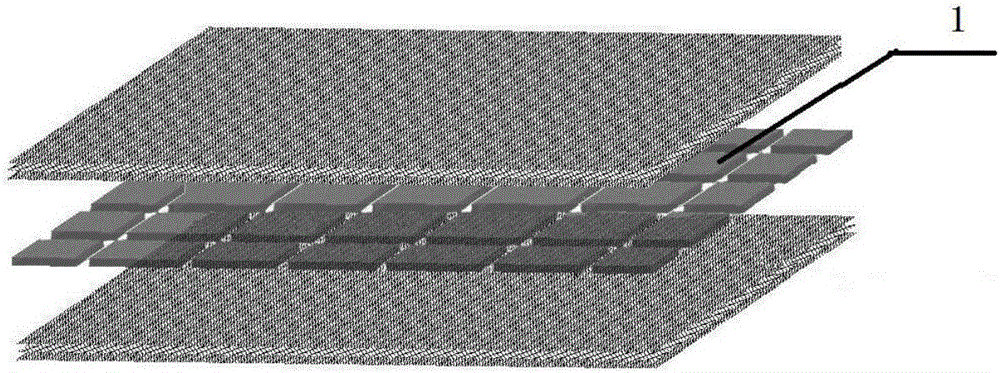

[0064] The damping layer 1 in the embedded co-cured composite material structure can be various, figure 1 It is the structure of embedded co-cured composite material of grid damping layer (here, grid pattern is used to represent complex pattern). After the composite material prepreg passes through the entire production line, the composite material prepreg with the complex pattern damping layer 1 is obtained. According to the designed laying sequence, it is laid and co-cured together with the composite material prepreg without the damping layer 1 to obtain The embedded co-cured composite material component of the complex pattern damping layer 1.

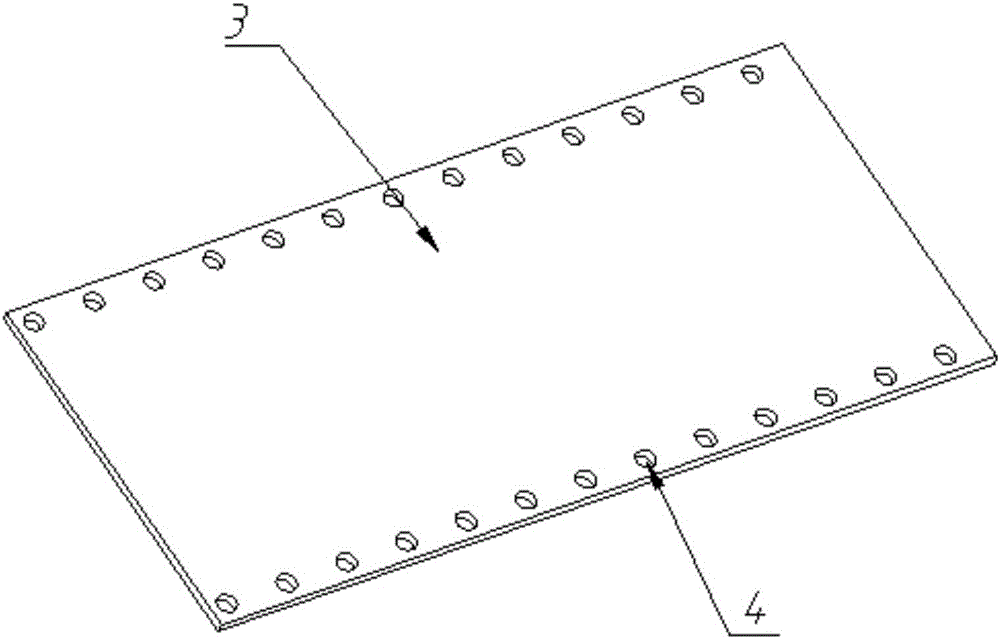

[0065] figure 2 For prepreg, there are circular positioning holes 4 equally spaced on both sides of the prepreg. The positioning holes can be periodically cut out on the prepreg by a row of sharp circular blades with the same size as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com