Patents

Literature

116 results about "Thin crystal" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing calcium sulfate crystal whiskers by using impurity-containing gypsum as raw material

InactiveCN101736403AHigh purityGood dispersionPolycrystalline material growthCalcium/strontium/barium sulfatesAnhydrous Calcium SulfateDihydrate Calcium Sulfate

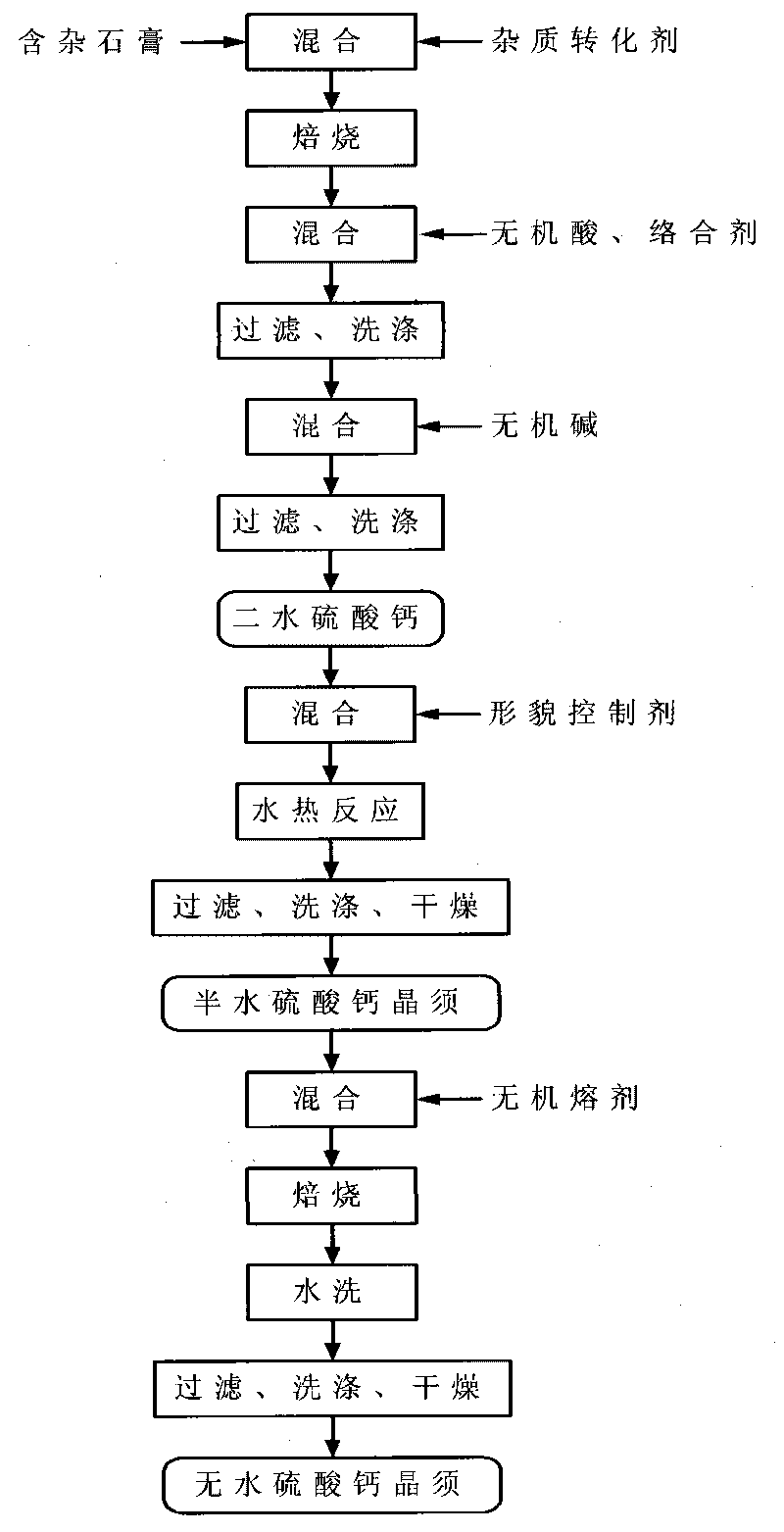

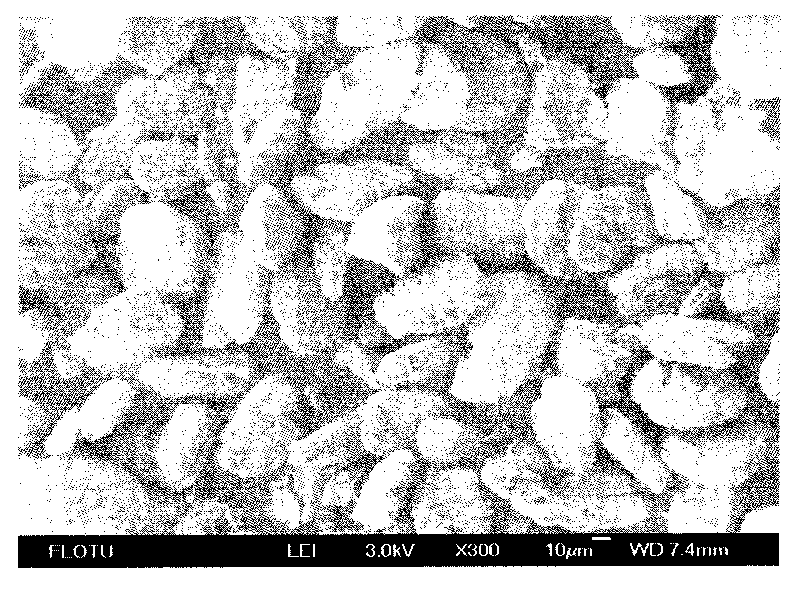

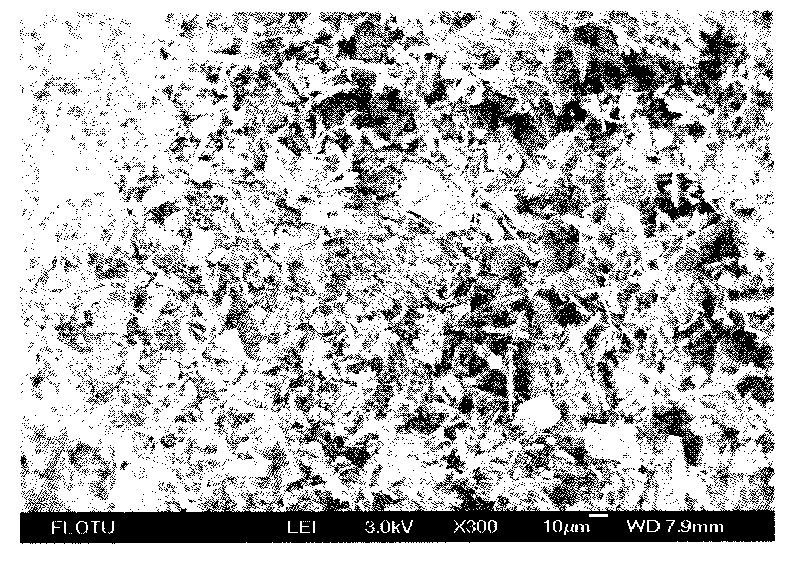

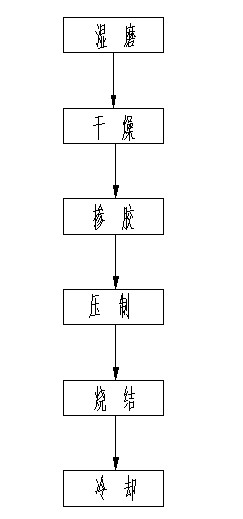

The invention relates to a method for preparing calcium sulfate crystal whiskers (CaSO4) by using impurity-containing gypsum as a raw material. The method comprises the following steps of: removing main impurities in the raw material which is the low-priced impurity-containing gypsum resource in a mode of roasting, acid-complex leaching and alkaline leaching and simultaneously thinning crystal grains to obtain a superfine dihydrate calcium sulfate precursor which is high in purity and dispersibility; and preparing the anhydrous calcium sulfate crystal whiskers with a length of 20 to 2,000mu m, a diameter of 0.5 to 20 mu m, a length-diameter ratio of 40 to 1,000 and a weight percent content of over 95 percent in a mode of hydrothermal conversion-roasting of a fluxing agent. The method has the advantages of low-priced and easily bought raw materials, simple process, wide application range, and high added value. The calcium sulfate crystal whiskers prepared by the method have a big length-diameter ratio and regular shape, and can be used as reinforcing, heat insulating or flame retardant materials in industries of plastics, rubbers, coatings, papermaking, building materials and the like.

Owner:KUNMING UNIV OF SCI & TECH

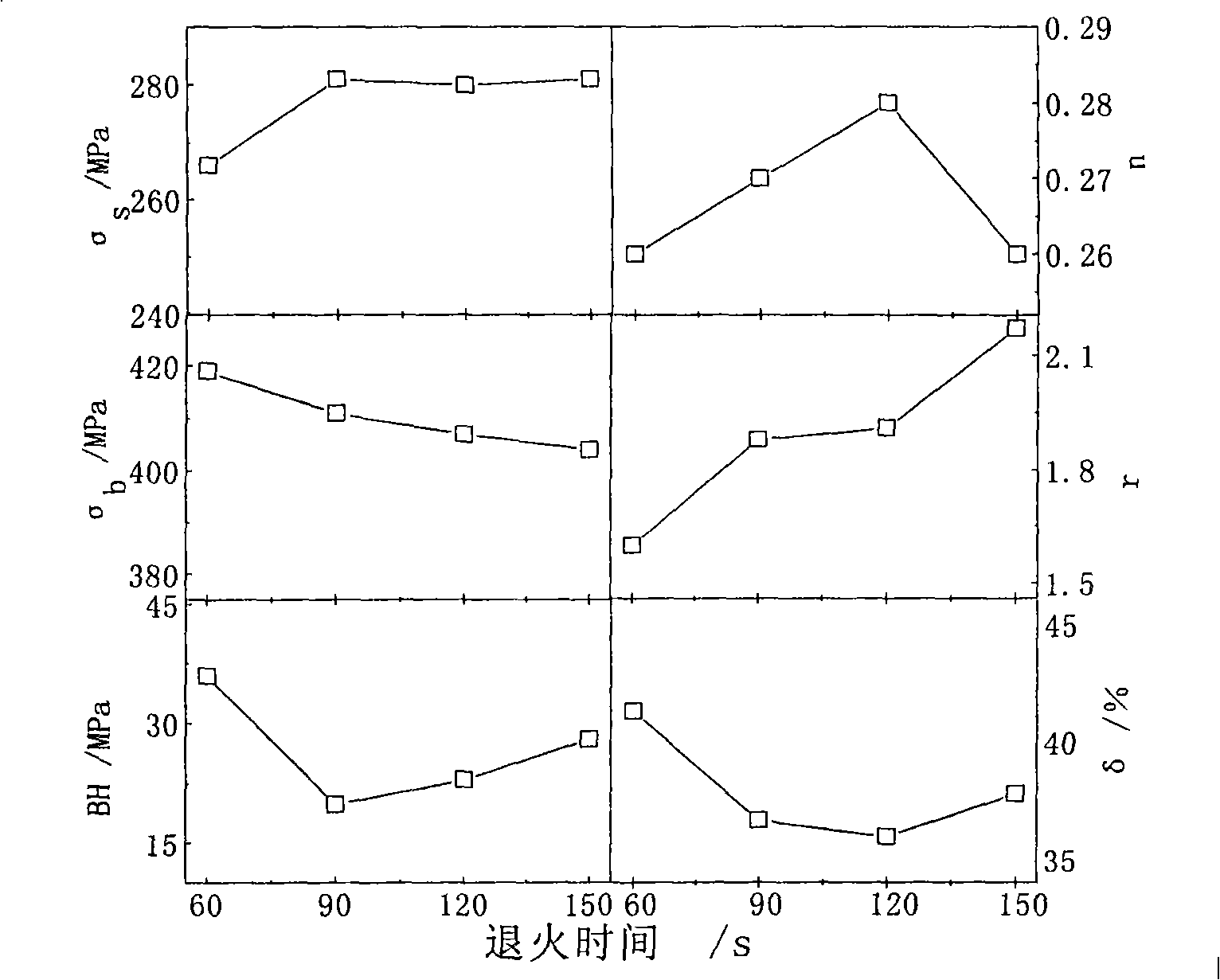

Niobium and titanium composite added ultra-low carbon baking hardening steel plate and manufacturing method thereof

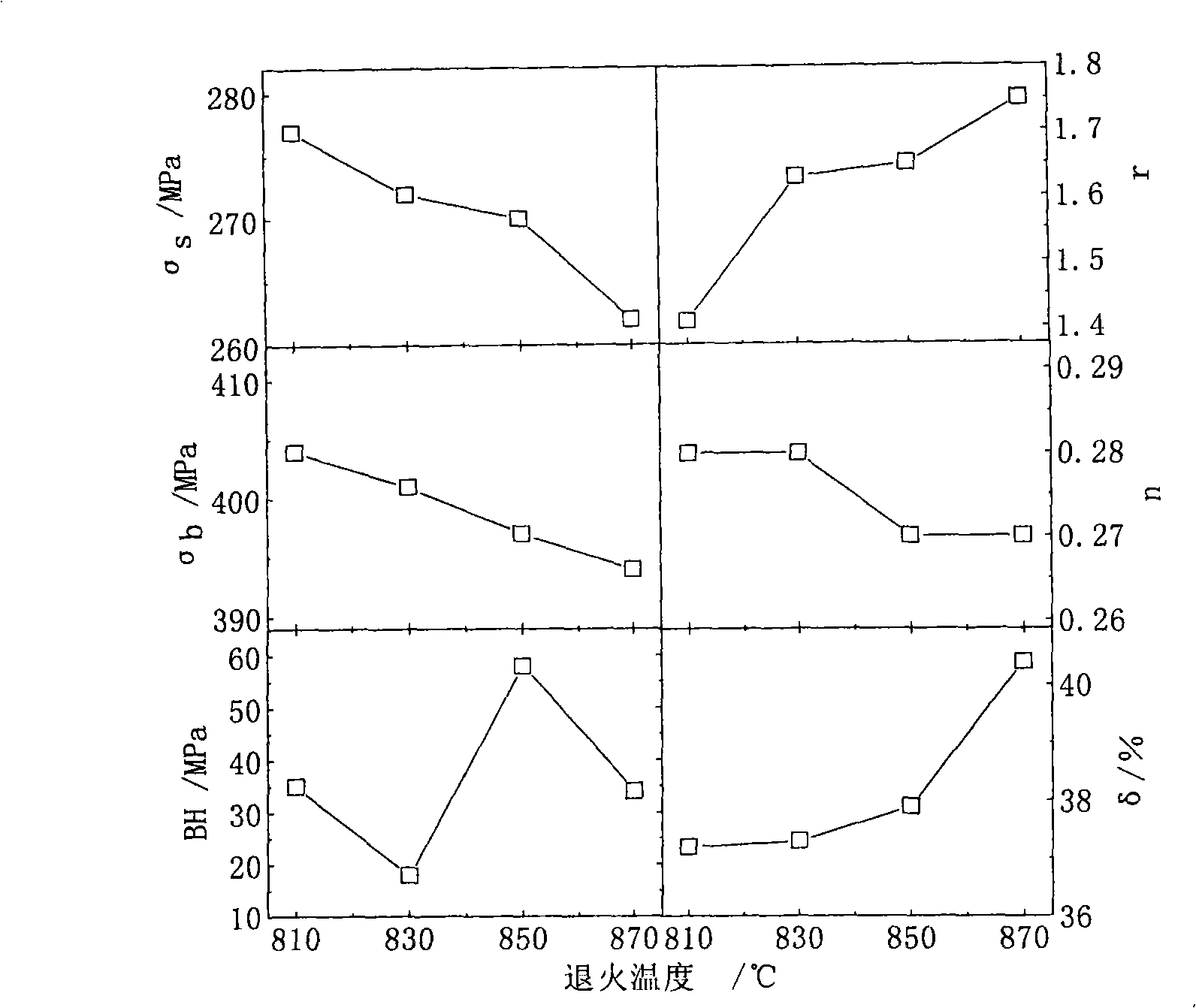

The invention relates to an ultra-low-carbon roasting hardened steel sheet with composite addition of niobium and titanium and a manufacturing method thereof, which belong to the material processing technical field. The compositions in weight percent of the ultra-low-carbon roasting hardened steel sheet are 0.002 to 0.005 percent of carbon, less than or equal to 0.5 percent of silicon, 0.9 to 1.2 percent of manganese, 0.08 to 0.1 phosphor, less than or equal to 0.06 percent of sulfur, 0.02 to 0.05 percent of aluminum, less than or equal to 0.06 percent of nitrogen, 0.01 to 0.02 percent of titanium, 0.01 to 0.02 percent of niobium, and the balance being iron. The microalloy titanium in the steel is used for fixing the carbon, the nitrogen, the sulfur and the niobium in the steel and controlling the carbon, and simultaneously has the function of thinning crystal grains. The the ultra-low-carbon roasting hardened steel sheet has the advantages that the ultra-low-carbon roasting hardened steel sheet can simultaneously have high strength, r value, extensibility and BH value and good room temperature resistant timeliness after the required steel undergoes hot rolling, cold rolling and continuous annealing.

Owner:UNIV OF SCI & TECH BEIJING +1

Method for producing iron oxide black

This is the producing method of a kind of oxidized iron oxide black including following contents: prepare ferrite watery solution; use sodium hydroxide as neutralizaing agent and react with ferrite watery solution to produce hydroxide ferrous; use oxygenous gas as oxidant, and react with said hydroxide ferrous to produce iron oxide black; make the prepared iron oxide black water washed, sieved, dried and comminuted orderly to get blue oxidized iron oxide black pigment product. The oxidized iron oxide black produced by this method has high purity and thin crystal grain, the grain size of produced pigment is thin and even, and has saturated blue ink light black and stable effect to light and atmosphere. It also has strong pigmentation strength and hiding power, and can be used in such fine chemical industry products as printing ink and carbon powder. The farther project is using waste residue containing ferrous sulfate and vented in titanium oxide powder production, to produce ferrous sulfate watery solution and produce oxidized iron oxide black, which can adequately use industry waste material to produce oxidized iron oxide black products of high quality, and reduce environmental pollution.

Owner:HUBEI WANRUN NEW ENERGY TECH DEV

High-purity stabilized aluminum alloy ingot and production method thereof

The invention discloses high-purity stabilized aluminum alloy ingot which comprises the following components in weight percent: 3.1-3.8% of Cu, 7.9-9.3% of Si, 0-0.1% of Mg, 0-2.3% of Zn, 0-0.9% of Fe, 0-0.5% of Mn, 0-0.5% of Ni, 0-0.35% of Sn, 0-0.1% of Ti, 0-0.25% of other trace elements and the balance of Al. The invention further discloses a production method of the high-purity stabilized aluminum alloy ingot. The high-purity stabilized aluminum alloy ingot of the invention has low gas and slag content, high cleanness of molten aluminum, uniform components of the product and thin crystal structure; and the production method has low production cost and high efficiency, and effectively solves the pollution problem of the secondary aluminum industry.

Owner:YE CHIU METAL RECYCLINGCHINALTD

Ultrathin hard alloy with high hardness and preparation method thereof

Owner:CHONGQING ACADEMY OF SCI & TECH

Low cost high performance X70 pipeline steel and production method thereof

The invention relates to a low-cost and high-performance X70 pipeline steel and a manufacturing method thereof, which belong to the steel material technical field and are used for solving the problem that production of the pipeline steel consumes noble metals such as molybdenum, nickel and so on. The low-cost and high-performance X70 pipeline steel is characterized by comprising the following main chemical compositions: 0.02 to 0.06 percent of carbon, 0.10 to 0.30 percent of silicon, 1.40 to 1.9 percent of manganese, 0.04 to 0.07 percent of vanadium, 0.040 to 0.070 percent of niobium, 0.020 to 0.040 percent of acid-soluble aluminum, less than or equal to 0.012 percent of phosphor, less than or equal to 0.006 percent of sulfur, and the balance being iron. The formula of the chemical compositions of the X70 pipeline steel adopts the production flow of continuous casting and tandem rolling of thin slabs and thins crystal grains by controlling technological parameters of continuous casting and tandem rolling, so as to achieve the aim of improving the strength and the toughness of the pipeline steel. The X70 pipeline steel produced by the method has high impact toughness; the average grain size is 3.5 micrometers; and the production cost is obviously reduced.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

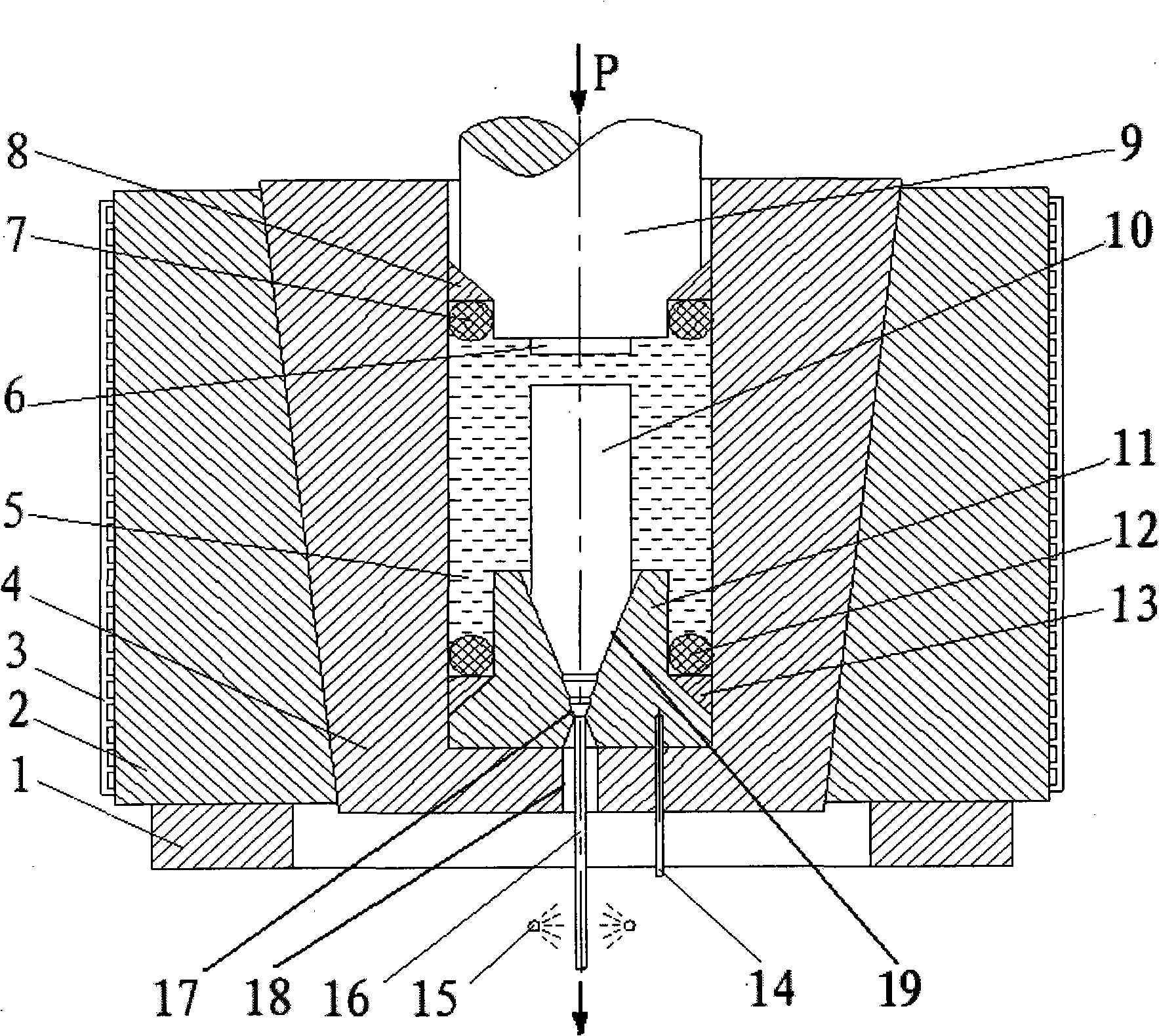

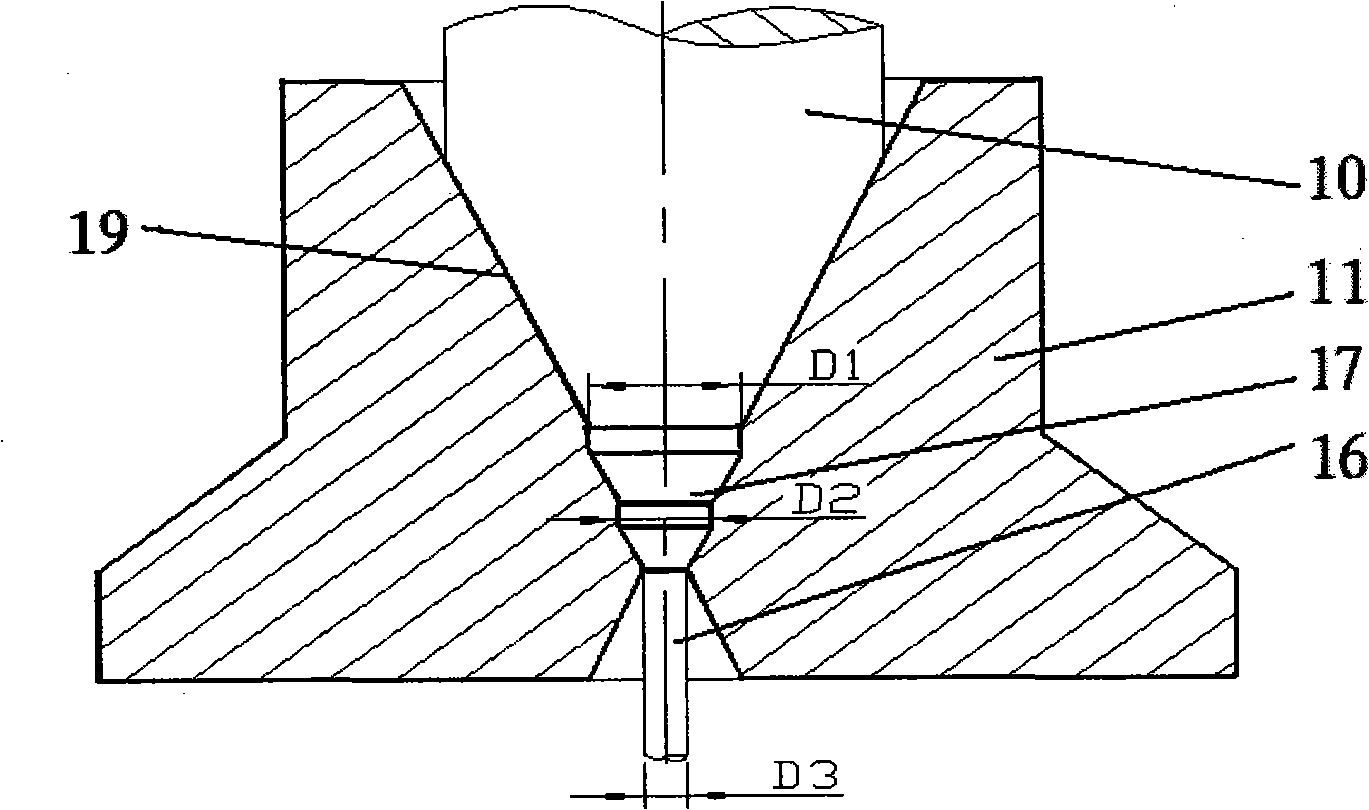

Wire hydrostatic extrusion device and method for extruding superfine grain wire using the device

