Electroforming composite processing apparatus and electroforming tank used by the apparatus

A composite processing and electroforming cell technology, applied in electroforming and electrolytic processes, etc., can solve the problems of low current density, poor electroforming layer uniformity, and low microstructure density, and achieves enhanced impact and disturbance effects and reduced concentration. The effect of homogeneous and dense tissue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

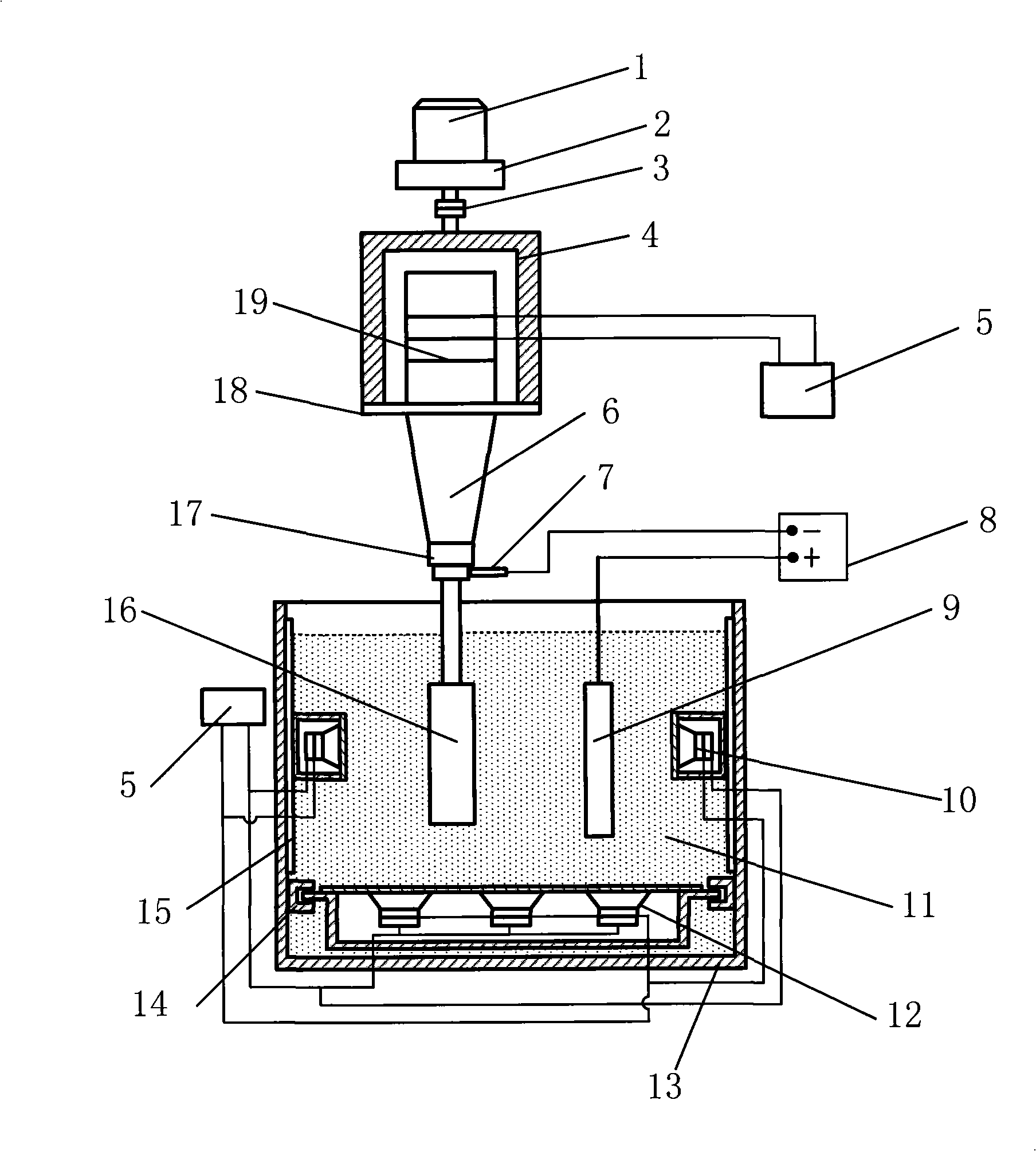

