Preparation method of curved-surface crystal for X-ray micro-imaging

A microscopic imaging and X-ray technology, applied in the field of inertial confinement fusion X-ray imaging, can solve the problems of difficulty in controlling the uniformity of the adhesive, the risk of deformation of the adhesive, temperature control and the control of the bonding surface, and achieves ingenious design. , long service life, easy to achieve effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with embodiment and accompanying drawing.

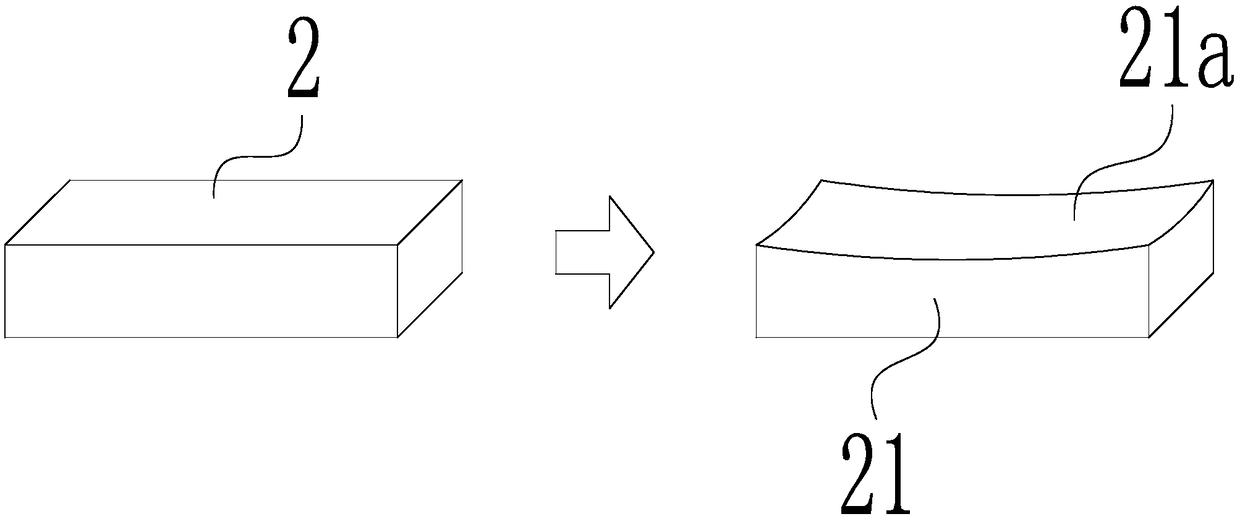

[0039] Such as Figure 1 ~ Figure 4 Shown, a kind of surface crystal preparation method for X-ray microscopic imaging comprises the following steps:

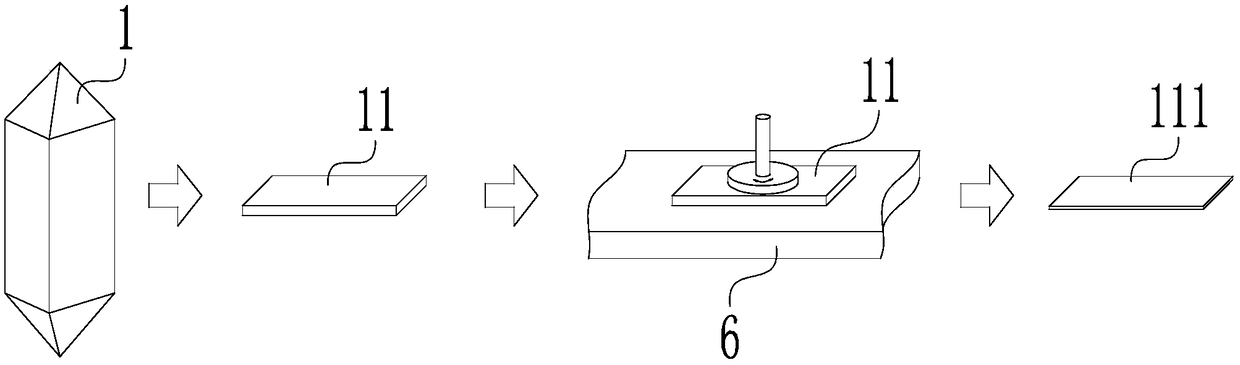

[0040] S1: Perform directional cutting on the single crystal 1 to obtain a thick wafer 11 with a preset thickness, wherein the material of the single crystal 1 is quartz, silicon, germanium, lithium fluoride, mica, etc., and the crystal orientation angle accuracy of the directional cutting single crystal 1 is less than or equal to 0.5°, the thickness of the thick wafer 11 in this embodiment is preferably 2 mm to 3 mm, and the size can be directional cut as required.