InactiveCN101279331AGuaranteed qualityWill not oxidizeExtrusion diesExtrusion control devicesWire rodEngineering

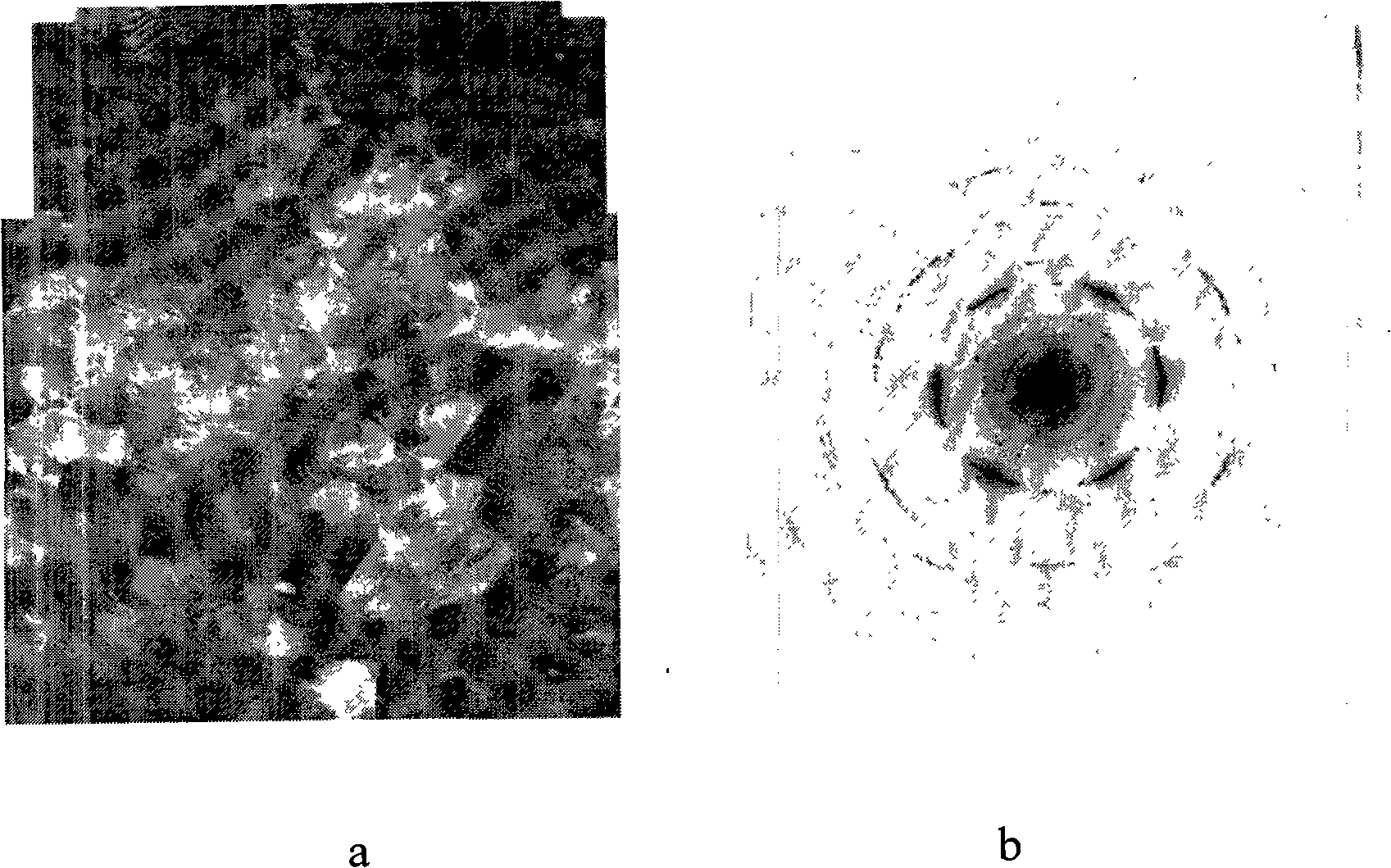

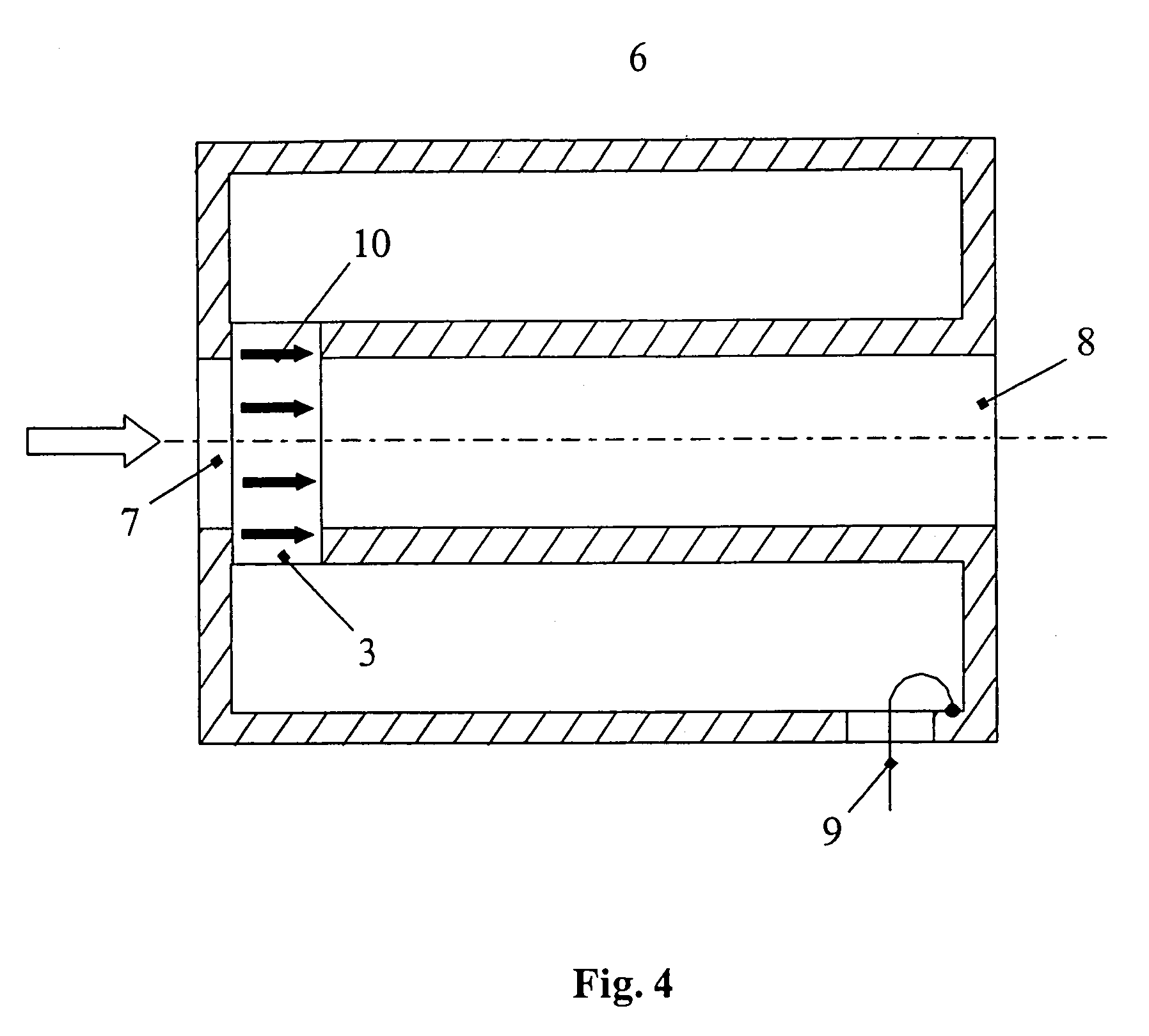

The invention discloses a linear material static liquid extruding device which comprises an external extruding cylinder; an internal extruding cylinder is sheathed in the external extruding cylinder; the empty cavity of the internal extruding cylinder is filled with a hydraulic medium; the upper end of the empty cavity of the internal extruding cylinder is connected with an extruding rod; a sealing device is arranged between the extruding rod and the internal extruding cylinder. The lower end surface of the empty cavity of the internal extruding cylinder is provided with a discharge channel along the axes direction; the inner side of the lower end surface of the empty cavity of the internal extruding cylinder is provided with an extruding mould; the sealing device is arranged between the extruding mould and the internal extruding cylinder; the extruding mould is provided with an leading-in hole and an extruding hole along the axes direction; the leading-in hole, the extruding hole and the discharge channel are arranged on the same axes and are permeable. The invention also discloses a method for preparing super-thining crystal grain linear materials by the extruding device; the whole device has the advantages of compact structure, simple technique and easy operation, which is suitable for static liquid extruding to prepare aluminum alloy linear materials with thin diameters and is applied to continuously extruding other light alloys or brittle alloy linear materials that are hard to be extruded.

Owner:XIAN UNIV OF TECH

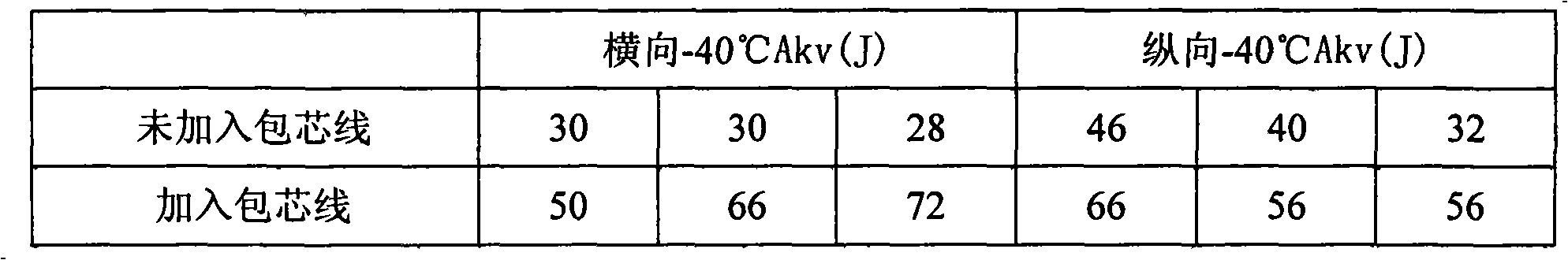

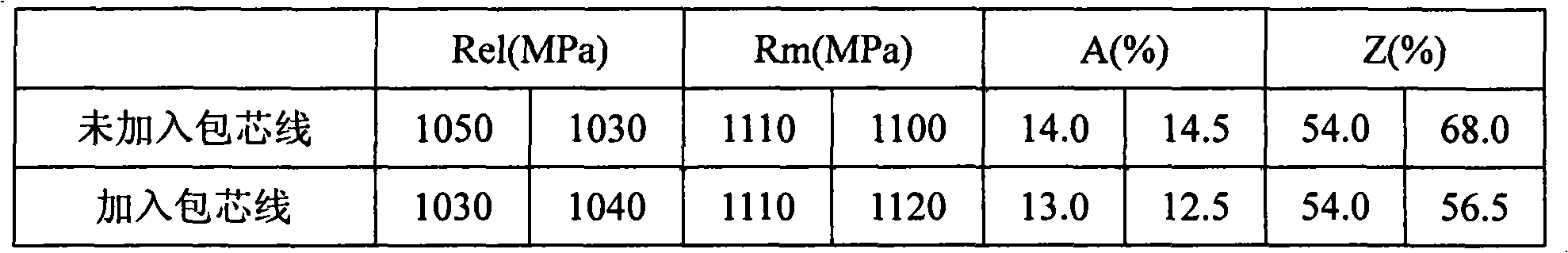

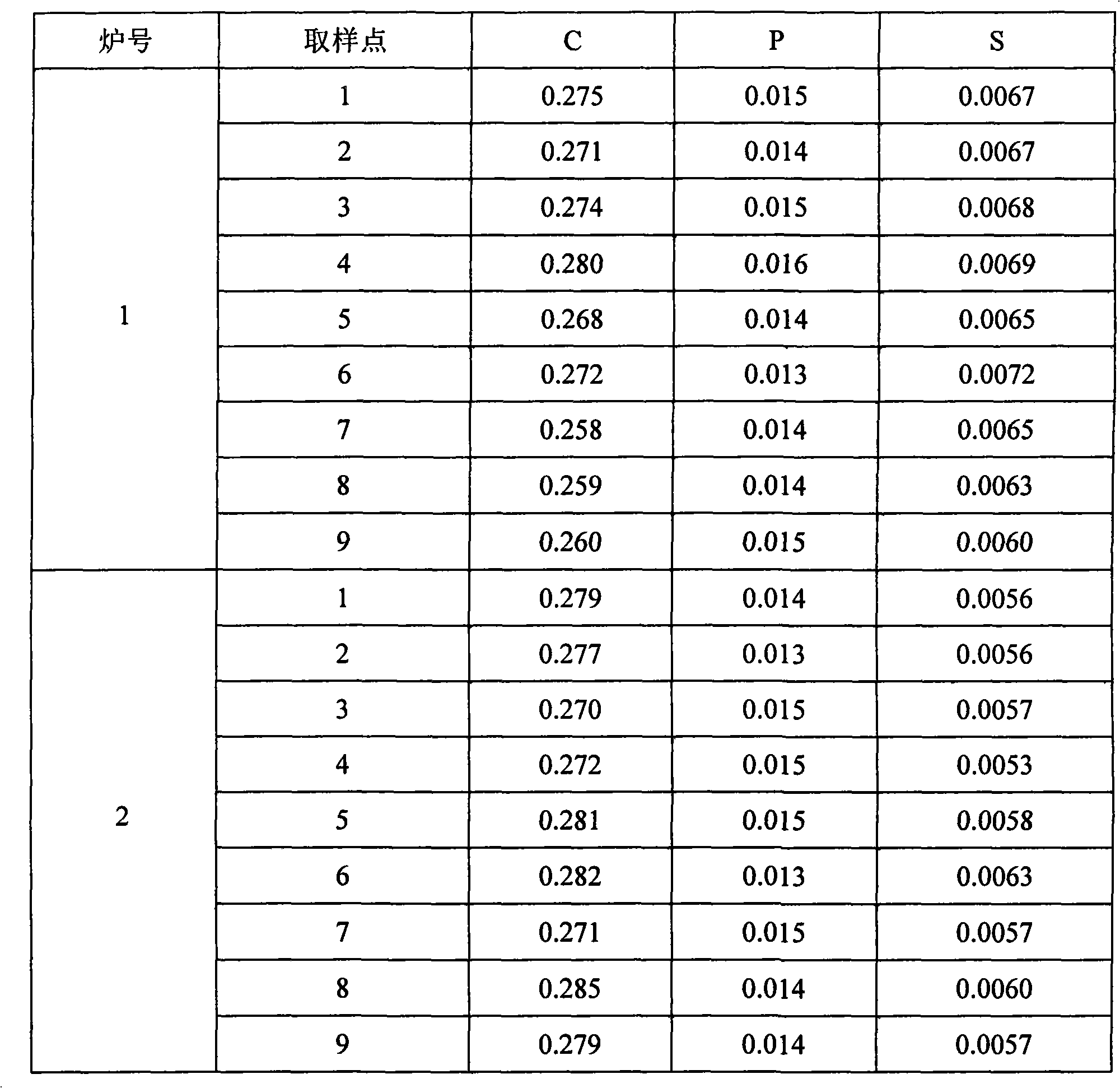

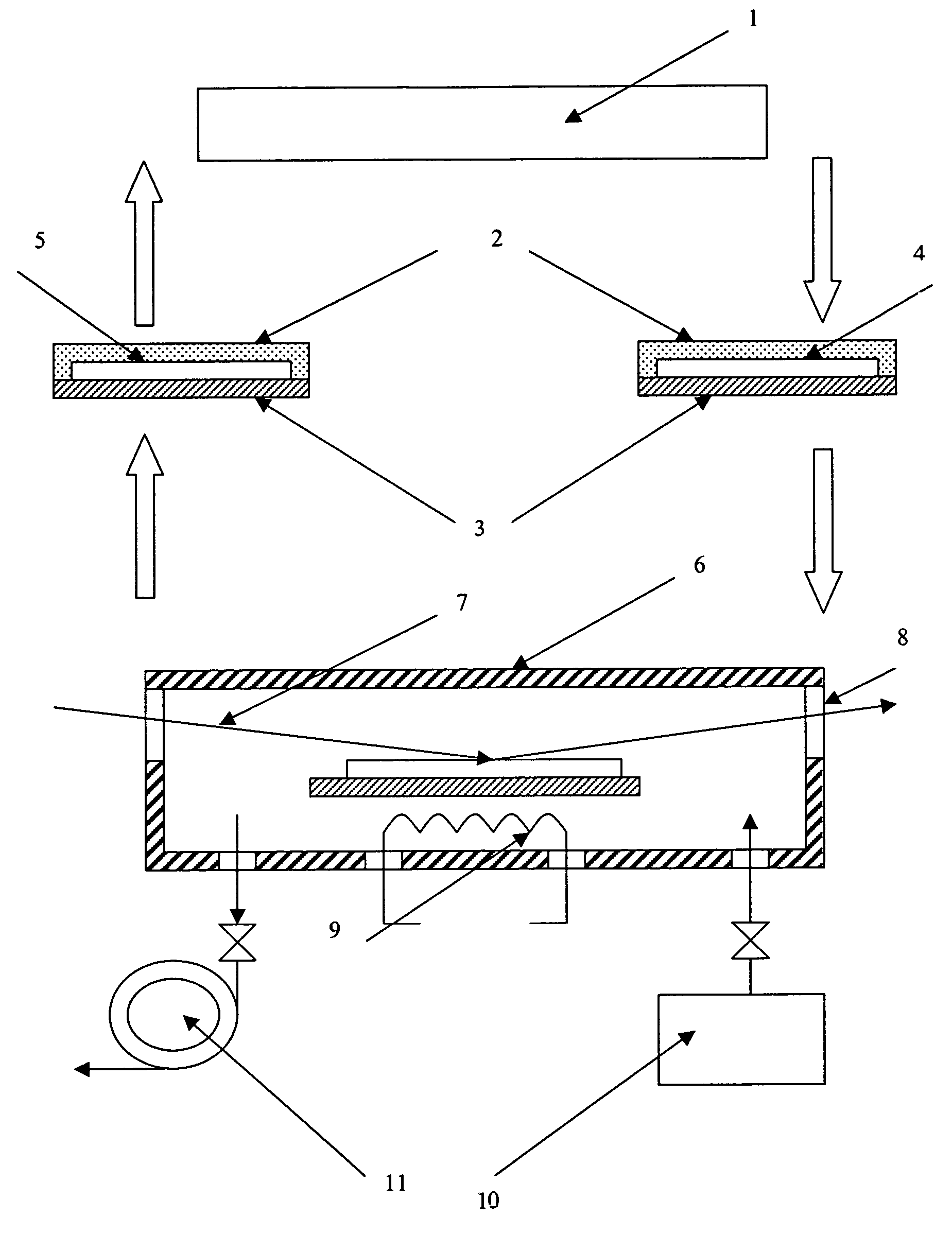

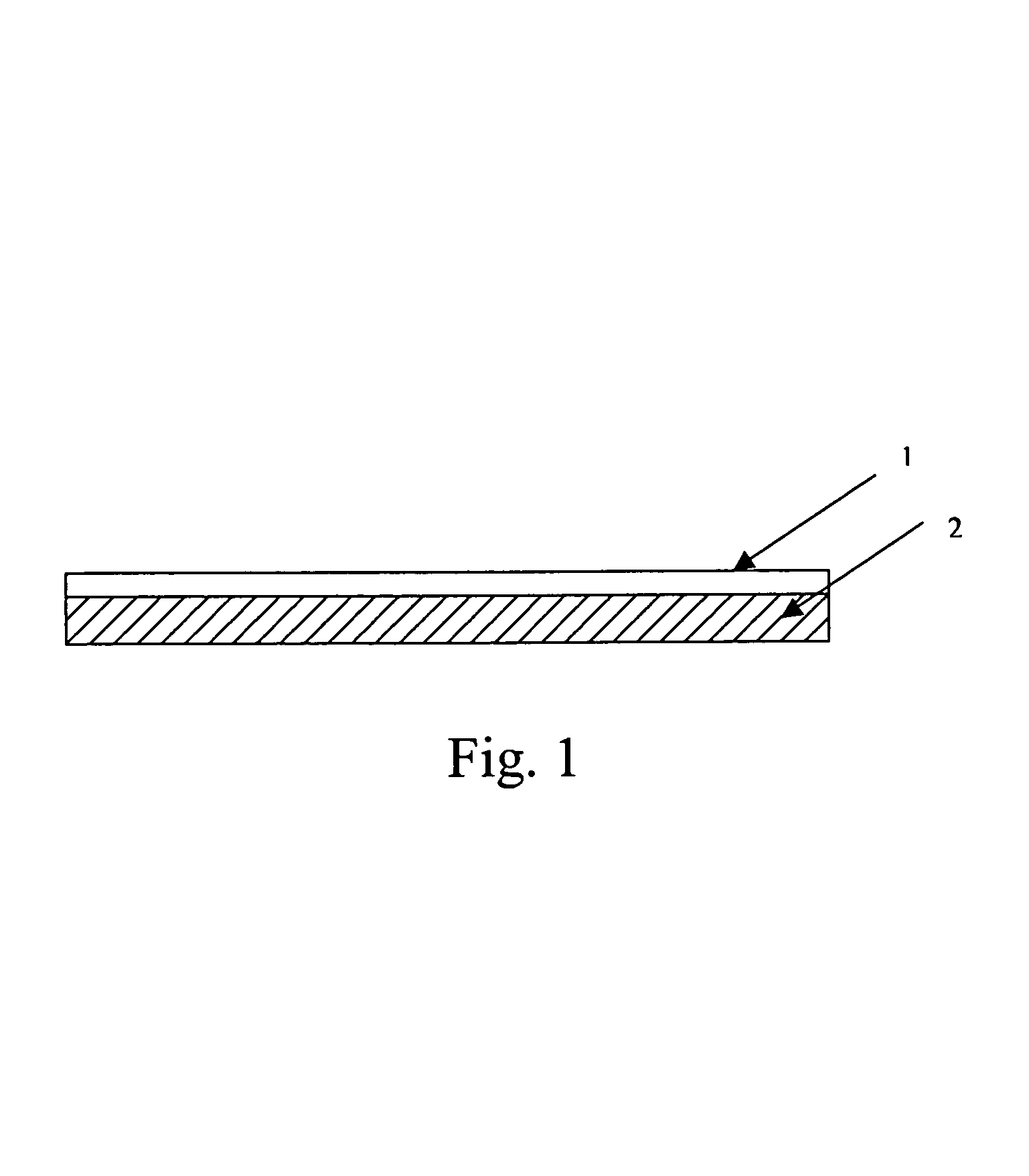

Micro-alloy composite core-spun yarn for high-strength structure steel

The invention provides a microalloy combined core-spun yarn for the high intensity structural steel, comprising a carbon steel sheath and a powder inner core, wherein, the element components and the mass percentage inside the powder inner core are as follows: C ranges from 0.6 to 0.9, Ca ranges from 18 to 22, Si ranges from 45 to 50, Mg ranges from 0.3 to 0.6, Ba ranges from 0.5 to 1.5, rare metal ranges from 0.2 to 0.5, B ranges from 0.3 to 0.7, Zr ranges from 1.6 to 2.0, Ti ranges from 1.2 to 1.8, Mn ranges from 0.08 to 0.12, P ranges from 0.2 to 0.6, S ranges from 0.2 to 0.6, and Fe occupies the rest percent. The microalloy combined core-spun yarn improves the steel intensity obviously, ensures that the lengthwise and transverse impact properties of the steel can be isotropic, thins crystal grains to ensure that the strip foreign substance is spherified and is distributed inside a base body, eliminates an aliquation line inside a continuously cast bloom, improves the performance, and is suitable for the outdoor refinement of the structural steel with the high intensity more than or equal to 800 MPa and the high impelling strength CV ranging from 250 to 300 J at 20 DEG C below zero.

Owner:HUBEI KMK WELDING MATERIALS

Anisotropic film manufacturing

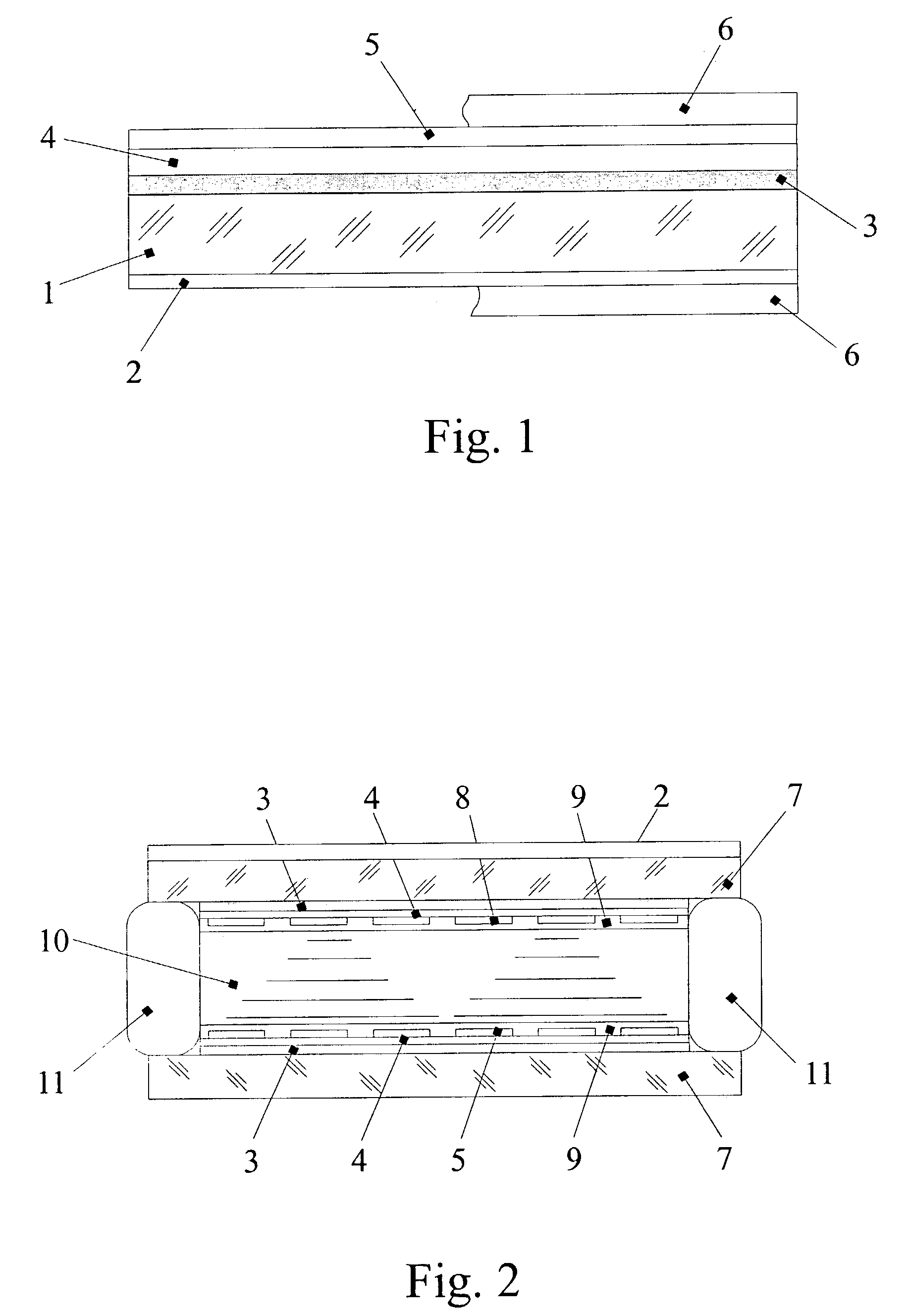

ActiveUS7166161B2Broadening functional possibilitySimple manufacturing methodFrom gel stateLiquid crystal compositionsFiberDisplay device

The present invention relates to an anisotropic films and method for obtaining the same. The film comprises substrate and at least one modified conjugated aromatic crystalline layer deposited onto said substrate. The said layer is characterized by globally ordered crystalline structure with intermolecular spacing of 3.4±0.3 Å along one of optical axes. The modified conjugated aromatic crystalline layer is formed by rodlike supramolecules, which comprise at least one polycyclic organic compound with conjugated π-system. At least part of the modified conjugated aromatic crystalline layer has electric conductivity and is slightly soluble or insoluble in polar solvents. The films are useful in optical applications, such as polarizers and retarders, and in electronic and light emitting devices, such as fiber optics modulators and switches, solar cells, charge-coupled device (CCD), thin film transistor integrated circuits, light emitting diodes, and light emitting displays. The invention features the use of organic compounds for manufacturing thin crystal films useful in various applications.