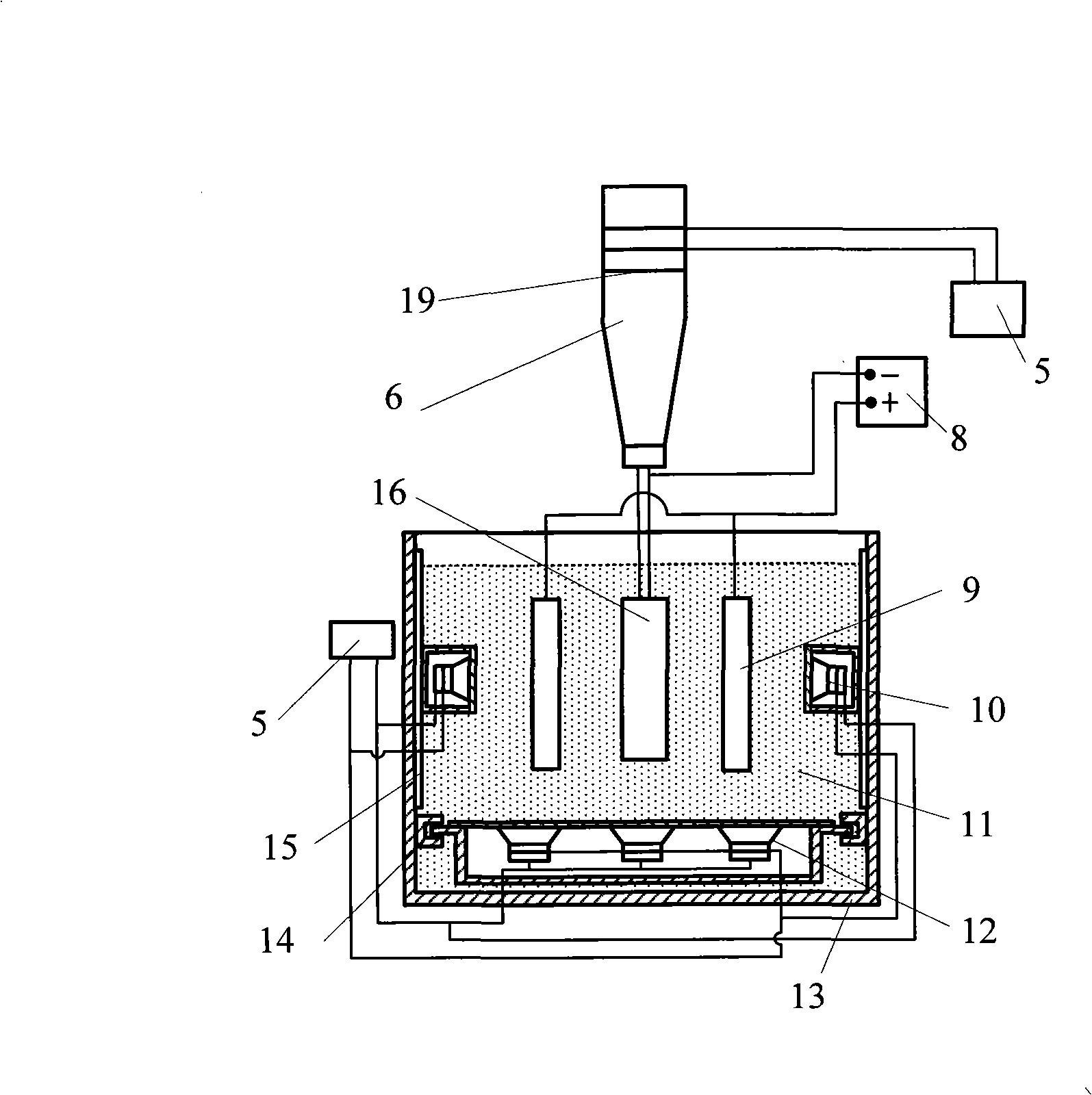

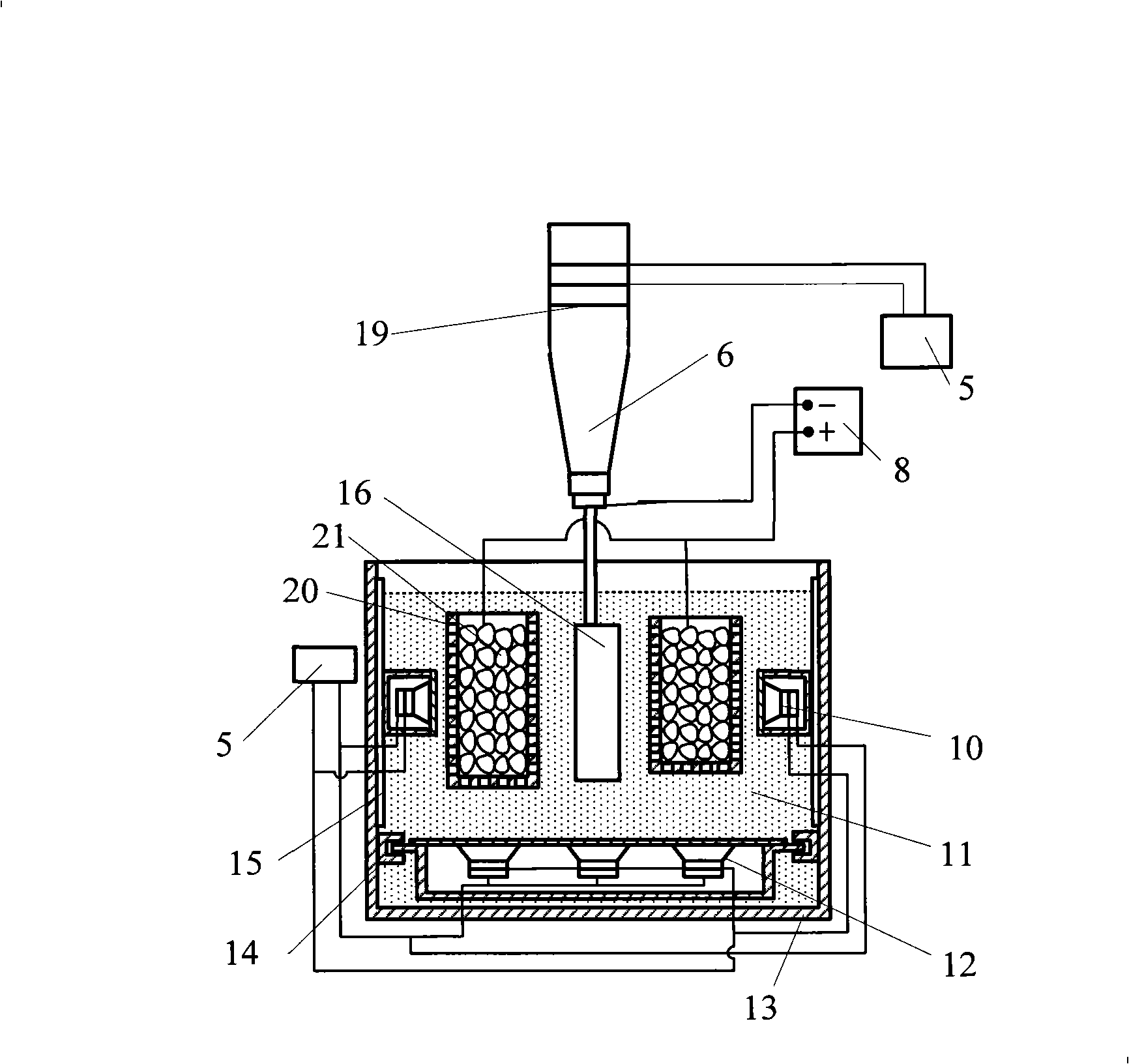

[0019] Figure 1 ~ Figure 3 Winning marks: 1. Motor, 2. Reduction device, 3. Coupling, 4. Hollow sleeve, 5. Ultrasonic generator, 6. Horn, 7. Carbon brush, 8. Power supply, 9. Anode, 10 , Transducer row on the tank side, 11, electroforming liquid, 12, transducer row on the bottom of the tank, 13, electroforming tank, 14, sliding track at the bottom of the tank, 15, sliding track on the tank side, 16, electroforming mandrel ( cathode), 17, connector, 18, flange, 19, transducer, 20, hanging basket, 21, granular anode.

[0020] figure 1 It is a schematic diagram of the electroforming composite processing device, including an electroforming mandrel supporting device and an electroforming tank 13, a transducer device is arranged on the electroforming mandrel supporting device and in the electroforming tank, and the transducer device The energy device is electrically connected with each ultrasonic generator 5. As a typical implementation, it is better to install a transducer devi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com