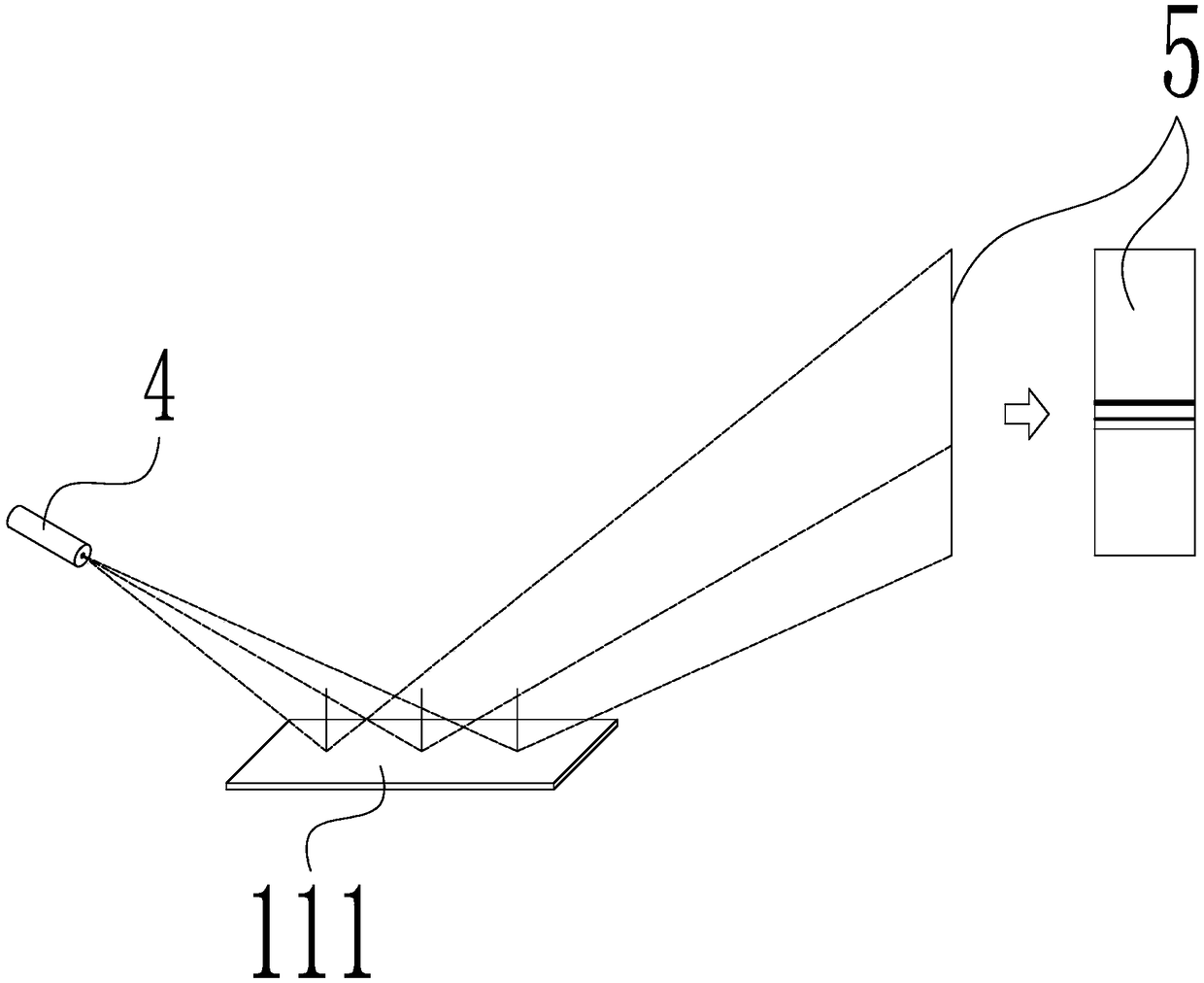

[0041] S2: Use the X light source 4 to inspect the lattice deformation of the thick wafer 11: if unqualified, discard the thick wafer 11, and return to step S1; if qualified, proceed to the next step. Wherein, the lattice deformation detection i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| surface smoothness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com