Owner:NITTO DENKO CORP

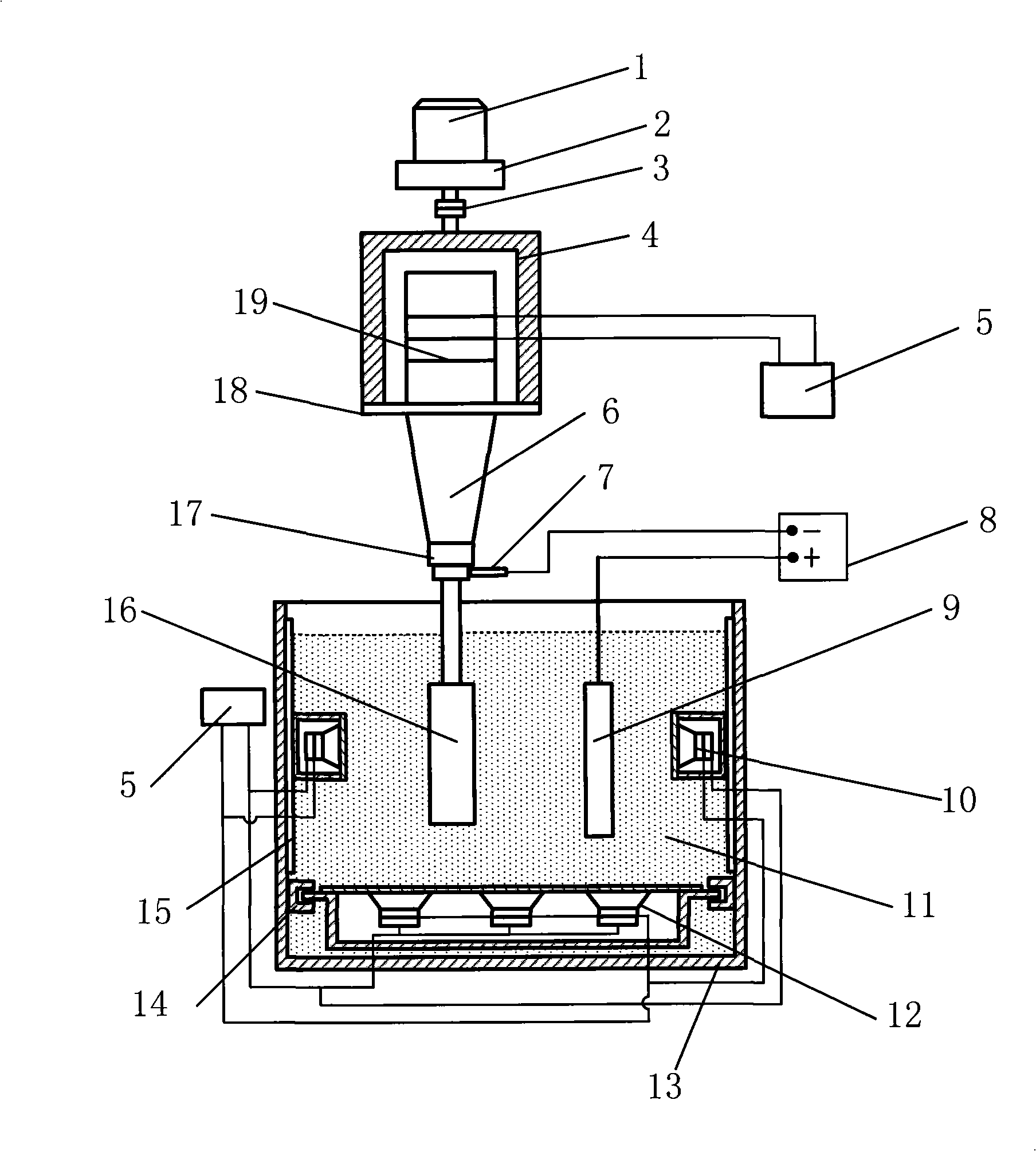

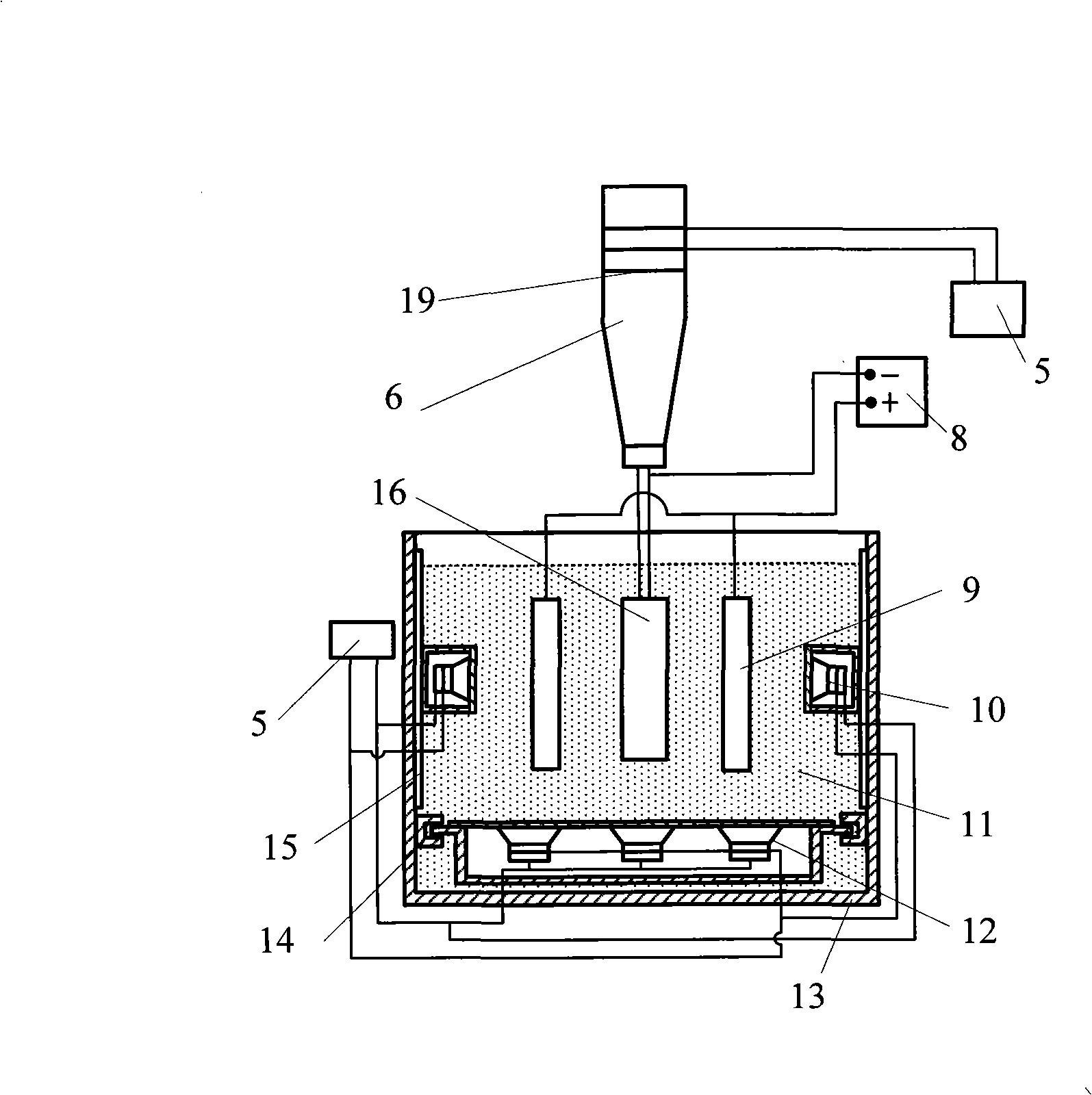

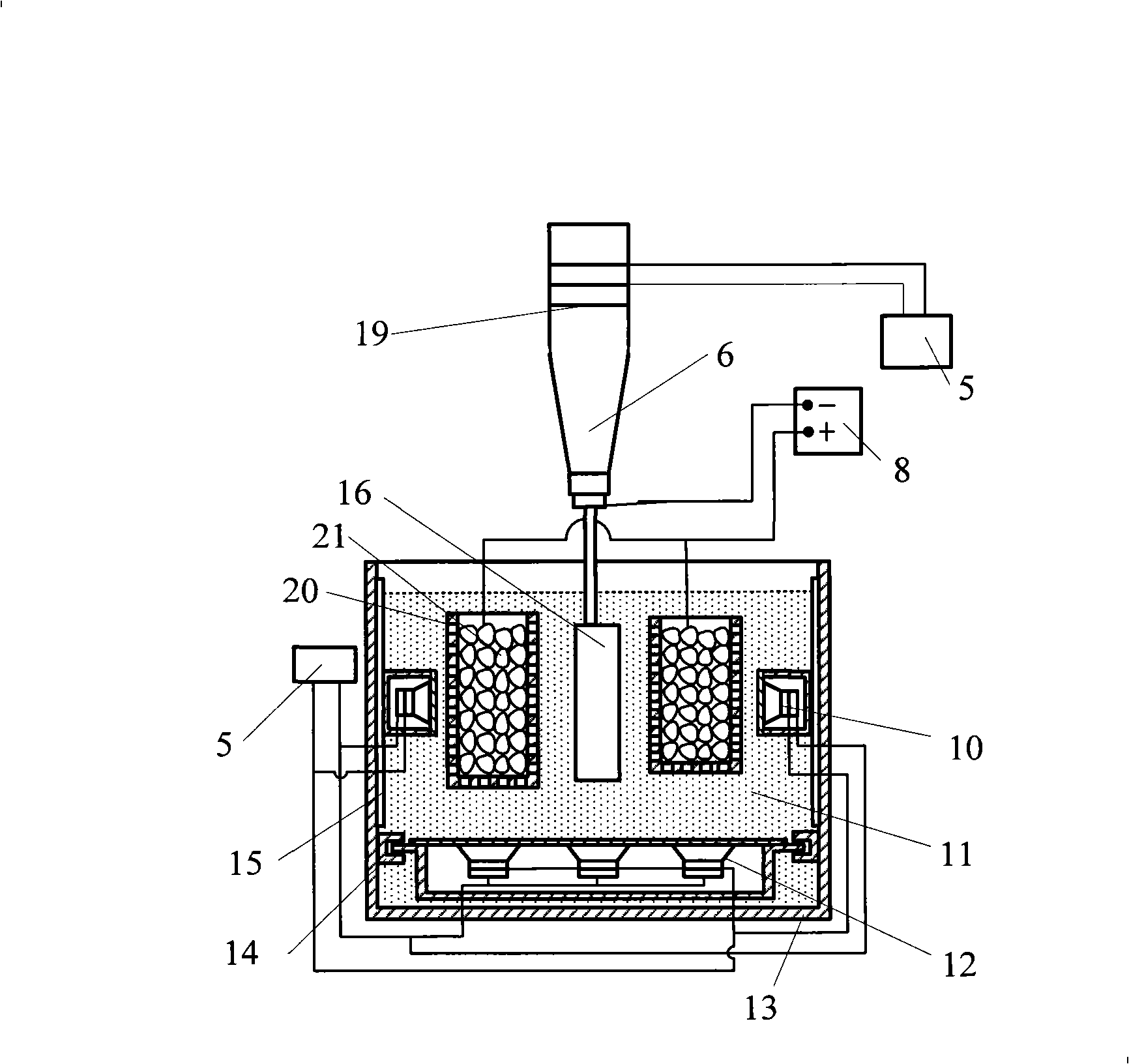

Electroforming composite processing apparatus and electroforming tank used by the apparatus

InactiveCN101328600AImprove impact performanceImprove the perturbation effectElectroforming processesElectrolysisConcentration polarization

The invention relates to an electroforming combined processing device and an electroforming groove used in the device. The device comprises an electroforming mandrel supporting device and the electroforming groove, wherein, an energy transducer device is arranged on the electroforming mandrel supporting device or / and inside the electroforming groove, and an energy transducer of the energy transducer device is in electric connection with an ultrasonic generator. A multi-frequency ultrasound irradiating system consisting of cathode ultrasound and groove type ultrasound is acted on the electroforming process in a way of alternating coupling, and more cavitation cases are generated by the ultrasound vibration of the cathode mandrel and the ultrasound vibration of an electrolysis bath to obtain intensified ultrasound cavitation effect, thereby intensifying the conflict and perturbation on the electroforming mandrel surface, effectively removing bubbles on the electrode surface, ensuring that the current passes through the electrode smoothly, increasing the moving speed of positive ions to the cathode, reducing the concentration polarization in order to increase the electroforming speed, thinning crystal grains of the metal electrocrystallization, and obtaining an electroforming product with even surface and even and compact tissue.

Owner:HENAN UNIV OF SCI & TECH

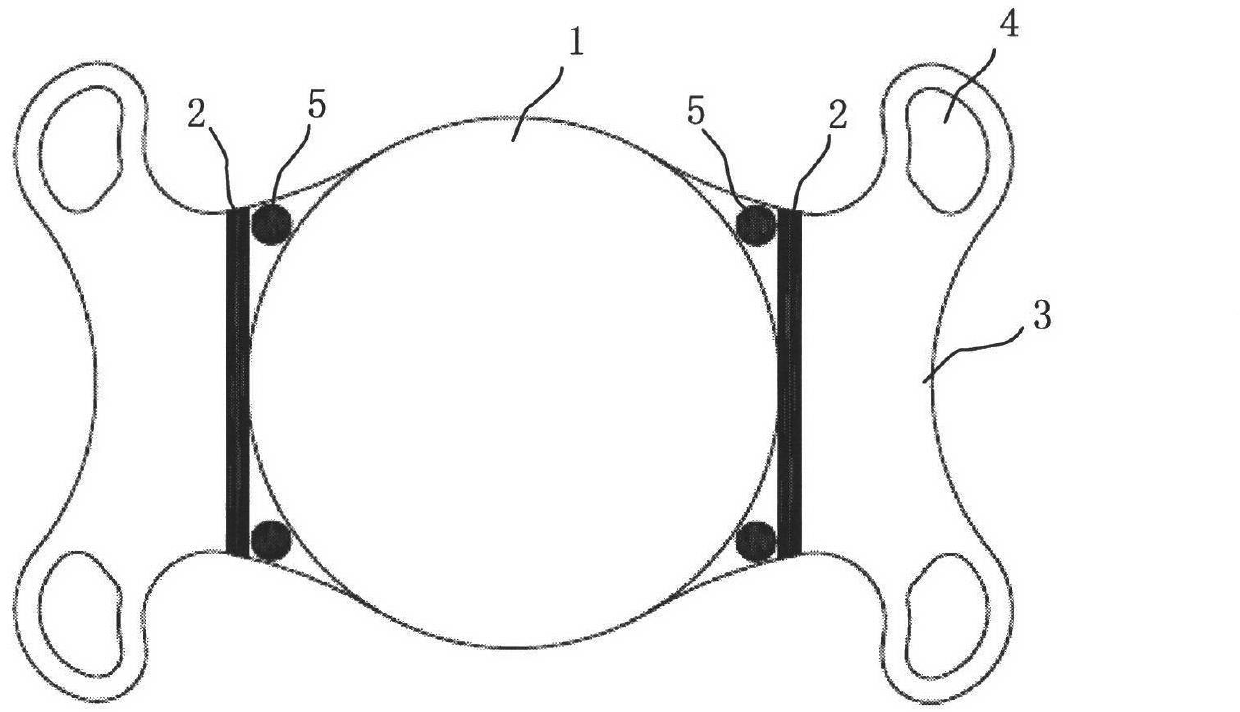

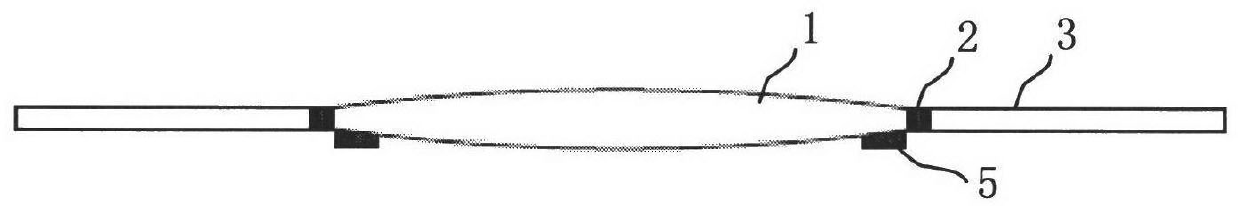

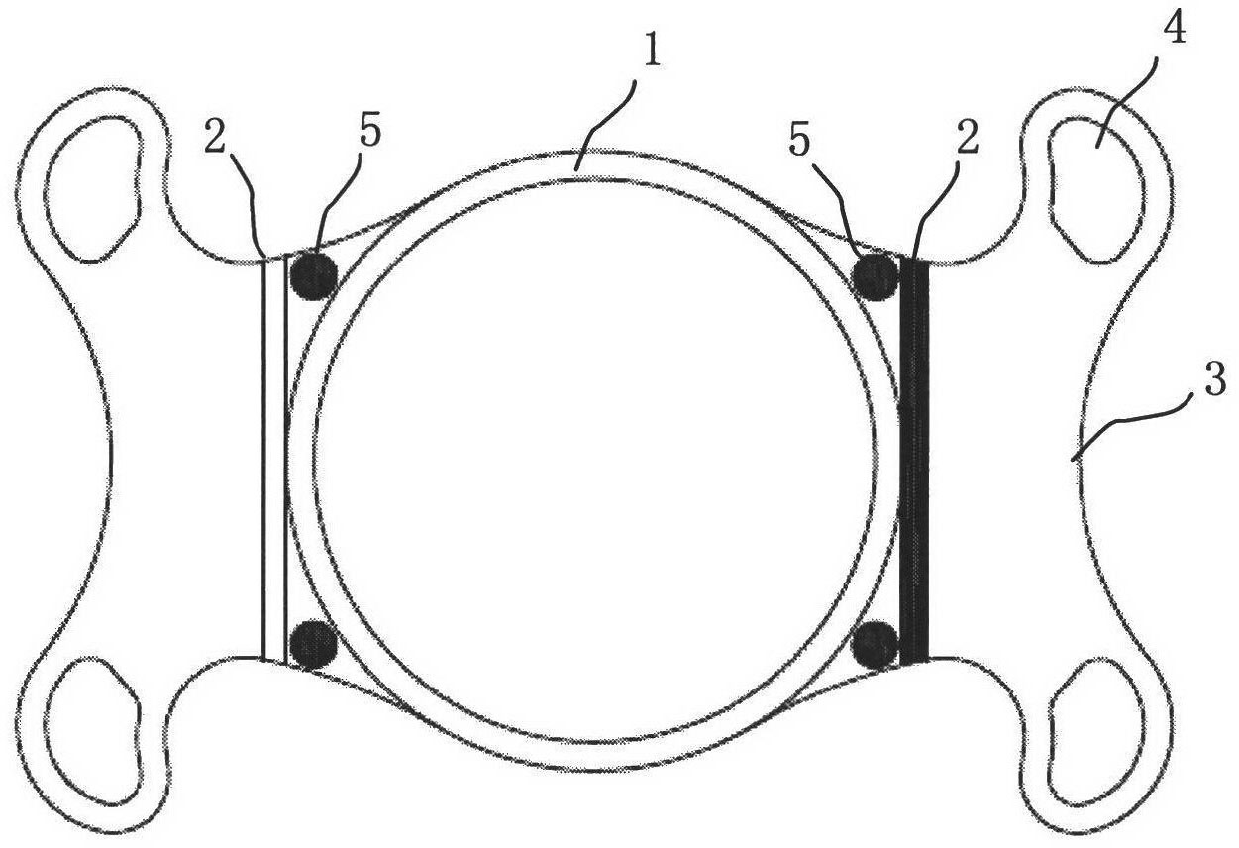

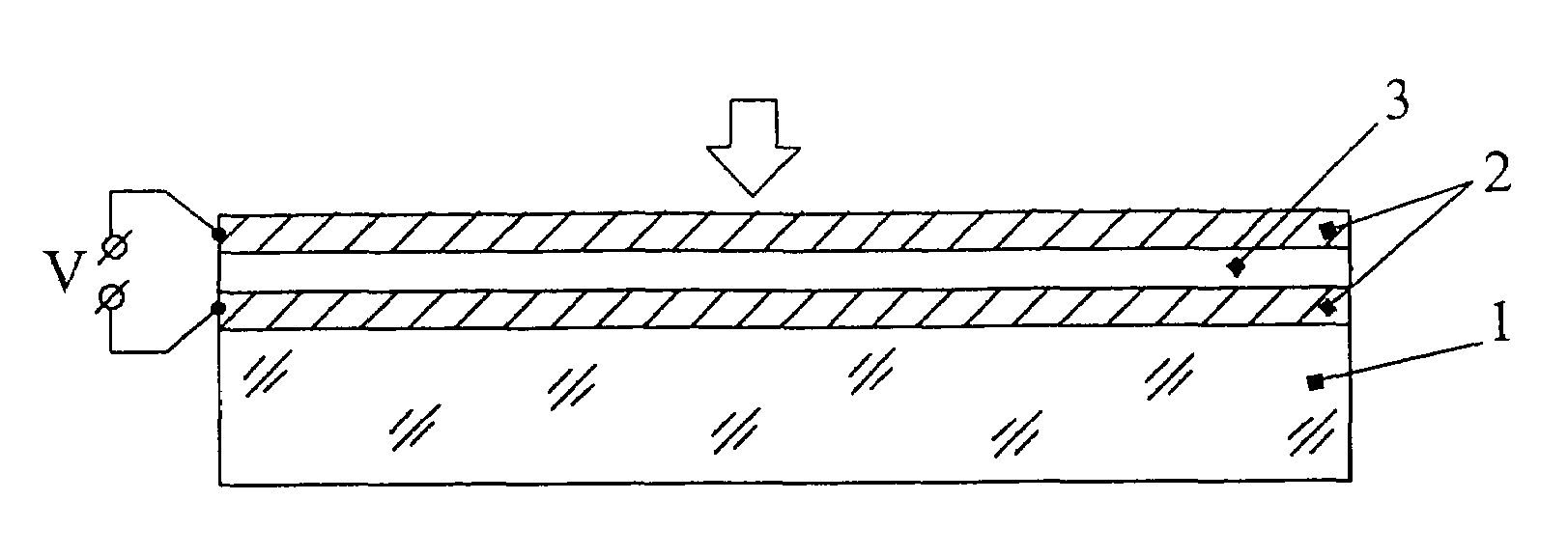

Dynamic zooming artificial lens and preparation method of dynamic zooming artificial lens

The invention discloses a dynamic zooming artificial lens and a preparation method of the dynamic zooming artificial lens. The artificial lens comprises a center transparent light guide region and a support arm, wherein a flexible telescopic region is arranged between the center transparent light guide region and the support arm, and the front end and the back end of the flexible telescopic region are provided with position limiting bulges. The dynamic zooming artificial lens and the preparation method of the dynamic zooming artificial lens provided by the invention have the characteristics of softness, high refractive index and thin crystal. Greater forward and back moving distance can be provided in the eyes of the human bodies, so greater optical intensity change can be provided, and the batter dynamic zooming is realized.

Owner:WUXI VISION PRO

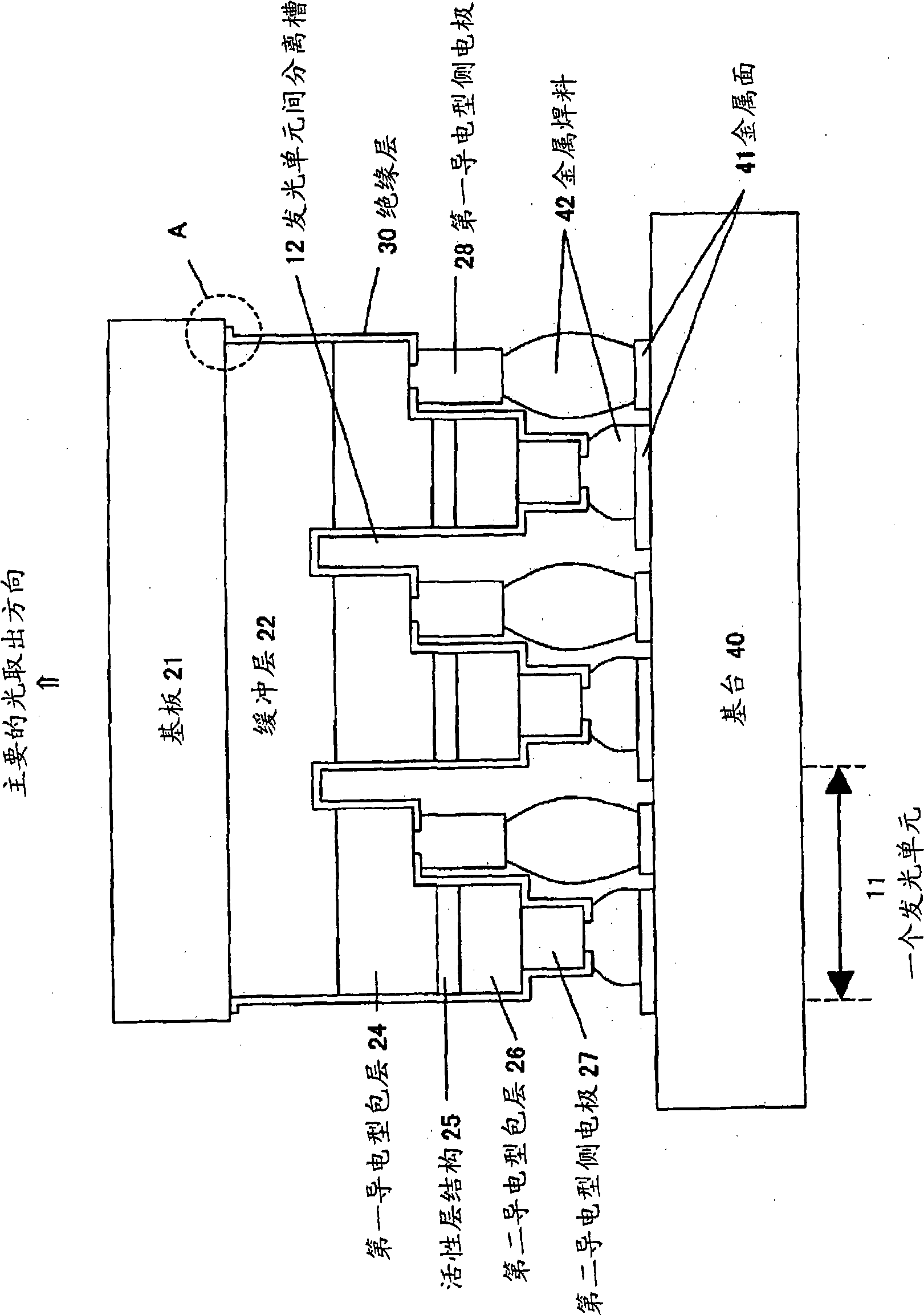

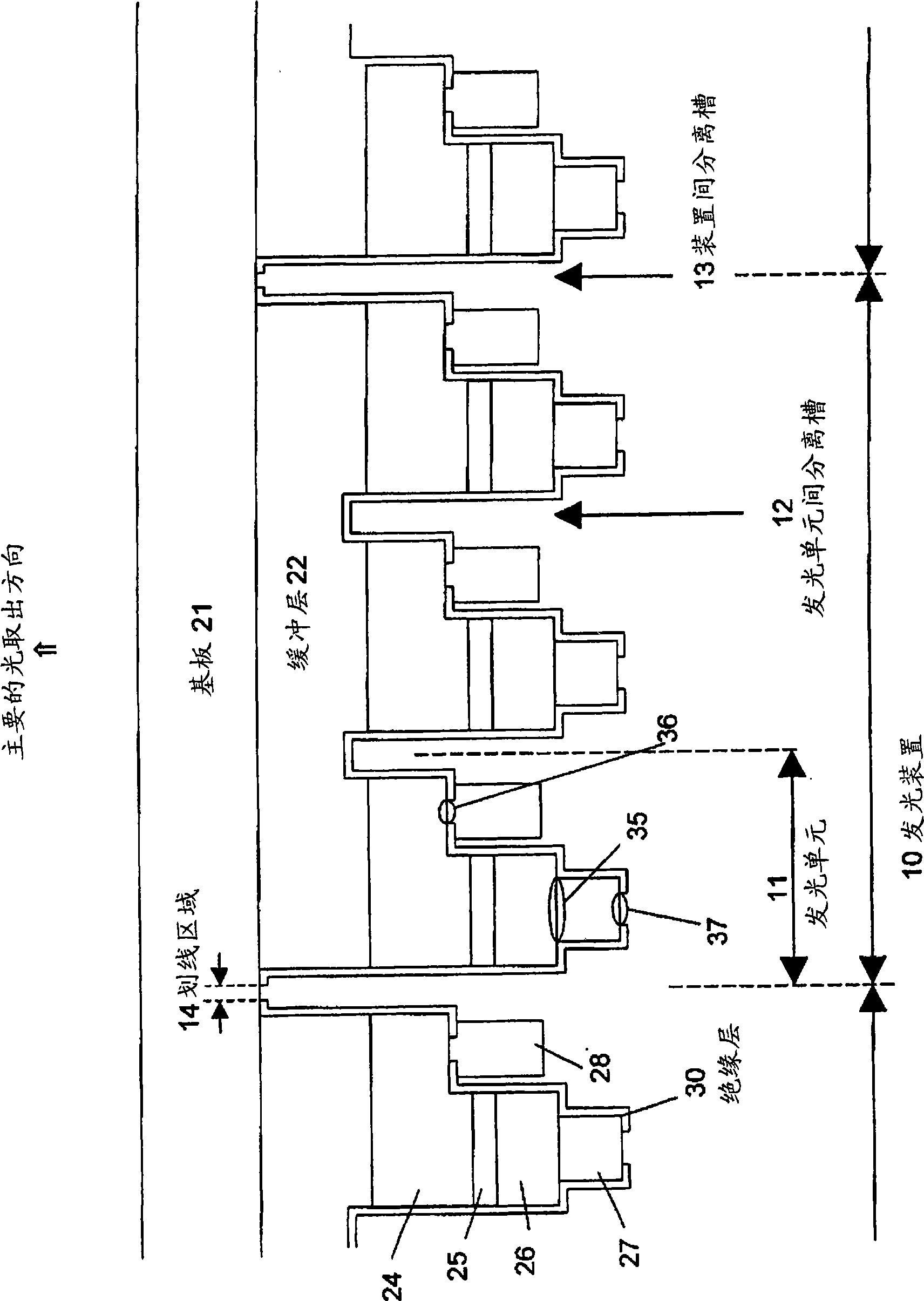

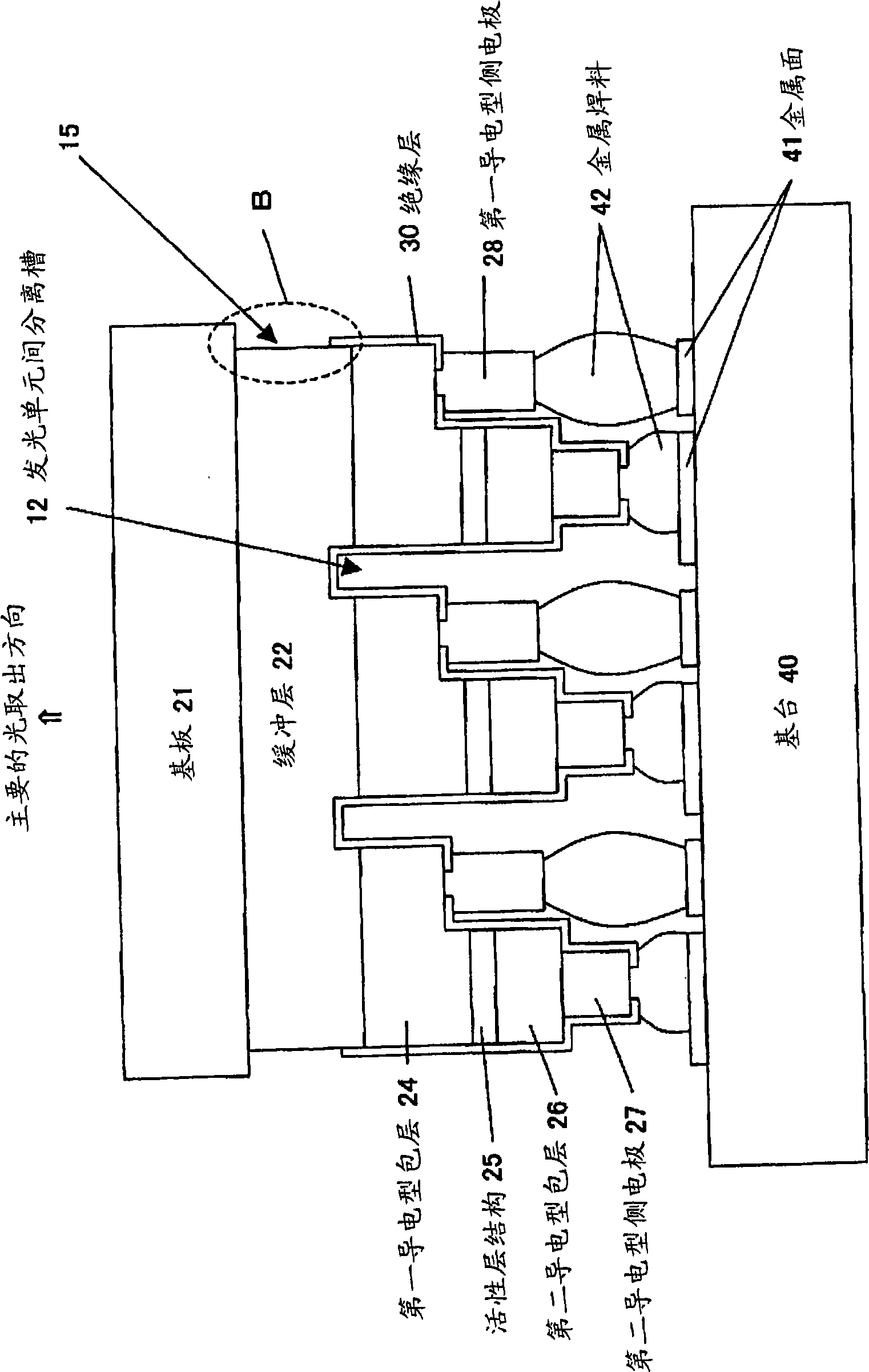

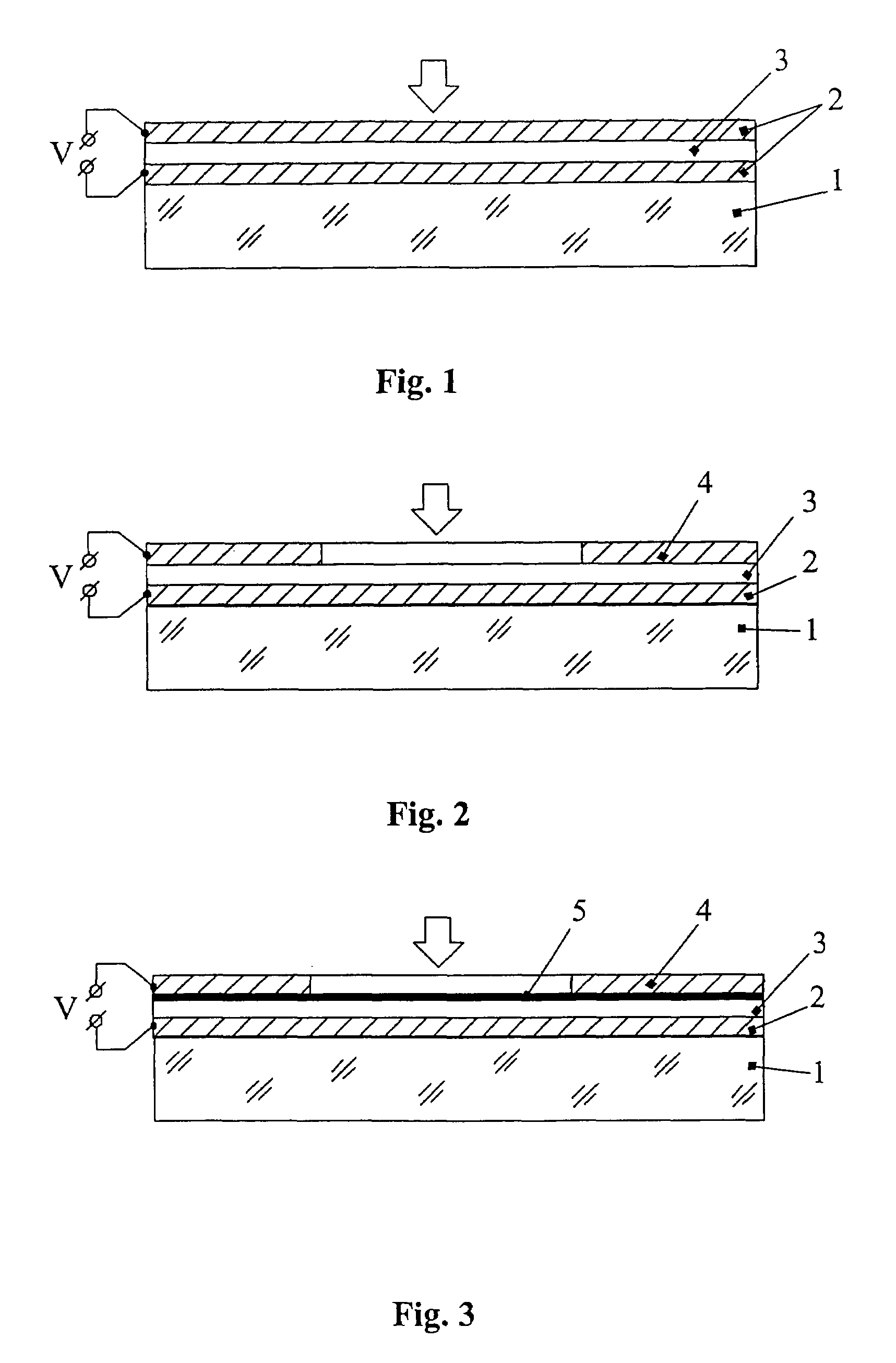

Integrated semiconductor light emitting device and method for manufacturing same

InactiveCN101485001AHigh uniformity of luminous intensityImprove light extraction efficiencySolid-state devicesSemiconductor/solid-state device manufacturingLight emissionLight emitting device

Provided is an integrated compound semiconductor light emitting device structure suitable for large-area light emission such as of a surface light source. A method for manufacturing such structure is also provided. The light emitting device is provided with a plurality of light emitting units (11) formed on a transparent substrate (21). The light emitting units are provided with thin film crystal growing layers (24, 25, 26) and first and second conductivity type side electrodes (27, 28). A light extracting direction is on a substrate side, and the first and the second conductivity type side electrodes are formed on a side opposite to the light extracting direction. The light emitting units are electrically separated by a groove (12), which is provided for separating the light emitting units and is formed by removing the thin crystal growing layer, from the surface up to a part of the buffer layer (22).

Owner:MITSUBISHI CHEM CORP

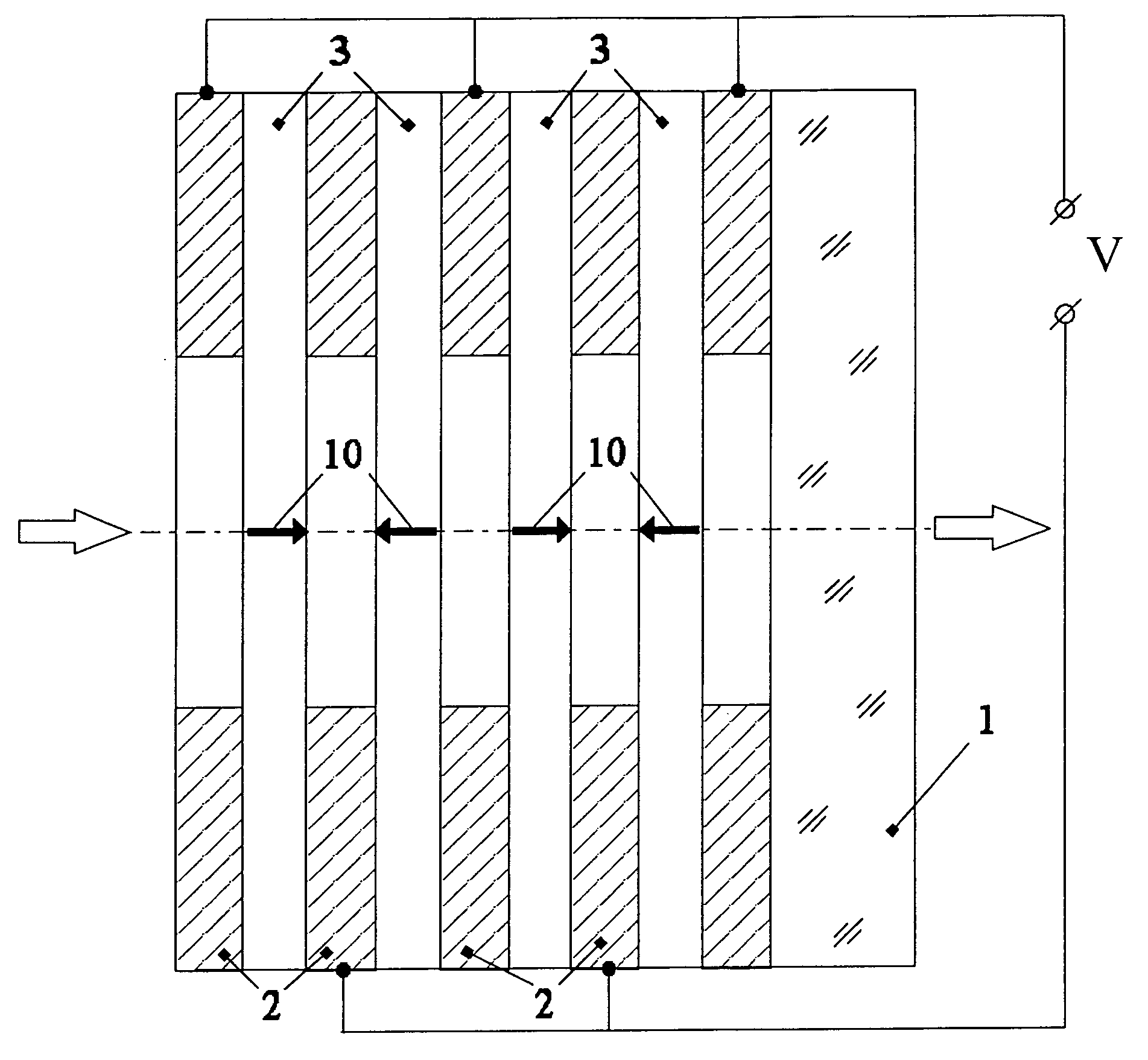

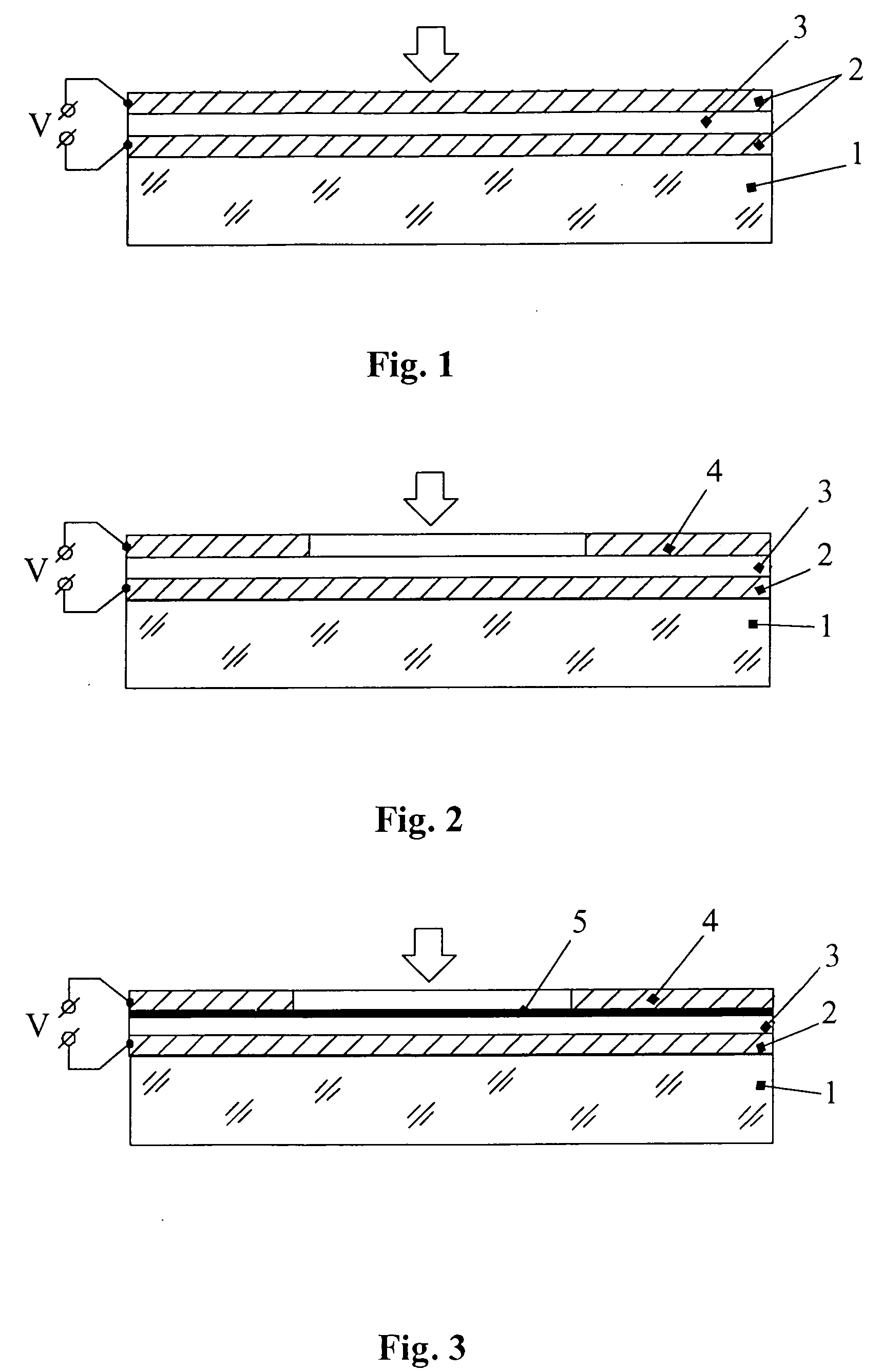

Electrooptical devices, electrooptical thin crystal films and methods making same

A method of fabrication of an electrooptical device comprises depositing a colloid system of anisometric particles onto at least one electrode and / or onto at least one substrate and / or onto at least one layer of an isotropic or anisotropic material to form at least one layer of an electrooptical material, externally aligning the colloid system to form a preferred alignment of the colloid system particles, drying the colloid system, and forming at least one electrode and / or at least one layer of an isotropic or anisotropic material on at least a portion of the layer of the electrooptical material.

Owner:NITTO DENKO CORP

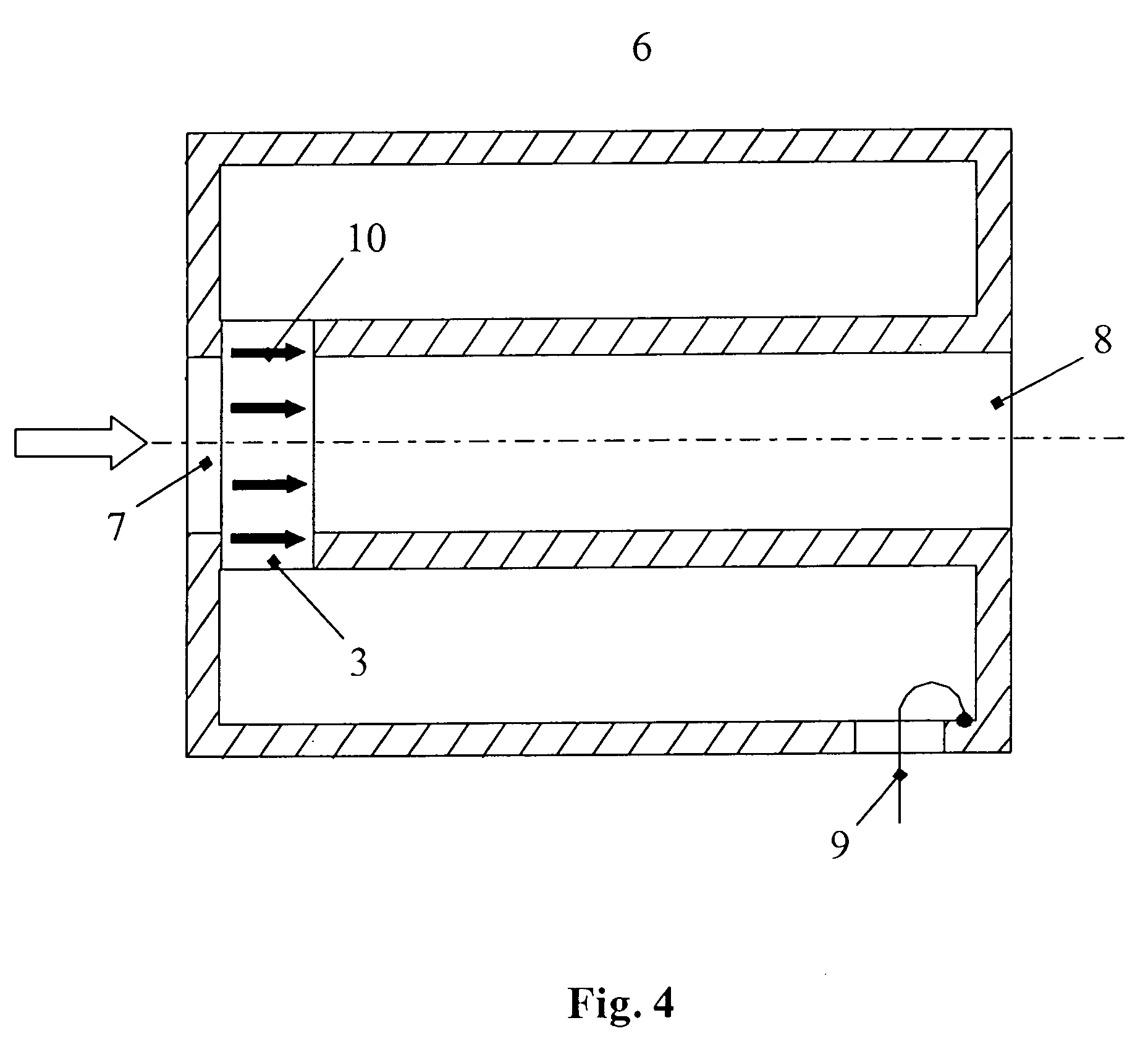

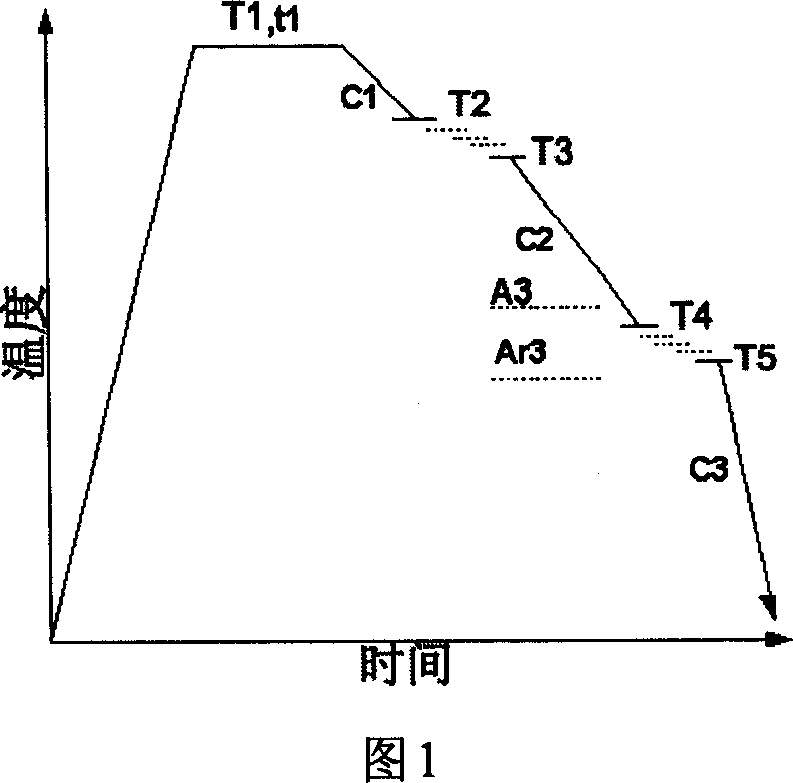

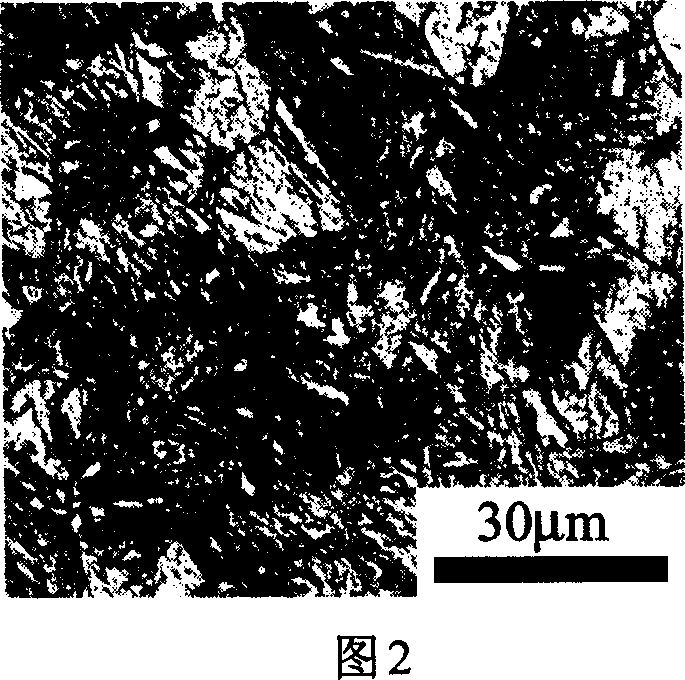

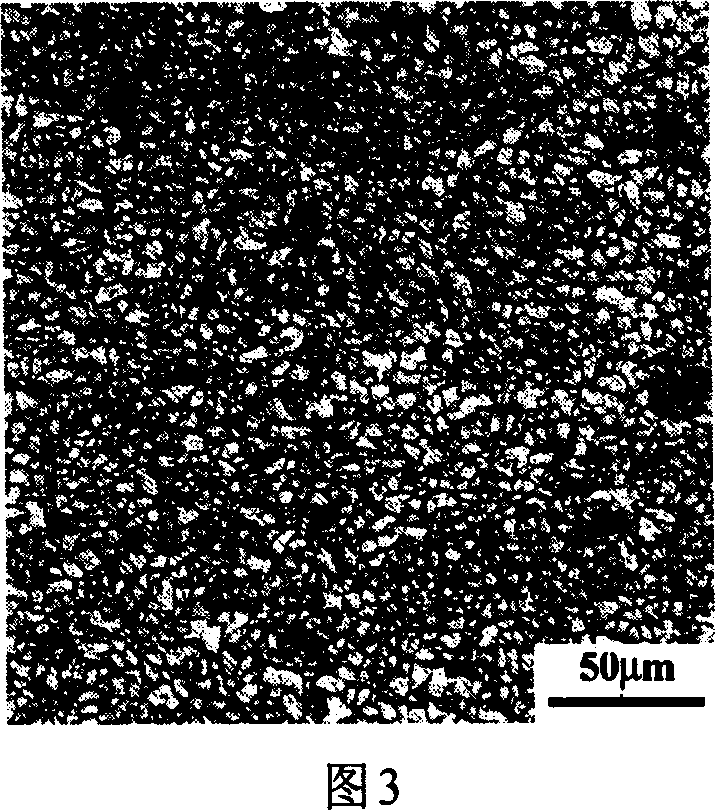

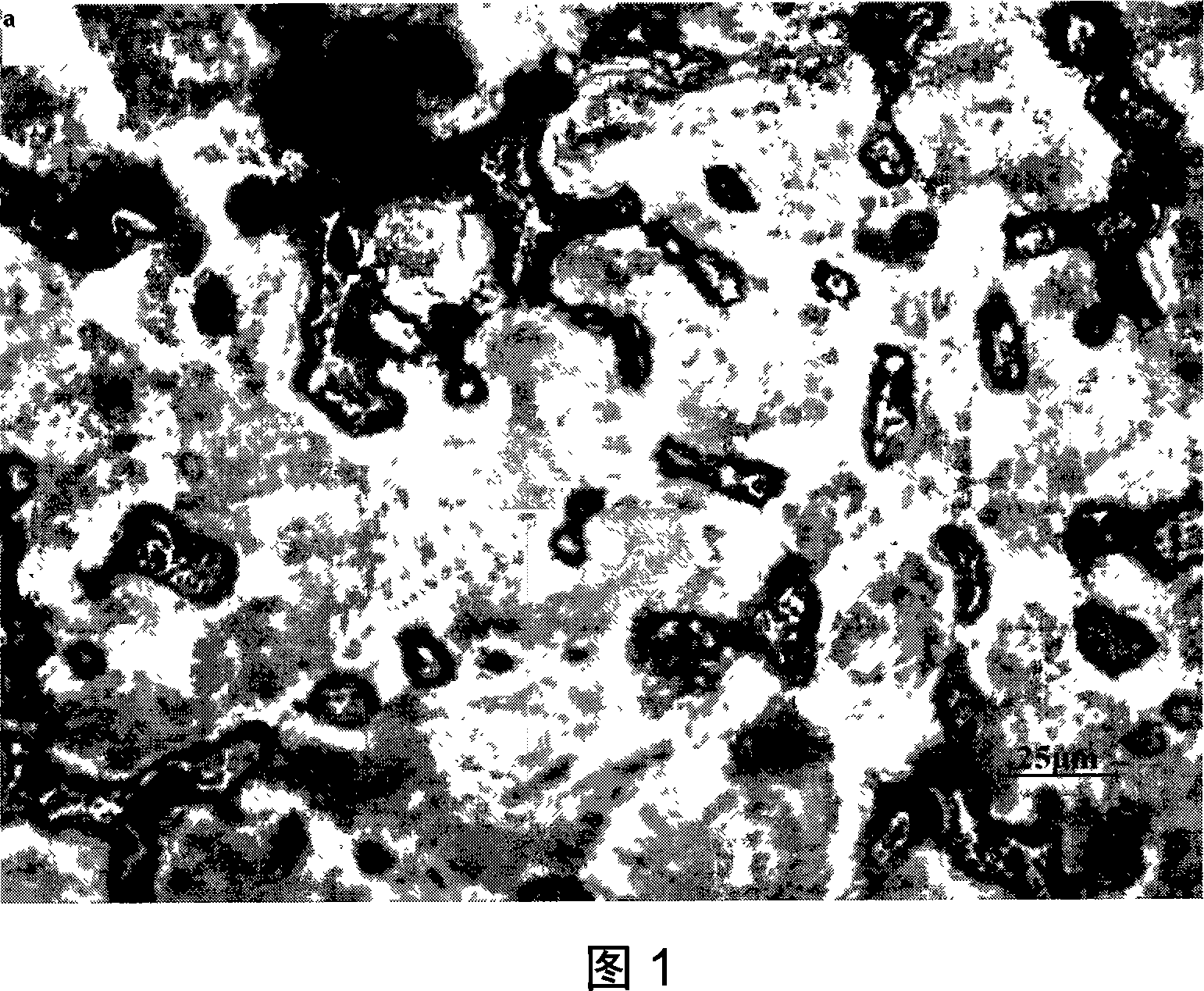

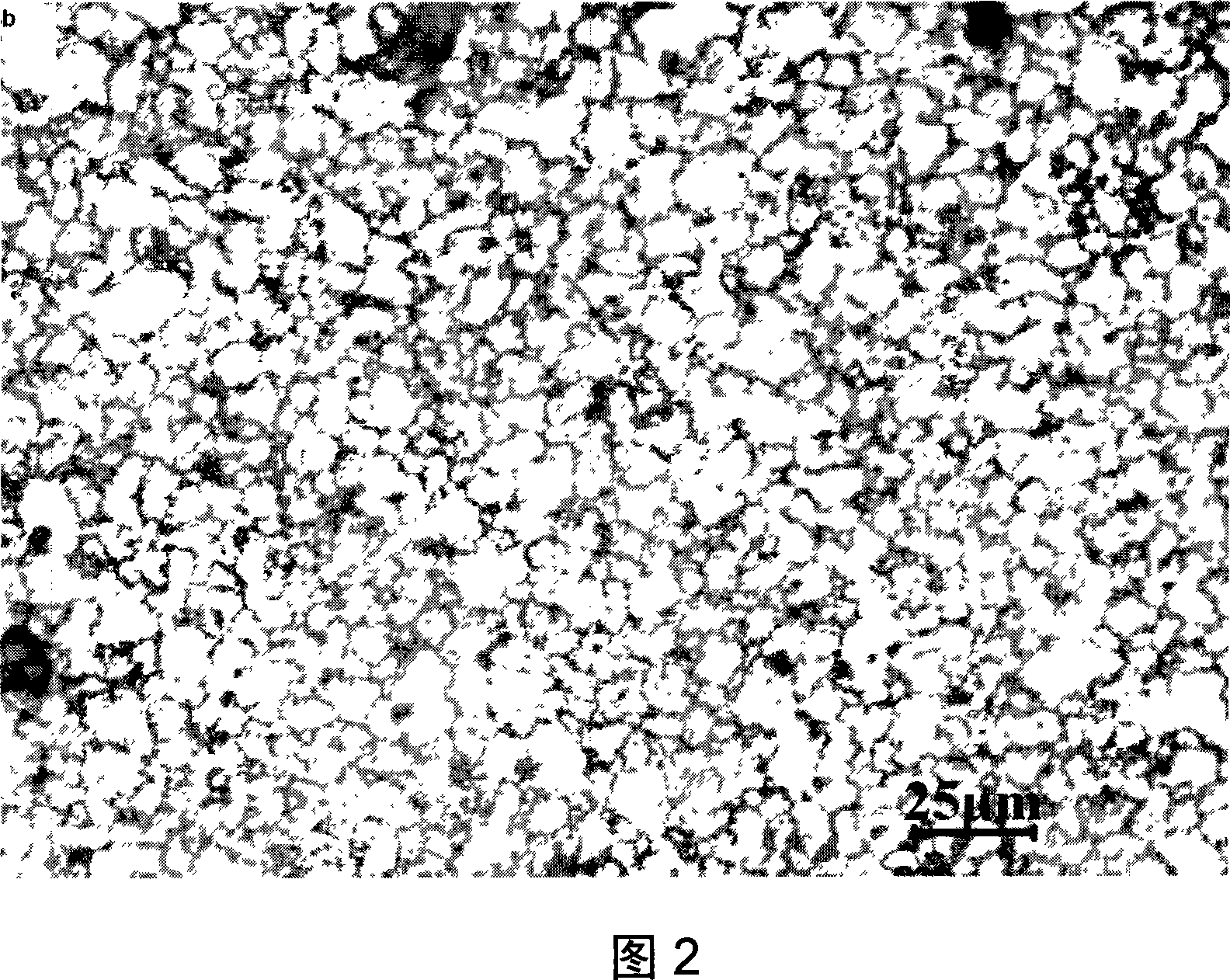

Method of preparing high-strength thin-crystal two-phase steel

InactiveCN101054621AHigh flex ratioImprove work hardening abilityHeat treatment process controlManganeseRoom temperature

The invention relates to a method for producing the fine grained dual phase steel, especially by low carbon(manganese) steel. The method comprises making the common low carbon(manganese) steel austenization, obtaining small austenitic organism after multi-pass deformation of recrystallized zone, over-cooling to a certain temperature in the temperature range of A3-Ar3 by proper cooling speed to apply multi-pass deformation with a strain rate between 0.1s-1 to 30s-1, getting 80-90% ferrite transforming mass by controlling each pass dependent variable, then quickly cooling or quenching to the room temperature. The average dimension of isometric ferrite grain in fine grained dual phase organism is less than 5 mum. The Martensite island integration number is 10-15% and the average dimension is less than 3 mum. The method is more controllable and is easy to apply on the conventional hot mill.

Owner:UNIV OF SCI & TECH BEIJING

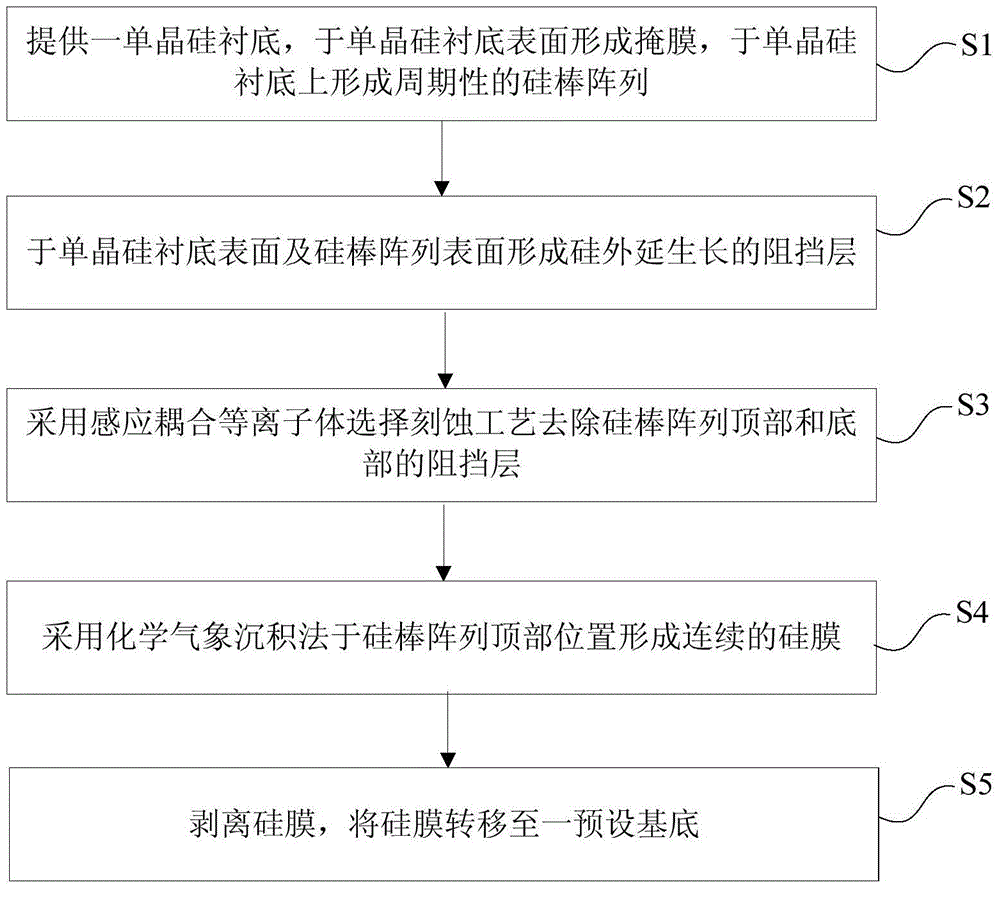

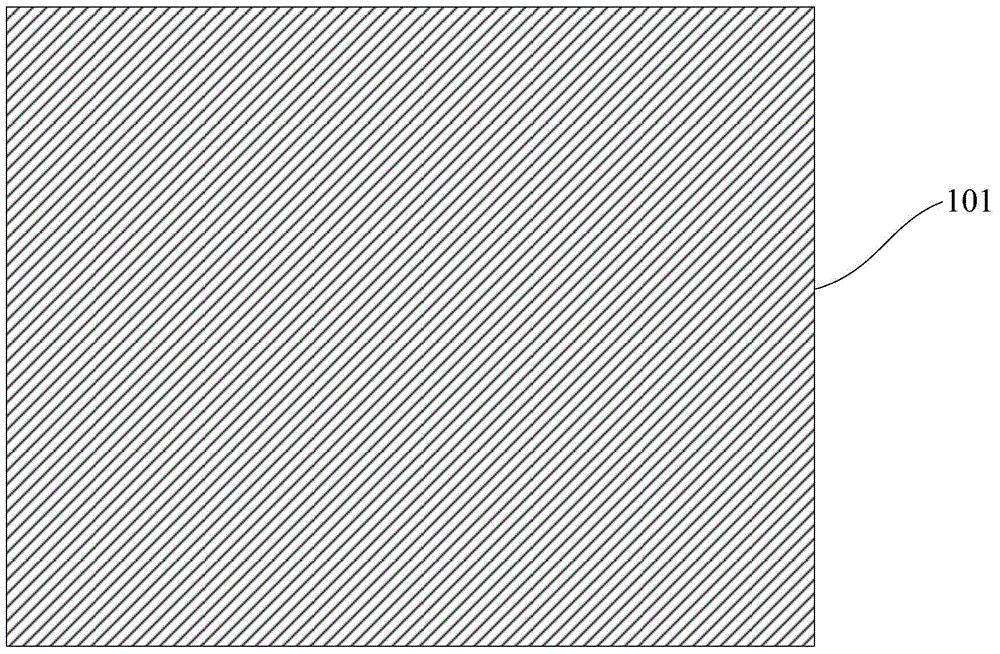

Technology for preparing layer transfer thin crystal silicon by adopting neighbor shadow effect auxiliary array method

ActiveCN106158582AImprove crystal qualityFacilitates chemical non-destructive etch strippingSemiconductor/solid-state device manufacturingNucleationShadow effect

The invention provides a technology for preparing layer transfer thin crystal silicon by adopting a neighbor shadow effect auxiliary array method. The technology comprises the steps of: 1), forming a mask used for manufacturing a periodic rod array on the surface of a monocrystal silicon substrate, and forming a periodic silicon rod array on the monocrystal silicon substrate by adopting dry etching or epitaxial growth technology; 2) forming barrier layers on the surface of a monocrystal silicon substrate and the surface of the periodic silicon rod array; 3) exposing silicon at the top part of the periodic silicon rod array by adopting a selective etching technology; 4) taking the exposed silicon at the top end of the periodic silicon rod array as seed crystal or nucleation sites of epitaxial growth, and forming a continuous silicon film on the top part of the periodic silicon rod array by adopting a chemical vapor phase deposition method; 5) and stripping the silicon film, and transferring the silicon film to a preset substrate. The technology provided by the invention adopts a monocrystal silicon wafer as the mother substrate, the grown thin film can inherit the crystal quality of the mother board, and the high crystal quality of the thin film is ensured; the substrate can be reused after simple treatment when the thin film is stripped off, the chemical vapor phase deposition thin film growing technology is simple, and the production cost can be effectively reduced.

Owner:SHANGHAI ADVANCED RES INST CHINESE ACADEMY OF SCI

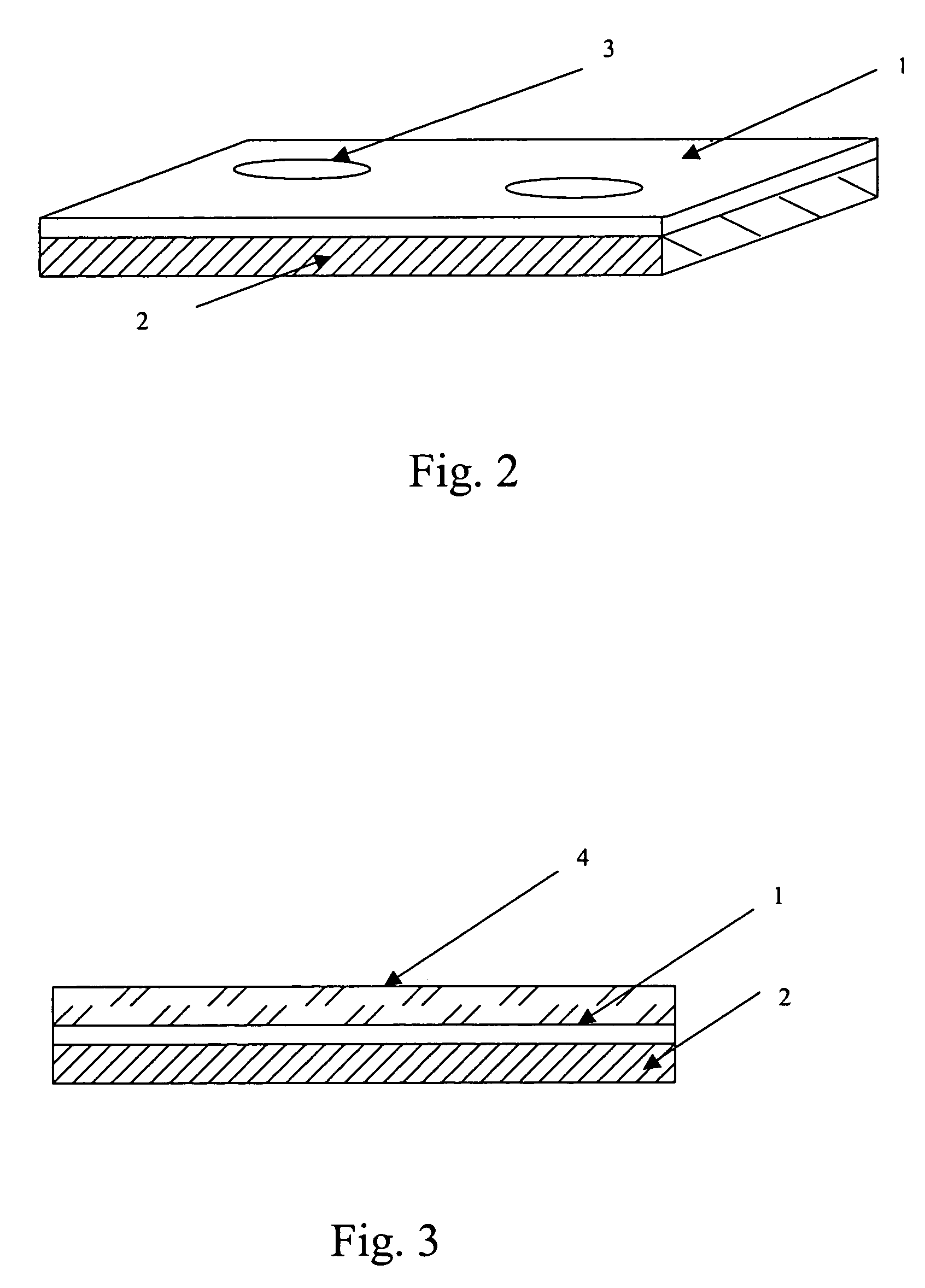

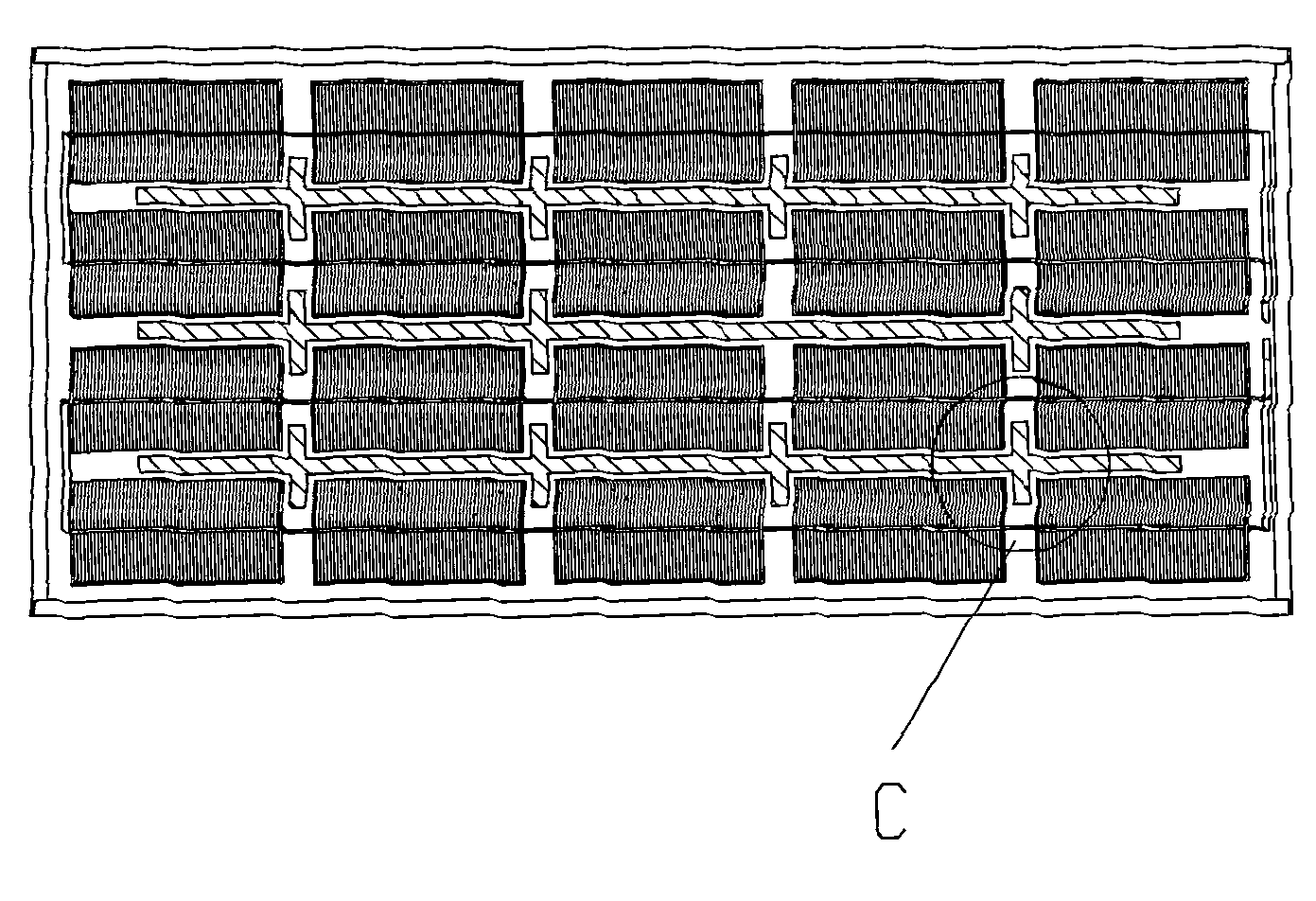

Structure of ultra-thin crystal-silicon solar battery pack and packaging method thereof

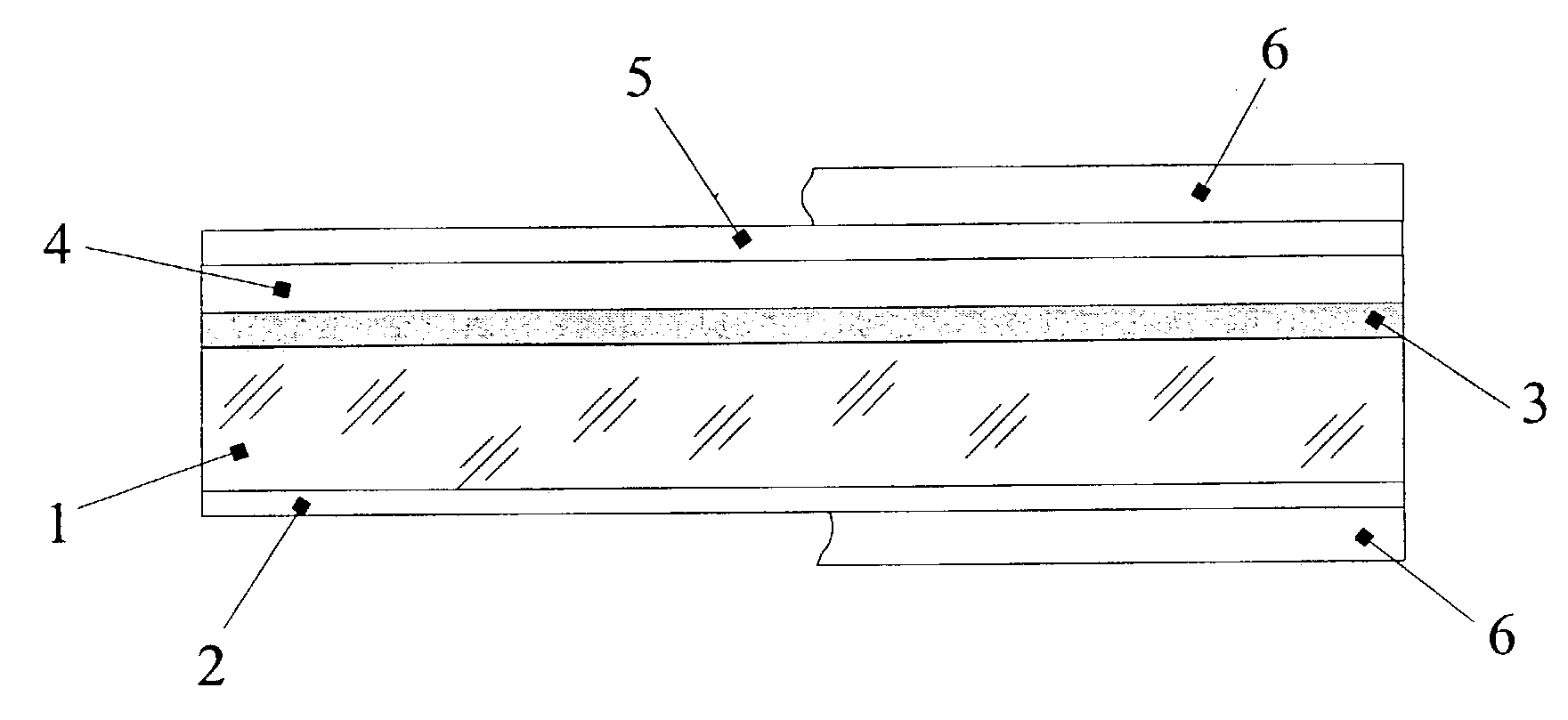

InactiveCN101976693AReduce manufacturing costReduce thicknessFinal product manufacturePhotovoltaic energy generationEngineeringSilicon solar cell

The invention provides a structure of an ultra-thin crystal-silicon solar battery pack, comprising a back plate; the back plate is provided with an EVA adhesive film in a laying manner; solar battery plates are arranged in the EVA adhesive film at intervals and are connected by photovoltaic welding strips; and the EVA adhesive film is provided with a surface cover plate in a laying manner. The reinforcing rib strips are individual components laid between the back plate and the surface plate. The structure of the invention is characterized in that reinforcing rib strips are arranged between the back plate and the surface cover and in interval regions among the solar battery plates. The invention also provides a packaging method of the structure. As the reinforcing rib strips are laid on the structure, the back plate and the surface plate can be prepared by lighter materials, but the whole structure strength can not be reduced. The structure of the ultra-thin crystal-silicon solar battery pack and the packing method of thereof of the invention not only can be applied in construction of photovoltaic power stations, and have larger advantages and application prospects in the field of photovoltaic application products, especially the field of portable photovoltaic power supplies.

Owner:厦门瑶光半导体科技有限公司

Electrooptical devices, electrooptical thin crystal films and methods making same

ActiveUS7042612B2Eliminate disadvantagesLow costNon-linear opticsOptical elementsElectrical field strengthOptical axis

An electrooptical device is provided comprising at least one substrate, at least one pair of electrodes and at least one layer of an electrooptical material. The electrooptical material represents an optically anisotropic thin crystal film and contains molecules having aromatic rings and possessing a lattice with an interplanar spacing (Bragg's reflection) of 3.4±0.2 Å along one of optical axes. The electrooptical material has anisotropic refractive indices and / or anisotropic absorption coefficients that are depended on an electric field strength.

Owner:NITTO DENKO CORP

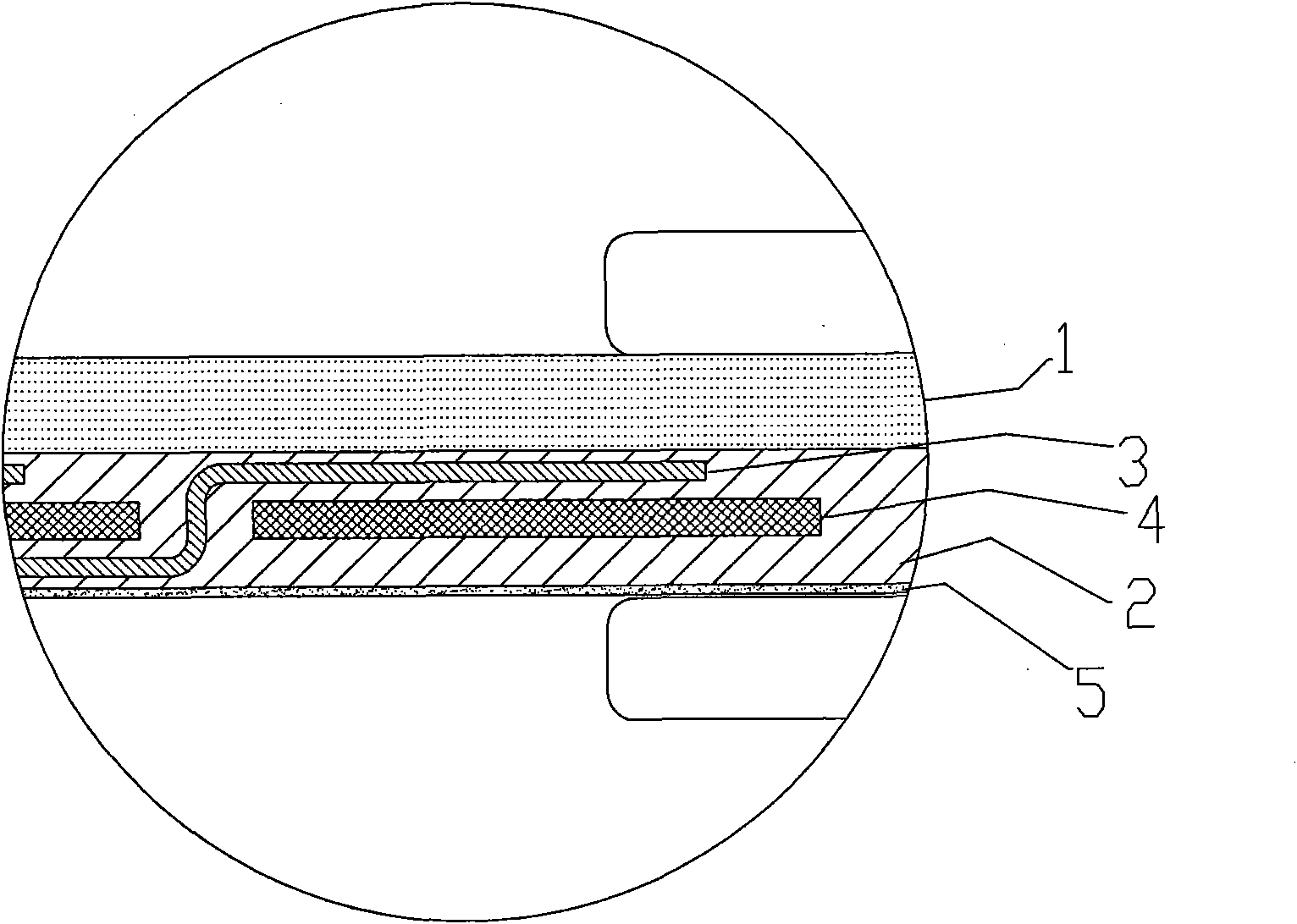

Multilayer plate and display panel with anisotropic crystal film and conducting protective layer

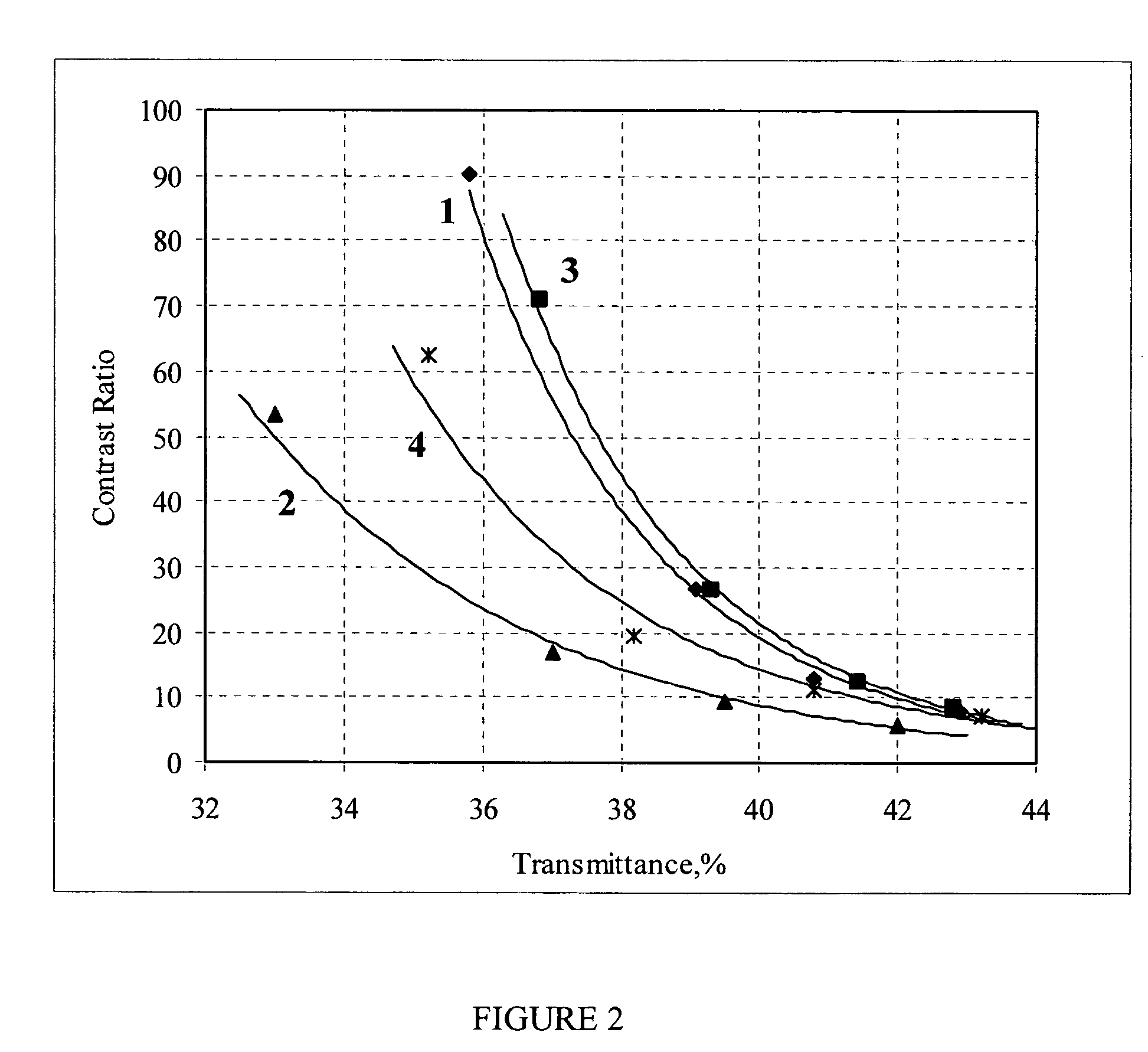

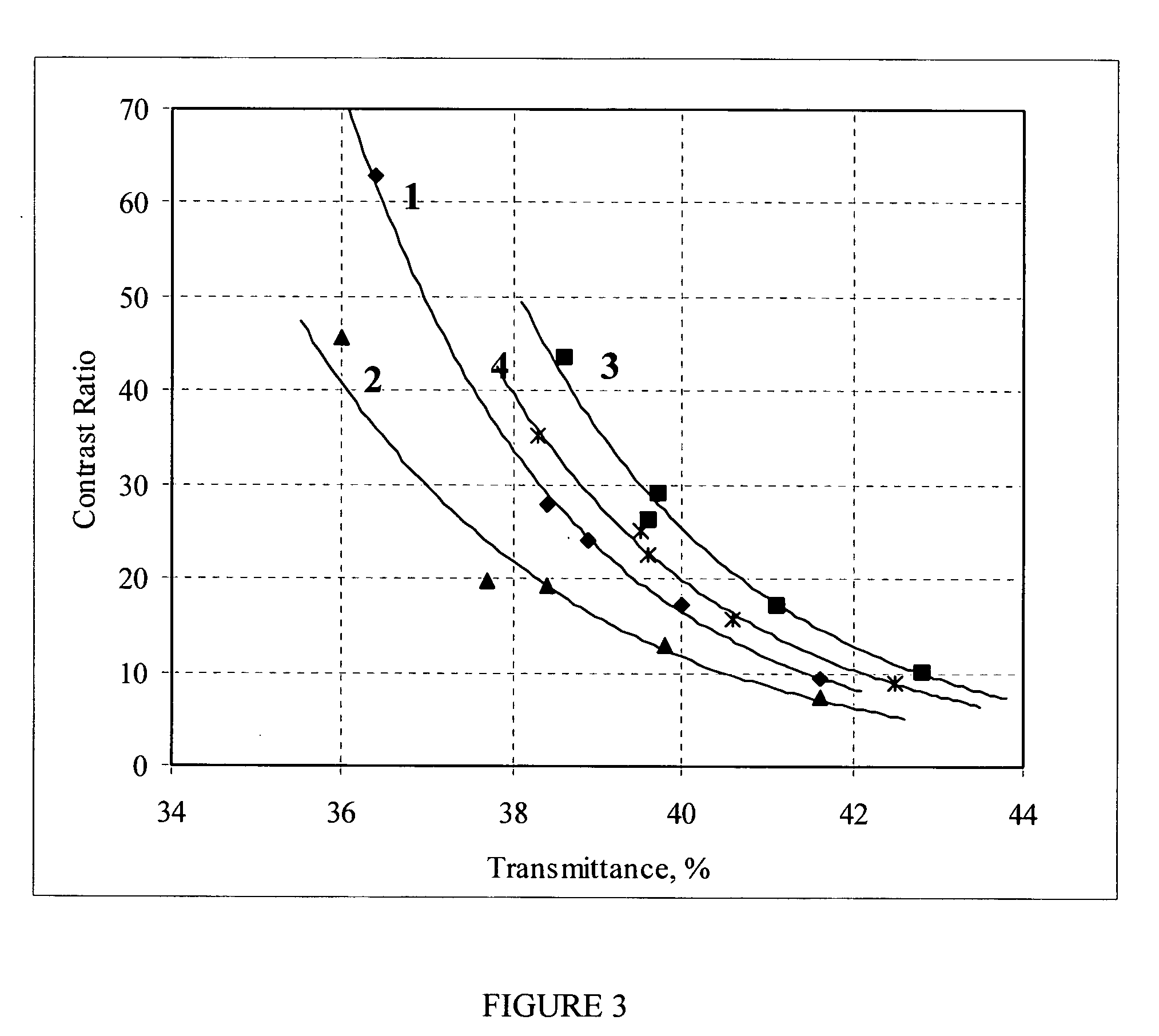

InactiveUS7317499B2Reduce thicknessImprove reliabilityLiquid crystal compositionsSynthetic resin layered productsOptical axisTransmittance

A multilayer plate is provided comprising an optically transparent substrate, a protective layer, a conducting layer, and at least one anisotropic thin crystal film. The anisotropic thin crystal film is made of a substance containing aromatic rings and possessing a structure with an interplanar spacing of 3.4±0.2 Å along one of optical axes. The thin crystal film is situated between the substrate and the conducting layer and is separated from the conducting layer by the protective layer. The transmission of the multilayer plate for UV radiation does not exceed 1% at any wavelength below 380 nm.

Owner:NITTO DENKO CORP

Method for producing potassium chloride by adopting carnallite hot-melt brine

The invention discloses a method for producing potassium chloride by adopting carnallite hot-melt brine. The method disclosed by the invention comprises the following steps of: (1) evaporating and crystallizing carnallite; (2) preparing a well mining injection agent and mining; (3) decomposing and crystallizing; (4) preparing agricultural-grade KCl; and (5) preparing industrial-grade KCl. According to the method, based on the decomposing and crystallizing characteristics of carnallite, KCl with thick crystal particles and KCl with thin crystal particles are processed by adopting different processes, so that the agricultural-grade and industrial-grade KCl products are obtained and the diversification of the products is realized; the process provided by the invention is low in overall energy consumption; by adopting the way of dissolving ores with a thermal injection agent, the mining rates of sodium chloride and magnesium chloride are greatly reduced during production of potassium chloride, so that the method disclosed by the invention has the advantages of saving production cost and achieving good comprehensive benefits.

Owner:CHANGSHA DESIGN & RES INST OF CHEM IND MIN

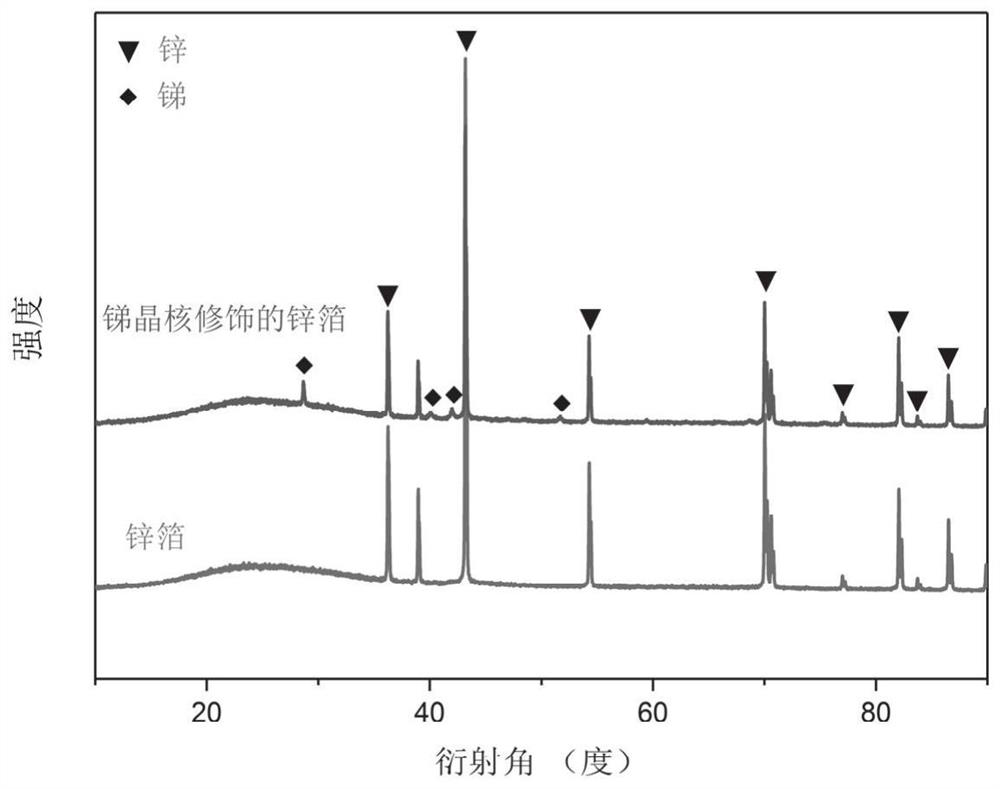

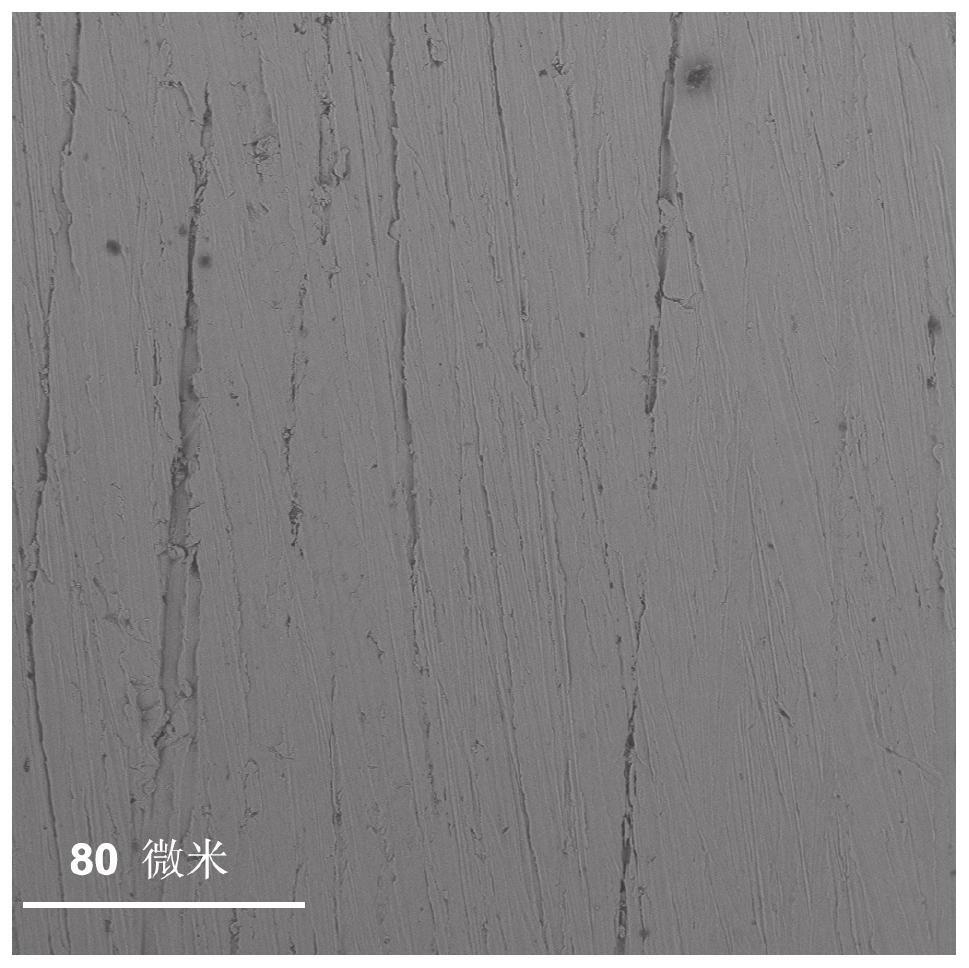

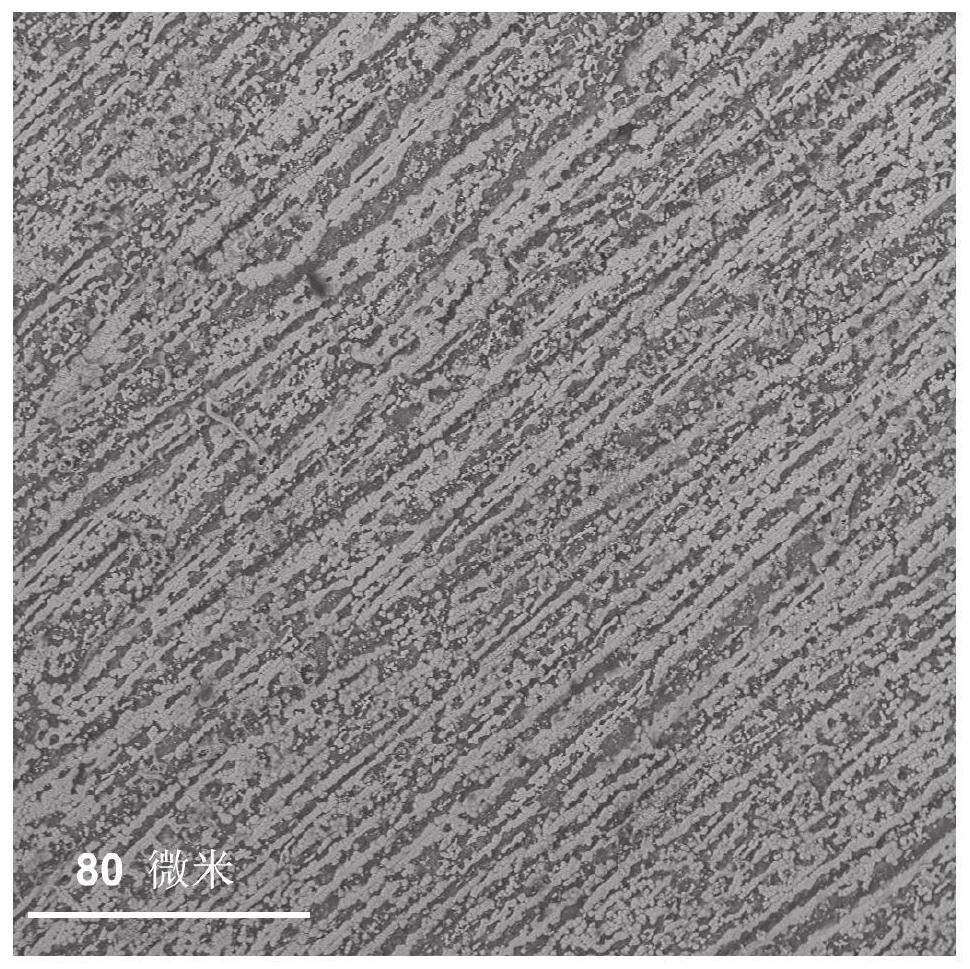

Composite material of metal zinc foil and zinc-affinity crystal nucleuses and preparation method and application thereof

ActiveCN111926313AReduce volumeAvoid negative effectsCell electrodesSecondary cellsDendrite (metal)Zinc

The invention provides a composite material of metal zinc foil and zinc- affinity crystal nucleuses and a preparation method and application thereof. The preparation of the composite material includesthe steps that metal salt solution is prepared as deposition solution, the metal zinc foil is placed in the deposition solution, and the composite material is obtained after in-situ chemical deposition. The volume of the zinc-affinity crystal nucleuses is smaller, thin crystal nucleuses can evenly cover the surfaces of the zinc foil, the unique structure can effectively inhibit zinc dendrite, furthermore, due to the fact that the thickness of the crystal nucleuses covering the surfaces of the zinc foil is comparatively thin, the zinc electrode reaction surface area is further maintained at alarge extent, so that the adverse impact on zinc negative electrode materials by modification can be prevented, and the circulating performance of a battery can be improved greatly.

Owner:SHANDONG UNIV

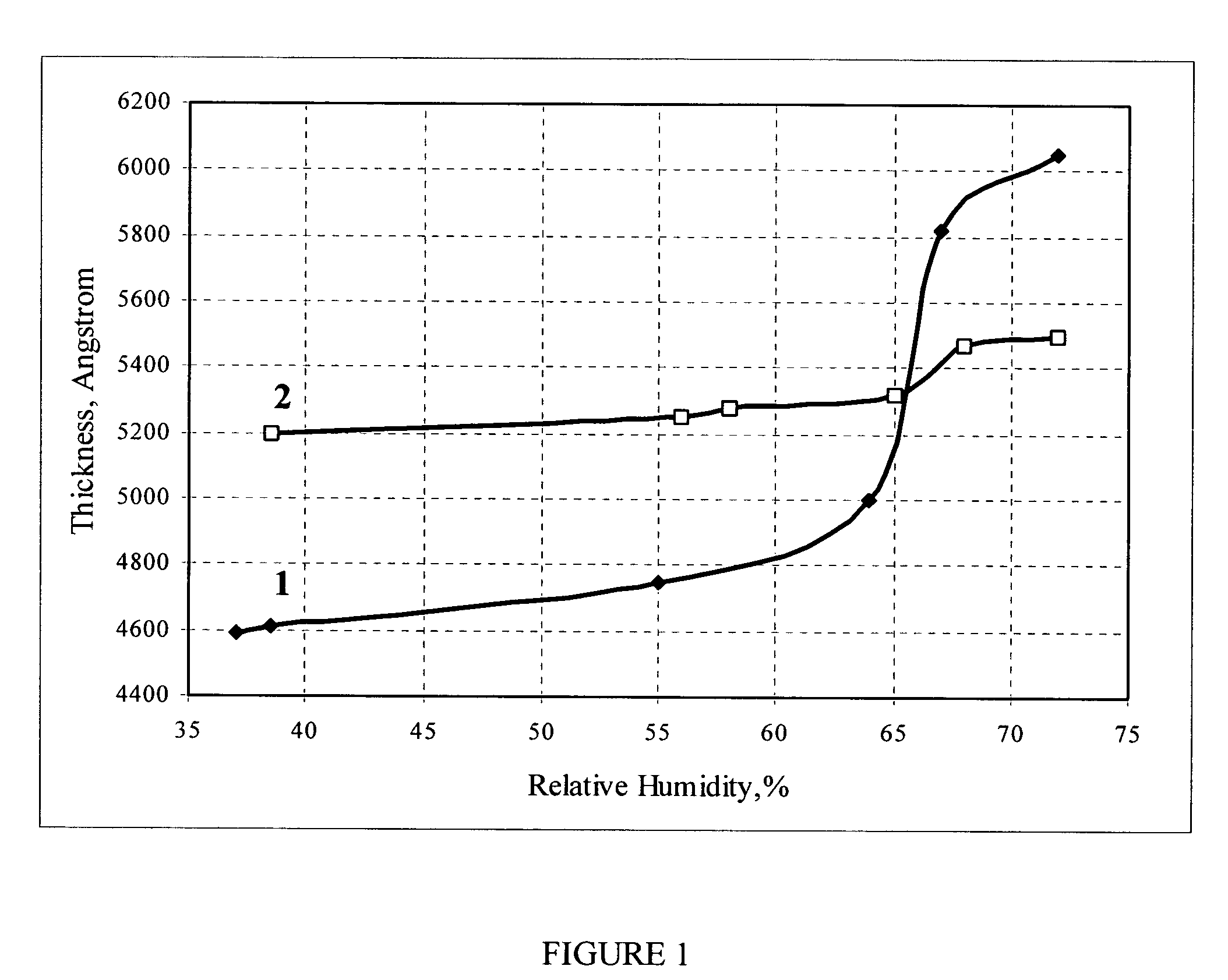

Supramolecular composite film material and method for fabricating

ActiveUS20050271878A1Improve working characteristicsLiquid crystal compositionsLayered productsComposite filmSolvent

The present invention provides an optically anisotropic composite film material possessing improved working characteristics, including hydrolytic stability and mechanical strength with respect to environmental factors. These and other advantages of the present invention may be achieved by creating a supramolecular composite film material. This supramolecular composite film material comprises a matrix of thin crystal film composed of organic supramolecules containing polar groups, and a binding agent representing a water-soluble aliphatic compound containing at least two functional groups. The present invention further provides a method for manufacturing supramolecular composite film materials possessing these advantageous properties. In one embodiment, the method comprises the following steps: (i) formation of a layer of lyotropic liquid crystal composed of supramolecules of a cyclic organic compound with conjugated π-systems and substituted polar groups; (ii) application of an external orienting force to said layer and further removal of a solvent with the resulting formation of a thin crystal film; (iii) treatment of the thin crystal film with a solution of inorganic salts leading to the formation of an insoluble crystalline film of supramolecules composed of said organic molecules; (iv) impregnation of said insoluble film with a binding agent capable of interacting with the polar groups with the subsequent formation of a filled film; and (v) drying of said filled film leading to the formation of a supramolecular composite film material.

Owner:NITTO DENKO CORP

Method for preparing aluminum-titanium-carbon intermediate alloy

One Al-Ti-C intermediate alloy preparation method, involves a kind to use in the aluminum alloy production crystal grain thin Al-Ti-C intermediate alloy production method. Its characteristic lies in with the calcium carbide does carbon source, the production craft completely dissolves after the aluminum, melts the body fever to join the electricity stone powder hydrofluotitanic acid armor the mixture, elevates temperature to 950deg.C~~1000deg.C, guarantees the wet 10~~30 minute, after melt body surface liquid state dregs casting.The invention characteristic is the raw material unites is easy, alloy production craft simple, production cost low, produces the alloy thin medicinal preparation thin crystal grain with this craft is incubation period short, specially suits outside the stove is continuously thin.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

Hot forging processing method for optimizing performance of polycrystal bismuth telluride-based thermoelectric alloy material

ActiveCN101502865ALow thermal conductivityHigh room temperature thermoelectric figure of meritMetal-working apparatusStress inducedBismuth telluride

The invention discloses a hot forging processing method for optimizing performance of a polycrystalline bismuth telluride-based thermoelectric alloy material. The polycrystalline bismuth telluride-based blocky thermoelectric alloy, which is subjected to one-time hot press molding, is directly put into a graphite die for hot forging deformation and pressure maintaining so as to obtain the final thermoelectric alloy material. The inventive mechanism mainly comprises that: due to the hot forging deformation, the microstructure of the material is changed; stress induces the generation of point defect and nanometer structure inside the material, and meanwhile, triggers the recrystallization of the material for thinning crystal grains, thus prominently ameliorating thermoelectric performances that impact the material self. The invention has the characteristics of simple technology, low cost, short period and great suitability for large-scale production and application, and the manufactured bismuth telluride-based blocky thermoelectric alloy material has lower thermal conductivity and higher room temperature thermoelectric merit figure than the material prior to the hot forging deformation processing.

Owner:浙江电联矿业科技发展有限公司

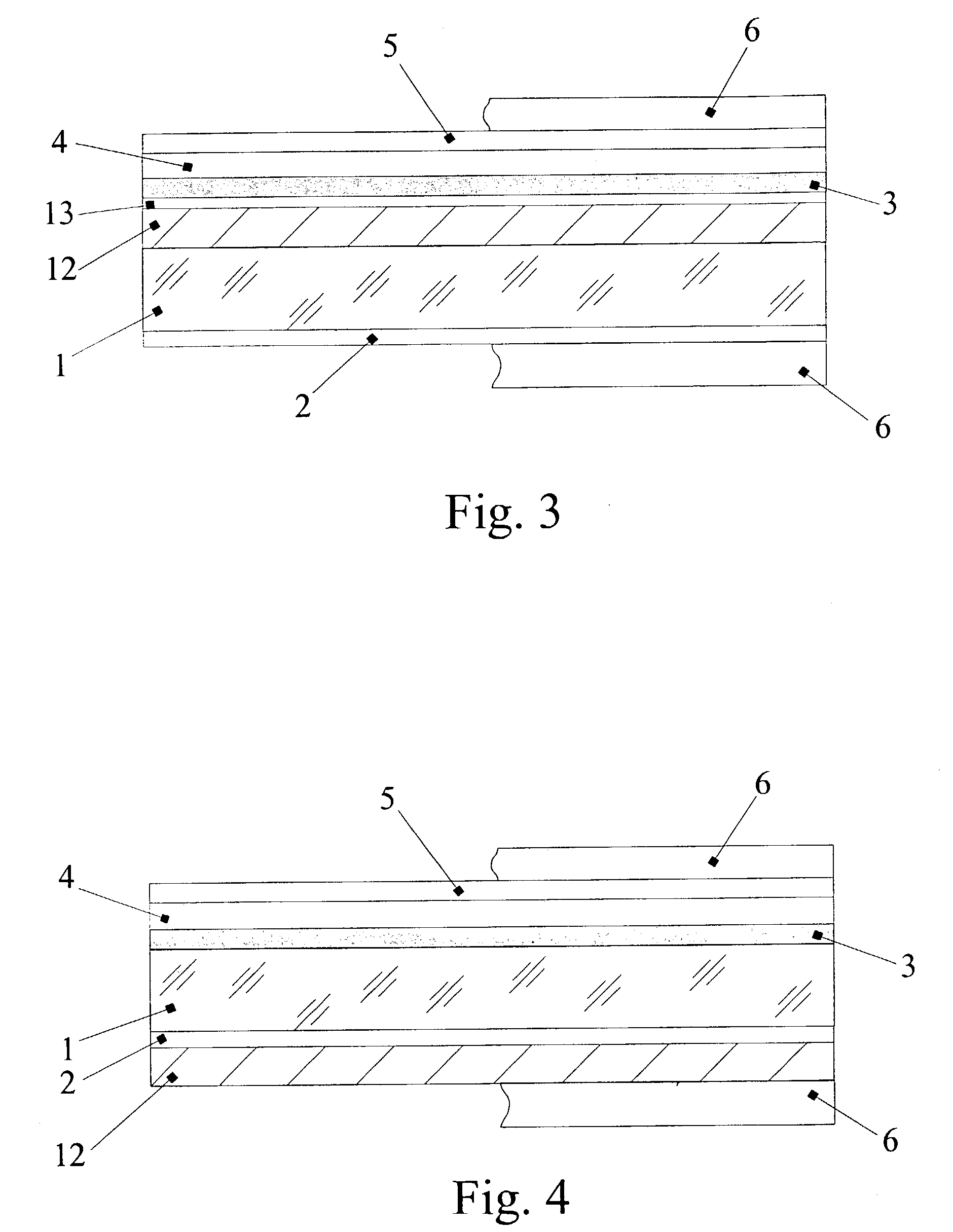

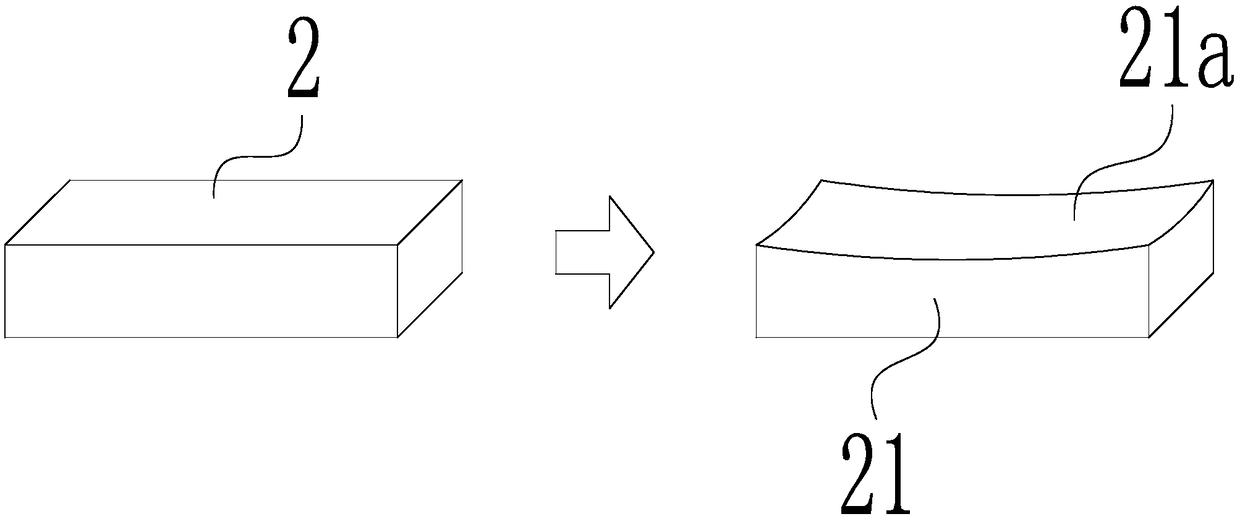

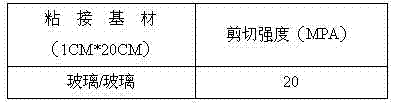

Preparation method of curved-surface crystal for X-ray micro-imaging

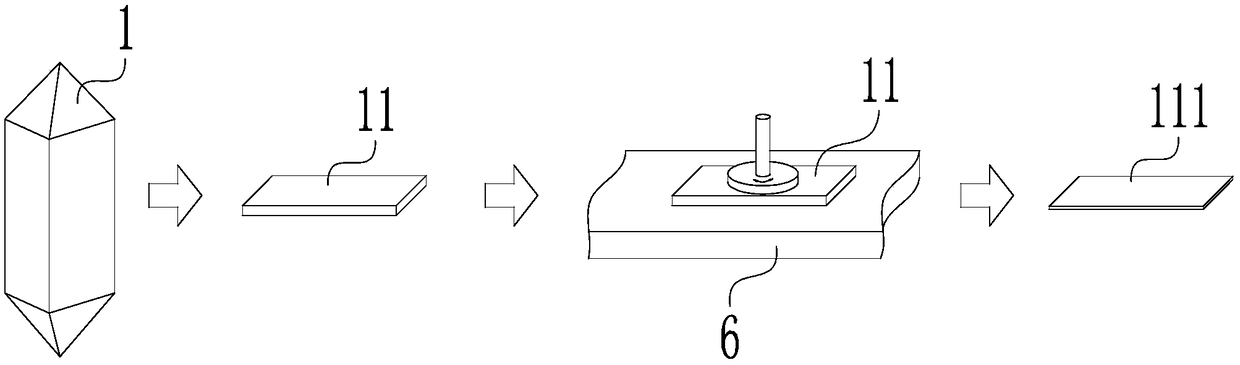

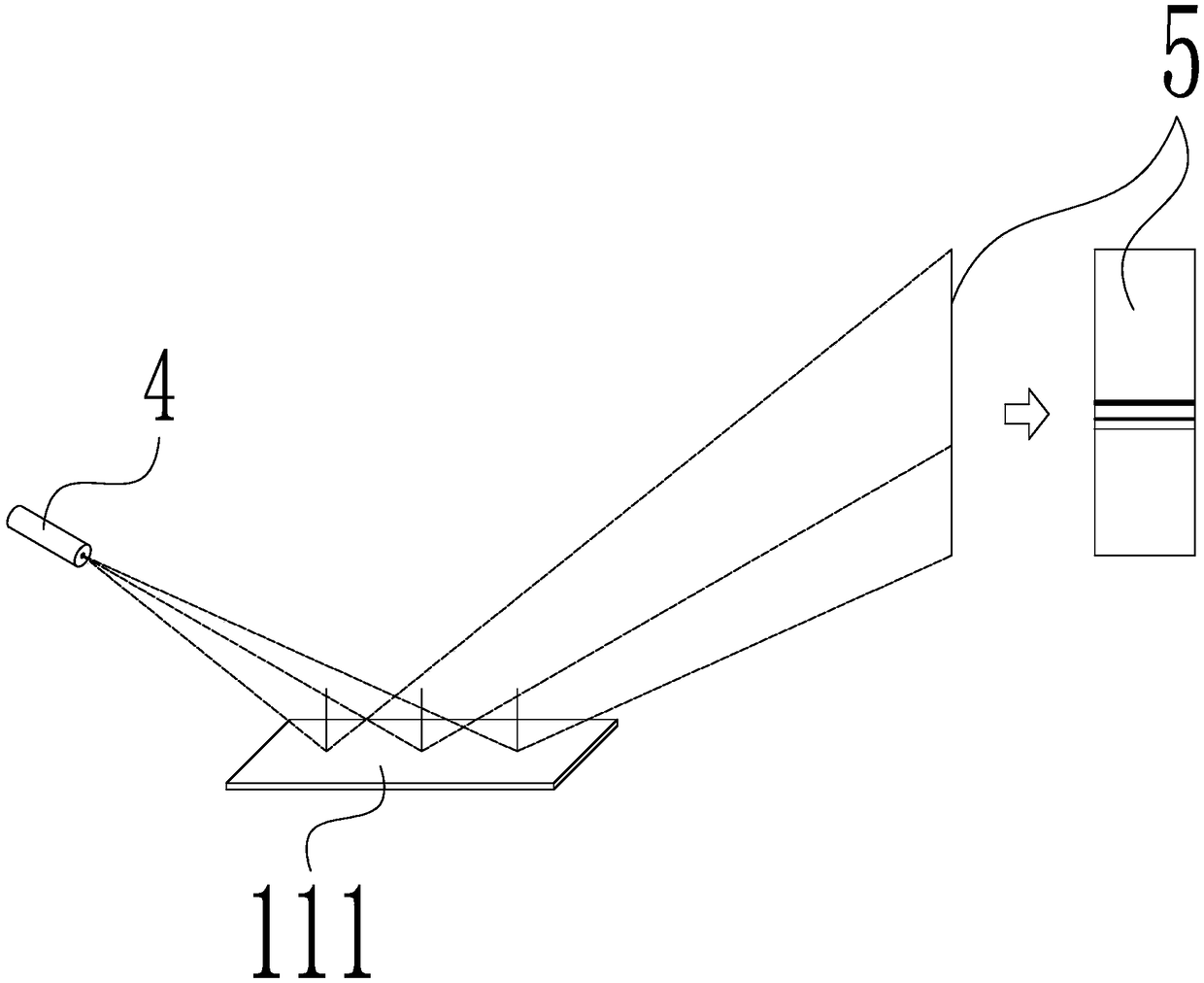

ActiveCN108789888AIngenious designEasy to implementFine working devicesUsing wave/particle radiation meansMicro imagingX-ray

The invention discloses a preparation method for a curved-surface crystal for X-ray micro-imaging. The preparation method comprises the following steps of: S1: cutting in a directional mode to obtaina thick crystal plate; S2: detecting whether the thick crystal plate is qualified or not; S3: grinding the thick crystal plate to obtain a thin crystal plate; S4: detecting whether the thin crystal plate is qualified or not; S5: grinding base blank to obtain a curved-surface base; S6: detecting whether the curved-surface base is qualified or not; S7: cleaning the thin crystal plate and the curved-surface base; S8: bonding the thin crystal plate and the curved-surface base by optical cement to obtain curved-surface crystal; and S9: checking whether the curved-surface crystal is qualified or not. With the adoption of the preparation method of the curved-surface crystal for X-ray micro-imaging disclosed by the invention, the thin crystal plate is combined with the curved-surface base by an optical cement bonding way to obtain the curved-surface crystal used for X-ray micro-imaging. The combination way is molecular bonding between the thin crystal plate and the base, so that the curved-surface crystal has the advantages of being free of an adhesive, free of a gap, high in surface shape quality, stable in performance, long in service life and the like.

Owner:LASER FUSION RES CENT CHINA ACAD OF ENG PHYSICS

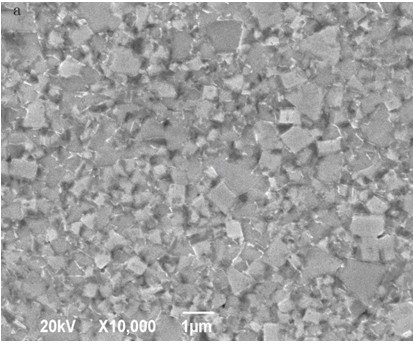

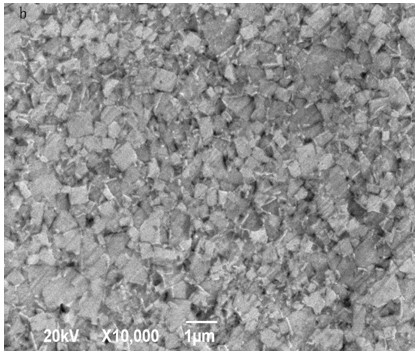

Method of preparing thin crystal layer on magnesium alloy surface

InactiveCN101058877AImprove organizationUniform tissuePressure inorganic powder coatingNon-electric welding apparatusFriction stir processingFine grain

The invention discloses a preparing method of fine-grained layer on the surface of magnesium alloy, which is characterized by the following: adopting casting shaping magnesium alloy as raw material; sanding the surface of magnesium alloy; stirring the surface; forming the fine-grained layer with high antirusting and anti-abrasion resistance.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

Fantastic artificial jewelry and preparation method thereof

ActiveCN102406290AImprove durabilityHigh strengthLayered productsDecorative surface effectsColor filmEngineering

The invention relates to a fantastic artificial jewelry and a preparation method thereof. The preparation method comprises the following steps of: coating a color film on leadless glass, connecting the color film with upper and lower layers of unleaded glass by glue, and generating different effects due to the thickness of the color film, the difference of the upper and lower positions of glue adhesion and different glue colors; reforming, cutting and angularly grinding to obtain fantastic stones with different angles, wherein the fantastic stones can be plated or not, and mainly used for jewelry, garments, shoes, luggage, artwares and the like. The fantastic jewelry manufactured according to the invention has different color changes in different angle views through four to five layers of mutual refractions, and has deep crystal effect on a thin crystal layer through light refraction. The fantastic artificial jewelry has strong dazzling degree and rich color change; the color change type can be over ten thousands; the fantastic artificial jewelry has the advantages of low cost, no processing amount requirement, simplicity and rapidness for production and proofing; and the fantastic artificial jewelry is leadless, so that the lead content can realize ROHS environment friendly standard.

Owner:牟小燕

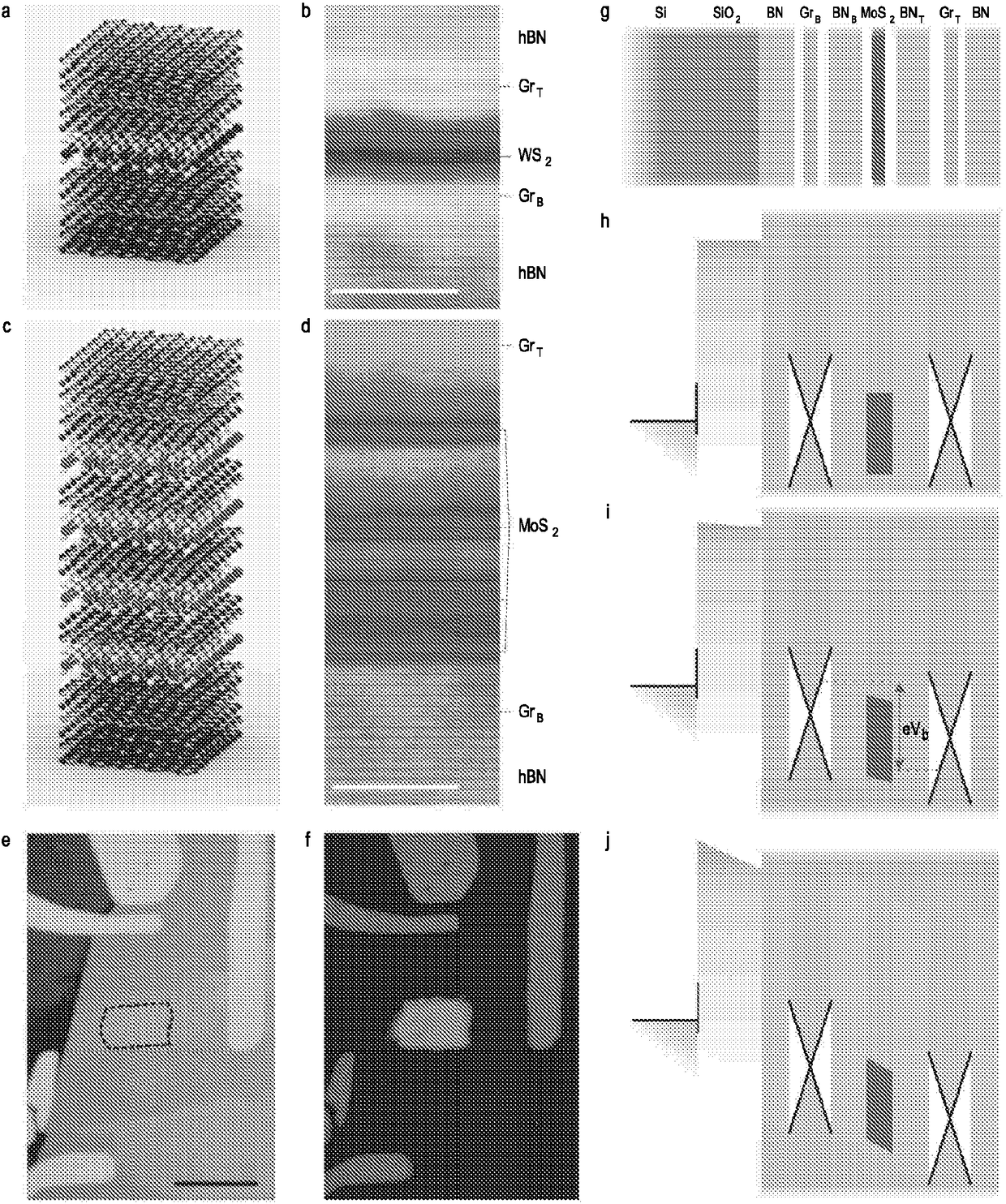

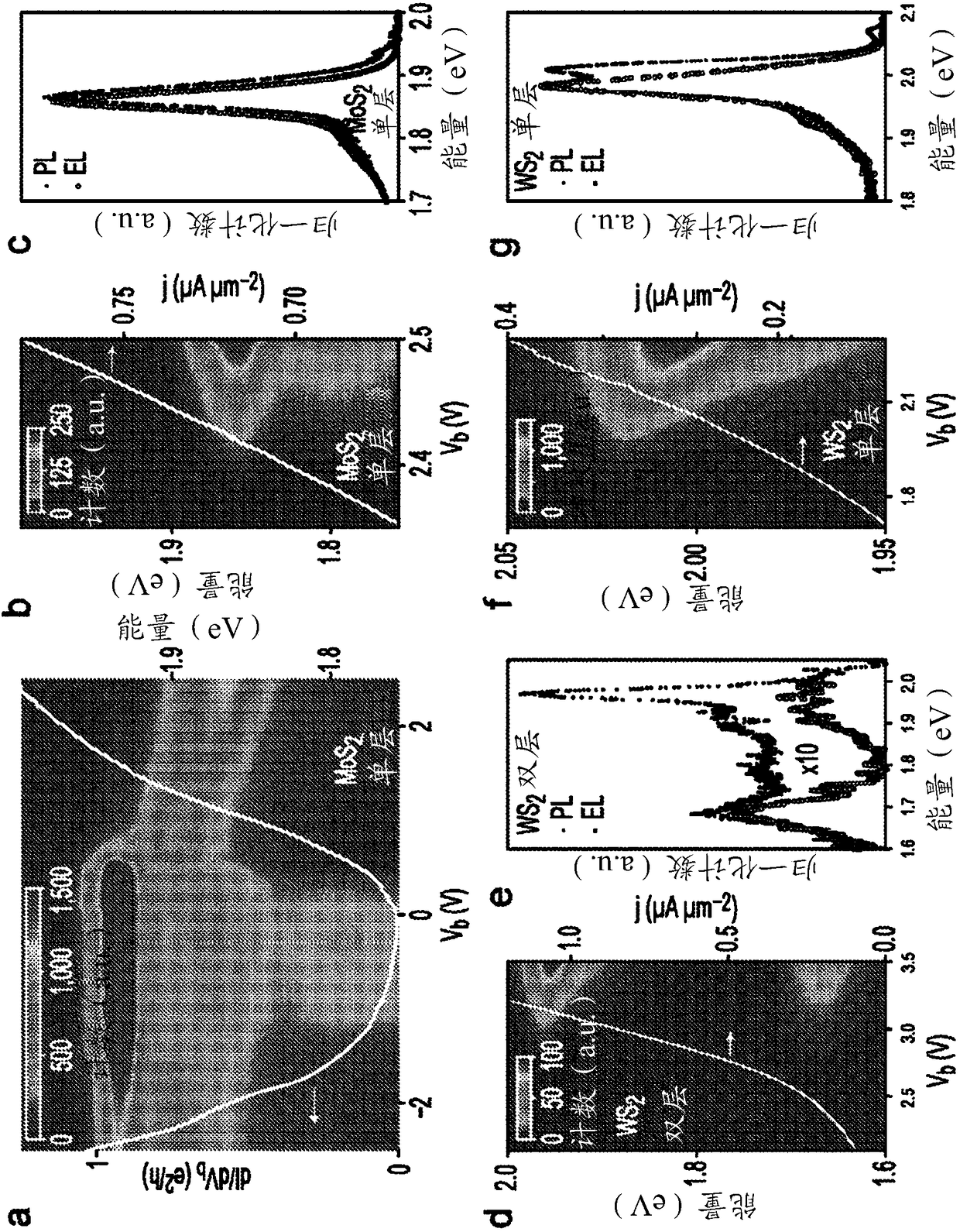

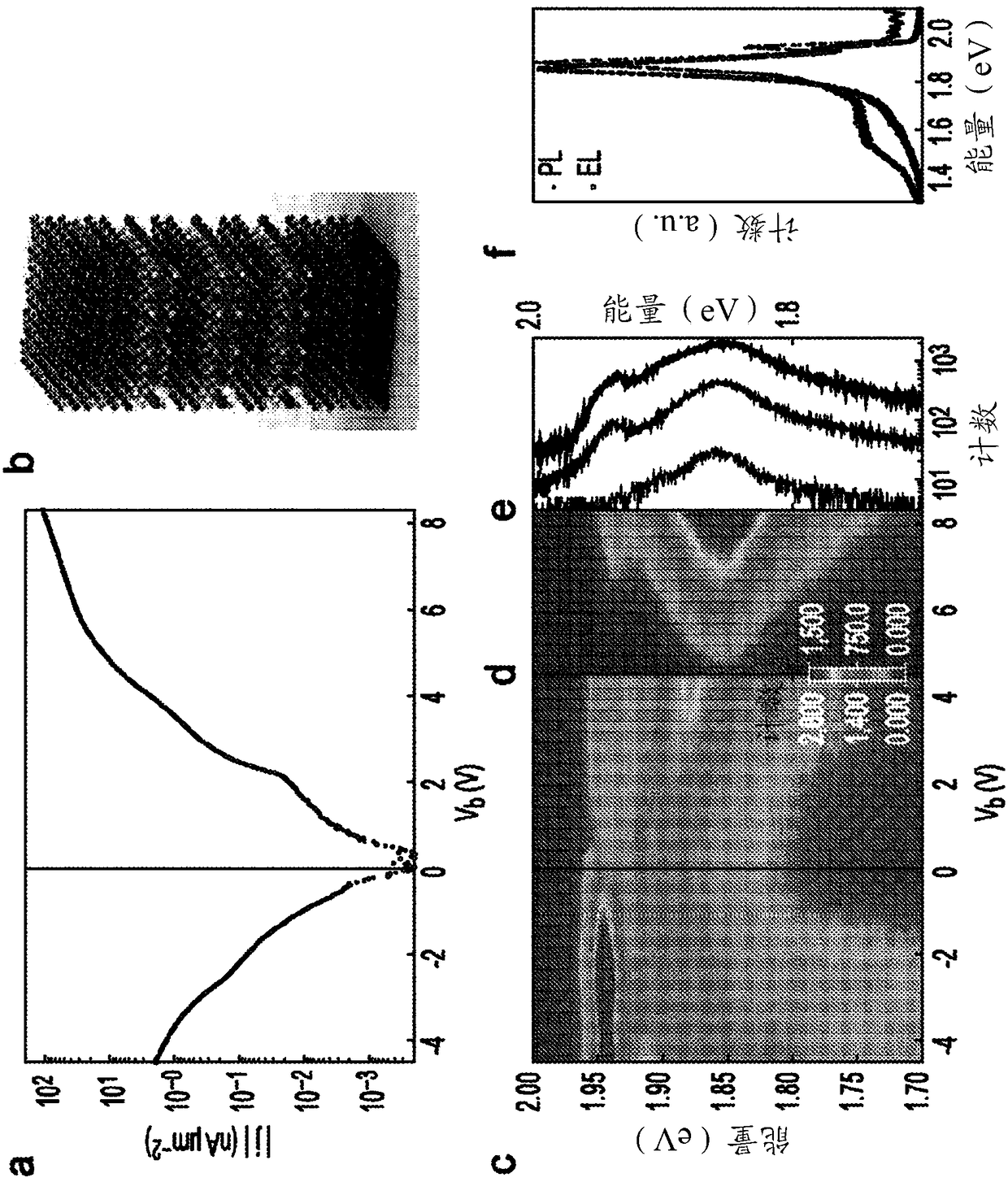

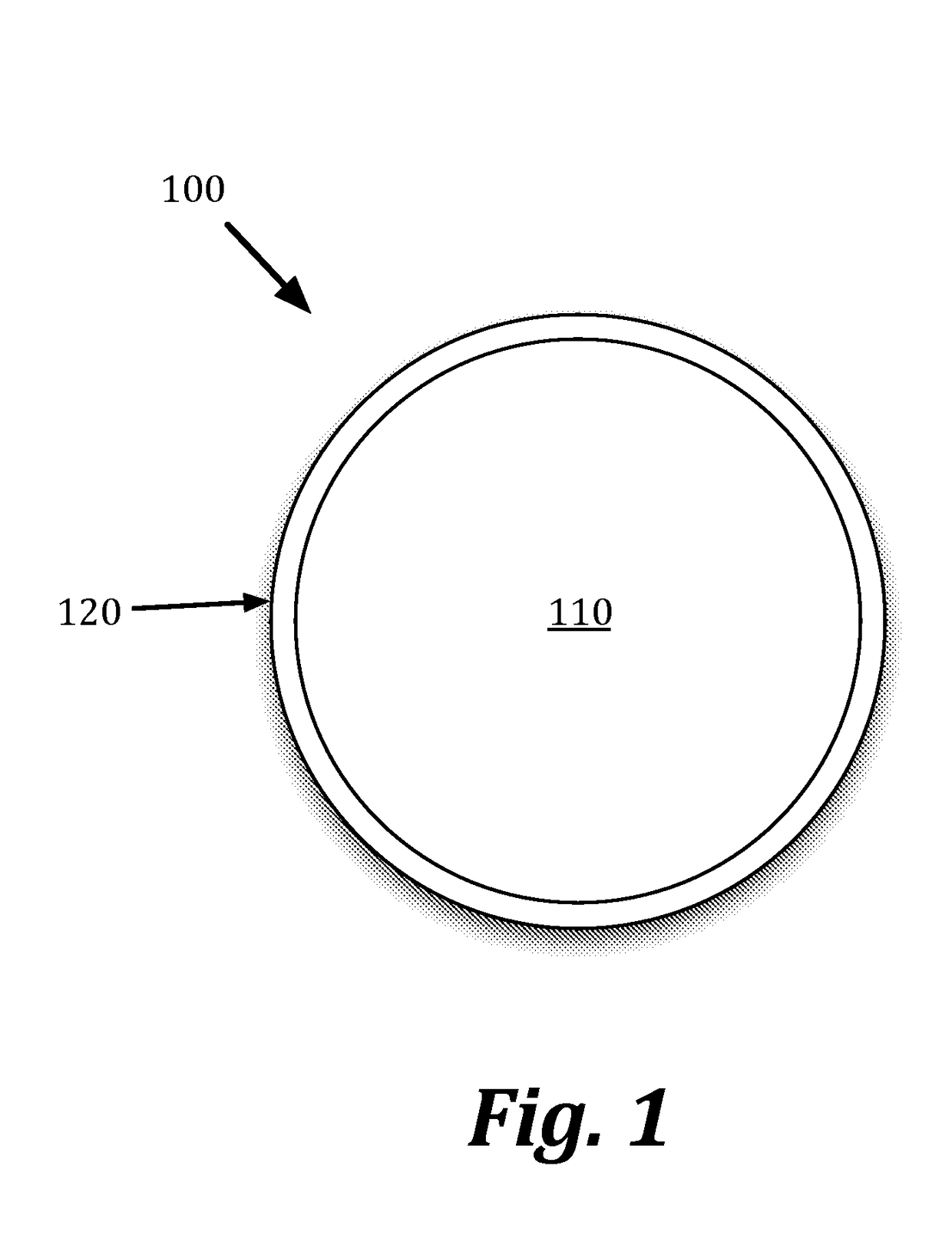

Heterostructures and electronic devices derived therefrom

InactiveCN108064420AElectroluminescent light sourcesSemiconductor devicesTunnel diodeHexagonal boron nitride

The advent of graphene and related 2D materials has recently led to a new technology: heterostructures based on these atomically thin crystals. The paradigm proved itself extremely versatile and led to rapid demonstration of tunnelling diodes with negative differential resistance, tunnelling transistors, photovoltaic devices and so on. In the present invention, the complexity and functionality ofsuch van der Waals heterostructures is taken to the next level by introducing quantum wells (QWs) engineered with one atomic plane precision. We describe light-emitting diodes (LEDs) made by stackingmetallic graphene, insulating hexagonal boron nitride and various semiconducting monolayers into complex but carefully designed sequences.

Owner:NANOCO 2D MATERIALS LTD

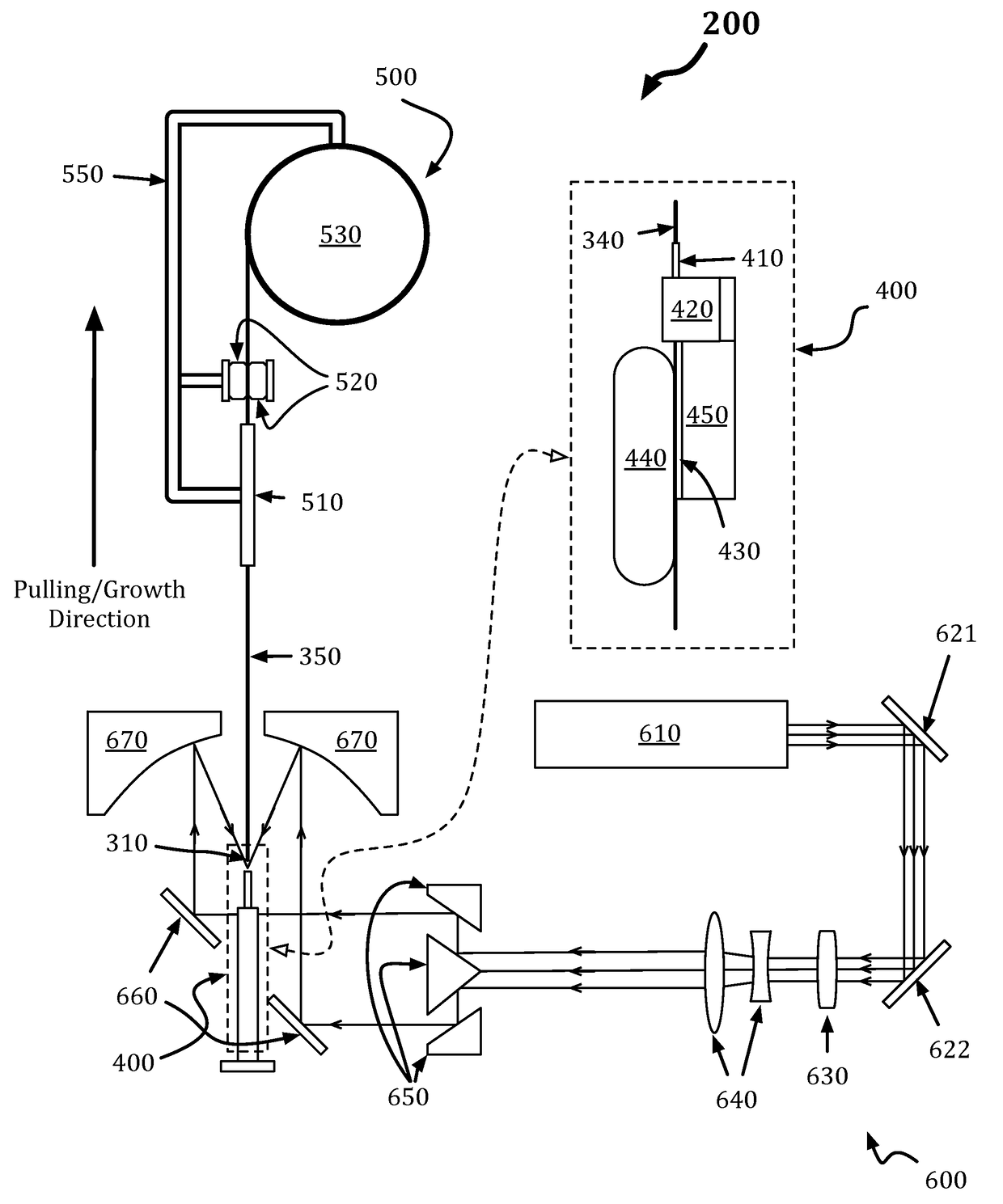

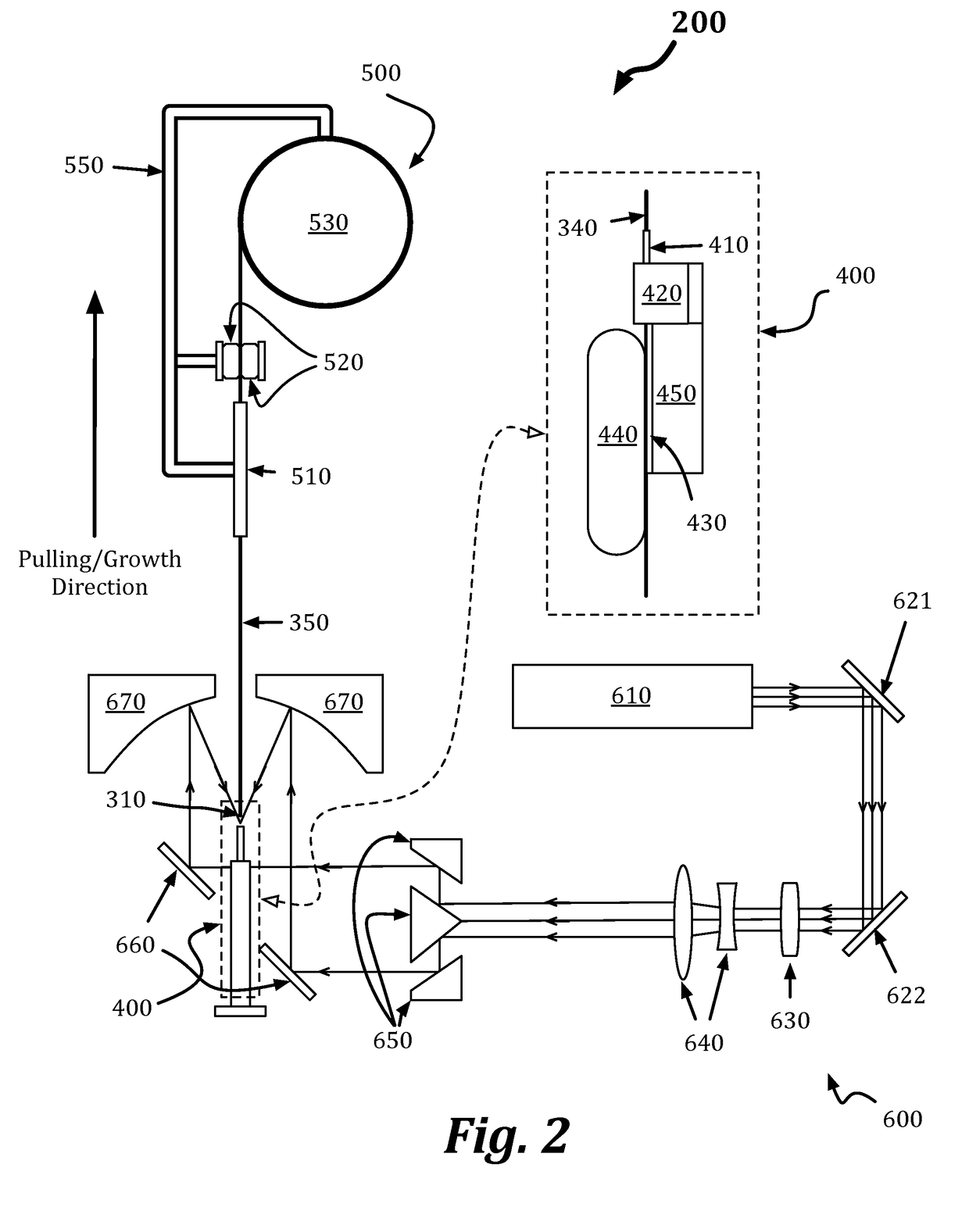

Apparatuses and methods for producing thin crystal fibers using laser heating pedestal growth

InactiveUS20180051389A1Constant diameterPolycrystalline material growthGlass making apparatusFiberSource material

Disclosed are apparatuses and methods for growing thin crystal fibers via optical heating. The apparatuses may include and the methods may employ a source of optical energy for heating a source material to form a molten zone of melted source material, an upper fiber guide for pulling a growing crystal fiber along a defined translational axis away from the molten zone, and a lower feed guide for pushing additional source material along a defined translational axis towards the molten zone. For certain such apparatuses and the methods that employ them, the lower feed guide's translational axis and upper fiber guide's translational axis are substantially aligned vertically and axially so as to horizontally locate the source material in the path of optical energy emitted from the optical energy source, in some cases to within a horizontal tolerance of about 5 μm.

Owner:SHASTA CRYSTALS

Method of preparing thin crystal composite layer on magnesium alloy surface

InactiveCN101058878AImprove corrosion resistanceHigh strengthPressure inorganic powder coatingNon-electric welding apparatusSemi solidFriction stir processing

The invention discloses a preparing method of composite fine-grained layer on the surface of magnesium alloy, which is characterized by the following: adopting casting shaping magnesium alloy or semi-solid pattern as raw material; sanding the surface of magnesium alloy; opening groove on the surface of magnesium alloy; filling powder-shaped Al+SiC in the groove; stirring the surface; forming the fine-grained layer with high antirusting and anti-abrasion resistance.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

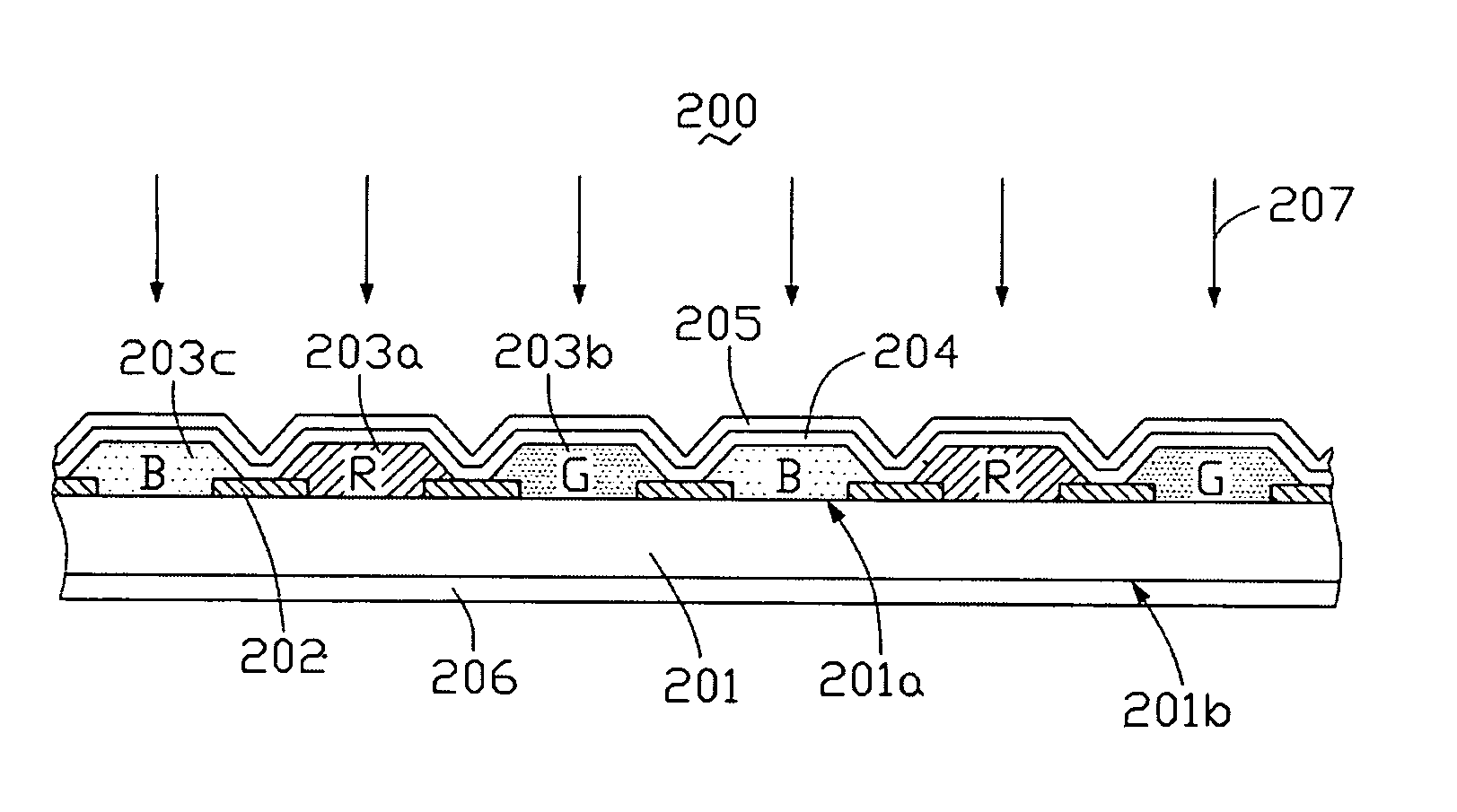

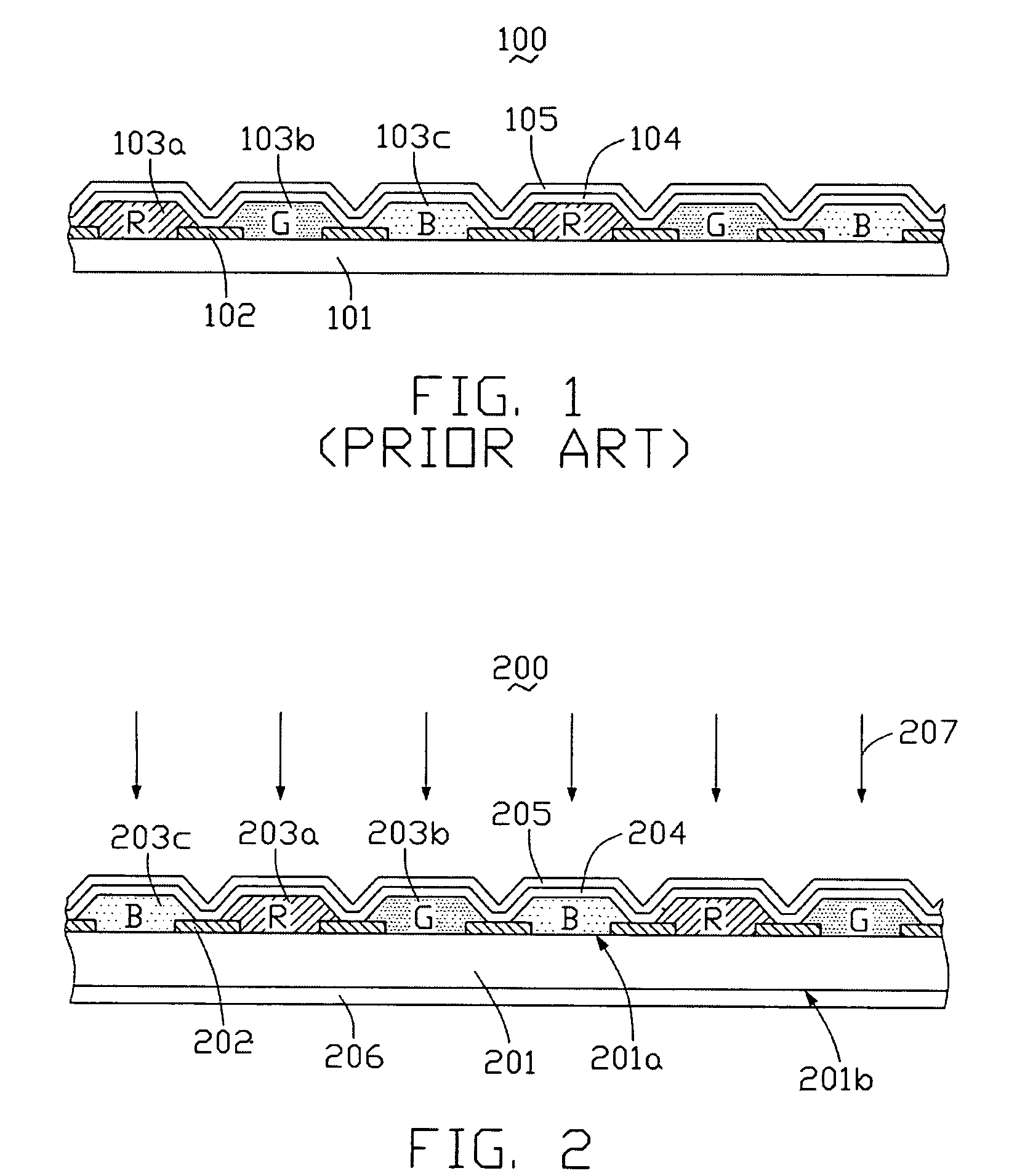

Color filter and method for manufacturing the same

A color filter and a method for manufacturing the same are provided. The color filter includes a polarizer matrix (202), which is patterned in accordance with the pixel arrangement of a liquid crystal display device. The polarizer matrix (202) is made of a thin crystal film material, which may linearly polarize incident light along one direction. By incorporating with a polarizer film (206), the polarizer matrix (202) becomes an effective black matrix. A thinner black matrix may thus be produced, and the manufacturing processes of the color filter are simplified.

Owner:INNOLUX CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com